If you want the best induction brazing machine for 2025, look at models from Canroon, Ultraflex Power Technologies, Fusion Inc., Radyne Corporation, and Siemens. You need a machine that works well, brazes fast, and is easy to move. Many professionals pick portable machines because they help you work better and let you do brazing almost anywhere. The US induction market is growing quickly.

The market size may reach about USD 3.5 billion in 2025.

Experts think it will grow by 5.6% each year for a while.

Choose the induction machine that fits your brazing jobs and how you like to work. The right machine will always give you good results and work well.

Key Takeaways

Portable induction brazing machines help professionals who move a lot. These machines make work fast and easy in many places. They help create strong joints quickly.

Induction brazing uses less energy and is safer than old ways. It heats metal right away. This saves power and there are no open flames.

When picking a brazing machine, think about how much power you need. Make sure it is easy to use and has good safety parts. Machines with digital controls and alarms work better and keep you safer.

More people are buying induction brazing machines now. Prices go from $600 to $9,000. Smart features and saving energy can make the price higher.

Top brands like Canroon, Ultraflex, and Siemens have special features. Pick a machine that matches your job and your budget.

Induction Brazing Machine Overview

What Is an Induction Brazing Machine

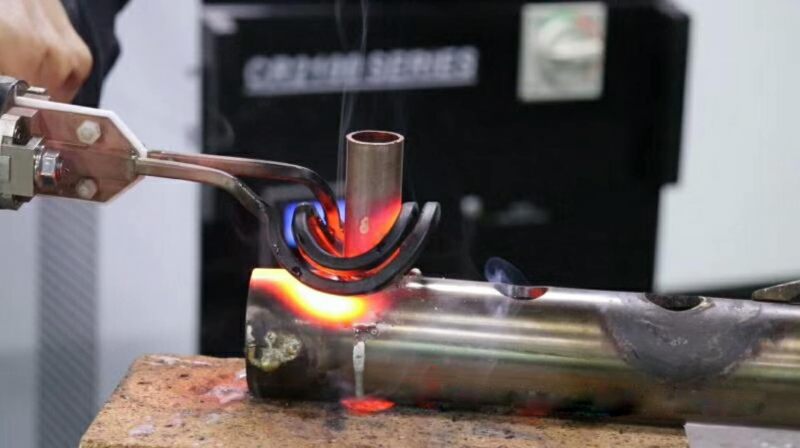

If you work with metal, joining parts fast is important. An induction brazing machine helps you do this job safely. It uses induction to heat metal parts and melt filler material. This joins the pieces together but does not melt the base metals. The process makes a strong bond between two parts. It is good for fixing things or making new products.

You might ask how this is different from other ways to braze. Here are some main differences:

Induction brazing saves energy. It changes electricity into heat right inside the metal. This means you use less power and save money.

Old methods like flame brazing or furnace brazing use more energy. They also take longer to heat up.

Induction brazing is safer. You do not need to worry about open flames or fire.

You get better joints because you can control the heat and time. This means less oxidation and fewer problems with your finished part.

There are two main types of induction brazing machines: portable and stationary. Portable machines are easy to move around your shop or to other places. Stationary machines stay in one spot and are used for bigger jobs.

Here is a quick table that shows how portable and stationary machines are different:

Key Features for Professionals

When you choose an induction brazing machine, you want features that help you work better and faster. Here are some things professionals want:

Very fast heating, sometimes in less than a second.

High energy efficiency, so you spend less on power.

Quiet and clean work, with no smoke or loud noise.

Easy to use, so one person can do the job.

Can work on many kinds of metal parts.

Works well even if you use it all day.

If you need to move your machine, portability is very helpful. Some machines, like the MiniMICO, are light and easy to set up anywhere. This makes it easier to finish jobs quickly and keeps your work going smoothly.

Portable Induction Brazing Machine Market

United States Induction Brazing Machine Market

The induction brazing machine market is changing quickly in the United States. Many workers want machines that are easy to move and simple to use. In the last five years, more companies have started using these machines. You see them in car shops, airplane factories, and places that make electronics. People want machines that save energy and use smart technology.

Here are some new trends in the United States induction brazing machine market:

Saving energy is very important for buyers.

Car and airplane companies buy many of these machines.

Portable machines with smart features change metal work.

IoT lets you check machines and get alerts for fixing.

The induction brazing machine market is not just getting bigger. It is also getting smarter and easier to use. You can find machines that match your needs and help you finish jobs faster.

Price Range and Trends

If you look at the United States induction brazing machine market, you will see many prices for portable models. Some machines cost about $600. Others can cost up to $9,000. The price depends on what features, power, and smart technology the machine has.

Many things affect the price of induction brazing machines. New technology makes machines work better, but can make them cost more. Special machines for unique jobs cost extra. Big brands and new companies compete, so prices change. Companies use digital data to set prices and learn what buyers want. Fast research brings new ideas and changes prices.

There are many choices in the United States induction brazing machine market. If you want a portable brazing machine, you can find one that fits your budget and work style. The market keeps growing, and new trends help you get the best machine for your job.

Top Induction Brazing Machines in 2025

If you want the best brazing machine, you should know what each one does. Let’s check out the top induction brazing machines for professionals in 2025. You will learn what makes each machine special. You will see how each machine helps you. You will also find out what to watch for.

Canroon Portable Induction Brazing Machine

The Canroon portable induction brazing machine has high power and is easy to move. Its frame is made from aluminum alloy, so you can carry it to different places. The digital touch screen shows feedback right away. This makes it easy to control the heat for each job. It gives you 10kW power output. You can use it for heavy-duty brazing, welding, and soldering.

Here are the main features:

You get these pros:

It saves energy

You can change the coil size

It works nonstop with a 100% duty cycle

It works for many industries

It is light and easy to move

But you should know:

You need a water cooling system

Setting it up the first time can be hard

If you want strong performance and easy movement, Canroon is a good choice.

Ultraflex Power Technologies

Ultraflex Power Technologies makes induction brazing machines that focus on precision and safety. You get the same results every time because the heat goes right to the joint. This machine uses electromagnetic fields, so you do not need open flames. You can use it in more places, and it is safer for you and your team.

Here is what stands out:

You get heating only where you need it

The process is repeatable, so jobs look the same

It is safer and works in more places

If you want clean, precise joints and a safe workspace, Ultraflex is a good pick.

Fusion Inc.

Fusion Inc. has portable induction brazing machines with smart features for professionals. You get an operator station with a PLC interface. You can change parts quickly and see diagnostics for troubleshooting. The quick-disconnect manifolds let you swap parts without tools. This saves you time. You can adjust the manifold position for different jobs.

You can use Fusion’s machine for many jobs. You save time with fast part changes. You get more control over each cycle. If you want to work faster and smarter, Fusion Inc. is worth a look.

Radyne Corporation

Radyne Corporation builds induction brazing machines for tough jobs. You get strong heating power and reliable performance. These machines work well for automotive, aerospace, and electronics. You can use them for small and large parts. Radyne’s machines are durable, so you can use them all day.

You get:

High heating power for thick metals

Reliable operation for long shifts

Flexible use for many jobs

If you need a machine for heavy work and long life, Radyne is a solid choice.

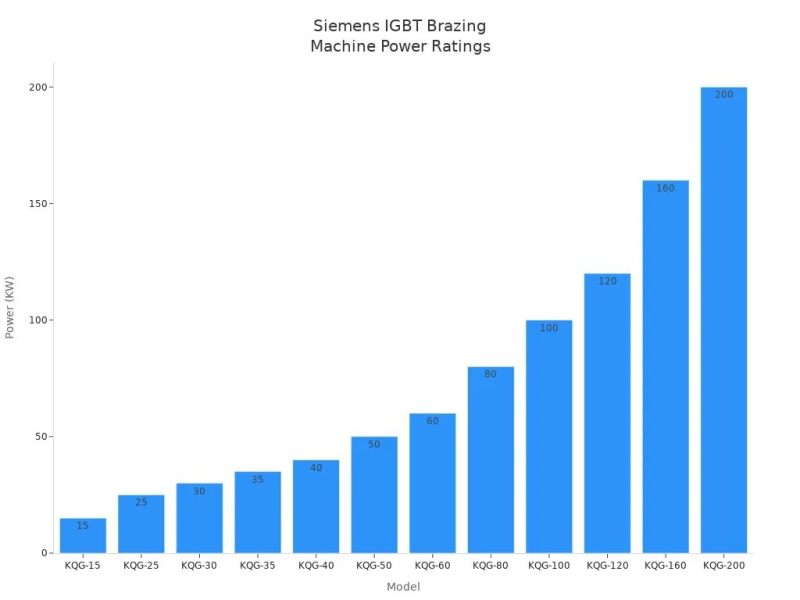

Siemens IGBT High Frequency Brazing Machine

Siemens makes IGBT high frequency brazing machines with many power options. You can pick a machine from 15KW up to 200KW. This means you always get the right power for your job. These machines heat parts fast and evenly. You get simple installation and easy operation. Siemens adds alarm protection to keep you safe.

You get these benefits:

Fast and even heating

Many uses for different jobs

Easy to install and use

Good alarm protection

If you want many power choices and strong safety, Siemens is a great option.

OEM DSP-50KW Model

The OEM DSP-50KW induction brazing machine gives you high power and digital control. You can use it for big jobs in workshops or factories. The digital system lets you set the heat and time for each job. You get steady performance and strong joints. This machine works well for copper, steel, and aluminum.

You get:

50KW power for large jobs

Digital control for easy settings

Steady heating for strong joints

Works for many metals

If you need a machine for big projects and want easy control, the OEM DSP-50KW model is a smart pick.

Tip: When you pick a brazing machine, think about your job size, how often you move the machine, and what metals you use. Each induction brazing machine has strengths for different needs.

Brazing Machine Comparison Table

It can be hard to pick the right brazing machine. You want a tool that matches how you work. It should help you finish jobs quickly. The table below shows top models. You can see what makes each one special. You will learn what is good and what is not.

Tip: When you look at brazing machines, check for safety features. Automatic shut-off helps keep you safe. Make sure the machine works with different metals. Efficiency is important too. A good brazing machine heats only where you need it. This gives you clean results. It also helps the environment. You avoid flux residue and lower oxidation.

This table helps you pick the right brazing machine. If you work outside, choose a lighter model. If you need more power, pick a machine with higher kilowatts. Always check if the machine fits your budget and job size.

How to Choose the Right Induction Brazing Machine

Power and Performance

You need enough power for your job. Thick metals need high power. Small parts need less power. Check if the machine works with your metals. Some metals need more heat. Coil design helps heat each part right. Custom coils give better results. Cooling systems keep machines safe. Strong cooling helps if you use it all day.

Power rating fits your job size

Coil design matches your parts

Cooling system stops overheating

Works with your metals

Portability

Do you move your machine a lot? If yes, pick a portable one. Light machines are easy to carry. Some have wheels or handles. You can set them up fast. Portable machines work anywhere. If you fix cars or trucks, portability saves time.

Ease of Use

Pick a machine that is easy to use. Look for simple controls and settings. Touch screens help set heat and time. If you work alone, easy controls help you focus. Fast part changes make work smoother. Smart features give you better results.

Tip: Try machines with digital controls. They help you get the same results every time.

Safety Features

Safety is very important. Good machines have alarms and shut-off. Wear gloves, goggles, and safe clothes. Make sure air moves in your workspace. Keep fire extinguishers close. Training keeps you and your team safe.

Value for Professionals

You want the best value for your money. Check if the power fits your needs. Look at frequency for heating depth. Make sure coils fit your parts. Good cooling keeps your machine working longer. If you work in car or factory jobs, these features help you. You get strong, clean joints. The right machine saves money and time.

Pick the right frequency for your parts

Use coils that fit your work

Choose machines with easy-to-maintain cooling

Note: The right induction brazing machine helps you work faster, safer, and with more precision. You get better results and spend less time fixing mistakes.

Recommendations for Professionals

For Field Technicians

If you work outside, you need a brazing machine that is easy to carry. It should be quick to set up and help you finish jobs fast. Safety is important, so you want a machine that keeps you safe. Many field technicians pick portable induction brazing machines. These are light and simple to use. They make strong joints and work well for HVAC and car repairs.

Here’s what you should look for:

You can move these machines easily from one job to another. Digital controls help you set the right heat every time. You stay safe because there are no flames. If you want a machine that works anywhere, this type is a great choice.

Tip: Always check if your brazing machine has safety features. This helps keep you and your team safe on every job.

For Workshop Use

If you work in a shop, you need a brazing machine that gives you control. It should help you finish more work in less time. Workshop models have digital controls and heat parts quickly. You get a safer workspace because there are no flames. These machines also save money by using less energy.

Here’s what makes a brazing machine good for shop use:

You can use these machines for many brazing jobs. The digital timer lets you set the exact time for each part. This means you get the same results every time. You also work in a cleaner and quieter shop.

Note: A good induction brazing machine in your shop helps you finish more jobs and keeps your workspace safe.

For Versatility

Sometimes you need a brazing machine that can do many jobs. You might work with aluminum, copper, brass, steel, or stainless steel. The best machines for versatility have features for switching between parts and metals. You get touch screen controls, sensors, and safety features that meet top standards.

Here’s a table showing what to look for in a versatile induction brazing machine:

You can use one brazing machine for many jobs. The touch screen makes it easy to change settings. Sensors tell you when parts are ready. You also meet safety rules for different industries.

Tip: If you switch between jobs often, pick a brazing machine with flexible controls and safety sensors. This saves time and helps you do more work.

Picking the right induction brazing machine helps you work better. You need a model that fits your job and is easy to move. It should also have new technology. Here is a table that shows what is important:

Canroon is great because it is easy to carry. Ultraflex, Fusion Inc., Radyne, and Siemens also have good machines. More companies now care about green technology. Machines keep getting better. To learn more, read reports, news, and expert articles for new updates.

FAQ

What metals can you braze with a portable induction brazing machine?

You can braze copper, aluminum, brass, steel, and stainless steel. Most machines work with many metals. Always check your machine’s manual for the best results.

Tip: Try different coils for different metals. You get better joints that way.

How do you keep your induction brazing machine safe during use?

You should check the cooling system before you start. Wear gloves and goggles. Keep your workspace clean. Use machines with automatic shut-off and alarms.

Inspect cables and coils

Keep water flowing for cooling

Follow safety instructions

Can you use a portable induction brazing machine outside?

Yes, you can use it outside. Make sure you have a power source. Protect the machine from rain and dust. Portable models work well for field repairs.

How do you choose the right coil for your job?

Pick a coil that matches the size and shape of your part. Small coils heat small parts fast. Large coils work for bigger pieces. Custom coils help with special jobs.

Note: Ask your supplier for coil options. You get better results with the right coil.

Sign up for updates