✅ Smart Frequency Management: Automatic current frequency tracking for optimal load matching

✅ Precision Power Control: Stepless 0–100% power adjustment capability

✅ Efficient Thermal Design: High-performance air cooling system

✅ Intelligent Monitoring: Real-time system diagnostics and protection

Overview

The CR1300 Series Intelligent Induction Heating Power Supply is a proven industrial workhorse, delivering precision heating for the most demanding screw machinery and plastic processing applications. Built on a robust IGBT full-bridge platform with advanced phase-shift PWM control, it ensures ultra-reliable performance and seamless 0–100% power adjustment under variable loads.

Engineered with an efficient air-cooled structure and intelligent frequency tracking, the CR1300 combines durability with consistent, high-efficiency operation—making it the trusted choice for injection molding, extrusion, and other industrial heating systems worldwide.

Key Features and Benefits

Precision Heating Control

The CR1300 uses phase-shift PWM technology to deliver accurate and repeatable thermal output.

0–100% continuous power adjustment

Automatic frequency tracking

Stable heating under variable loads

These features make it ideal for screw barrels, nozzles, hot runner systems, and plastic processing lines.

High Reliability and Energy Efficiency

Built with high-quality industrial IGBT modules, the CR1300 ensures strong load capacity and long service life.

Up to 95% electro-thermal conversion efficiency

Low energy loss

Designed for 24/7 continuous operation

This efficiency helps manufacturers significantly reduce electricity consumption and operating costs.

Intelligent Monitoring and Safety

The CR1300 includes smart monitoring and protection systems to ensure safe operation:

Real-time temperature and electrical monitoring

Overvoltage, overcurrent, and overtemperature protection

Fast-response safety mechanism (<10 μs)

Fault diagnosis and alarm system

These protections make the CR1300 suitable for harsh industrial environments.

Core Application Industries

The CR1300 Series Induction Heating Power Supply is widely used in industries requiring precise and stable heating:

Plastic Processing

A leading choice for:

Injection molding machines

Extruders

Blow molding systems

Hot runner controllers

Screw barrel and die-head heating

Its uniform heating improves product quality and reduces startup time.

Industrial Process Heating

Suitable for various process heating applications:

Preheating

Metal and non-metal thermal conditioning

Thermal treatment for continuous production lines

Energy-Saving Retrofit Projects

Manufacturers oftens upgrade to the CR1300 to replace traditional resistance heaters, achieving:

Lower energy consumption

Faster heating

Reduced maintenance

More stable thermal control

Specialty Industry Applications

The CR1300 is also used in:

Chemical fiber production

Food machinery

Pharmaceutical heating systems

Extrusion coating and laminating equipment

Its compatibility and adjustable output make it suitable for diverse application needs.

Why Choose the CR1300 Series?

The CR1300 stands out due to its combination of performance, stability, and long-term reliability.

Key advantages include:

High heating accuracy

Energy-efficient operation

Durable IGBT architecture

Easy integration with industrial automation

Low maintenance and long equipment life

For manufacturers looking to improve production output while reducing energy costs, the CR1300 provides a proven and scalable solution.

Technical Highlights (Summary)

Control Technology: Phase-shift PWM

Power Adjustment Range: 0–100% stepless control

Core Components: Industrial-grade IGBT modules

Cooling Method: Forced air cooling

Efficiency: Up to 95%

Safety Protection: Overvoltage, overcurrent, overtemperature, short-circuit

Full technical specifications can be provided upon request.

Global Use and Industry Adoption

The CR1300 Series is used globally across plastic processing factories, industrial automation lines, and retrofit modernization projects. Its strong performance, flexible configuration, and long-term stability make it a preferred heating solution for OEMs and end-users.

Request a Quote or Technical Consultation

To learn more about the CR1300 Series or receive technical assistance, please contact our engineering team. We provide customized solutions designed to optimize heating efficiency, reduce energy usage, and enhance production stability.

Specifications

Downloads

File name

Language

File Type

Update

Download

Application

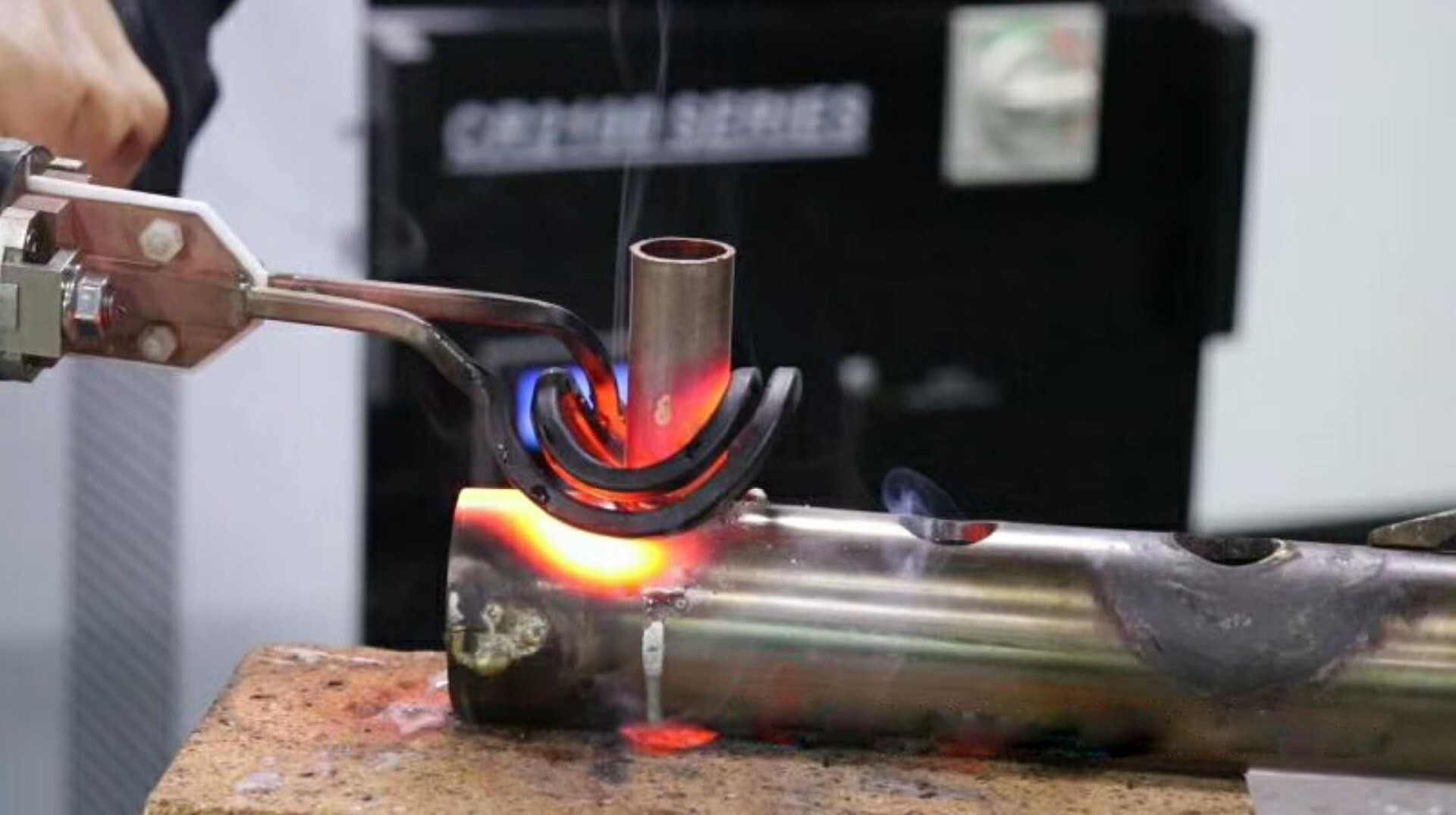

![Brazing & Soldering Brazing & Soldering]() Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.![PWHT PWHT]() PWHTProject Introduction: After the completion of welding, heat treatment should be carried out on the weld position to eliminate the stress.

PWHTProject Introduction: After the completion of welding, heat treatment should be carried out on the weld position to eliminate the stress.

Equipment used: CR2000-010B-14TF![Coating & Adhesive Curing Coating & Adhesive Curing]() Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Induction heating provides a highly efficient and localized method for coating curing and adhesive activation, offering precise thermal control with rapid heat-up — ideal for paint drying, powder coating, epoxy bonding, or glue line curing.

Whether applied to electric motor housings, automotive body parts, or steel structural components, induction delivers reliable results with reduced cycle times and superior energy efficiency compared to ovens or IR lamps.![Annealing & Stress Relieving Annealing & Stress Relieving]() Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Induction annealing and stress relieving are essential heat treatment processes used to soften metals, improve ductility, and relieve residual stresses introduced during forming, machining, or welding. Unlike traditional furnace methods, induction heating provides rapid, localized, and highly controllable thermal processing — ideal for applications such as steel tubing, copper pipe, metal wire, and strip materials.

Related Products

Send Inquiry Now

Sign up for updates