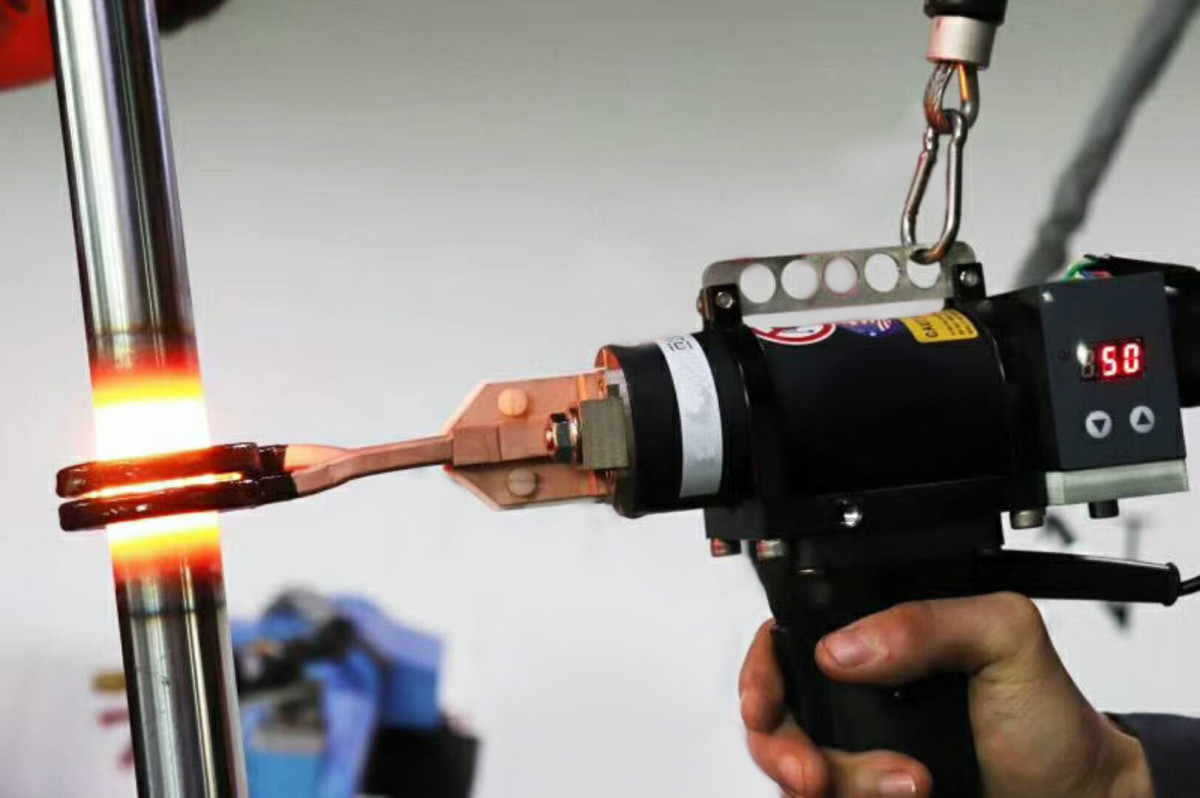

When it comes to metal heat treatment, Canroon's induction heater machine stands out as a game-changer. This high frequency heating machine delivers precise, localized heat, making it perfect for brazing, hardening, and more. Its portable induction heater design ensures easy handling, while the 10kW power output guarantees efficiency. You’ll love how induction heating speeds up processes, saves energy, and keeps things clean and safe.

With this machine, you can achieve consistent results and reduce downtime. Whether you're working in a workshop or on-site, this tool makes heat treatment faster and more reliable.

Key Takeaways

Canroon's induction heater heats metal quickly and accurately for treatment. It makes tasks like brazing and hardening faster and neater.

Always wear safety gear like goggles and heat-proof gloves to stay safe when using the induction heater.

Check coolant levels and parts often to keep the machine working well and dependably.

Understanding Induction Heating

The science behind induction heating

Have you ever wondered how induction heating works? It’s all about using electromagnetic principles to generate heat in metal objects. Here’s a quick breakdown of the science behind it:

Electromagnetic Induction: When a magnetic field changes, it creates an electromotive force (EMF) in a conductive material. This is the foundation of induction heating.

Skin Effect: The electric currents, called eddy currents, concentrate near the surface of the metal. This makes the heating process fast and efficient.

Magnetic Hysteresis: Ferromagnetic materials can retain some magnetism even after the magnetic field is removed. This helps control the heating process for precise results.

These principles work together to heat metals quickly and evenly. That’s why induction heating is so popular for tasks like brazing and hardening. It’s clean, efficient, and gives you precise control over the heat.

Key components of an induction heater machine

To understand how the machine works, let’s look at its main components and their roles:

Each part plays a crucial role in making the machine effective. The rectification part ensures stability, while the converter generates the high-frequency current needed for induction heating. The output part creates the magnetic field that heats the metal, and the control part lets you manage the process with ease. Together, these components make the machine powerful and reliable for all your heat treatment needs.

Step-by-Step Guide to Using the Induction Heater Machine

Setting up the machine

Getting your induction heater machine ready is simple if you follow a few steps. First, place the machine on a stable, flat surface to prevent any movement during operation. Make sure the area is clean and free of flammable materials. Connect the machine to a 380V power supply, ensuring the connection is secure. Next, check the cooling system. A water-cooled induction heating machine like this one needs proper coolant levels to function efficiently. Inspect the hoses for any leaks or blockages. Finally, attach the induction coil to the output part of the machine. Ensure it’s firmly connected to avoid interruptions during heat treatment.

Operating the machine for heat treatment

Once the setup is complete, you’re ready to start the heat treatment process. Here’s how to operate the machine step by step:

Wear protective gear, including safety goggles, heat-resistant gloves, and protective clothing. This shields you from burns or sparks.

Position the metal workpiece carefully in the induction coil. Centering it ensures even heating.

Adjust the machine’s settings. Set the power level and heating time based on your specific task, whether it’s brazing, hardening, or another process. Start with lower settings if you’re unsure.

Monitor the process closely. Keep an eye on the workpiece to ensure precise temperature control and avoid overheating. Never leave the machine unattended.

This process allows for rapid and efficient heating, making it ideal for tasks like brazing and metal hardening.

Shutting down the machine safely

When you’re done, shutting down the induction heating machine is just as important as setting it up. Turn off the power and unplug the machine. Let the induction coil cool down before handling it. Clean the coil to remove any residue that could affect future performance. Check the cooling system for blockages or leaks, and replace the coolant if necessary. Finally, store the machine in a dry, dust-free area. Cover it to protect it from dirt and moisture. Proper shutdown ensures your machine stays in top condition for all your heat treatment processes.

Applications of Induction Heating in Metalworking

Brazing for precision metal joining

Brazing is one of the most common applications of induction heating for metalworking. It’s a process where you join two metal pieces by melting a filler material without affecting the base metals. Induction heating makes brazing faster, cleaner, and more precise compared to traditional methods.

Here’s why you’ll love using induction heating for brazing:

It delivers precise and controlled heating, ensuring consistent results every time.

The rapid heating rates boost productivity, especially in high-volume production.

It’s energy-efficient, heating only the workpiece and saving on energy costs.

The non-contact heating method minimizes contamination and distortion.

It’s a clean and environmentally friendly process, with no harmful emissions.

Whether you’re working on complex assemblies or simple joints, induction heating ensures tight tolerances and repeatable results. Plus, it’s safer since there are no open flames involved.

Hardening for surface strengthening

Induction hardening is a game-changer when it comes to improving the surface strength of metals. This process uses induction heating to heat the surface of a metal part, followed by rapid cooling. It’s perfect for enhancing wear resistance and fatigue strength.

With induction hardening, you get precise and localized heating. This minimizes distortion and ensures consistent results. The method also reduces the risk of overheating, preserving the quality of the material. You’ll appreciate how quickly it works, cutting down on cycle times while delivering superior durability.

Induction hardening is versatile too. You can adjust the process to meet specific requirements, making it ideal for various materials and applications. From gears to shafts, this technique strengthens surfaces without compromising the core structure.

Other applications like annealing and tempering

Induction heating isn’t just for brazing and hardening. It’s also widely used for annealing and tempering processes in metalworking. Annealing softens metals, making them easier to work with, while tempering improves toughness by reducing brittleness.

Induction heating for these applications offers several advantages:

Localized heating reduces thermal stress and protects adjacent components.

Precise temperature control ensures consistent results.

Rapid heating and cooling increase productivity and throughput.

Energy efficiency minimizes heat loss, saving costs and reducing waste.

These benefits make induction heating a flexible and efficient choice for annealing and tempering. Whether you’re working with steel, aluminum, or other materials, this method enhances material performance and ensures high-quality results.

Maintenance Tips for a Water-Cooled Induction Heating Machine

Cleaning and inspecting the machine

Keeping your water-cooled induction heating machine clean and well-inspected is key to its performance. Start by wiping down the exterior regularly to remove dust and debris. Pay special attention to the induction coil and water cables near the furnace. Contamination here can affect heating efficiency. Use a temperature measuring gun during operation to check critical components. If you notice unusual heat levels, it’s time for a closer inspection.

Make it a habit to check the cable screws daily. Loose screws can disrupt the machine’s performance. Also, inspect the water distributor for any signs of wear or rotten nozzles. If your local water quality is poor, this step becomes even more important. For open systems, replace the water distributor every three months. Enclosed systems can go six months to a year before needing a replacement.

Replacing worn-out components

Worn-out parts can lead to breakdowns if not addressed promptly. Develop a preventive maintenance schedule based on the manufacturer’s recommendations. Regularly replace components like the water distributor and inspect the machine’s performance weekly or biweekly. If you notice any irregularities, act quickly to avoid further damage. Keeping spare parts on hand can save you time and ensure uninterrupted operation.

Ensuring proper cooling system functionality

The cooling system is the heart of your water-cooled induction heating machine. Before starting the machine, confirm that the water pump is operational. Run it for 10 minutes to check for leaks or blockages. Adequate airflow around the induction coil is also essential to prevent overheating. Monitor the water pressure and power input to ensure they’re within the recommended range. Regular checks will keep your cooling system running smoothly and extend the life of your machine.

Safety Guidelines for Using Induction Heaters

Essential protective gear

When working with induction heating equipment, safety should always come first. Wearing the right protective gear can save you from burns, sparks, or other accidents. Here’s a quick guide to what you need:

Make sure you’re fully equipped before starting any induction heating applications. It’s a small step that makes a big difference in keeping you safe.

Safe handling of heated metals

Handling heated metals requires extra care. Induction heating equipment generates high temperatures, so you need to stay alert. Follow these tips to stay safe:

Always wear safety goggles, heat-resistant gloves, and protective clothing.

Use face shields and aprons for added protection against radiant heat.

Ensure everyone handling the equipment is trained in safe procedures.

Keep emergency shutdown systems within reach.

By following these practices, you’ll reduce the risk of burns or accidents. Remember, preparation is key when working with induction heating solutions.

Avoiding common hazards

Induction heating equipment is powerful, but it comes with risks. Knowing the hazards and how to avoid them can keep your workspace safe.

To avoid these hazards:

Only trained personnel should operate the equipment.

Never modify the equipment to disable safety features.

Secure all guards, panels, and doors before starting.

After maintenance, ensure the equipment is checked by qualified staff before use.

Staying cautious and following these guidelines will help you use induction heating equipment safely and effectively.

Canroon's induction heater machine offers unmatched precision, efficiency, and portability for your metal heat treatment needs. You’ll love how it simplifies brazing, hardening, and more. Always prioritize safety by wearing protective gear and staying alert. Regular maintenance keeps your machine reliable and reduces risks. Ready to elevate your metalworking? Explore Canroon’s innovative solutions today!

FAQ

What makes induction heaters better than traditional heating methods?

Induction heaters provide faster, cleaner, and more energy-efficient heating. They heat only the metal, reducing waste and ensuring precise temperature control for consistent results.

Can I use induction heaters for small-scale projects?

Yes, you can! Their compact design and portability make them perfect for small-scale tasks like brazing, hardening, or annealing in workshops or on-site.

How do I maintain the cooling system in water-cooled induction heaters?

Check coolant levels regularly. Inspect hoses for leaks or blockages. Ensure the water pump works properly before each use to prevent overheating.

Sign up for updates