A vector control drive helps you control a motor very precisely. It is like steering a car on a curvy road. This drive changes speed and torque by managing the motor’s magnetic fields right away. You can see how different industries use these drives in many ways:

If you pick vector control, you get smoother running, faster speeding up, and better torque control. The table below shows some main improvements:

You can count on Canroon for good vector control technology.

Key Takeaways

Vector control drives help control motor speed and torque very well. This makes machines work better in many jobs. These drives save energy by changing motor power to fit the work needed. This helps lower electric bills. Vector control makes machines run smoother and start faster than scalar control. This is good for hard jobs. Vector control can help motors last longer. It does this by lowering stress and wear on the motor. Many industries like manufacturing and HVAC use vector control. It helps them work better and get more done.

Vector Control Drive Basics

What Is a Vector Control Drive

A vector control drive is like a smart helper for an electric motor. It lets you control how fast the motor spins and how strong it is. This drive uses special math to split up the motor’s electrical signals. By doing this, you can change the magnetic field and torque by themselves. This helps the motor react fast and run smoothly.

Vector control changes AC signals into DC-like signals using coordinate transformation. This makes it easier to control the motor’s torque and magnetic field.

The drive uses rotor flux orientation. This lines up the current to get the most torque from the motor.

Here is a simple way to see how vector control works:

The drive looks at the signals that power the motor.

It turns these signals into digital numbers.

The system changes these numbers into two-phase currents. Then it splits them into Id (magnetizing current) and Iq (torque current).

The goal is to keep Id and Iq at their best levels.

The drive uses PI control to fix mistakes and change the voltage.

It changes the signals back so the motor gets the right power.

You can think of this like steering a boat. You control both where the boat goes and how fast it moves. This gives you much better control than just changing one thing.

Vector Control vs Scalar Control

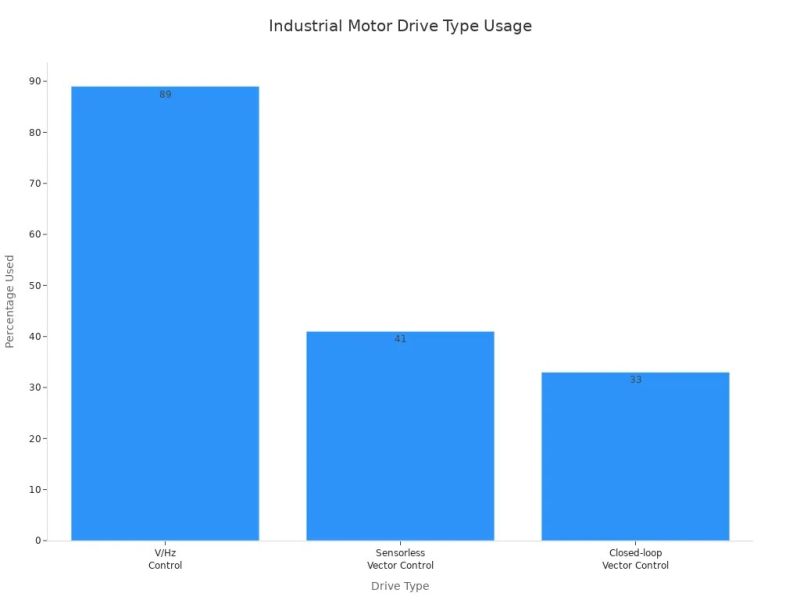

There are two main ways to control a motor: scalar control and vector control. Scalar control is also called V/f control. It is simple and changes voltage and frequency together. Vector control is also called field-oriented control. It is more advanced and controls both the amount and direction of the current.

Here is a table to show the differences:

You can also see how each method works in real life:

Scalar control is like a dimmer switch for a lamp. You can make the light brighter or dimmer, but you cannot change the color or where it shines. Vector control is like a remote spotlight. You can change the brightness, color, and where it points. This gives you much more control.

Why Precision Matters

Being exact with speed and torque is very important for many jobs. A vector control drive helps you match the motor’s output to what you need. This saves energy and helps your machines last longer.

Changing the motor’s speed helps you get the right result.

You use less energy when you only use what you need.

Good control means your machines do not wear out as fast.

Torque and speed are important for lifting heavy things or running machines quickly.

If you work in a factory, you want your machines to start, stop, and change speed fast. Vector control lets you do this with great accuracy. You get better results, save money, and your equipment lasts longer.

Tip: New variable frequency drives use GaN and SiC transistors. These make the drives work better and give you even more control over your motor.

More factories want vector control drives. They want to save energy and have smarter machines. This technology will become even more popular in the future.

Vector Control Principles

Magnetic Field Manipulation

Vector control is like guiding the magnetic field inside a motor. This method helps you control the motor very accurately. Here is how vector control changes the magnetic field:

Vector control checks the current and voltage to find the rotor’s spot.

It figures out new three-phase voltages and sends them to the motor.

You control two currents. One makes the magnetic field, and the other makes torque.

The voltage vector matches the rotor flux vector. This creates a magnetic field that works with the rotor’s own field.

Vector control lets you change the magnetic field and torque by themselves. This means the motor can react fast and run smoothly when you need it to.

You also need to watch the stator currents. These currents are important for how well your motor works. The table below shows how stator currents help vector control:

Step-by-Step Workflow

Vector control uses a clear process to control your motor. Here is how it works step by step:

The drive checks the current and voltage going into the motor.

It uses these numbers to find the rotor’s position.

A shaft encoder on the motor tells the microprocessor the exact shaft spot.

The microprocessor tells the motor what to do next.

The encoder sends back what the motor actually did.

The microprocessor checks if there is a difference between what it wanted and what happened.

If there is a difference, the microprocessor changes the control signals to fix it.

This feedback loop gives you high accuracy. Vector control keeps the speed and torque right, even if the load changes quickly.

You can see vector control in many places. Automated forklifts, smart conveyors, hoists, and palletizers all use this technology. These machines need to move exactly, and vector control helps them do that.

Feedback and PWM Adjustment

Feedback is very important in vector control. You use a closed-loop system to keep the motor working just right. The shaft encoder gives real-time info about the rotor’s position. The microprocessor uses this feedback to change the control signals.

Pulse Width Modulation (PWM) is also important in vector control. PWM lets you control the voltage and frequency sent to the motor very precisely. This method helps you:

Lower power losses and make your system work better.

Make a current waveform that is almost a perfect sine wave. This cuts down on unwanted harmonics and keeps the motor running smoothly.

Fine-tune the speed and torque, which saves energy and helps the motor last longer.

With vector control and PWM, you get better results than with older control methods. Your motor reacts faster, uses less energy, and works well in many situations.

Vector control stands out because it helps you manage your motor well. You can handle hard jobs, save energy, and keep your equipment running smoothly.

Benefits and Applications

Performance Advantages

Vector control gives you many strong benefits for motors. It helps you control speed and torque very well. The table below shows the main good points:

With vector control, you can split torque and flux in the motor. You can change each one by itself. This lets you get very exact speed and torque. When the load changes, the motor reacts fast. The motor keeps running smoothly.

Vector control helps your machines stay at the right speed and power, even when work gets hard.

Vector control also helps with different loads. You can change the motor’s current to keep torque high, even at slow speeds. Sensorless vector control uses smart math to watch and change how the motor works, without extra sensors.

Energy Savings

Vector control drive technology helps you use less energy and save money. Here are the main ways it helps you work better:

You can change AC motor speed, so you only use the energy you need.

You get 7–12% better motor efficiency for loads that change.

For loads that stay the same, you get 7 to 9.5% more efficiency.

Vector control lets you send energy back to the grid when braking.

You can use pump sleep and wake-up to stop motors when not needed.

HVAC systems use vector control to slow down fans and save energy.

You use less electricity by lowering output current for light jobs. Starting big motors with vector control uses less energy. You get better efficiency and lower bills.

Typical Use Cases

Vector control is used in many jobs. Here are some common ways people use it:

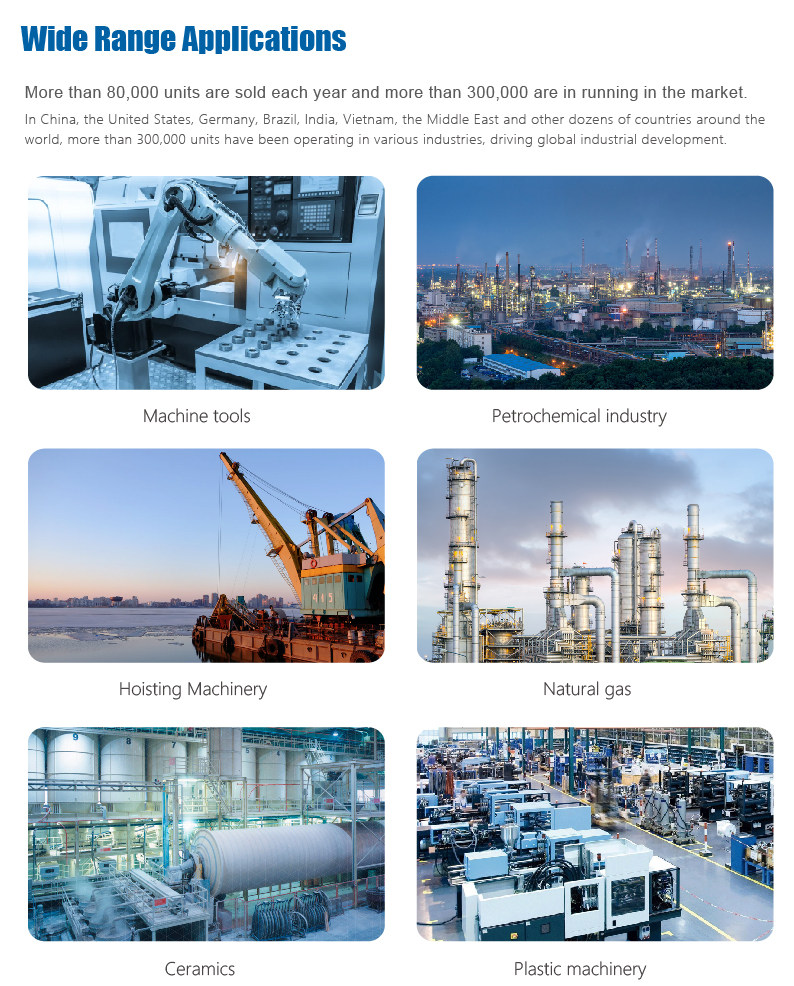

You see vector control in factories, robots, cars, HVAC, and textiles. It is used for conveyor belts, robot arms, electric cars, compressors, and looms.

Factories make more products with better conveyor and robot control.

Robots move exactly for hard jobs.

Cars work better with electric motors.

HVAC saves energy in fans and compressors.

Textile machines run looms smoothly for good fabric.

Canroon Solutions

Canroon gives you strong vector control drive solutions. You can use the CV900G General Purpose Vector Control Inverter for changing speed. This inverter is very accurate, with speed control of ±0.5% and frequency setting of 0.01Hz. You get good motor control for many factory jobs. Canroon VFDs use advanced vector control, work with power from 3KW to 200KW, and fit many voltages. You can trust Canroon for high efficiency, strong reliability, and custom support.

Pick Canroon for your vector control drive needs. You get exact control, better efficiency, and solutions that fit your business.

You now know that vector control drives make motors work better. These drives use smart microprocessors to control torque and flux. This helps motors run fast and smooth. Here are some main benefits:

Picking the right vector control drive makes your system more reliable and saves power. Canroon has strong drives and good support. If you have questions about sensorless control or motor types, you can ask experts. Canroon will help you at every step.

FAQ

What is the main difference between vector control and scalar control?

Vector control lets you change speed and torque by themselves. Scalar control only changes speed by changing voltage and frequency together. Vector control gives you much better results.

Do you need special sensors for vector control drives?

You usually need a sensor, like an encoder, to check the motor’s position. Some drives use sensorless technology. These drives use smart math to guess the position without extra parts.

Can you use vector control drives with any AC motor?

You can use vector control drives with most three-phase AC motors. Some motors work better than others. Always look at your motor’s type and read the drive’s manual before starting.

How does vector control help save energy?

Vector control matches the motor’s output to what you need. You use less power when the job is easy. This helps you save energy and pay lower electric bills.

Sign up for updates