An ac motor drive helps you change how fast or strong an electric motor works. You can use it to make machines go faster or slower. This depends on what you want. It helps save energy and money. This is very useful in factories and big buildings.

Quick Fact: Studies show that using variable frequency drives (VFDs) in motor systems can cut energy use by up to 50%. This depends on how you use them.

More companies are starting to use these drives. The global market for them grows every year.

Key Takeaways

AC motor drives help you change how fast and strong motors work. This helps machines use less energy and work better.

Using AC motor drives can cut energy bills by half. This makes them a good choice for factories and buildings.

These drives help motors start and stop smoothly. This means motors last longer and do not break as much.

Advanced control methods in AC motor drives let you change speed and torque exactly. This helps machines work better.

Picking the right AC motor drive can save a lot of energy. It also means you spend less on fixing machines later.

What Is an AC Motor Drive

Definition

An ac motor drive is a device that helps you control how an electric motor works. You can use it to change the speed or strength of the motor. This device connects between the power supply and the motor. When you use an ac motor drive, you get to decide how fast or slow your machine runs. You also get to choose how much force the motor uses.

Tip: If you want your machines to work smarter and save energy, an ac motor drive is a great choice.

Main Function

The main job of an ac motor drive is to give you control over your motor. You can adjust the speed, torque, and even how quickly the motor starts or stops. This helps you match the motor’s performance to what your machine needs.

Here are some important things an ac motor drive does for you:

Lets you change the speed of your motor by controlling the frequency and voltage.

Helps your motor start and stop smoothly, which protects it from damage.

Limits the amount of current going to the motor, so it does not overheat.

Offers different control modes, such as constant torque for machines like conveyors, or variable torque for fans and pumps.

You might think all electric motors work the same way, but that is not true. Many people believe electric motors always run at high efficiency. In reality, the efficiency can change based on how you use the motor. For example, motors in electric vehicles often work in changing conditions, so their efficiency is lower than motors in factories. Industrial motors can reach up to 90% efficiency when running at steady speeds, but this number drops when the motor speeds up or slows down a lot.

Note: When you use an ac motor drive, you help your motor work at its best for each task. This means you save energy and reduce wear on your equipment.

How AC Motor Drives Work

AC to DC Conversion

When you use an ac motor drive, you start with power from your wall. This power is called AC, which means alternating current. The drive changes AC power into DC power, which means direct current. Here is how it works:

Rectifier (AC to DC Conversion): The drive uses a rectifier. This is a group of special electronic parts. These parts change AC power into DC power.

DC Bus (Intermediate Circuit): The DC power goes into a DC bus. The DC bus uses capacitors and sometimes inductors. These parts smooth out the power. You get steady DC voltage for the next step.

Inverter Stage (DC to Variable-Frequency AC): The inverter takes DC power and turns it back into AC power. This new AC power can change its frequency and voltage. The inverter uses advanced electronics for this. You can control how fast and strong your motor runs.

Did you know? Most modern drives work very well. They can reach efficiency rates above 90% when running at steady speeds.

Inverter and Output Control

The inverter is the most important part of the ac motor drive. You use it to control the speed and torque of your motor. The inverter changes the frequency and voltage of the electricity going to the motor. This lets you decide how fast the motor spins and how much force it uses.

Vector control, also called field-oriented control, lets you adjust speed and torque separately. You control the strength and timing of the electricity. This helps you get the exact performance you want.

For fans and pumps, the inverter matches the voltage to the load. This keeps your motor working smoothly, even when the job changes.

Advanced control methods, like vector control and direct torque control, help you manage the motor’s power with great accuracy. You can control the magnetic force and mechanical torque. This is important for machines that need precise movement.

Tip: Modern drives use these control methods to save energy. They help machines work better. You get smoother starts, stops, and changes in speed.

New ac motor drives are safer and more efficient than older ones. They have better safety features, like network safety protocols and hazard detection. You also get more advanced control schemes. These help you manage speed and torque with high precision. Materials like soft magnetic composites help motors run cooler and save electricity. This is very helpful in air conditioning systems. These changes can help you save up to 20% on energy costs.

Manufacturers like Canroon make drives that last a long time and work well. Here are some features you might find in a Canroon ac motor drive:

Note: When you pick a reliable ac motor drive, your machines work better. You get more safety and save energy.

AC Motor Drive Components

Rectifier

The rectifier is the first part you use. It changes electricity from AC to DC. There are two main types of rectifiers in motor drives. Each type works differently and has its own efficiency. The table below shows how well each one works:

Full-wave rectifiers are better for most motor drives. They give you more power and waste less energy. If you use a half-wave rectifier, you lose more energy.

Tip: Picking the right rectifier helps your motor run better and saves power.

DC Bus

After the rectifier, the DC bus comes next. This part stores and cleans the DC voltage. You need steady voltage for your motor to work well. The DC bus uses capacitors and sometimes inductors to smooth the power. Keeping the voltage steady helps you control speed and frequency. If the voltage changes too much, your motor might not work right.

The DC bus is important for cleaning the DC voltage. This helps the solid-state parts work well. It is needed to control the motor’s speed and frequency. The DC bus keeps the voltage at the right level for good operation.

Inverter

The inverter is the next part in the drive. It changes DC power back into AC power. This new AC power can have different frequencies and voltages. There are different inverter designs in motor drives. Voltage Source Inverters (VSI) are common because they are simple and cheap. For bigger jobs, you might use a 3-Level Neutral Point Clamped (NPC) inverter. This design gives better waveforms and protects the inside parts. Current Source Inverters (CSI) are good when you need smooth power for many motors. Matrix converters are rare but can switch power directly and handle energy well.

If you choose the right inverter, your motor works its best.

Control System

The control system lets you manage everything. It watches the motor and makes changes as needed. Sensors check speed, torque, and temperature. The control system uses this information to change how the motor works. You can make the motor go faster, slower, or stop safely. Modern drives use advanced methods like Vector Control and Direct Torque Control. These methods let you change torque and speed very accurately.

Modern Variable Frequency Drives (VFDs) use advanced control methods like Vector Control and Direct Torque Control (DTC).

These methods help you adjust torque and speed exactly, so the motor works well.

Using a smart control system makes your machines safer and more reliable.

Compatible Motors and Uses

3-Phase AC Induction Motors

Most ac motor drives work best with 3-phase AC induction motors. These motors are strong and last a long time. They are easy to control. You can use them in many machines. They handle different speeds and loads well. When you use an ac motor drive with a 3-phase motor, you get smooth starts and stops. This helps protect your motor from damage. It also helps you save energy and makes your equipment last longer.

Industrial and Home Applications

You can use ac motor drives in lots of places. In factories, they help control machines like conveyors, pumps, and fans. You get better control and use less energy. At home, you find them in HVAC systems and washing machines. They also work in other appliances. These drives make your devices quieter and more efficient.

Here is a table that shows where ac motor drives are used:

An ac motor drive is important for controlling how fast and well an electric motor works. It helps you control machines, lowers stress on parts, saves energy, and makes your machines work better.

Energy Efficiency Benefits

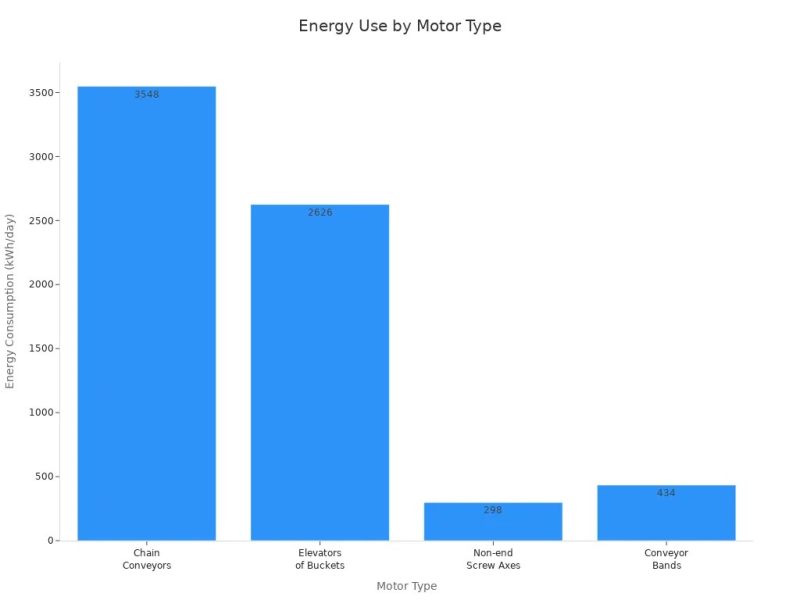

You can save a lot of energy with ac motor drives. By changing the speed of your motor, you only use the power you need. This means you waste less electricity and pay lower bills. In factories, these drives can cut energy use by a lot. For example, chain conveyors and bucket elevators use thousands of kilowatt-hours every day. Adding ac motor drives can lower this number.

Canroon has solutions for many places. You can find their drives in factories, homes, and renewable energy systems. Their products help you get the most from your motors and save energy and money.

Benefits of AC Motor Drives

Energy Savings

You can save lots of energy with an ac motor drive. These drives let you set the motor speed for your machine. You do not waste power by running motors too fast. In factories, energy savings can reach 31%. This number comes from a study of over 2,000 systems. Using less energy also means you spend less money. Many companies see a quick payback after installing AC drives. Most projects pay for themselves in 1.5 to 3 years. Fans and pumps often pay back in just 1 to 2 years. If your system needs different speeds, you save even more. Utility rebates and high electricity prices make payback even faster.

Tip: AC motor drives help you save money and energy, especially if your machines run all day.

Precise Control

AC motor drives give you exact control over speed and torque. You can change the frequency and voltage to fit your needs. This lets your machines work just how you want. Old starters only turn motors on or off. AC motor drives let you change speed and torque anytime. This makes your equipment more flexible and efficient.

You can use ac motor drives in many machines, like fans and pumps. You get better results and use less energy.

Reduced Maintenance

You will need less maintenance with AC motor drives. These drives help motors run smoother and avoid hard starts or stops. Motors last longer because they face less stress. AC motors also need less care than DC motors. Places that use AC motor drives often spend less on repairs. This helps you save money and avoid surprise problems.

Note: AC motor drives help your machines work better and last longer, so you spend less time and money on maintenance.

Now you know an ac motor drive helps control speed and torque. It uses a rectifier, DC bus, inverter, and a smart control system. Most drives work best with 3-phase motors. You get big benefits like saving energy and making motors last longer. Here are the main advantages:

AC motor drives help you use less electricity and support green goals.

Many companies pick Canroon for good and trusted products.

Start saving energy and make your machines smarter today! 🚀

FAQ

What is the difference between an AC motor drive and a DC motor drive?

You use an AC motor drive to control AC motors. You use a DC motor drive for DC motors. AC drives work with changing current. DC drives work with steady current. Each type fits different machines.

Can you install an AC motor drive by yourself?

You can install small AC motor drives if you follow the manual. For big systems, you should ask a professional. Safety matters. Always turn off power before you start.

How do you know which AC motor drive to choose?

You check your motor type, voltage, and power needs. You look at your machine’s speed and torque requirements. You pick a drive that matches these details. Ask your supplier for help if you are unsure.

Do AC motor drives save money over time?

You save money because you use less energy. Your motors last longer. You spend less on repairs. Many users see payback in one to three years.

What happens if your AC motor drive stops working?

Your motor may not run or may run at full speed. You should check for error codes. You can reset the drive or call a technician. Regular checks help prevent problems.

Previous:

Next:

Sign up for updates