If you want the best induction brazing machine for 2025, you should check top brands like Canroon, Ultraflex, Fusion Inc., and Radyne. These induction brazing machines heat things quickly. They save a lot of energy. They are safe and do not make loud noises. You should look at important features like power and frequency. See how well the machine works with your materials. Picking the right induction heating system gives you faster brazing. It makes automation easier. You get better results than older methods.

Key Takeaways

Pick the induction brazing machine that fits your needs. Think about power, frequency, and if it works with your materials. This helps the machine work well for you.

Brands like Canroon, Ultraflex, Fusion Inc., and Radyne have special features. Learn about each brand before you choose one for your projects.

Using automation in induction brazing can save time and money. Automated systems help your work go faster and stay the same each time.

Safety is very important when using induction brazing machines. Find machines with safety features and flameless heating. These features help keep your workspace safe.

Buying good induction brazing machines can save you money over time. They use less energy and help you make fewer mistakes when brazing.

Top Induction Brazing Machines

If you want the best induction brazing machines in 2025, you will notice four main brands. Canroon, Ultraflex, Fusion Inc., and Radyne are popular in the United States and other countries. Each company has machines with special features for different jobs. You can pick machines for small tasks or big factories.

Canroon

Canroon makes induction brazing machines with smart technology. You get digital temperature control to keep the heat steady. The machines use copper, stainless steel, or aluminum coils. You can use them for automotive, aerospace, and medical jobs. Canroon machines run all day without stopping. You can change the coil size for your project. The machines are easy to move and have different control modes. You get strong protection from problems and simple controls. Canroon can make up to 300 machines each week, so you get your order fast.

Tip: Canroon induction brazing machines have CE and ISO9001 certification. You can trust their safety and quality.

Ultraflex

Ultraflex induction brazing machines help you work with care. You can heat only the spot you need. This keeps your work neat and safe. Ultraflex machines give you the same results every time. You do not need open flames, so your work area is safer. Many factories use Ultraflex because they want good quality and safety.

Precision heating warms only the spot you need.

You get the same results every time for better quality.

Safety features protect you and your team from open flames.

Fusion Inc.

Fusion Inc. makes induction brazing machines for fast and big jobs. You can join steel, stainless steel, copper, brass, and aluminum. Fusion Inc. machines use induction, resistance, and flame heat sources. You can use machines to do work automatically and save money on labor. The machines can handle hundreds or thousands of parts each hour. You can order custom machines for your special needs. Fusion Inc. helps you get better quality with fewer mistakes.

Note: Fusion Inc. induction brazing machines help you work faster and safer. You can ask for custom machines for your special jobs.

Radyne

Radyne makes induction brazing machines for big factories and fast jobs. You can use their machines for large tubes, many tubes, fluid and fuel lines, and rotor parts. Radyne also has systems with special air for better brazing. You can use machines to feed parts automatically and work faster. Many companies trust Radyne because they need strong and quick brazing.

Alert: Radyne induction brazing machines are best for factories that need to braze many parts quickly and with high accuracy.

Canroon, Ultraflex, Fusion Inc., and Radyne are top brands for induction brazing machines in 2025. Each brand has special features for different jobs. You should pick the induction brazing machine that fits your needs, whether you work in a small shop or a big factory.

Induction Brazing Machine Features

Power & Frequency

When you pick induction brazing machines, check the power and frequency. These features decide how fast and deep the machine heats. Most top machines in 2025 have flexible power supplies. You can choose machines with power from 5 kW to 50 kW. Some machines have even more power for big jobs. The frequency range is usually between 15 kHz and 300 kHz. Lower frequencies work best for thick metals. Higher frequencies are good for thin parts and delicate brazing.

Tip: Using the right power and frequency helps you get strong joints. It also saves energy.

Automation

You can make your work faster with automated induction brazing systems. Automation uses robots and sensors to control the process. You get precise heating and steady results every time. In car and airplane factories, automation helps you reach high standards. Automated systems can cut production times by up to 60%. You also spend less on labor and make fewer mistakes. Many factories use these systems to keep their brazing work quick and reliable.

Material Compatibility

Induction brazing machines work with many types of metal. You can braze steel, stainless steel, copper, brass, aluminum, nickel alloys, titanium alloys, and bronze alloys. This means you can use one machine for different jobs. Some machines need special coils or settings for certain alloys. Always check if your machine matches your materials before you start.

Remember:

Some induction brazing machines cost more at first.

Energy efficiency and running costs matter when you plan your budget.

Safety & Cooling

Safety is important when you use induction brazing machines. Top models use flameless heating, so there is less risk of fire. You get built-in safety features to stop accidents. Cooling systems use water to keep the machine at the right temperature. Most machines need at least 2 gallons of cooling water each minute. The water should not be hotter than 95°F (35°C). These features help you run your brazing process safely and smoothly.

Most induction brazing machines have extra safety systems to protect you and your team.

Brazing Applications

Induction brazing machines help join metals in many fields. You can use them for steel, copper, aluminum, and many alloys. They work for both small and big metal jobs. Let’s see how induction brazing machines are used in cars, electronics, HVAC, and jewelry.

Automotive

Many car factories use induction brazing machines. These machines help make strong joints in car parts. You can use them for:

Joining gears in transmissions

Joining exhaust pipes

Induction brazing is fast and gives the same results each time. The joints are cleaner and other parts stay safe. This helps car makers meet tough quality rules.

Electronics

Electronics need careful and clean brazing. Induction brazing machines heat only the spot you want. This keeps parts safe and your work neat. Here is how these machines help in electronics:

You save time and use less energy. Your work area stays safe and tidy.

HVAC

Induction brazing is good for HVAC jobs. These machines make strong bonds in HVAC systems. The process is clean and easy to control. You get better quality and save time. Here are some benefits:

Focused heating for better quality

Faster than old brazing ways

Safer with less risk of dirt

Uses less energy and saves money

Induction brazing machines make HVAC work safer and easier.

Jewelry

Jewelry makers use induction brazing for tiny work. You can join small parts with great care. The process is quick and saves energy. Here is why it is good for jewelry:

Careful, fast, and saves energy for small designs

Better joints for nicer jewelry

You get pretty results and a safer place to work.

Compare Induction Brazing Machines

There are three main types of induction brazing machines. These are mini machines, portable machines, and automated systems. Each type is good for different brazing jobs. You should learn how each one works before you pick.

Mini Machines

Mini induction brazing machines are small and simple to use. They are great for small workshops or fixing things. These machines heat up quickly and are easy to control. You can join small metal pieces like wires or jewelry. Mini machines are good for learning and do not need much power. They are a smart choice if you want to try brazing and save money.

Tip: Mini machines let you practice brazing and finish small jobs fast.

Portable Machines

Portable induction brazing machines have more power and can be moved easily. You can use them outside or in a factory. These machines have power from 5KW to 300KW. They work at frequencies from 1KHz to 1MHz. You can use them for brazing metal tools or welding parts. They also help make composite pot bottoms. These machines heat up fast and give even results. You can use them for car air conditioner parts. Many experts like these machines for field work. They save energy and work with metals like iron, steel, copper, and aluminum.

Heats up fast and gives steady results

Even heating makes strong joints

Good for diamond tools and metal parts

Can melt less than 1kg to 200kg of metal

Automated Systems

Automated induction brazing systems help you work faster and easier. These systems use electromagnetic induction to heat things very accurately. You get the same results every time. This is important for big jobs in cars, planes, and electronics. Automated systems use less energy and make your work better. Many factories use them for car air conditioner parts. You can trust these systems to make your production line work well.

Note: Automated systems help you meet tough standards and finish more brazing jobs quickly.

Choosing the Right Induction Brazing Machine

Power Needs

First, think about how much power you need. The right power makes strong brazing joints. Thick metals need more power to heat well. Thin parts need less power but higher frequency. Check the size and shape of your materials. The coil design is important for even heating. A good coil fits your job and heats evenly. Cooling systems stop your machine from getting too hot. Control systems help you get the same results each time. Safety features keep you and your team safe.

The type and thickness of your material decide power needs.

Coil design and frequency change how fast and deep it heats.

Cooling and control systems keep your work safe and steady.

Materials

Pick a machine that works with your metals. Not every induction brazing machine fits all metals. Check if your machine matches steel, copper, aluminum, or alloys. The joint type matters for your job. Some machines need special settings for certain alloys. You get better results when power and frequency match your job size and part volume.

Make sure your machine works with your metals.

Match power and frequency to your job size.

Find the best brazing alloys for your work.

Industry Fit

Your industry helps you choose the right machine. Different industries use brazing in special ways. Induction brazing machines are used in many fields:

Automotive – You join gears, axles, and crankshafts for strong cars.

Aerospace – You need careful heating for light, tough materials.

Oil & Gas – You weld pipes and treat metals for safety.

Power Generation – You remove boiler tubes and fix parts fast.

Manufacturing – You get steady heat for forging and brazing.

Electronics – You solder parts without hurting circuits.

Railroad – You repair wheels and axles quickly.

Shipbuilding – You join hulls and engines under high demand.

Construction – You heat bolts and rebar for safe installs.

Renewable Energy – You maintain wind turbines with less impact.

Set clear goals for your brazing work. Ask experts if you need help testing your process.

Budget

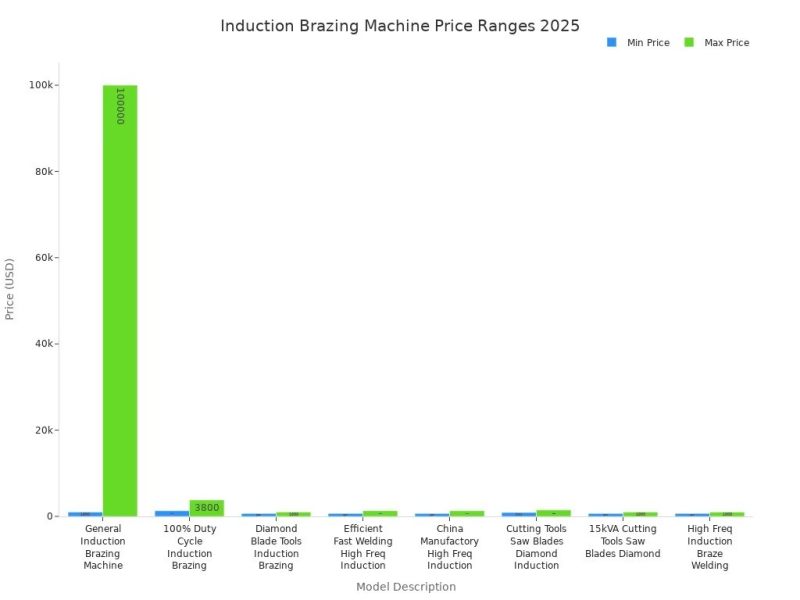

Your budget is important when picking a machine. Induction brazing machines cost from $1,000 to $100,000. The price depends on power, duty cycle, and features. Compare models and see what you get for your money. Look for machines with good support and long-lasting reliability. Automated induction brazing systems cost more but save labor and energy.

Tip: Always check support and warranty before you buy. A reliable machine saves you money over time.

Canroon in the 2025 Market

Advantages

Canroon is easy to spot in the induction brazing machine market for 2025. Canroon machines let you control the heat very well. You can put heat right on the joint. This helps you make strong and clean connections. The machines use smart technology to keep the temperature steady. You get the same results every time you use them.

Canroon machines help you save time and money. You finish brazing jobs faster than with older ways. The machines work well, so you can do more projects in less time. You also use less energy, which lowers your costs. The system helps you make fewer mistakes and get better results.

Here are Canroon’s main advantages:

Tip: Canroon machines help you work better and get more done.

Feedback

Many people say Canroon induction brazing machines make their work easier. You can read stories from car and electronics companies that switched to Canroon. They say they make fewer mistakes and get stronger joints. One factory manager said his team finished twice as many parts each day after switching to Canroon. Jewelry makers also like the machines for gentle heating and steady results.

Customers like the simple controls and quick setup. You do not need much training to use the machine. The machines run quietly and safely, so your workspace is better. You can find reviews that mention fast delivery and helpful support from Canroon’s team.

“We switched to Canroon and saw our production speed double. The joints are cleaner, and our team feels safer.” – Factory Manager, Automotive Industry

You can trust Canroon to give you quality, efficiency, and support for your brazing needs.

You can buy induction brazing machines from Canroon, Ultraflex, Fusion Inc., and Radyne. These machines keep the temperature steady and use energy well. They work reliably for many jobs. You get the same results every time you use them. The heat spreads evenly for good quality. Suppliers have ISO 9001 certification for safety and quality. You can get help quickly if you have problems. Spare parts are easy to find when you need them. Automated systems can handle more parts than old machines. They also use less power and save energy.

Always look at the features before you buy. Pick a supplier who helps you after you buy the machine. This gives you better value for a long time.

FAQ

What metals can you braze with induction brazing machines?

You can braze steel, copper, aluminum, and brass. Many alloys also work with these machines. Most machines handle these metals well. Always read your machine’s manual for a full list. Some alloys need special coils to work right.

How do you choose the right induction brazing machine size?

Match the machine’s power to your job size. Small parts need less power to heat. Big parts need more power to work well. Check the metal’s thickness and type before you choose. Ask the supplier for help if you are not sure.

Are induction brazing machines safe to use?

Induction brazing machines heat without flames. They have safety features like temperature controls and cooling systems. Always follow safety rules when you use them. Wear protective gear to stay safe. Keep your workspace clean and dry.

Can you use induction brazing for jewelry making?

Yes, induction brazing works for jewelry jobs. The machines heat small spots very fast. You get clean joints and save energy. Jewelry makers like induction brazing because it is precise and safe.

How much does an induction brazing machine cost?

Prices go from $1,000 up to $100,000. The cost depends on power, size, and features. Mini machines cost less money. Automated systems cost more money. Compare models and check for warranty and support before you buy.

Previous:

Next:

Sign up for updates