✅ Complete protection system with over 20 fault safeguards

✅ Wide frequency range (1-20kHz) for versatile applications

✅ User-friendly interface with multiple heating modes

✅ Rugged design built for harsh operating conditions

✅ Tailored solutions for your specific industrial needs

Overview

The CR1000 Series is a high-performance intelligent induction heating system engineered for industrial applications that require precision, efficiency, and long-term reliability. Equipped with an optimized HMI, advanced digital control, and multiple heating modes, the CR1000 is widely used in metal smelting, casting, forging, and other demanding thermal processes.

Designed for harsh environments and continuous operation, it offers exceptional heating accuracy, stability, and system protection—making it an ideal choice for modern industrial production lines.

Key Features

Advanced Digital Control Technology

Uses phase-shift PWM digital control

IGBT inverter series resonance design ensures high efficiency

Stable output under variable loads

This architecture significantly boosts energy conversion efficiency and enhances system durability.

Wide Output Frequency Range (1–20 kHz)

Suitable for diverse heating applications, including:

Melting

Casting

Forging

Metal treatment

Industrial thermal processing

The broad frequency range allows precise matching with different inductors and workpiece requirements.

Precise Temperature Control

Integrated PID temperature control module

Ensures consistent, accurate temperature regulation

Ideal for processes requiring stable and repeatable heating

User-Friendly HMI

The intuitive human–machine interface supports:

Quick parameter setup

Real-time operating data display

Efficient and safe system operation

Multiple Heating Modes

Supports flexible industrial process control:

Curve heating

Multi-stage heating

Maximum power mode

Continuous or intermittent heating cycles

These modes enable manufacturers to tailor heating profiles for optimal production results.

Comprehensive Safety Protection (20+ Protections)

Built-in advanced protections include:

Overcurrent / Overvoltage / Low Voltage

Short circuit / Inductor short / Workpiece short

Phase loss / Overtemperature

Protection against unstable grid conditions

These systems ensure reliable operation even in challenging environments.

Stepless Power Adjustment (1%–100%)

Provides precise output control and supports different process requirements without performance fluctuation.

Engineered for Harsh Environments

With a large design margin and specialized protective coating, the CR1000 performs reliably in:

High-temperature workshops

Oil-contaminated areas

Dusty or dirty industrial environments

Its robust build ensures long service life and reduced maintenance.

Application Environment

The CR1000 Series is engineered to excel in challenging industrial settings, including:

Metal smelting, casting, and forging

High-temperature processing environments

Areas with exposure to oil, dirt, and dust

Its durable design and comprehensive protection features guarantee consistent performance and longevity, even under extreme conditions.

Why Choose CR1000?

The CR1000 combines advanced digital induction heating technology with flexible process control and high system reliability.

Manufacturers choose the CR1000 for:

Accurate temperature and power control

High efficiency and lower energy costs

Excellent stability under heavy workloads

Enhanced operational safety

Long-term durability in harsh conditions

Canroon delivers not only equipment—but a complete, optimized induction heating solution tailored to your industrial needs.

Specifications

Application environment:

Features:

Downloads

File name

Language

File Type

Update

Download

Application

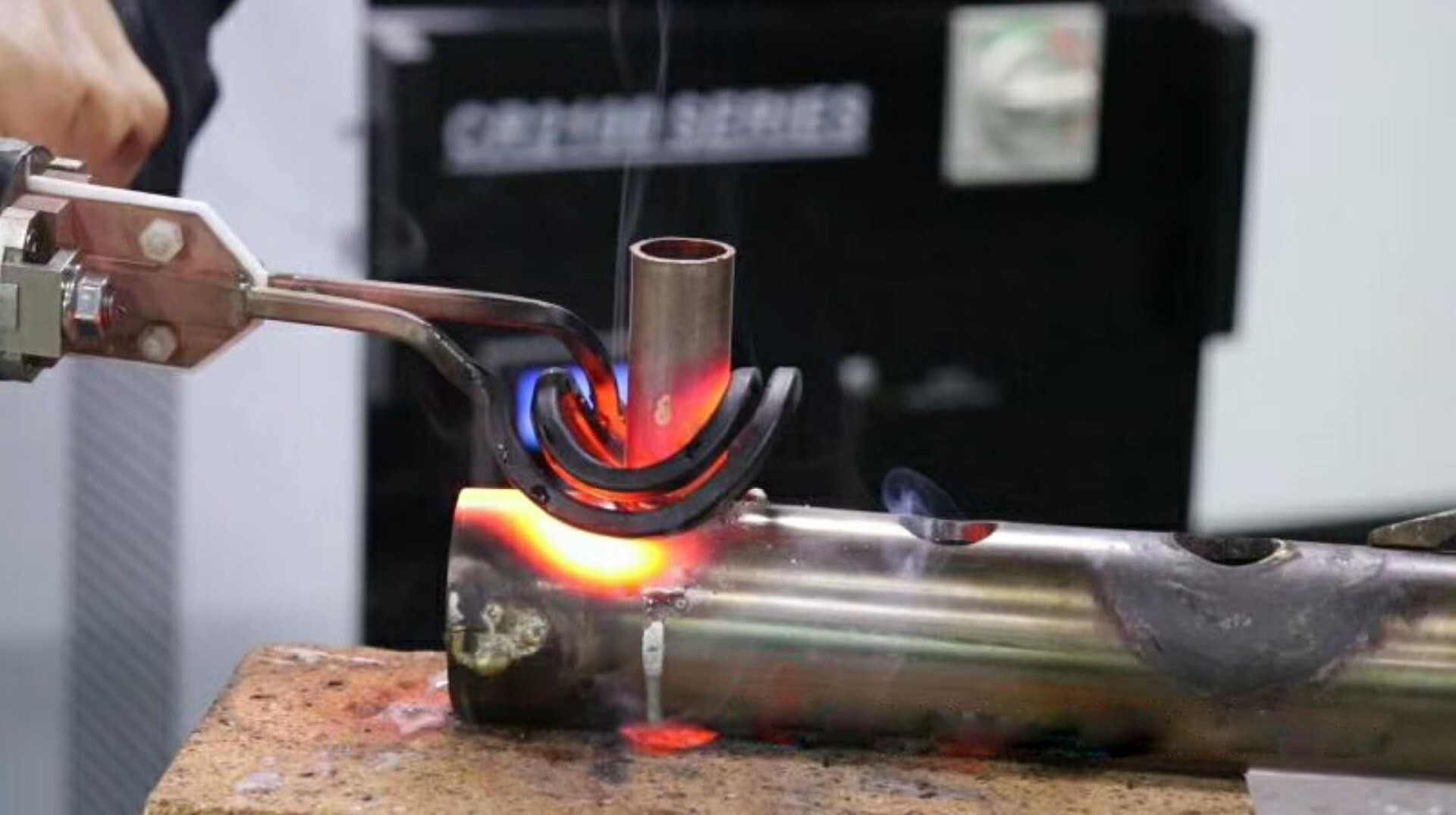

![Brazing & Soldering Brazing & Soldering]() Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.![Coating & Adhesive Curing Coating & Adhesive Curing]() Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Induction heating provides a highly efficient and localized method for coating curing and adhesive activation, offering precise thermal control with rapid heat-up — ideal for paint drying, powder coating, epoxy bonding, or glue line curing.

Whether applied to electric motor housings, automotive body parts, or steel structural components, induction delivers reliable results with reduced cycle times and superior energy efficiency compared to ovens or IR lamps.![PWHT PWHT]() PWHTWelding Preheating & PWHT with Induction Heating

PWHTWelding Preheating & PWHT with Induction Heating

Improve Weld Quality and Safety with Precision Induction Preheating and Post-Weld Heat Treatment

Induction heating offers a fast, accurate, and energy-efficient solution for welding preheating and post-weld heat treatment (PWHT) across various industrial sectors. Whether you're working on pipeline welding, pressure vessel fabrication, or offshore structure maintenance, our advanced induction heating machines ensure uniform temperature control and superior metallurgical performance.![Annealing & Stress Relieving Annealing & Stress Relieving]() Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Induction annealing and stress relieving are essential heat treatment processes used to soften metals, improve ductility, and relieve residual stresses introduced during forming, machining, or welding. Unlike traditional furnace methods, induction heating provides rapid, localized, and highly controllable thermal processing — ideal for applications such as steel tubing, copper pipe, metal wire, and strip materials.

Related Products

Send Inquiry Now

Sign up for updates