Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.

Brazing & Soldering with Induction Heating

Clean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.

Why Induction for Brazing & Soldering?

· Flame-Free Heating: Eliminates gas cylinders, fire hazards, and operator exposure

· Targeted Precision: Heats only the joint area, protecting surrounding components

· Fast Heat-Up: Joints reach brazing temperature in seconds

· Clean and Repeatable: Ideal for automated or high-volume production

· Energy Efficient: Reduces energy waste compared to torches or ovens

Recommended Induction System Configurations

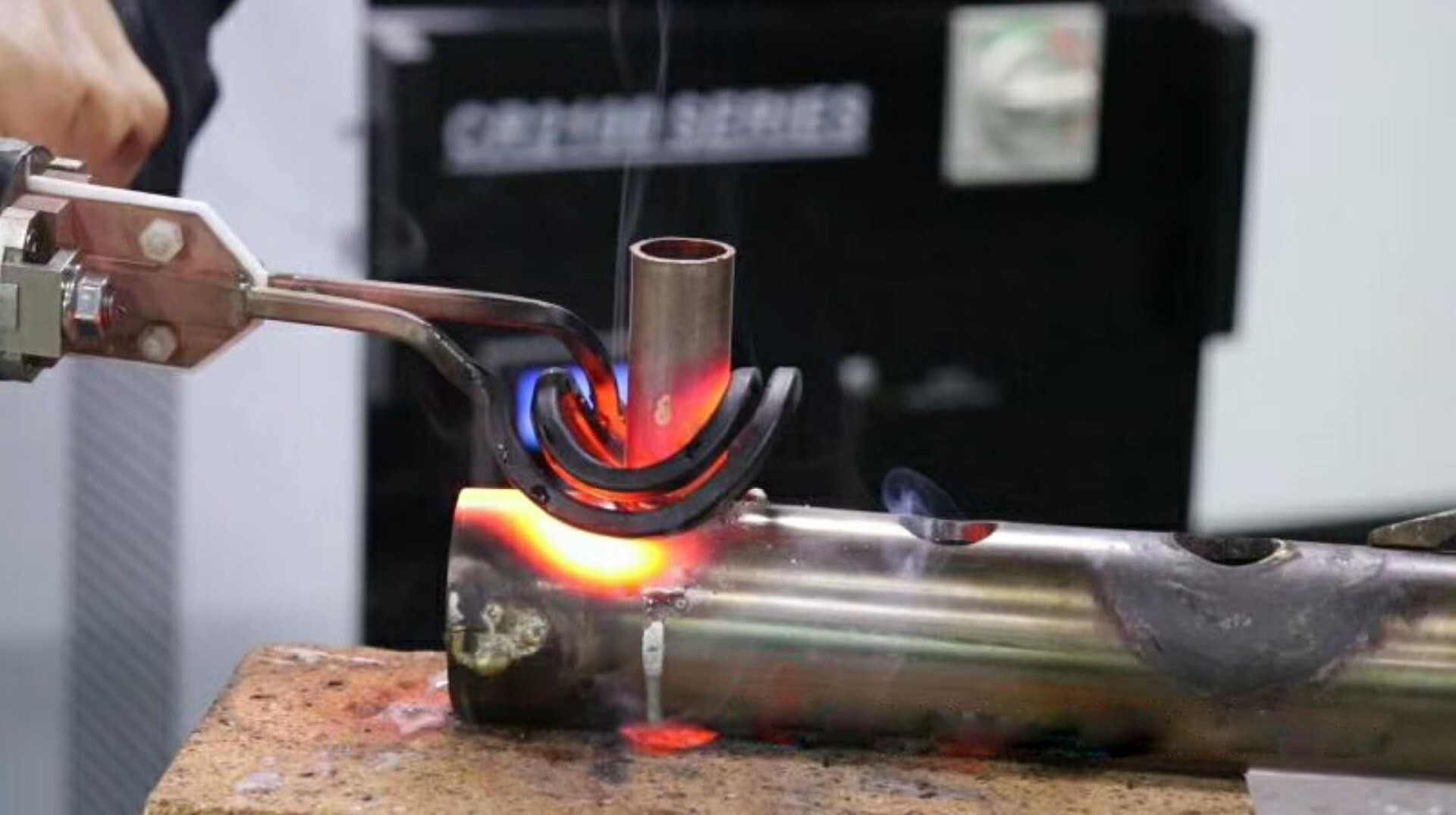

Custom Coils & Process Tooling

We supply custom brazing coils engineered for optimal heat delivery based on joint geometry, material, and filler type:

· Single-turn or multi-turn coils for copper/aluminum tubes

· U-shaped coils for electrical connectors or terminal lugs

· Coil holders, fixture jigs, foot pedals for manual setups

· IR sensors or thermocouples for closed-loop temperature control

· Optional water-cooling systems for intensive brazing cycles

We support quick-change coil designs for different joint types in the same production environment.

Typical Applications

· HVAC Industry: Brazing copper and aluminum tubing, Y-joints, elbows, compressors

· Automotive: Joining aluminum radiators, fuel lines, brake lines

· Electrical Components: Soldering terminals, circuit board connectors, copper contacts

· Household Appliances: Condensers, heat exchangers, copper pipe manifolds

· Aerospace & Defense: Precision brazing of dissimilar metals and alloys

· Refrigeration Systems: Leak-proof joint formation under pressure requirements

Brazing & Soldering Benefits with Induction

· Strong, clean joints with minimal oxidation

· No need for flux in many applications

· Reduced post-braze cleaning

· Repeatable results ideal for robotic or semi-auto production

· Supports high-mix, low-volume or high-volume manufacturing

Technical Highlights

· Output Power Range: 4.5kW–680kW, depending on part size and material

· Frequency Options: High-frequency systems (100–400kHz) ideal for small, thin joints

· Control Options: HMI or PLC with pre-set temperature curves and timers

· Coil Cooling: Air-cooled or water-cooled coils depending on application intensity

· Mounting Options: Benchtop, cart-mounted, or fully integrated production line setups

Keywords :

· Induction brazing machine

· Copper tube brazing system

· Induction soldering equipment

· Brazing aluminum with induction

· Portable induction heating for HVAC

· High-frequency brazing system

· Induction heating for copper and aluminum joints

· Flame-free brazing machine supplier

Looking to automate your brazing process or improve joint quality?

Send us your tube diameter, material, and filler metal — we’ll recommend the ideal induction brazing solution and custom coil design to meet your production goals.

Sign up for updates