You want to save money and help the planet, right? AC drive applications, like the ones from Canroon, make this simple. When you use ac drives with your ac motors, you can change the motor speed. This means you only use the power you really need. Look at these numbers:

With ac drives, you use less energy, make less pollution, and your ac motors last longer.

Key Takeaways

AC drives help you change motor speed. This means you only use the energy you need. It can lower wasted energy by up to 50%.

When you use AC drives, motors start and stop gently. This helps motors last longer. It also means less damage and fewer repairs.

AC drives make things work better. They lower your power bills. They do this by matching motor speed to the real job. They also stop big jumps in power use.

These drives are easy to add to new systems. They give you more control. They also warn you early if something is wrong. This helps stop breakdowns.

AC drives save energy and cut waste. This helps your business spend less money. It also helps keep the planet clean and green.

AC Drives vs Traditional Motor Control

How AC Drives Work

You might wonder how ac drives actually help you save energy. When you use ac drives with your ac motors, you get to control how fast the motor spins. Instead of running at full speed all the time, ac drives let you match the speed to what your equipment really needs. This is possible because ac drives use advanced electronics to change the frequency and voltage sent to ac motors. With this technology, you can start and stop motors smoothly, avoid sudden jolts, and even recover energy when slowing down. Variable frequency drives, a type of ac drive, make it easy to adjust motor speed for fans, pumps, and conveyors. You get more control, less waste, and a system that responds quickly to changes.

Key Differences

Let’s look at what sets ac drives apart from traditional motor starters:

Ac drives adjust the speed, torque, and voltage of ac motors in real time, while traditional starters only turn motors on or off at full speed.

Ac drives monitor things like voltage, current, and power use, so you can spot problems and fix them before they get worse.

With ac drives, you get protection from voltage spikes and drops, which helps your ac motors last longer.

Ac drives connect to modern networks, making it easy to track performance and plan maintenance.

Traditional starters don’t offer these features, so you miss out on energy savings and better control.

Tip: Ac drives also keep a log of any faults or issues, which helps you prevent breakdowns and keep your ac motors running smoothly.

Why Speed Control Matters

Speed control is a game-changer for energy savings. When you run ac motors at the exact speed needed, you avoid wasting energy. Here’s a quick look at why this matters:

When you use ac drives with your ac motors, you get more than just energy savings. You also reduce stress on your equipment, cut down on maintenance, and help your business run more efficiently.

Energy Efficiency Benefits of AC Drives

Variable Speed and Load Matching

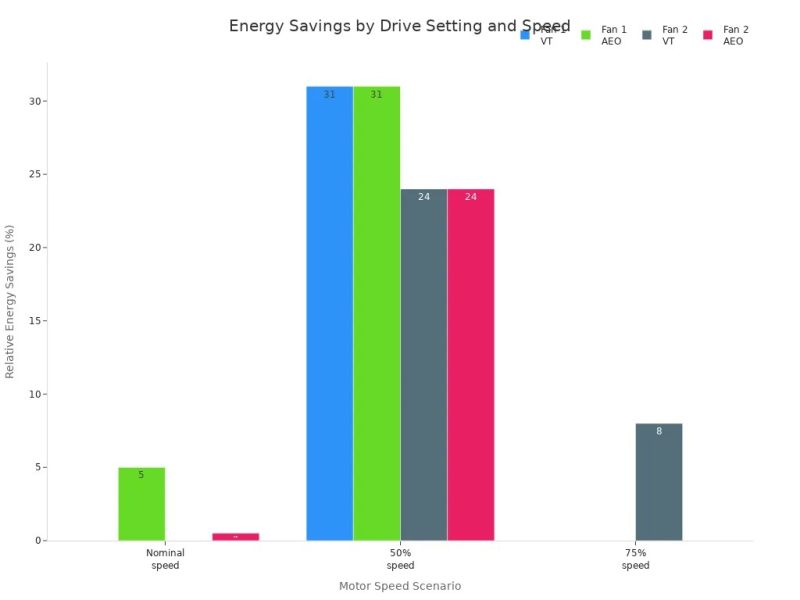

You want your ac motors to work in a smart way. Ac drives help you do this. They let you change how fast and strong your motor works. This means your equipment does only what is needed. If you use a fan or pump, you do not always need full speed. Ac drives let you slow down when less is needed. This helps save energy and lowers your bills.

Let’s look at the numbers. If you slow a fan or pump by 20%, you can save up to half the energy. That is a big deal! Ac drives do this by changing the voltage and frequency sent to your ac motors. You get exact control, so your motors use only the power they need. You do not waste energy by running too fast.

Did you know? Fans and pumps use much less power when you lower speed. If you cut speed in half, you can save up to 80% energy.

Ac drives use smart controls like PID loops. These loops watch what is happening and change motor speed to fit the job. This gives you better system performance and energy use. You do not have to guess or make changes by hand. The system does it for you.

Reduced Energy Consumption

You want to see real results, right? Ac drives give you that. In many cases, you can get up to 50-80% better energy use than old motor controls. Here is how it works. Ac drives match speed and torque to what is needed. For example, air compressors with old motors run at full speed and waste energy. Ac drives change speed to match demand, saving 30-50% energy when loads change.

Modern ac drives use smart programs to keep torque steady, even at low speeds. They connect to automation systems and react fast to changes. You get a system that always looks for the best way to run your ac motors. This means less wasted energy and lower costs.

Check out this table to see how ac drives help in different cases:

Ac drives also help your motors last longer. They lower the starting current, reduce stress, and stop motors gently. You get less wear, fewer breakdowns, and more reliable machines.

Lower Peak Demand

Peak demand can make your power bills go up. Ac drives help you avoid these high points. They let you run motors during off-peak times and speed up slowly. You do not get big jumps in power use. This keeps your bills steady and helps you manage energy.

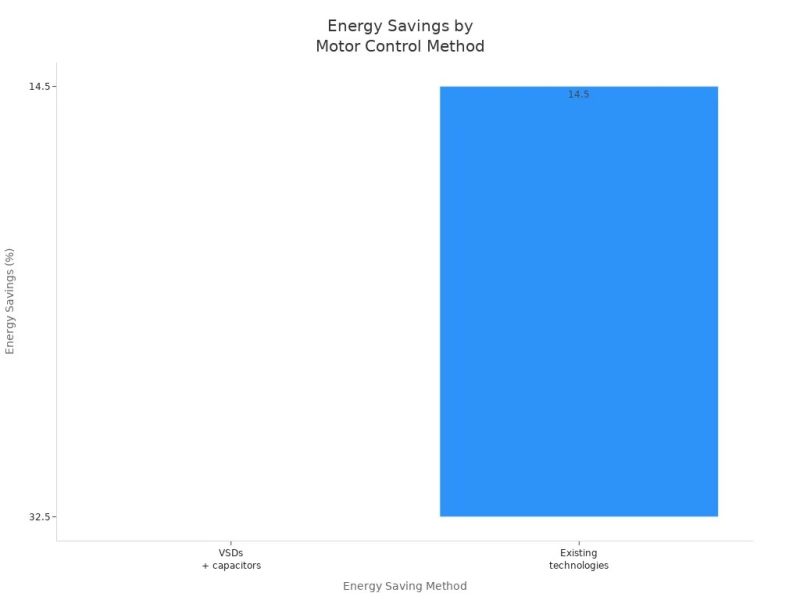

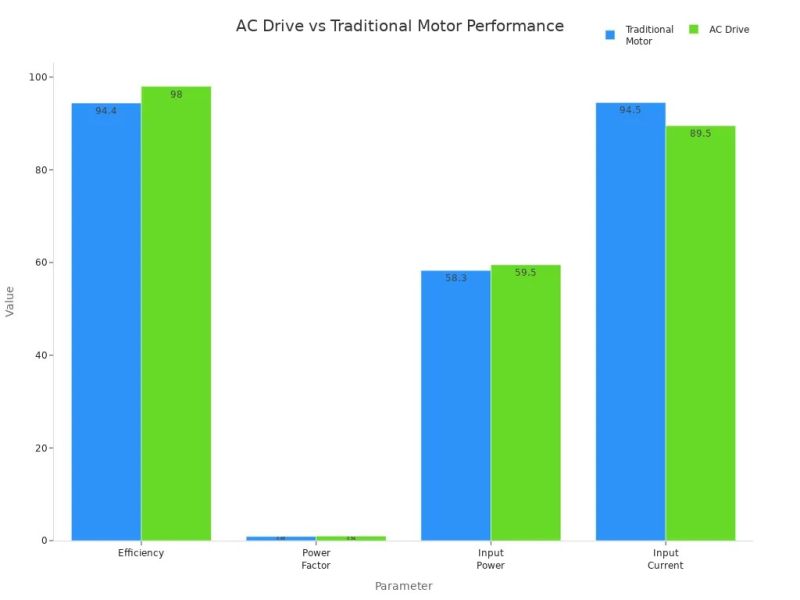

Ac drives also make power factor better and cut system losses. Look at this comparison:

You get higher efficiency, better power factor, and lower input current. This means less energy lost in wires and transformers. Ac drives also help you meet energy rules, so you stay ahead.

Here are some extra benefits you get with ac drives:

They switch frequencies when speeding up to save power.

They lower starting current, so motors are less stressed.

They let motors start and stop smoothly, avoiding shocks.

They let you set torque limits, so you do not waste power.

They remove the need for mechanical speed controls, so you do less maintenance.

They match motor output to the job, making things work better.

When you use ac drives, you get smarter control, lower costs, and help the planet. Your ac motors work better, last longer, and help your business run well.

AC Drive Application in Real-World Settings

Fans and Pumps

You see fans and pumps everywhere—in factories, water plants, and even big buildings. When you use an ac drive application with your ac motors, you get real control over speed. This means your fans and pumps do not have to run at full speed all the time. You can slow them down when you need less air or water. Here’s what happens when you add ac drives to these systems:

You can cut energy use by up to 50% for fans.

Your ac motors last longer because they start and stop smoothly.

You spend less on repairs since there is less stress on your equipment.

You get quieter machines, which makes your workplace more comfortable.

Canroon helped a water treatment plant install ac drives on their pumps. The plant saw a 25% drop in power use. The ac drive application matched the pump speed to the water flow, so the ac motors only worked as hard as needed. The plant saved money and had fewer breakdowns.

HVAC and Chillers

Heating, ventilation, and air conditioning (HVAC) systems use a lot of energy. If you add an ac drive application to your ac motors in chillers and fans, you can save a lot. For example, a cooling tower in Kuwait used ac drives and saw a 5.8% drop in power use and a 13% drop in water use. The ac drive application let the system slow down when less cooling was needed. This made the ac motors work smarter, not harder.

Modern ac drives also connect to building management systems. You can watch and control your HVAC from one place. This helps you spot problems early and keep everything running smoothly. You save energy and keep your building comfortable.

Manufacturing Equipment

Factories use many ac motors for machines like conveyors, compressors, and mixers. When you use an ac drive application, you match motor speed to what your process needs. This can save up to 50% energy. You also get:

Less wear and tear on your ac motors.

Fewer repairs and less downtime.

Better control over your product quality.

One Canroon customer in the food industry added ac drives to their conveyor belts. They saw lower energy bills and fewer breakdowns. The ac drive application let them adjust speed for each product, making their process more flexible and reliable.

Tip: Always check your equipment needs before choosing an ac drive. Make sure it matches your ac motors and your process.

Additional Advantages of AC Drives

Maintenance Reduction

You want your machines to work well and not break often. AC drives help with this. They let motors start and stop slowly. This gentle action means your equipment does not wear out fast. You spend less time fixing things and more time working. AC drives have special checks built in. They find problems early, so you can fix them before they get worse. Here is a table that shows the difference:

You need less maintenance, so you save money and have less downtime.

Equipment Longevity

You want your machines to last a long time. AC drives help by matching motor speed and torque to the job. This means motors and machines do not work too hard. Soft starts and stops protect pumps, fans, and conveyors from sudden shocks. Load balancing keeps everything running smoothly. This stops bad vibrations. Real-time checks help you find problems early. You can plan repairs before something breaks. All these things help your equipment last longer and avoid surprises.

AC drives help motors last longer.

You do not have to pay for repairs as often.

Your machines work better and break down less.

Sustainability Impact

If you care about the earth, AC drives are a good choice. They let motors use only the energy needed. This means you do not waste electricity and your carbon footprint is smaller. Using less energy helps fight climate change and saves you money. AC drives also help you watch and control your power use. Many big companies use AC drives to reach their green goals and follow world rules.

Less waste and longer machine life help the earth

Smart controls make your system work better

With AC drives, your business and the planet both win.

You have learned that AC drive applications help save energy and money. They also help make the world cleaner. When you upgrade, you get many benefits. You can get your money back in two years. Your monthly bills go down. Your business saves money for a long time. You spend less on fixing machines because AC motors last longer.

Are you ready to save more? Check out Canroon’s AC drive solutions or ask for a special review today! ????

FAQ

What is an AC drive?

An AC drive lets you control how fast your motor runs. You can save energy and make your machines last longer. It’s like a smart speed dial for your equipment.

How much money can I save with AC drives?

You can cut your energy bills by up to 50%. Many people see their investment pay off in less than a year. Your savings depend on how you use your motors.

Are AC drives hard to install?

Not at all! Most AC drives fit right into your current setup. You just connect them to your motor and power supply. Many brands, like Canroon, offer support if you need help.

Do AC drives need a lot of maintenance?

You do not need to worry much. AC drives have fewer moving parts than old systems. They check themselves for problems and help you spot issues early. This means less work for you.

Previous:

Next:

Sign up for updates