✅ Intelligent Control: Achieve precise heating with advanced PID temperature closed-loop and power control via an intuitive LCD interface.

✅ Built for Safety: Operate with confidence with no open flame, no toxic emissions, and comprehensive fault protection (35+ codes) for ultimate worksite safety.

✅ Clean & Green: Eliminate harmful flue gas and open flames for an environmentally friendly and operator-safe heating process.

✅ Modular & Air-Cooled: Enjoy simplified maintenance with a robust module design and eliminate the hassle of water cooling with our reliable air-cooling system.

✅ All-Weather Ready: Dependable performance even in extreme cold, operating reliably in temperatures as low as -40°C with an IP54 rating.

Overview

The CR2000 Series is a high-performance induction heating system designed for precision, reliability, and versatility in industrial applications. This advanced induction heating machine delivers exceptional performance acrossa wide 5KW to 160KW power range, making it the ideal induction heating equipment for everything from delicate component processing to large-scale industrial projects.

Customizable heating tools tailored to specific workpieces make it the ideal solution for welding preheat, PWHT, shrink fitting, anti-corrosion coating, and more.

Key Features & Benefits

Wide Power Range & Customizability

5KW–160KW Flexibility: This induction heating equipment adapts seamlessly to various scales, from precision localized heating to large-surface applications.

Custom Heating Tools: Tailored inductors and coils designed to fit unique workpiece geometries, ensuring optimal energy transfer and efficiency.

Intelligent Control & Precision

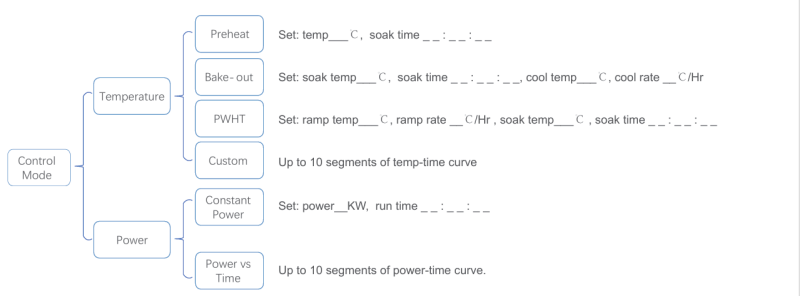

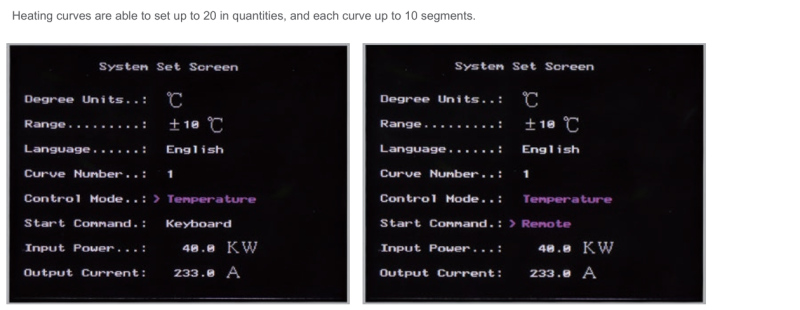

PID Closed-Loop Temperature Control: Delivers accurate and consistent heating curves for critical processes like PWHT.

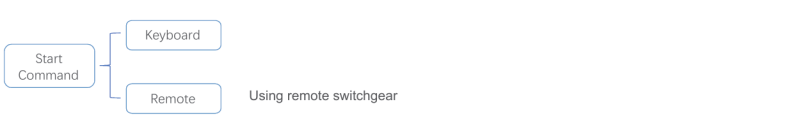

Multi-Mode Operation: Supports both temperature and power control modes, easily configured via an intuitive LCD interface.

Enhanced Safety & Reliability

Isolation Transformer Output: Provides galvanic isolation, reducing risks of electrical faults and ensuring operator safety.

No Open Flame or Toxins: Eliminates fire hazards and toxic emissions, ideal for confined or hazardous environments.

Comprehensive Fault Protection: 35+ fault and alarm codes (e.g., overcurrent, phase loss, overheating) with automatic shutdown and diagnostic logging.

Efficiency & Performance

Rapid Heating Technology: Reaches up to 788°C for magnetic materials (e.g., steel, iron) significantly faster than resistance or gas-based heating.

Air-Cooled Design: Removes the complexity and maintenance of water cooling while ensuring efficient thermal management.

Durability & Adaptability

Proven Craftsmanship: Built on over 10 years of engineering expertise, ensuring longevity and high cost-effectiveness.

Extreme Environment Ready: Operates reliably in temperatures as low as -40°C with IP54-rated protection against dust and moisture.

Eco-Friendly & Operator-Friendly

Zero Emissions: Clean, electric-based heating reduces environmental impact.

Modular Design: Simplifies maintenance and reduces downtime with easily replaceable components.

Core Industrial Applications:

The CR2000 Series delivers powerful, high-performance induction heating from 5kW to 160kW, engineered to meet the demands of diverse and specialized industrial processes.

Welding & Metal Fabrication: Ideal for Welding Preheating and serving as a precise PWHT Machine for post-weld heat treatment, ensuring joint integrity and compliance.

Assembly & Disassembly: Perfect for Shrink Fitting & Assembly operations, allowing for the secure fitting and removal of bearings, gears, and other components.

Surface Treatment: Highly effective for Anti-Corrosion Coating Curing, ensuring uniform and durable coating adhesion.

Material Forming: Provides controlled heat for various Bending & Forming Operations, facilitating easier shaping of metals.

Versatile Heating Solutions: Covers all aspects of General Industrial Heating for annealing, hardening, brazing, and more.

System Highlights:

Wide Power Range: 5 kW to 160 kW to suit various workpiece demands.

Custom Solutions: Tailored heating fixtures for any geometry.

Proven Reliability: Over a decade of precision engineering for exceptional cost-effectiveness.

Enhanced Safety: Isolated transformer output for safer operation.

Full Air-Cooling: No complex water-cooling systems required.

Customization & Support

As a leading induction heater manufacturer, Canroon provides complete induction heating solutions, including:

Custom inductor design for specific applications and workpieces

System integration support for CNC and automated production lines

Technical training and maintenance services

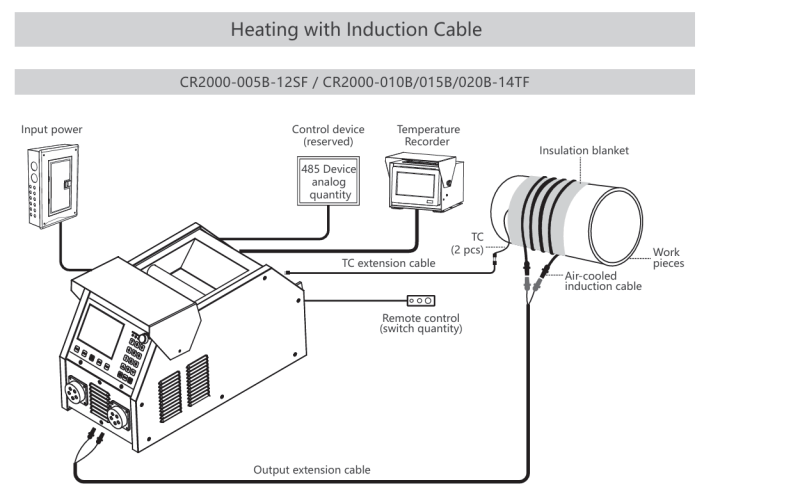

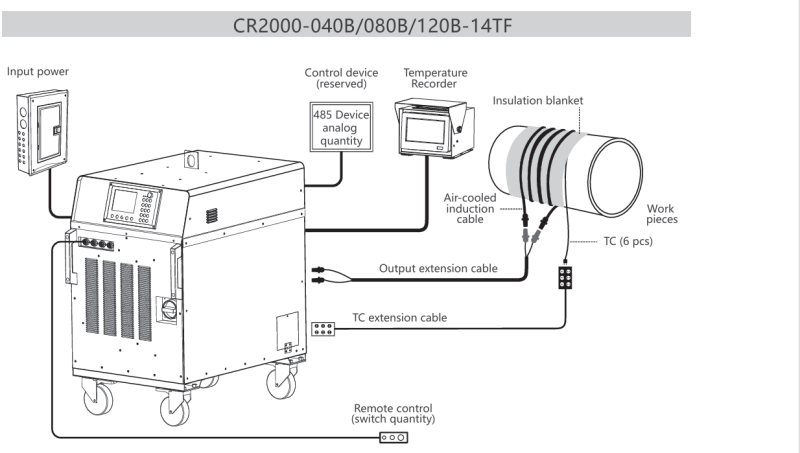

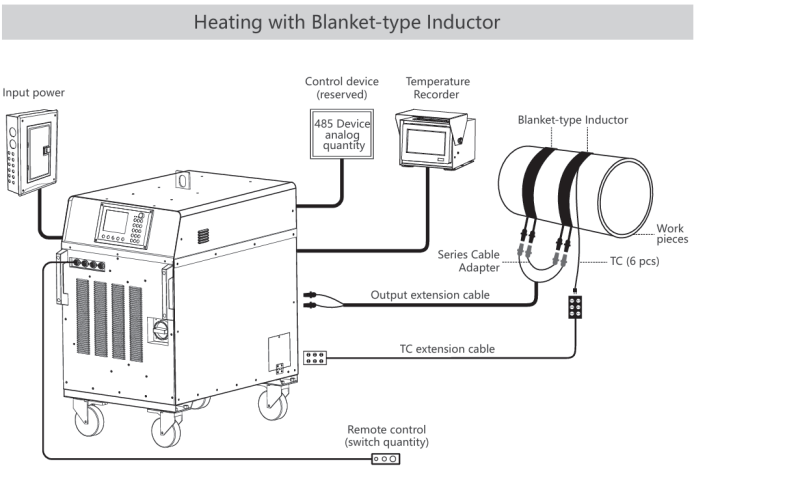

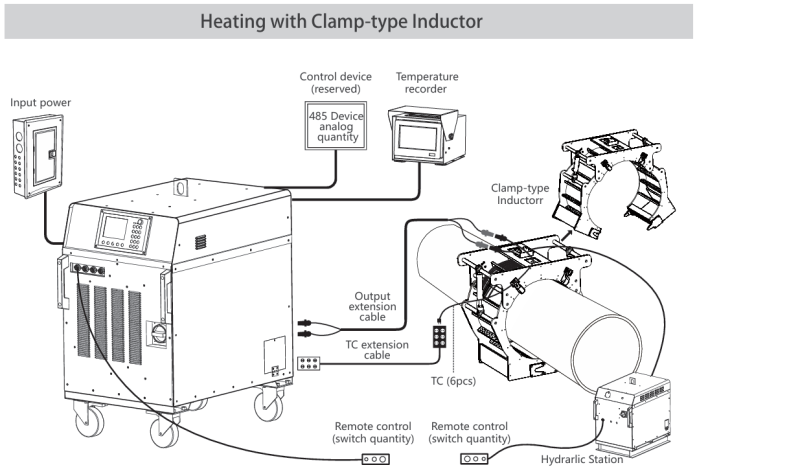

CR2000 series – System Wiring Diagram

Experience the CR2000 Difference

This advanced induction heater system offers unparalleled versatility for industrial heating applications. Its robust design as a high-frequency induction heating machine ensures reliable performance in the most demanding environments. The CR2000 induction heating equipment represents the perfect fusion of innovation and practicality, delivering exceptional results across numerous industrial sectors.

Specifications

Standard specifications (Temperature rating Operation: -20℃~+50℃)

Downloads

File name

Language

File Type

Update

Download

Application

![Shell Oil Daya Bay offshore sewage pipe joint anti-corrosion project Shell Oil Daya Bay offshore sewage pipe joint anti-corrosion project]() Shell Oil Daya Bay offshore sewage pipe joint anti-corrosion projectProject: Shell Oil Daya Bay DN1422 offshore sewage pipe joint anti-corrosion project

Shell Oil Daya Bay offshore sewage pipe joint anti-corrosion projectProject: Shell Oil Daya Bay DN1422 offshore sewage pipe joint anti-corrosion project

Project introduction: The total length of the project pipeline is 30KM, and the pipe diameter is 1422MM

Equipment used: CR2000-120B-14TF![Brazing & Soldering Brazing & Soldering]() Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

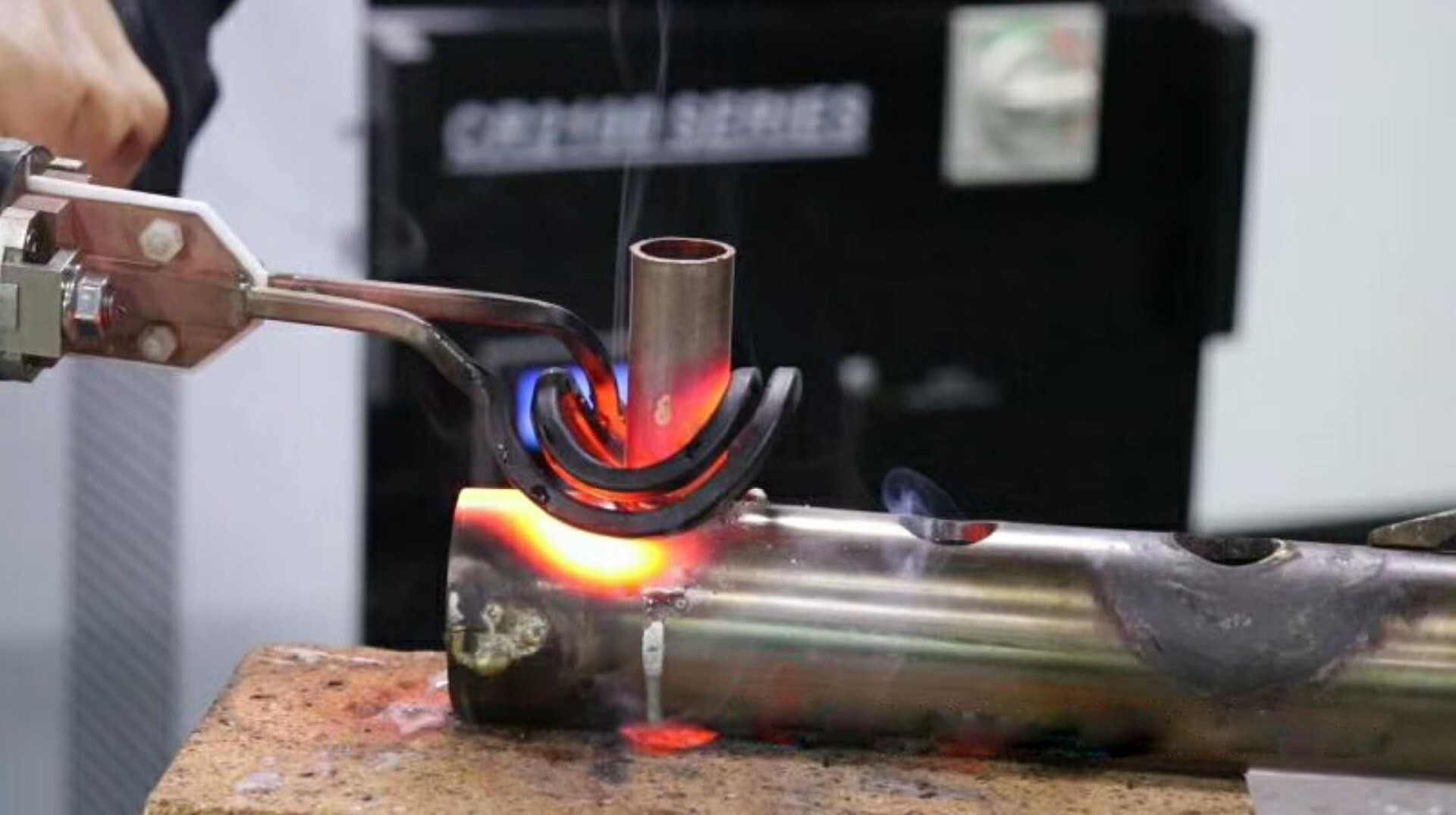

Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.![China Merchants Heavy Industry Ore Ship Block Preheating Project before Welding China Merchants Heavy Industry Ore Ship Block Preheating Project before Welding]() China Merchants Heavy Industry Ore Ship Block Preheating Project before WeldingProject introduction: straight seam length 18M, plate thickness 45MM, heating width 300MM;

China Merchants Heavy Industry Ore Ship Block Preheating Project before WeldingProject introduction: straight seam length 18M, plate thickness 45MM, heating width 300MM;

The right and left of the weld are heated simultaneously through an 18M long inductor.

Equipment used: CR2000-080B-14TF2![PWHT PWHT]() PWHTProject Introduction: After the completion of welding, heat treatment should be carried out on the weld position to eliminate the stress.

PWHTProject Introduction: After the completion of welding, heat treatment should be carried out on the weld position to eliminate the stress.

Equipment used: CR2000-010B-14TF

Related Products

Send Inquiry Now

Sign up for updates