Precise Vector Control for Maximum Industrial Performance

✅ Maintain high torque and stable operation from 0.01Hz.

✅ Achieve energy efficiency through automatic V/F tuning.

✅ Feature an integrated braking system (0.4–37 kW, up to 140%).

✅ Support wide voltage input (380–480V) with CE/ISO certification.

✅ Boast a robust industrial design with a formed coating.

✅ Trusted by global operations with over 300,000 drives worldwide.

Overview

CV900N High-Performance 380V-480V Variable Frequency Drive (VFD)

The CV900N is a high-performance 380V-480V frequency inverter designed for industrial applications that require precise vector control, high torque at low frequencies, and fast dynamic response. This variable frequency drive (VFD) provides stable and accurate speed regulation, ensuring reliable control of electric motors under demanding operating conditions.

Equipped with advanced vector control technology, the CV900N 380V frequency inverter combines a robust structure, high power density, and intelligent design, serving as an efficient frequency converter for diverse industrial systems. Its optimized architecture ensures consistent performance, even in heavy-load applications and continuous operation.

Engineered to meet the needs of various industrial sectors—including machine tools, petrochemicals, lifting equipment, natural gas, ceramics, and plastics—the CV900N variable speed drive offers intuitive functionality, international certifications, and high operational reliability. With balanced technical performance and competitive cost positioning, this 380V industrial VFD is an ideal solution for modernizing and efficiently controlling industrial motors.

Precision Control with Superior Performance

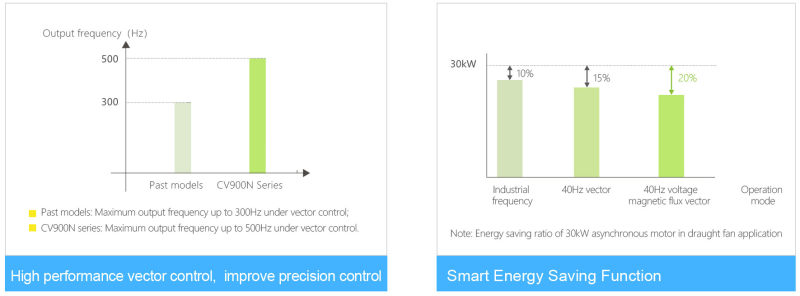

The advanced vector control technology ensures high torque even at low frequencies, rapid dynamic response, and exceptional speed accuracy. It supports output frequencies of up to 500Hz in vector drive mode, enabling precise speed regulation within a 10:1 range and efficient weak field control.

Energy-Saving Intelligence

The CV900N employs closed-loop voltage and flux vector control to automatically adjust the excitation current based on the load, maximizing motor efficiency. This technology significantly reduces energy and motor losses, contributing to lower operating costs and more sustainable operation.High Torque at Low Speeds and Stable Operation

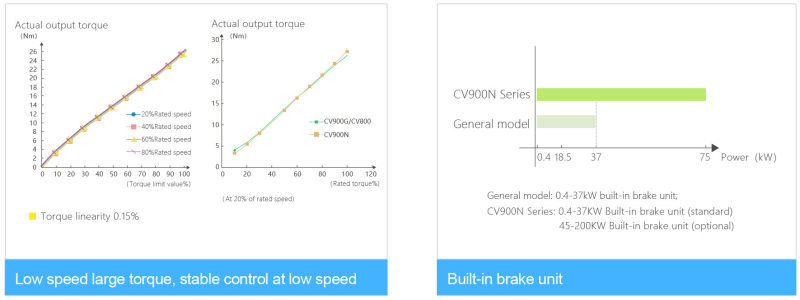

It provides smooth torque and exceptional performance at low frequencies. The drive enables stable operation even at ultra-low speeds of 0.01Hz, ensuring reliability and precision in demanding industrial applications.

Integrated Braking Unit (0.4kW–37kW Type G)

A high-performance integrated braking unit provides short-term braking capacity up to 110%–140% of the rated power. Comprehensive protection includes: braking resistor short-circuit, overcurrent, overload, and open-circuit detection.Robust and Durable Construction

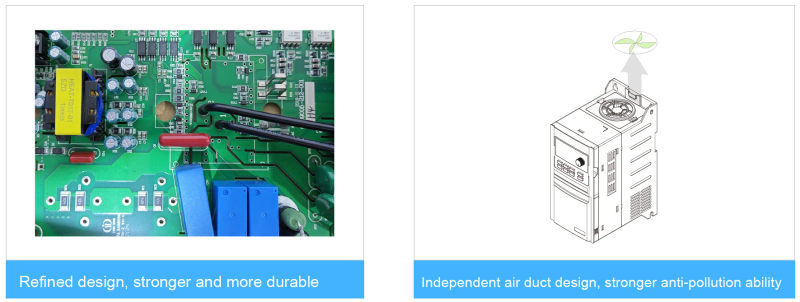

A modular hardware design with high-quality components ensures stability throughout the product lifecycle. An automatically sprayed conformal coating enhances environmental resistance and PCB protection.

Dust Resistant with Independent Air Duct

A separable independent air duct structure effectively prevents dust ingress and reduces short-circuit risks. Equipped with high-flow, long-life cooling fans to minimize temperature rise and enhance operational reliability.Globally Certified and Compatible

Certified with CE and ISO9001:2015, meeting export requirements for high-quality applications. Wide voltage design supports 380–480V three-phase grids, suitable for use in Europe, the Americas, India, and beyond.

Wide Power Range and Broad Application Scope

Covers a power range from 0.4KW to 1500KW, supporting both constant and variable torque loads. Offers three-phase/single-phase output; air-cooled models are available with optional integrated braking. Ideal for applications such as VFDs for pumps, machine tools, petrochemicals, lifting, natural gas, ceramics, plastics, and more.Over 80,000 units sold annually, with more than 300,000 frequency inverters in operation globally.

Why Choose the CV900N Series?

Over 300,000 units in operation worldwide

Annual production exceeding 80,000 units

Advanced vector control technology

Competitive pricing as a variable speed drive

Global technical support and service

Discover the CV900N Series: High-Performance VFD for Sale

The CV900N Series is a high-performance VFD for sale that combines precision control, energy efficiency, and exceptional reliability. As a versatile frequency converter, AC drive, and vector inverter, it is designed to meet the demands of critical motion control applications, including VFDs for pumping systems and robust VFDs for crane operations.

Key Applications:

Precision for Demanding Uses: An ideal VFD for crane applications, providing smooth control and reliable performance for heavy-duty tasks.

Optimized for Critical Systems: Excels as a VFD for pump control and other complex industrial processes.

Superior Engineering: Delivers the performance of a top-tier vector inverter and variable frequency drive.

Contact us today for the competitive AC drive price and detailed technical specifications of this leading frequency inverter solution.

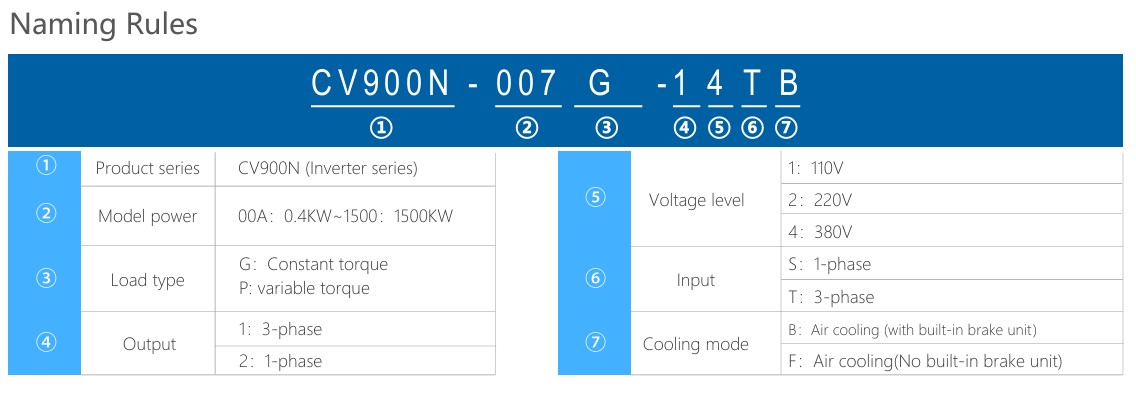

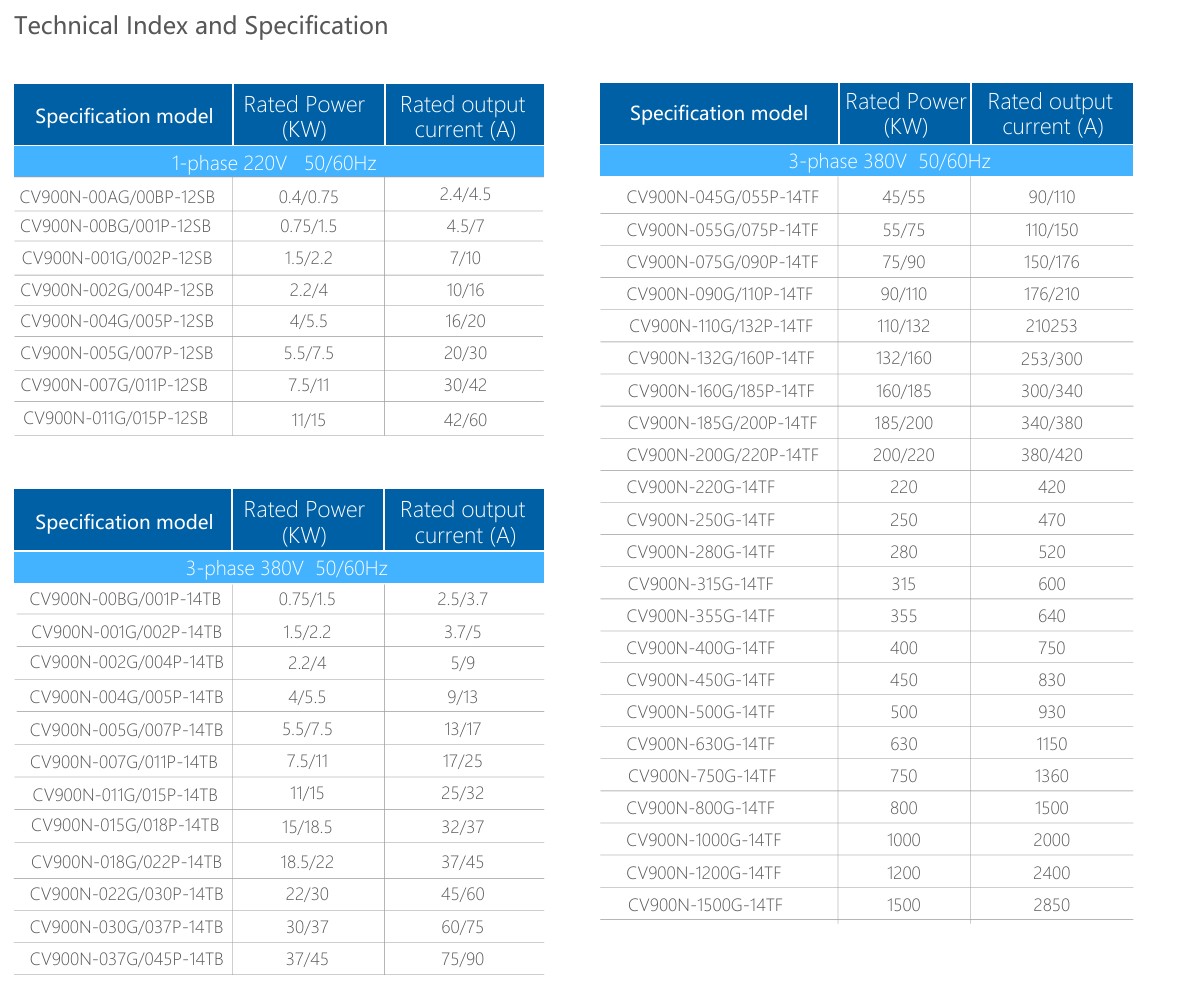

Model Selection

Specifications

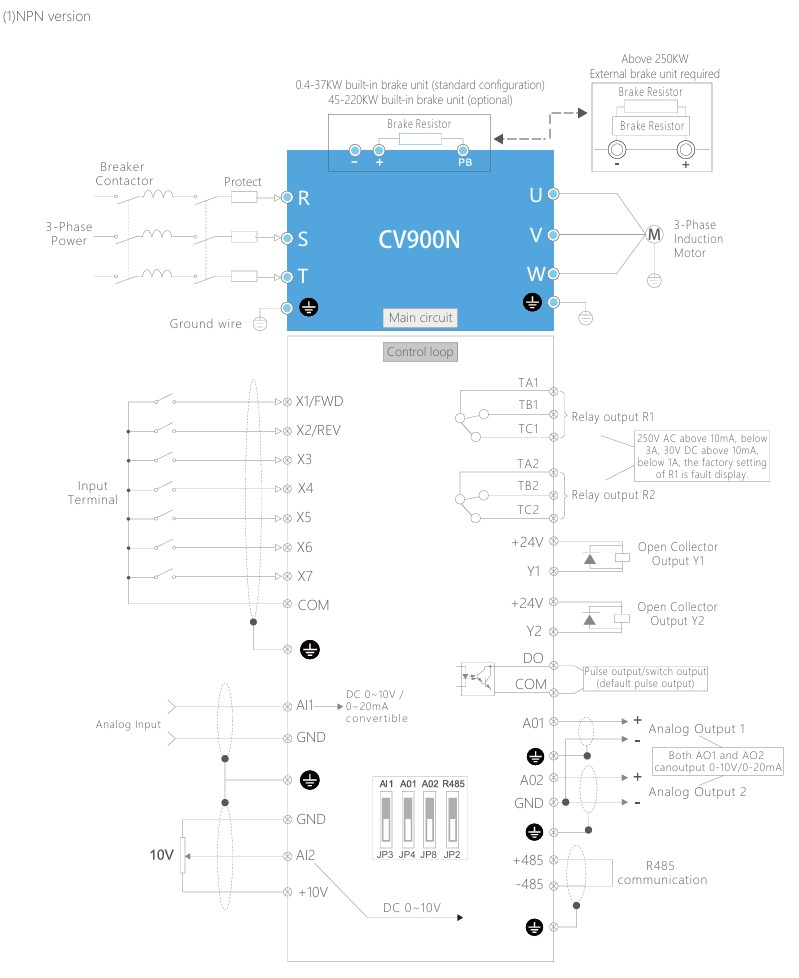

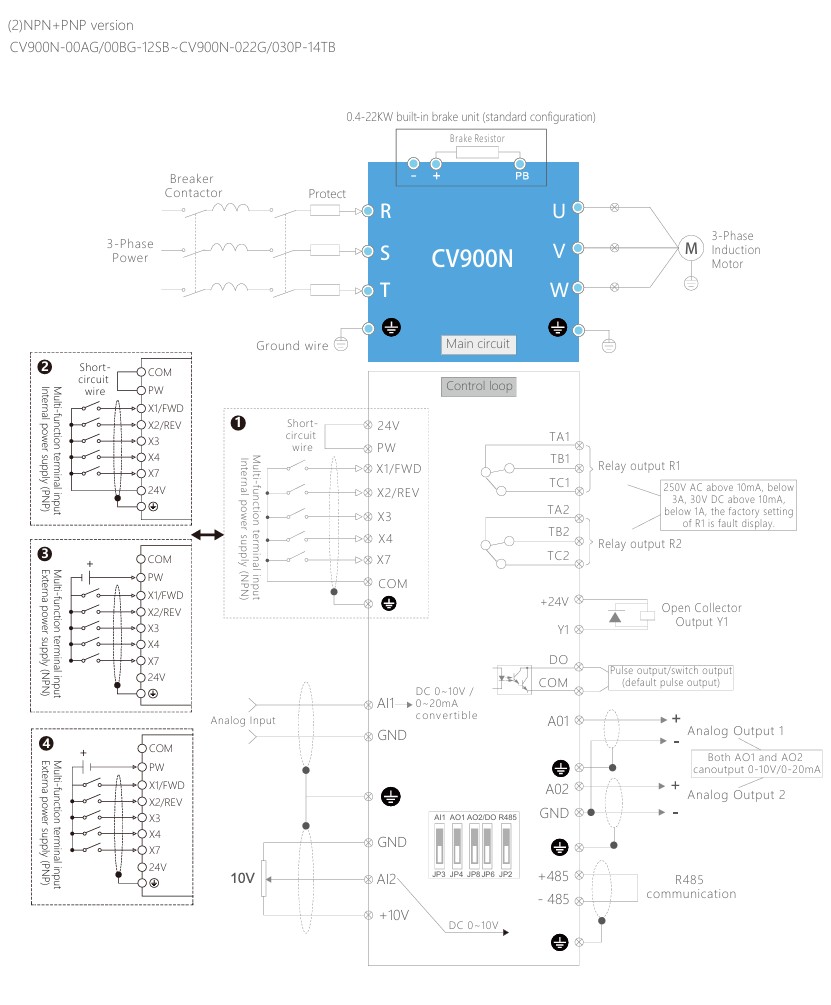

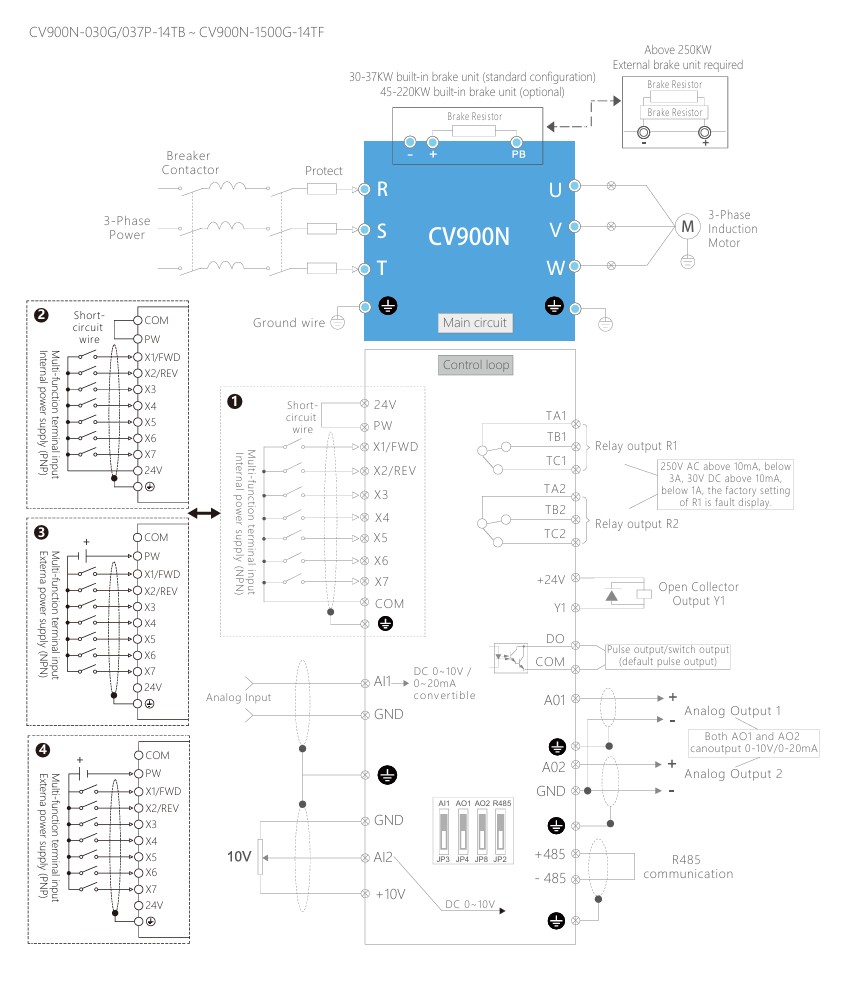

Wiring Diagram

The connection parts of the VFD include the main circuit and the control circuit. By opening the I/O terminal cover, users can see the main circuit and control circuit terminals. They should clearly select the model and connect correctly according to the connection diagrams listed below for different models.

Downloads

File name

Language

File Type

Update

Download

Application

![Pump Control Solutions Pump Control Solutions]() Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

VFDs offer intelligent, variable-speed control for all types of pumps—centrifugal, positive displacement, and submersible—enabling precise flow and pressure regulation while reducing energy usage and extending equipment life. They are widely used in water supply, wastewater treatment, irrigation, and chemical processing.![Machine Tool Machine Tool]() Machine ToolPrecision Motor Control for CNC Machines, Grinders, Lathes, and More

Machine ToolPrecision Motor Control for CNC Machines, Grinders, Lathes, and More

In the machine tool industry, precision and stability are critical. VFDs provide smooth, stepless speed regulation and dynamic torque response, making them ideal for controlling spindle motors, feed motors, and auxiliary drives in CNC machines and conventional tools.

Our VFDs are designed for high-performance motor control, with support for sensorless or closed-loop vector modes, enabling reliable operation even under demanding load variations.![HVAC System Control HVAC System Control]() HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

Variable Frequency Drives (VFDs) play a vital role in modern HVAC systems by controlling the speed of motors driving fans, blowers, and pumps. By adjusting motor speed to meet real-time demand, VFDs deliver significant energy savings, reduce mechanical stress, and improve indoor comfort and air quality.

Our VFD solutions are designed with robust hardware, advanced control algorithms, and flexible communication options, making them ideal for various HVAC applications, from commercial buildings to industrial facilities.![Conveyor & Material Handling Conveyor & Material Handling]() Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

VFDs are ideal for conveying systems, offering precise speed regulation, torque control, and automation compatibility. They help eliminate jerks, reduce product spillage, and ensure synchronized movement in complex logistics or production environments.

Related Products

Send Inquiry Now

Sign up for updates