✅ Enhanced Noise Immunity - Stable operation in electrically noisy environments

✅ Fully Sealed Protection - Dust-resistant construction for extended durability

✅ One-Button Quick Start - Pre-set modes for immediate operation

✅ Rapid Deceleration - Stops in just 0.22 seconds

✅ High Overload Capacity - Handles heavy loads without tripping

✅ Built-in Modbus - Easy integration with automation systems

✅ Flexible Installation - DIN rail or screw mounting options

✅ Multi-Industry Application - Ideal for packaging, medical, woodworking and spindle equipment.

Overview

CV800D Series Frequency Inverter: Compact Power, Superior Control

The CV800D Series frequency inverter (also known as a variable frequency drive or VFD) from Canroon is a compact, high-performance AC drive solution engineered for low-power applications where space savings and reliable speed regulation are critical. This advanced frequency converter delivers robust functionality in a minimal footprint, making it an ideal variable speed drive for a wide range of automation equipment.

Available in single-phase 220V AC and three-phase 380V AC models, the CV800D combines a space-optimized design with advanced features, offering exceptional value for those comparing variable speed drive price and performance. It is more than just a VFD; it's an intelligent vector inverter designed for stability, ease of use, and seamless integration. As a versatile VFD for sale, it represents a cost-effective entry into advanced motor control.

Core Features & Benefits

Ultra-Compact, Space-Saving Design

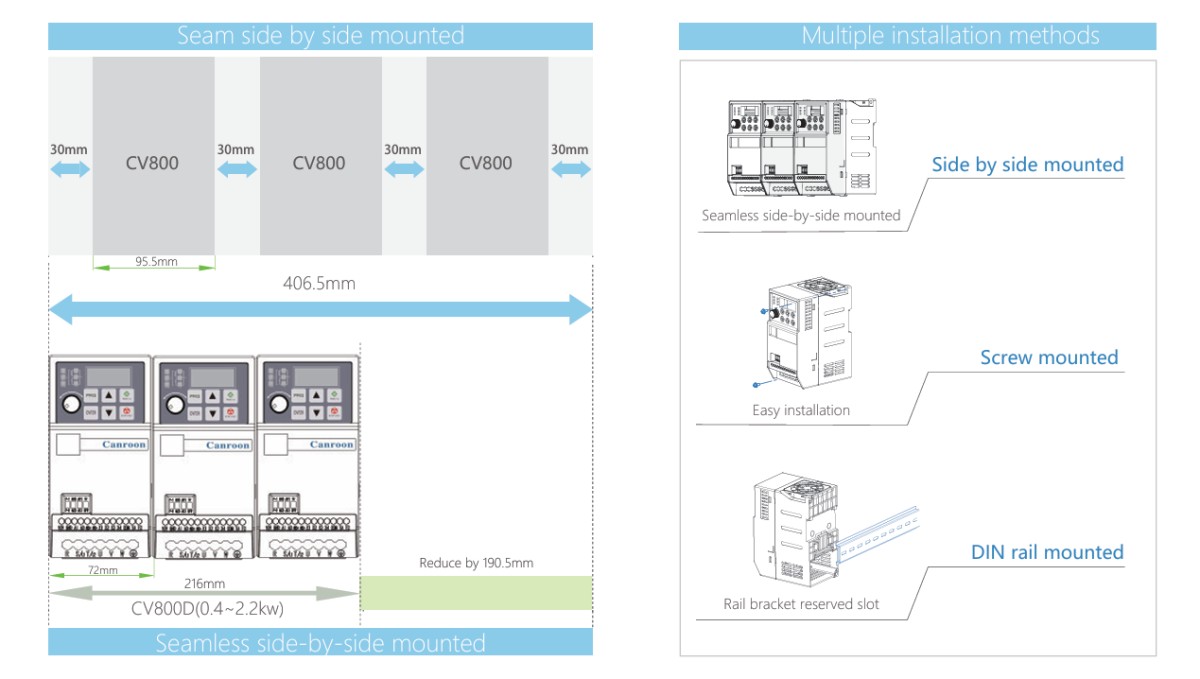

High Power Density: This AC drive maximizes output relative to its size, ideal for compact control cabinets, establishing it as a leading compact inverter.

Uniform Book-Style Design: Ensures easy, side-by-side installation across the entire power range for efficient panel space utilization.

Flexible Mounting Options: Supports both direct screw mounting and DIN rail (35mm) installation for effortless deployment of this mini VFD.

Unmatched Reliability & Stability

Superior EMC Performance: Designed to minimize electromagnetic interference, ensuring stable operation in sensitive environments.

Full Enclosure & Isolated Cooling: Protects internal components from dust and contaminants, guaranteeing long-term durability for all VFD drives.

Vibration-Resistant Construction: Features like thickened conformal coating and reinforced IGBT modules enhance reliability in harsh conditions.

Advanced Performance & Control

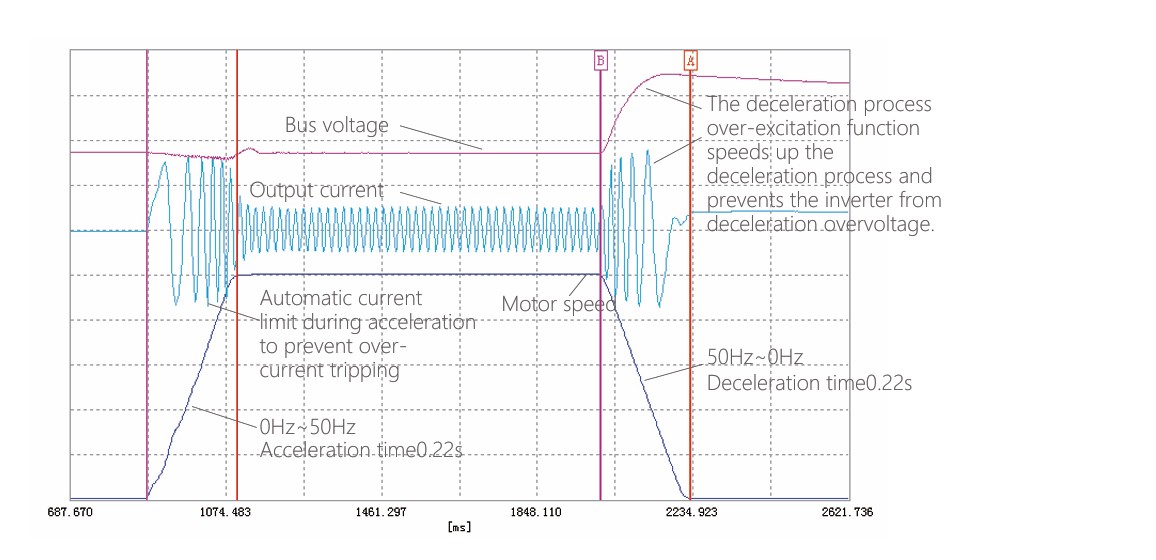

High Overload Capacity: Provides strong starting torque and rapid acceleration/deceleration (e.g., 0.22s from 50Hz to 0Hz).

Fast Braking with Overexcitation: Reduces deceleration time for improved productivity.

Overmodulation Technology: Boosts output voltage from the same input, enhancing motor efficiency.

Smart Overload Management: Prevents nuisance tripping during transient load conditions, even at maximum output.

Built-in Modbus (RS485): Enables simple integration into industrial networks for centralized control and monitoring of your variable speed drive systems.

Simplified Operation & Setup

Pre-Configured Application Macros: One-click setup for common machinery types, streamlining commissioning for specific uses like VFD for pump or VFD for fan control.

External Control Panel Support: Allows for convenient parameter adjustment and real-time monitoring.

Applications:

This mini VFD and compact inverter solution delivers full performance where space is limited, making it an ideal small VFD for a wide range of applications. Perfect for use as a VFD for pump control, VFD for fan systems, conveyors, packaging machinery, and other small automated equipment requiring precise variable frequency drive control.

Discover the CV800D Series

The cost-effective and versatile VFD for sale that delivers powerful performance in a compact package. As a leading small VFD and compact inverter solution, it offers the ideal balance of advanced features, competitive variable speed drive price, and reliable operation.

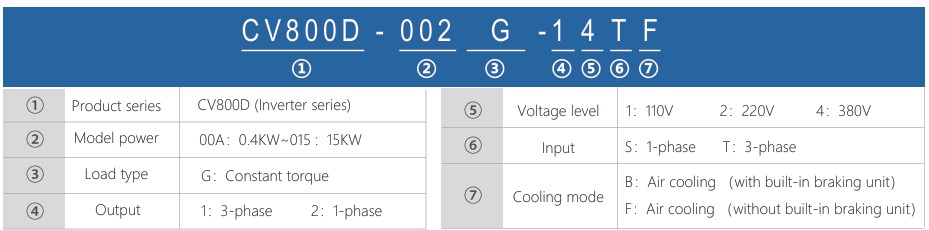

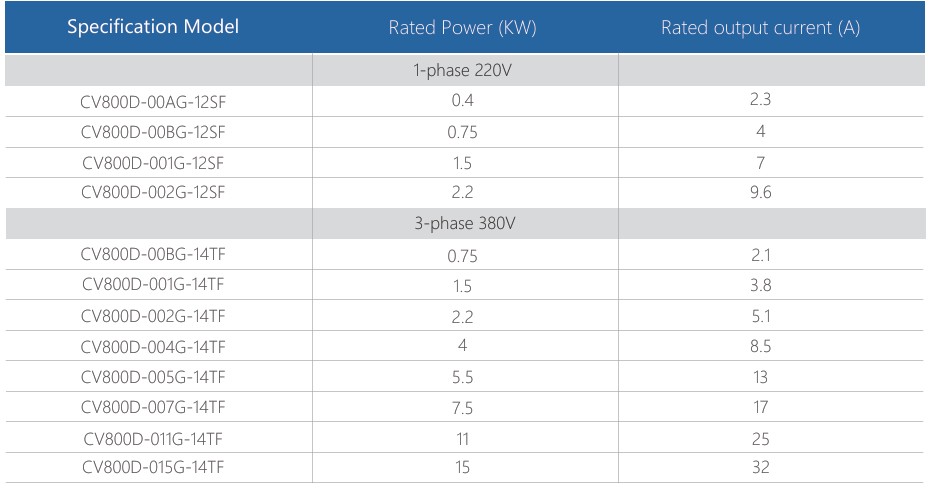

Model Selection

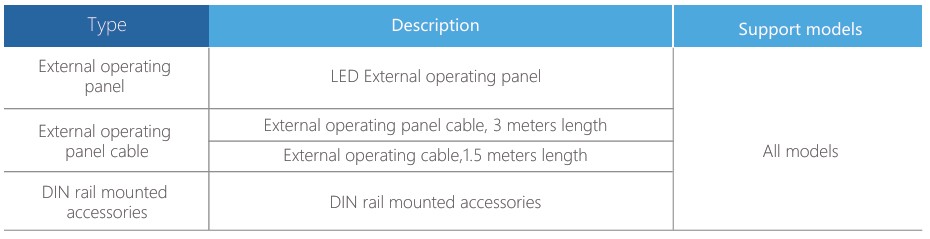

Optional accessories

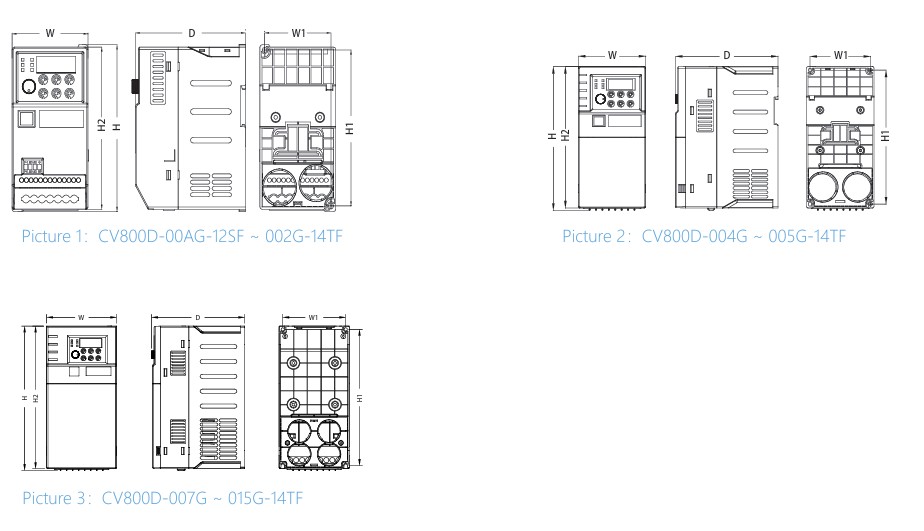

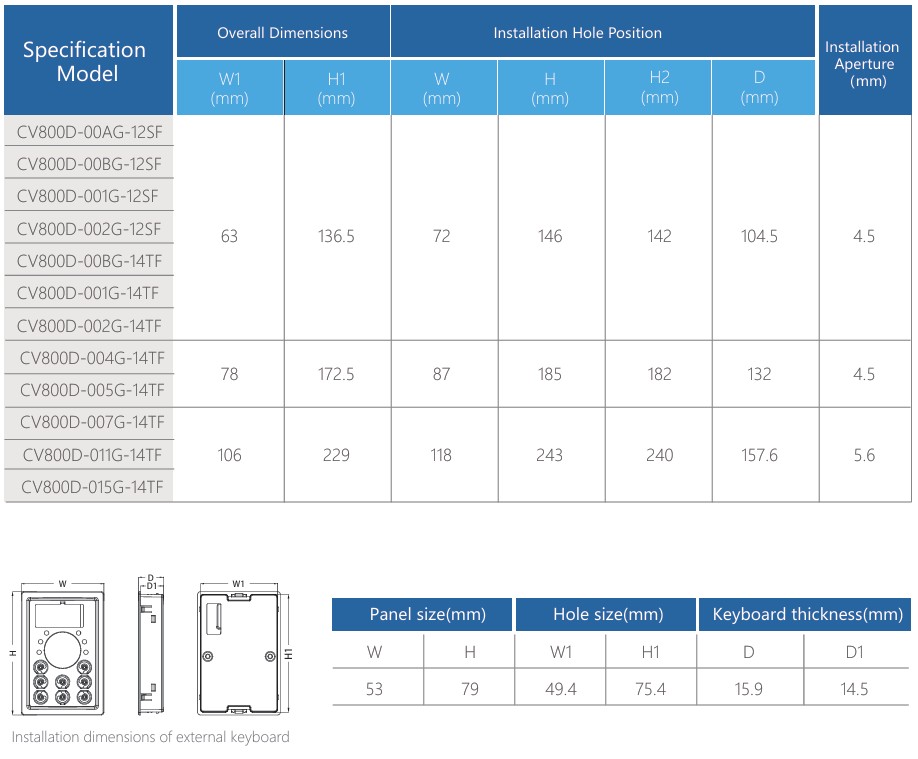

Structure And Dimensions

Specifications

Downloads

File name

Language

File Type

Update

Download

Application

![Pump Control Solutions Pump Control Solutions]() Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

Pump Control SolutionsEfficient and Reliable Motor Control for Water, Wastewater, and Industrial Pumping Systems

VFDs offer intelligent, variable-speed control for all types of pumps—centrifugal, positive displacement, and submersible—enabling precise flow and pressure regulation while reducing energy usage and extending equipment life. They are widely used in water supply, wastewater treatment, irrigation, and chemical processing.![HVAC System Control HVAC System Control]() HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

HVAC System ControlPrecise Speed and Energy Control for Heating, Ventilation, and Air Conditioning Systems

Variable Frequency Drives (VFDs) play a vital role in modern HVAC systems by controlling the speed of motors driving fans, blowers, and pumps. By adjusting motor speed to meet real-time demand, VFDs deliver significant energy savings, reduce mechanical stress, and improve indoor comfort and air quality.

Our VFD solutions are designed with robust hardware, advanced control algorithms, and flexible communication options, making them ideal for various HVAC applications, from commercial buildings to industrial facilities.![Conveyor & Material Handling Conveyor & Material Handling]() Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

Conveyor & Material HandlingSmooth and Accurate Motion Control for Conveyor Belts, Sorters, and Lifting Systems

VFDs are ideal for conveying systems, offering precise speed regulation, torque control, and automation compatibility. They help eliminate jerks, reduce product spillage, and ensure synchronized movement in complex logistics or production environments.

Related Products

Send Inquiry Now

Sign up for updates