If you want a fast and safe way to make strong joints, induction brazing equipment is often the best choice for modern factories. This system works very well for big jobs and careful work. It is used for things like annealing, hardening, and brazing in car, medical, and appliance companies. Traditional brazing methods are better for small projects and special jobs. There are clear differences in speed, joint strength, and safety between these two ways.

Common uses include:

Annealing

Brazing

Catheter tipping

Cleaning

Hardening

Heat treating

Nanoparticle research

Soldering

Testing

Key Takeaways

Induction brazing works faster than old methods. It heats just the joint and saves time.

Induction brazing is safer because there are no open flames. This lowers the chance of fire at work.

Induction brazing makes joints that are stronger and cleaner. It uses exact heat, so products are better.

Induction brazing costs more at first, but it saves money later. It uses less energy and makes less waste.

Use induction brazing for making many items. Use old methods for small jobs or repairs that need more choices.

Induction Brazing Equipment vs. Traditional Methods

Induction Brazing Equipment Overview

Induction brazing equipment helps join metals fast and with care. It uses electromagnetic induction to heat only the spot you want. The induction coil fits around the part and sends energy to the joint. This makes the metal heat up quickly, usually in 15 seconds to a few minutes. The system has a power supply, cooling, and controls to keep things safe. Operators can watch and change settings with a simple interface.

Induction brazing works with many metals. You can join copper, brass, aluminum, iron, steel, stainless steel, tungsten, chromium, nickel, cobalt, and precious metals. It also works for joining different metals together. You can control the temperature well, so joints are strong and clean. Portable units let you work in small spaces or on-site. Custom systems can be made for special jobs or big factories.

Main features of induction brazing equipment include:

Each workpiece gets its own induction coil.

Electromagnetic induction heats the metal inside.

Only the joint gets hot for better control.

Filler metal melts and fills the space.

Power and cooling keep the process steady.

Controls help heat things just right.

Safety features protect people and machines.

Operators can make changes easily.

Induction brazing is good for big jobs and parts that need exact heat. The process is clean and saves energy. There are no open flames, so it is safer and makes less pollution.

Traditional Brazing Methods Overview

Traditional brazing uses heat from a torch, furnace, or other tools to join metals. You must heat the whole part, not just the joint. This can take a long time, sometimes hours in a furnace. You need to clean the surfaces, add flux, put the filler metal in place, and heat until it melts. The melted metal flows into the joint by capillary action. When it cools, the joint becomes solid.

Traditional flame brazing works with many metals like aluminum alloys, stainless steels, copper, and nickel alloys. You can also join metals to ceramics and thin parts like radiators. This method is used in cars, planes, and power plants.

Basic steps for traditional brazing are:

Clean the parts to remove dirt and oil.

Add flux to stop oxidation.

Put filler metal at the joint.

Heat until the filler melts.

Let the melted metal flow into the gap.

Cool the part to make the joint solid.

Traditional brazing is flexible for small jobs and repairs. You can use it to join different materials. You must watch the heat to avoid hurting the base metals.

Main Differences in Process and Application

There are big differences between induction brazing and traditional methods. Induction brazing uses electromagnetic fields to heat just the joint. Traditional brazing heats the whole part. Induction brazing is much faster and gives better joints because you control the heat. There are no open flames, so it is safer and cleaner.

Here is a table that shows the main differences:

You should pick induction brazing for big, careful jobs and when you want strong, clean joints. Traditional flame brazing is good for small or special projects and for joining unusual materials.

Speed and Efficiency in Induction Brazing

Faster Heating Cycles

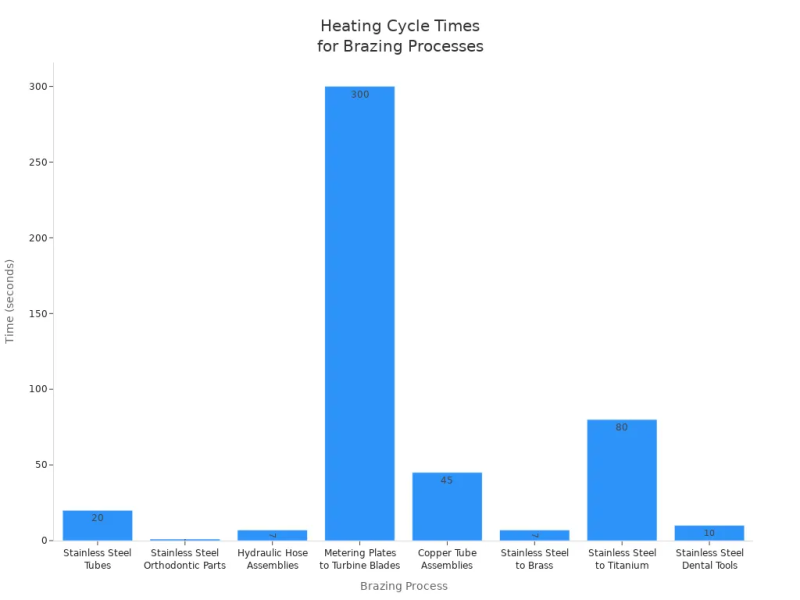

Induction brazing heats up joints much faster than old ways. It only heats the spot you need, not the whole part. This saves a lot of time. For example, stainless steel tubes can be brazed in 20 seconds. Orthodontic parts take just 1 second. Copper tube assemblies need about 45 seconds. Brazing metering plates to turbine blades with nickel takes 5 minutes. Here is a table that shows how long different jobs take:

Induction lets you pick the right temperature and time for each job. This stops overheating and keeps joints strong and clean. You can make more parts faster and use your time better.

Production Throughput

Induction brazing helps factories make more parts in less time. It heats only the joint, so you do not waste time on the rest of the part. This means you can finish more jobs than with old methods.

Induction heating puts energy right into the joint. It does not heat the whole part. This makes heating much faster than using a furnace or torch. You get shorter cycles and can make more parts.

Induction brazing machines are fast and accurate. They make good joints every time. They save energy and are safer to use. These machines help factories work better and make higher quality parts.

Many companies have made more parts after switching to induction. Here are some results:

A big bearing company made more parts after getting an automated induction billet-heating line.

The new system made heating times shorter and more even.

The plant could use its press more because billets heated faster.

Better temperature control meant more good parts and less fixing.

Fewer bad parts and less scrap happened because of steady heat and less oxidation.

Safety got better because workers did not have to touch hot parts and there was less risk of contamination.

Induction brazing helps you make more parts, get better quality, and keep workers safe. This is why it is a smart choice for today’s factories.

Quality of Joint and Precision

Induction Brazing Joint Quality

Induction brazing lets you make strong and clean joints. The equipment heats only the spot you need. This helps you control the temperature very well. You do not overheat the part. You can repeat the process and get the same results each time. The heat stays in one area, so the rest of the part stays cool. This means the metal does not bend or weaken. Your joints will be better and your products will work well.

Induction brazing is good for small and detailed parts. It works fast and does not leave much mess or mistakes. The heat is focused, so the joints are high quality. Here is a table to compare:

Induction brazing gives you results you can trust. It is best when you need many parts to be the same.

Traditional Brazing Joint Quality

Traditional brazing, like using a flame or furnace, can also make good joints. But it is harder to control the heat. The whole part gets hot, which can bend the metal and make it weaker. The joints may not always look or work the same.

Problems with traditional brazing include:

Holes or bubbles if the filler does not flow right

Flux stuck inside if the joint cannot vent

Broken lines on the joint surface

Metal wearing away, which makes the joint weak

Bad surface that can rust

Cracks that make the joint last less time

If you want better joints and more trust in your products, induction brazing is a better choice. Traditional methods are still useful for some jobs, but they may not be as exact or steady as induction.

Energy Efficiency and Safety

Induction Brazing Energy Use

Induction brazing helps you save energy and money. It heats metal only where you need it. You do not have to heat a whole furnace. This makes the process use less energy. The heat goes right into the joint, so it works faster.

Induction brazing makes heat inside the workpiece. This means you use less power.

You do not have to heat big spaces or the whole furnace like with traditional brazing.

Less energy is lost to the air, so your work is more efficient.

You spend less on energy because you only heat what you need.

Traditional brazing uses more energy. You must heat bigger areas, so your bills go up. Induction brazing keeps costs low and your process cleaner.

Induction brazing helps you work better. You use less energy and get good results. It is a smart way to make factories more efficient.

Safety Advantages

Induction brazing makes your workplace safer. It does not use open flames, so there is less fire risk. You do not have to worry about burning or dangerous gases. Induction brazing keeps your space clean and safe.

Induction brazing has no open flames, so burns are less likely.

You do not have to worry about fires, which can happen with traditional brazing.

The process keeps your workspace safer and cleaner for everyone.

Traditional brazing uses torches or furnaces. These tools can cause accidents and make work less safe. Induction brazing helps protect your team and equipment.

You can trust induction brazing to keep your factory safe. It helps stop accidents and keeps your work area clean.

Cost Considerations

Initial Equipment Investment

Induction brazing equipment costs more when you first buy it. You need special machines, coils, and controls for this method. Many factories use induction brazing all over the world. In 2023, the global market for induction brazing equipment was about $2.5 billion USD. This means lots of companies think induction brazing is worth the money.

Here are some things to remember:

Induction brazing equipment costs more at first than traditional setups.

You pay more at the start, but you can save money later.

Other advanced systems, like HHO welding machines, also cost more at first. They help you save money over time, just like induction brazing.

If you do small jobs or want more choices, traditional brazing may be cheaper for you. If you work on big jobs or need very exact work, induction equipment can save you money in the future.

Operating and Maintenance Costs

Induction brazing costs less to run and fix than traditional brazing. It works faster and keeps things cleaner. It heats only the part you need, so you use less energy. This helps you spend less on power bills.

You also get these good things:

Induction brazing can turn up to 90% of energy into heat. Traditional batch furnaces only reach about 45% efficiency.

One company spent $10,000 a year to run a furnace. With induction, the cost dropped to $1,000.

Preheating with a torch cost $6.37 per part. Induction did the same job for only $0.58.

Induction brazing uses simple fixtures that last longer and need less fixing.

You get steady, high-quality joints with less waste and fewer repairs.

Traditional brazing can cost more to run and fix. You may need to buy new parts more often and pay higher energy bills. Induction brazing helps you save money and makes your work easier.

Application Suitability

High-Volume and Precise Manufacturing

When you make lots of parts every day, you need tools you can trust. Induction brazing is best for big jobs that need to be fast and exact. This method lets you join parts quickly and get the same results each time. The equipment heats only the joint, so the rest of the part stays safe. There are no open flames, so your workspace is safer.

Many companies use induction brazing for important parts. Here is a table that shows where this method is most helpful:

Induction brazing helps you make strong, clean joints in parts that cannot break. You get better quality and waste less material. This method is best for factories that need to work fast and make exact parts.

Flexible and Small-Scale Projects

Sometimes you need to fix things right where they are or work with parts that are not regular shapes. Traditional brazing gives you more choices. You can use a torch almost anywhere, even outside the shop. This makes it easy to fix pipes or join big, odd-shaped parts. You do not need big machines or special setups.

Here is a table that shows the main ideas:

You can take your tools with you to different places. You can work on small jobs or special projects. You need to know what you are doing, and you must be careful about fire. Traditional brazing is good when you want to save money and need to work in many places.

Tip: Pick induction brazing for big jobs that need to be fast and exact. Use traditional methods for repairs, small batches, or when you need to move your tools.

Pros and Cons Summary

Induction Brazing Equipment Pros and Cons

Induction brazing equipment helps factories in many ways. You heat just the joint, so you save energy. The rest of the part stays cool and safe. You can finish jobs faster and make more parts. The joints are strong and clean, with fewer mistakes. There are no open flames, so your workspace is safer.

Here is a simple table of the main pros and cons:

Tip: Choose induction brazing equipment if you want quick, safe, and high-quality joints in your factory.

Traditional Methods Pros and Cons

Traditional brazing methods are flexible and good for repairs. You can use a torch almost anywhere. You do not need special machines. You can join different metals and odd shapes. Many experts say these methods make strong joints. Some jobs can even be automated.

But there are some problems. Fuels like acetylene can cause oxidation. This may make joints fail early. Flame temperatures can change, so it is hard to keep quality steady. Soot from the flame can get into the joint and cause trouble. The flame can also hurt nearby materials, which costs more and lowers efficiency.

Pros:

Strong joints

Ability to join dissimilar metals

Lower temperatures help prevent distortion

Easy to automate for some tasks

Cons:

Fuels can cause oxidation and early failures

Flame temperatures are not always steady

Soot can contaminate joints

Flame may damage surrounding materials

Note: Traditional brazing is good for small jobs and repairs, but you must watch out for safety and quality problems.

Choosing the Right Brazing Method

Decision Factors for Manufacturers

When you pick a brazing method, you have many things to think about. You need to know how fast you want to work. You should look at what materials you use. You must decide how strong you want your joints. Safety is important too. You also need to think about cost and how many parts you make.

Here is a table that lists the main pros and cons for each way:

Ask yourself these questions before you choose:

Can the equipment reach the right temperature for your filler metal?

Does the fuel type match your materials?

Will the equipment work with your brazing rods?

Can you control the flame or heat for precise work?

Is the equipment comfortable and built to last?

Does it have safety features to protect your team?

Is it certified to meet safety standards?

Think about how many parts you make each day. If you make lots of parts, induction brazing helps you work faster and safer. If you use many types of metals or odd shapes, traditional brazing gives you more choices.

You should also think about how heat moves in your joint. The heat capacity of your base metals matters. The shape of your joint can change which method works best. You need to match your method to your materials and your goals.

Switching from torch brazing to induction brazing gives you better thermal efficiency and joint quality. You also get a safer workplace because there are no open flames. But induction brazing costs more at first and your workers need special training.

Quick Selection Guide

This guide can help you pick the right brazing method:

Production Volume

Use induction brazing for big jobs.

Pick traditional brazing for small batches or repairs.

Material Type

Choose induction brazing for conductive metals.

Use traditional brazing for non-conductive or mixed materials.

Joint Quality

Pick induction brazing for strong, repeatable joints.

Use traditional brazing if you need flexible joint shapes.

Safety

Induction brazing is safer because it does not use open flames.

Traditional brazing needs careful handling to avoid burns and fire.

Cost

Induction brazing costs more at first but saves money later.

Traditional brazing costs less to start but may use more energy and need more repairs.

💡 Tip: If you want fast, clean, and strong joints for many parts, induction brazing is your best choice. If you need to fix things on-site or work with many types of metals, traditional brazing gives you more options.

Here is a simple checklist to help you decide:

- Do you need to make many parts quickly? - Are your materials mostly conductive metals? - Is joint quality and repeatability important? - Do you want a safer workspace with no open flames? - Can you invest in new equipment and training?

If you answer "yes" to most of these, induction brazing is a good fit. If you answer "no," traditional brazing may work better for your shop.

You should match your brazing method to your production goals, material types, and safety needs. This helps you get the best results for your business.

You can make things faster, safer, and use less energy with induction brazing equipment. One company brazed fishhooks in only 35 seconds. This shows how helpful induction brazing is for today’s factories. The table below shows the main differences:

Metal brazing helps you waste less and make more money. Before you choose, think about what your project needs and how much you want to spend. This will help you get the best results for your business.

FAQ

What is the main benefit of induction brazing for factories?

Induction brazing helps factories work faster and make stronger joints. It heats just the joint, not the whole part. This saves both time and energy. There are no open flames, so it is safer for workers.

Can you use induction brazing on all metals?

Induction brazing works on most metals that conduct electricity, like copper, steel, and aluminum. It does not work well on materials that do not conduct. Always check what your metal is before you start.

Is induction brazing safer than traditional brazing?

Induction brazing is safer because there are no open flames. This lowers the chance of burns or fires. The process keeps the workspace cleaner and helps stop accidents.

Does induction brazing cost more to start?

Induction equipment costs more at the beginning. But you save money later on energy and repairs. Many factories think the savings over time are worth the higher starting price.

When should you choose traditional brazing?

Pick traditional brazing for small jobs, repairs, or when you need to work at the job site. It is good for odd shapes and mixed materials. You do not need special machines to use it.

Sign up for updates