Precision Heating Technology for Modern Metal Processing

✅ Fully Safe & Clean Operation: Zero open flame, fumes, or toxic emissions. Multi-level fault protection ensures complete safety for both operators and equipment.

✅ Flexible Integration & Easy Operation: Supports 0-10V / 4-20mA / RS-485 communication protocols. Compatible with automation, CNC systems, and robotic arms. Features an intuitive human-machine interface for ease of use.

✅ Modular Design & Customization: Available in portable, cabinet, or all-in-one configurations. Custom inductors easily adapt to various coil types and complex workpiece shapes.

✅ Efficient Production & Wide Applicability: Significantly reduces rework rates and improves productivity. Ideal for welding preheating, annealing, post-weld heat treatment, anti-corrosion coating, and more.

Overview

The CR2100 Series induction heater represents a breakthrough in industrial heating technology, combining precision engineering with intelligent control systems. This advanced induction heating system delivers exceptional performance for a wide range of metal processing applications. Designed with both operator safety and production efficiency in mind, the induction heater tool features zero emissions operation, rapid heating capabilities, and seamless integration with automated production environments. Whether you're working with steel, aluminum, copper, or specialized alloys, the CR2100 series induction heating machine provides consistent, reliable results while reducing energy consumption and maintenance requirements.

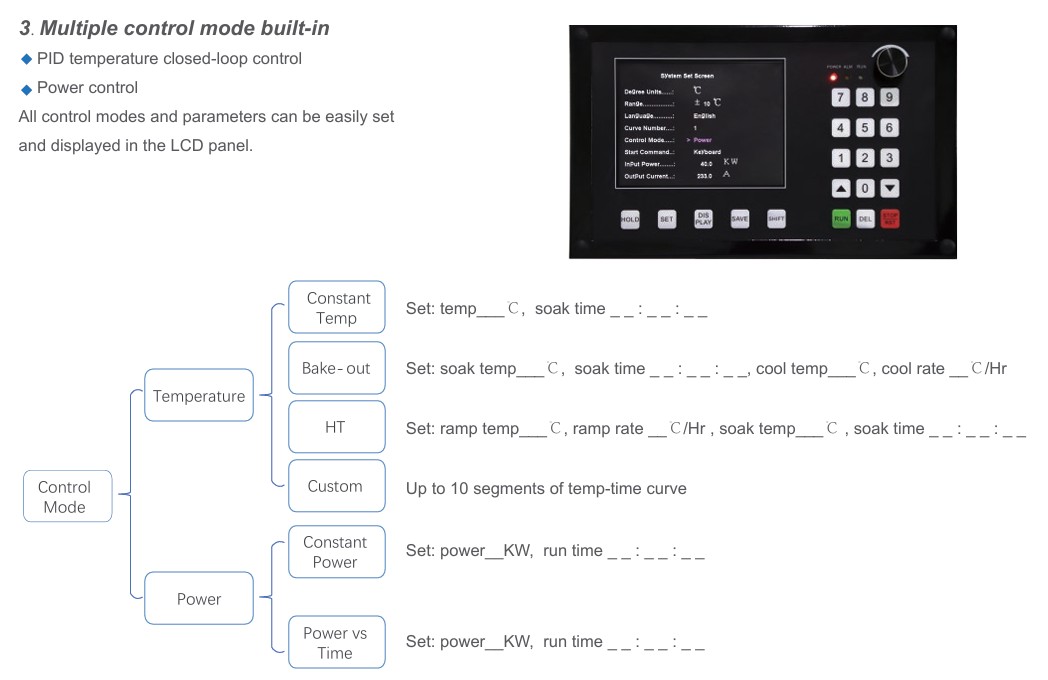

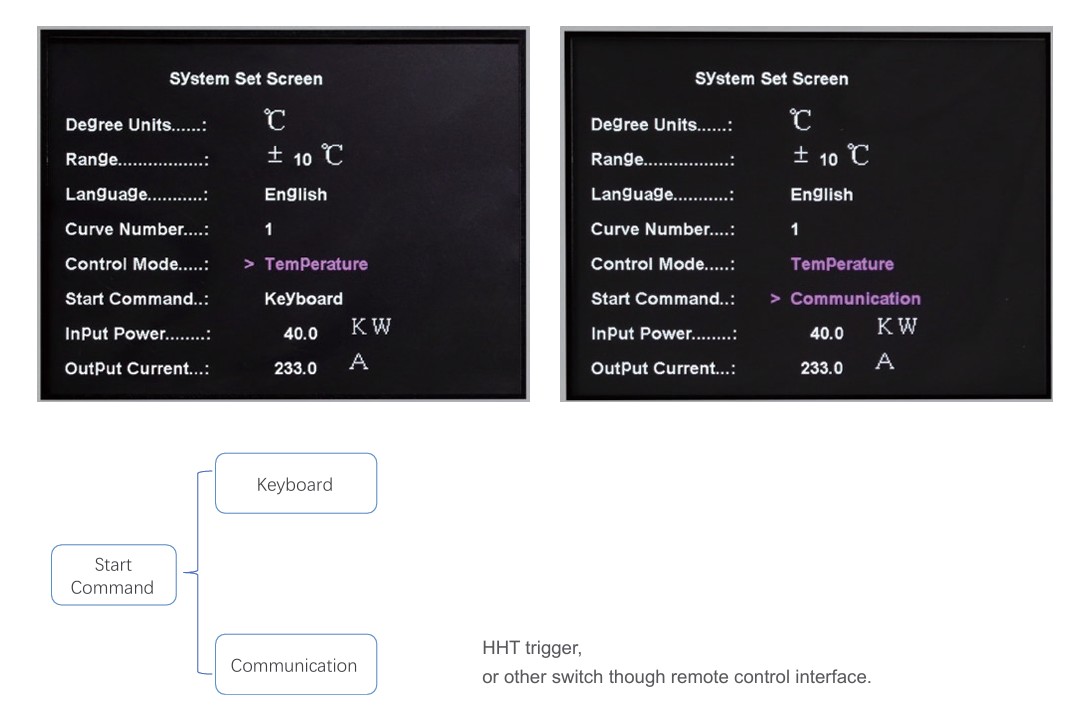

Smart Control & User-Friendly Operation

Intuitive human-machine interface with LCD touch panel

Multiple control modes: PID closed-loop temperature control, power control, and custom programs

Real-time monitoring of operational status and fault diagnostics

Comprehensive Safety System

No open flame, fumes, or toxic emissions

35 fault codes and 11 alarm types including over-current, over-voltage, phase loss, and cooling failures

Automatic shutdown and fault logging for easy maintenance

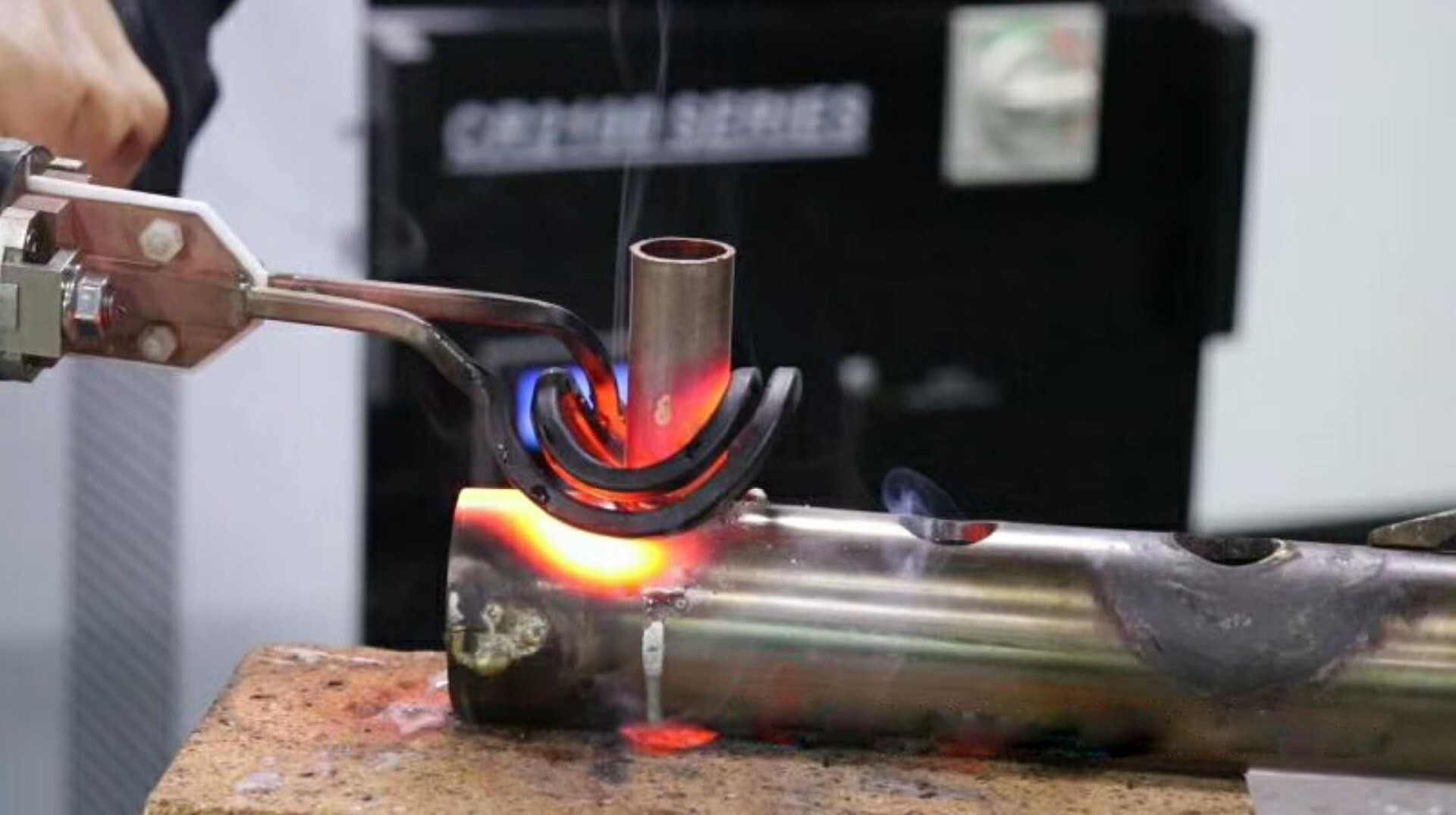

Rapid & Clean Heating

Achieve temperatures exceeding 1000°C within seconds using our high frequency induction heater

Energy-efficient performance without combustion or pollution

Consistent results with minimal rework

Modular & Flexible Design

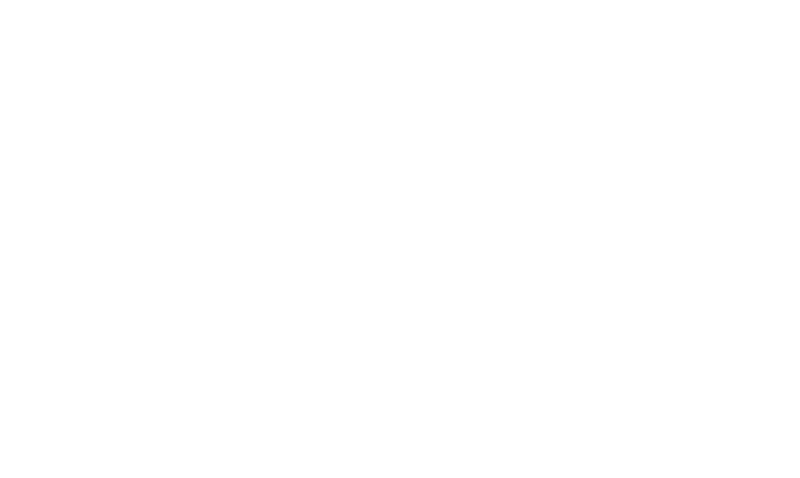

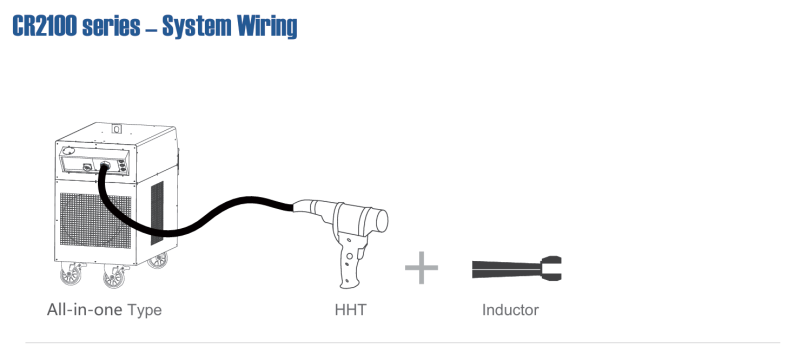

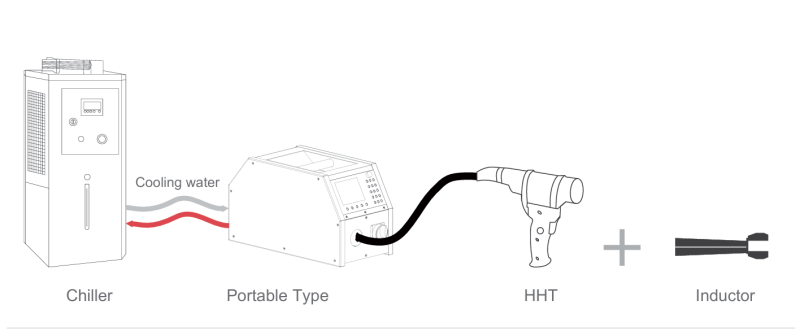

Three configurations: Portable, Cabinet, and All-in-One (with built-in chiller)

Supports external control via 0-10V/4-20mA analog signals and RS-485 communication

Compatible with automation systems and robotic integration

Wide Application Support

Our induction heating systems are engineered for versatility across a broad spectrum of industrial processes, including: annealing, hardening, brazing, curing, shrink-fitting, coating removal, and pre/post-weld heating.

They serve as a highly efficient induction heater for metal, processing everything from steel, copper, and aluminum to titanium, precious metals, and more.

The equipment is highly adaptable to various workpiece shapes and sizes through the use of custom-designed inductors.

Precision Solutions for Key Processes

Beyond general applications, our machines are optimized to excel in specific critical operations, offering targeted solutions for your most demanding needs:

Hardening Machine: Achieve superior surface hardness and wear resistance with our precision induction hardening machines .

Post-Weld Heat Treatment (PWHT): Ensure weld integrity and relieve stresses with our precise PWHT machines .

Targeted Thermal Assembly: From robust induction bolt heaters for fittings and disassembly to delicate induction soldering machines for electronics, we provide controlled, clean heat.

Advanced Joining Technology: Achieve superior, flux-free joints in aerospace and automotive components with our specialized brazing induction heaters .

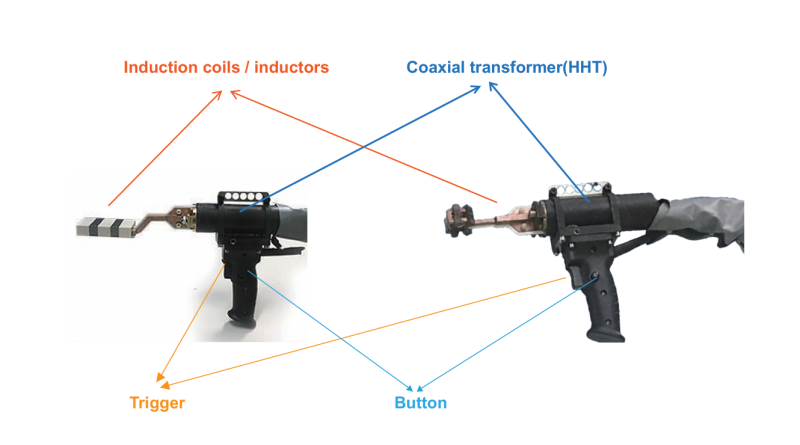

HHT Hand-Held Transformer

Lightweight, ergonomic design for manual operation or robotic integration

Quick-connect interchangeable coils

Dual-control operation: trigger for manual heating, button lock for continuous mode

Customization & Support

Canroon provides complete induction heating solutions, including:

Custom inductor design for specific applications and workpieces

System integration support for CNC and automated production lines

Technical training and maintenance services

Explore the CR2100 induction heater machine - your reliable partner for industrial heating applications, engineered by Canroon, a professional induction heating machine manufacturer. This high-performance induction heater combines innovative technology with practical functionality to meet your most demanding metal processing requirements. As a versatile induction heater for metal and advanced high frequency induction heater, the CR2100 series delivers unmatched performance and reliability for your industrial heating needs.

Specifications

Note: The standard frequency configuration for the CR2100-160B-14TW, CR2100-200B-14TW, CR2100-250B-14TW, and CR2100-300B-14TW models is 10-25kHz. Below 10kHz require customization.

The standard frequency configuration for the CR2100-400B-14TW, CR2100-500B-14TW, CR2100-600B-14TW, and CR2100-800B-14TW models is 10-20kHz. Below 10kHz require customization.

Downloads

File name

Language

File Type

Update

Download

Application

![Brazing & Soldering Brazing & Soldering]() Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Brazing & SolderingClean, Consistent, and Flame-Free Metal Joining for HVAC, Copper, and Aluminum Components

Induction brazing and soldering are highly efficient methods for joining metals using a filler material. Unlike traditional torch brazing, induction delivers precise, localized heat to the joint area — making it ideal for applications in HVAC systems, copper piping, electrical contacts, and automotive aluminum parts.

Our induction heating machines ensure repeatable, high-quality joints with faster cycle times and improved safety — all without an open flame.![Coating & Adhesive Curing Coating & Adhesive Curing]() Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Coating & Adhesive CuringFast, Clean, and Controlled Heat for Paint, Powder, and Structural Adhesive Curing

Induction heating provides a highly efficient and localized method for coating curing and adhesive activation, offering precise thermal control with rapid heat-up — ideal for paint drying, powder coating, epoxy bonding, or glue line curing.

Whether applied to electric motor housings, automotive body parts, or steel structural components, induction delivers reliable results with reduced cycle times and superior energy efficiency compared to ovens or IR lamps.![PWHT PWHT]() PWHTWelding Preheating & PWHT with Induction Heating

PWHTWelding Preheating & PWHT with Induction Heating

Improve Weld Quality and Safety with Precision Induction Preheating and Post-Weld Heat Treatment

Induction heating offers a fast, accurate, and energy-efficient solution for welding preheating and post-weld heat treatment (PWHT) across various industrial sectors. Whether you're working on pipeline welding, pressure vessel fabrication, or offshore structure maintenance, our advanced induction heating machines ensure uniform temperature control and superior metallurgical performance.![Annealing & Stress Relieving Annealing & Stress Relieving]() Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Annealing & Stress RelievingEnhance Metal Ductility, Stability, and Workability with Precise Thermal Processing

Induction annealing and stress relieving are essential heat treatment processes used to soften metals, improve ductility, and relieve residual stresses introduced during forming, machining, or welding. Unlike traditional furnace methods, induction heating provides rapid, localized, and highly controllable thermal processing — ideal for applications such as steel tubing, copper pipe, metal wire, and strip materials.

Related Products

Send Inquiry Now

Sign up for updates