Reliable Performance for Diverse Industrial Applications

Overview

CV800 Series Multi-Function Vector Control Inverter

Compact Design, Powerful Performance for Small to Medium Power Applications

The CV800 Series Multi-Function Vector Control Inverter delivers exceptional value with advanced vector V/f control technology in a space-saving design. Engineered specifically for small and medium power equipment, this versatile drive combines robust performance with user-friendly operation for diverse industrial applications.

Key Product Features & Benefits

Space-Optimized Design

Compact footprint reduces installation space requirements

Efficient thermal management for reliable operation

Streamlined wiring for easier installation and maintenance

Advanced Control Technology

Vectorized V/f control for precise motor performance

Built-in PID controller for closed-loop process control

Multi-speed operation for flexible application setup

Programmable operation control for customized functionality

Superior Performance Characteristics

High starting torque capability for demanding loads

Enhanced overload capacity for tough applications

Rapid acceleration with optimized ramp times

Stable operation across varying load conditions

Connectivity & Integration

Standard Modbus communication for seamless system integration

Flexible I/O configuration for various control scenarios

User-friendly programming for quick setup and adjustment

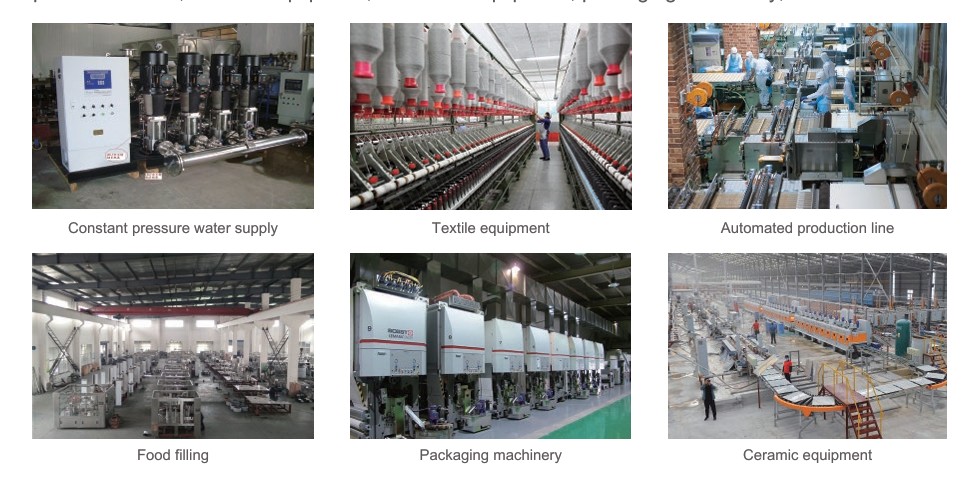

Industry Applications

Perfect for Multiple Sectors & Equipment

Water Supply Systems - Constant pressure water supply applications

Woodworking Machinery - Saws, routers, and processing equipment

Textile Equipment - Spinning, weaving, and fabric processing

Food & Beverage - Filling machines and processing equipment

Logistics & Material Handling - Conveyors and transport systems

Automated Production Lines - Precision manufacturing equipment

Ceramic Processing - Kiln and processing machinery

Electronic Manufacturing - Assembly and test equipment

Packaging Machinery - Wrapping, sealing, and labeling systems

Technical Advantages

Reliable Operation & Protection

Comprehensive protection functions

Overcurrent and overload protection

Overvoltage and undervoltage protection

Motor overheating protection

Short circuit protection

Energy Efficiency

Optimized power consumption for reduced operating costs

Smart energy management features

Power factor correction capabilities

Easy Operation & Maintenance

Intuitive parameter setting via keypad or software

Comprehensive monitoring of operating status

Fault diagnosis and history tracking

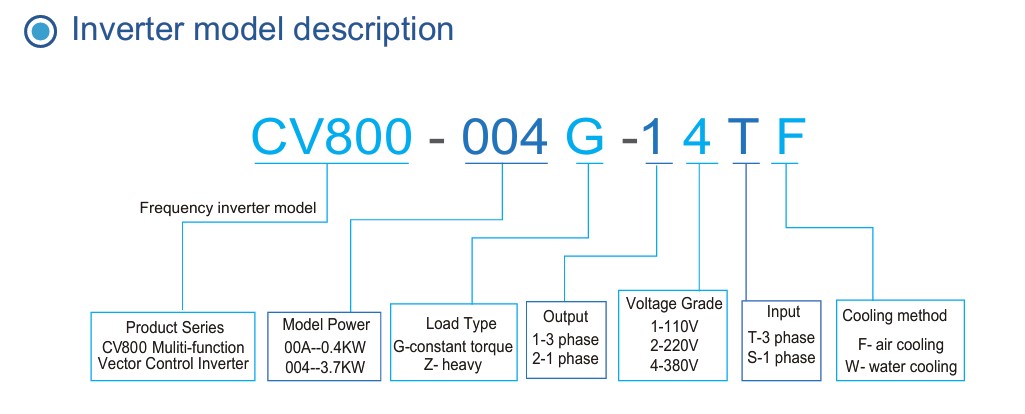

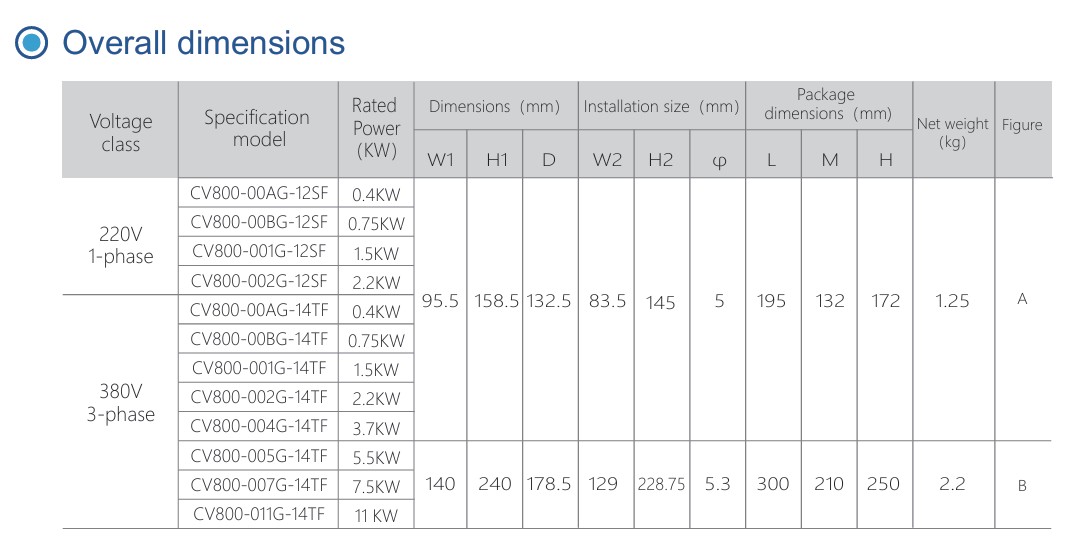

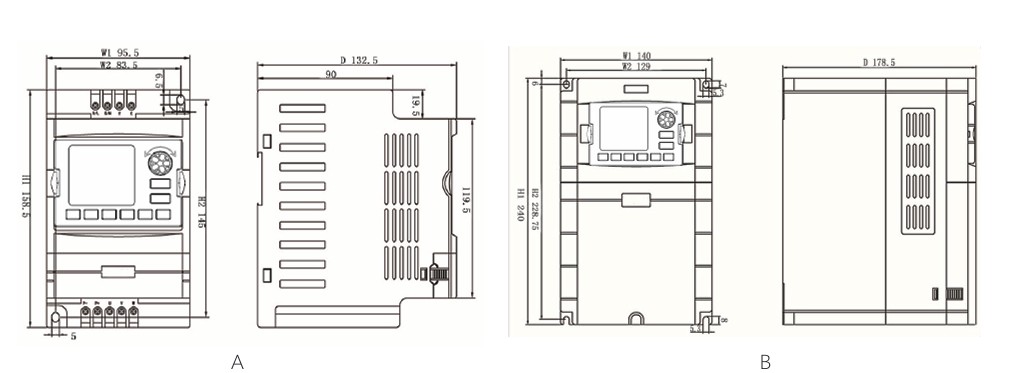

Specifications & Configuration

Why Choose CV800 Series?

Cost-Effective Solution

Competitive pricing with premium features

Reduced installation costs with compact design

Lower maintenance requirements for decreased downtime

Application Flexibility

Wide compatibility with various motor types

Multiple control modes for different applications

Scalable solution for growing operations

Technical Support

Expert application assistance

Comprehensive documentation

Reliable customer service

Frequently Asked Questions

Q: What is the main advantage of CV800's vector V/f control?

A: It provides improved motor control with better torque response and speed accuracy compared to standard V/f control.

Q: Can CV800 be used for constant pressure water supply systems?

A: Yes, with its built-in PID control, it's ideal for constant pressure water supply applications.

Q: Does the CV800 support communication with PLC systems?

A: Yes, it features standard Modbus communication for easy integration with PLCs and control systems.

Q: What makes the CV800 suitable for automated production lines?

A: Its programmable operation control and multi-speed functions allow flexible integration into automated systems.

Q: How does the compact design benefit installation?

A: The space-saving design allows installation in tight control panels and reduces overall system footprint.

Get Your CV800 Inverter Today

Upgrade your equipment with the reliable performance of CV800 Series Multi-Function Vector Control Inverter. Contact us for:

Technical Consultation - Get expert application advice

Custom Quotes - Receive competitive pricing

Fast Delivery - Quick shipping options available

Installation Support - Professional technical guidance

Specifications

Downloads

File name

Language

File Type

Update

Download

Application

![Pump Control Solutions Pump Control Solutions]() Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

VFDs offer intelligent, variable-speed control for all types of pumps—centrifugal, positive displacement, and submersible—enabling precise flow and pressure regulation while reducing energy usage and extending equipment life. They are widely used in water supply, wastewater treatment, irrigation, and chemical processing.![Machine Tool Machine Tool]() Machine ToolPrecision Motor Control for CNC Machines, Grinders, Lathes, and More

Machine ToolPrecision Motor Control for CNC Machines, Grinders, Lathes, and More

In the machine tool industry, precision and stability are critical. VFDs provide smooth, stepless speed regulation and dynamic torque response, making them ideal for controlling spindle motors, feed motors, and auxiliary drives in CNC machines and conventional tools.

Our VFDs are designed for high-performance motor control, with support for sensorless or closed-loop vector modes, enabling reliable operation even under demanding load variations.![HVAC System Control HVAC System Control]() HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

Variable Frequency Drives (VFDs) play a vital role in modern HVAC systems by controlling the speed of motors driving fans, blowers, and pumps. By adjusting motor speed to meet real-time demand, VFDs deliver significant energy savings, reduce mechanical stress, and improve indoor comfort and air quality.

Our VFD solutions are designed with robust hardware, advanced control algorithms, and flexible communication options, making them ideal for various HVAC applications, from commercial buildings to industrial facilities.![Conveyor & Material Handling Conveyor & Material Handling]() Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

VFDs are ideal for conveying systems, offering precise speed regulation, torque control, and automation compatibility. They help eliminate jerks, reduce product spillage, and ensure synchronized movement in complex logistics or production environments.

Related Products

Send Inquiry Now

Sign up for updates