You need the best VFD controller to help your machines work better and last longer. Picking the right drive saves energy and helps your equipment last more years. New VFDs use IoT and AI to make factories smarter. These tools let you watch machines in real time and fix problems before they get worse. This smart tech makes systems more flexible and cuts down on machine stops. Top brands like Canroon are leaders. They bring new ideas and strong results to your work.

Key Takeaways

Picking the right VFD controller helps machines work better and last longer. - Find VFDs with smart tools like IoT and AI. These tools help watch how things work and stop problems before they start. - The right VFD can save up to 50% energy. This can make running costs much lower. - Choose a VFD that fits your motor’s needs. This helps it work well and stay safe. - Pick brands that give good help and strong warranties. This will help you do well for a long time.

Best VFD Controllers 2025

Top Picks Overview

You want the best vfd controllers to keep your factory working well. In 2025, many companies have good choices for factories. The table below shows the top picks. Each company has something special. Some focus on making things automatic. Others give smart features or strong help.

There are many choices for the best variable frequency drive. Each brand helps you save energy and work better. You can pick a vfd controller that fits your needs. Some give smart monitoring. Others are very reliable.

Why These VFD Controllers Lead

You should know why these vfd controllers are the best. Experts look at many things to pick the top ones for factories. You want a drive that fits your motor and job. You also want it easy to set up and get good help.

Tip: Always check how the vfd controller works with torque and speed. This helps your motor work better and saves energy.

Here are the main things experts check to pick the best variable frequency drive:

Know how torque and speed work together.

Make sure the vfd matches the motor.

Set up the drive right for smooth work.

Adjust the drive for your job.

Check the technical details for a good fit.

Pick a brand with good help and quality.

Make sure it is easy to watch and control.

See if it meets your control needs.

Look at the motor details for the right match.

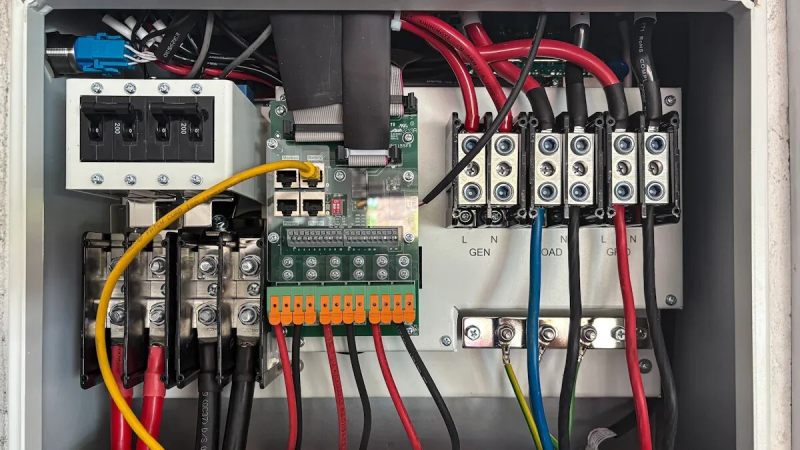

Think about the vfd control panel design.

Find strong technical help.

You want a vfd that saves energy and works well. New drives can make motors 20-50% more efficient. In HVAC, you can save up to 30% on energy. Features like sensorless vector control help you control speed well. Built-in communication lets you watch your system live. These new features make variable frequency drives smarter and more flexible.

You can trust these brands to give you the best vfd controllers for your factory. They help you save energy, stop less, and get more work done. When you pick a top brand, you get strong help and reliability. This keeps your machines running and your power bills low.

What Makes a VFD Controller Efficient

Key Performance Factors

You want your factory to work well and save money. The right vfd controller helps you reach these goals. New variable frequency drives use smart tech like IoT and AI. These tools make machines more reliable and efficient. You can watch your machines as they work. This helps you find problems early and fix them fast. AI can guess when loads will change. It also warns you if something is wrong.

Here are the most important things that make a vfd efficient:

Motor compatibility: Make sure the drive matches your motor’s voltage, current, and frequency.

Energy savings: Variable frequency drives adjust motor speed to match the load. This can cut energy use by up to 50%.

Proper installation: Good wiring and setup prevent overheating and power loss.

Understanding settings: Adjust acceleration and deceleration times for smooth starts and stops.

Regular maintenance: Clean and check your drive often to keep it reliable.

Harmonics and power quality: Use filters to reduce electrical noise and keep your system stable.

Built-in innovative features: Use built-in tools for better monitoring and energy efficiency.

Note: In water and wastewater plants, electric motors use about 85% of the total electricity. Adding a variable frequency drive can save hundreds of thousands of dollars over time.

Essential Features for Industry

You need variable frequency drives that fit your factory needs. Look for drives that save energy and have smart controls. These features help your machines work better and cost less.

The best drives give you:

Energy savings for big cost cuts.

Longer machine life with less damage.

Lower repair costs and fewer breakdowns.

Flexibility for many jobs like pumps and fans.

More safety to stop overloads and overheating.

When you pick a vfd with these features, your plant works better and is more reliable. You also use less power. Smart tools help you fix problems fast. This keeps your factory running strong.

Leading Brands in Variable Frequency Drives

Canroon VFD Controller

You want a vfd controller that works well and uses smart tech. Canroon is known for making strong variable frequency drives for factories. Their drives are small but can handle lots of power. You can set the output frequency very exactly with digital controls. The drive reacts fast when you change speed or torque. Special cooling keeps the drive from getting too hot. It has IP20 protection and important safety certificates like CE and ISO9001. Canroon gives you good prices and fast shipping. You can ask for custom designs with OEM or ODM help. They use vector control for better speed and torque control. Their products work with most factory voltages. Canroon has great reviews from customers.

Siemens SINAMICS

Siemens SINAMICS is a good choice for many jobs. The SINAMICS V20 is easy to set up and use. It helps save energy and works for many power needs. It gives you very exact control. The design lets you use it for one or more motors. It has safety features and can connect to networks. You can use digital tools to watch and control it.

ABB ACS880

ABB ACS880 drives give you strong control. Direct Torque Control helps the drive react quickly and work well at low speeds. You can set it up easily with special software and macros. It saves energy by changing speed as needed. Built-in features make it last longer and cost less to keep running. ABB ACS880 helps you handle sudden load changes and work more efficiently.

Direct Torque Control reacts fast

Easy to set up with special software

Saves energy by changing speed

Works well and lasts long in factories

Schneider Electric Altivar

Schneider Electric Altivar drives help many factory and utility jobs. They use special tech to save energy. It is easy to install, set up, and take care of. Extra features help you find problems and keep things running. Some products are made to handle earthquakes. You get new ways to watch and control your machines.

Rockwell Automation Allen-Bradley

Allen-Bradley drives are easy to set up with special tools. You can make your factory work better and more accurately. These drives help you automate jobs and stop machines from breaking down. Workers are safer because you can watch the drives from far away. You save money by making fewer mistakes and wasting less. Allen-Bradley drives are used in cars, planes, and chemical factories.

Yaskawa VFD

Yaskawa drives can be used for many things. You can use them for fans, pumps, or test benches. They work with different control systems, like hard wired, analog, or network. You can change the programming to fit your needs. Yaskawa drives help motors work better in factories, HVAC, and water plants. They help machines last longer and use less energy. These drives are good for jobs where the load changes, like HVAC and pumps.

Fuji Electric VFD

Fuji Electric drives save energy and work well. People pick Fuji Electric for good performance and quality. These drives work in tough places. Fuji Electric makes new and energy-saving features. You get flexible solutions for factories. The company cares about the environment and making things efficient.

Works very well and is reliable

Can be used in hard places

Has new and energy-saving features

Focuses on helping the environment

Best Variable Frequency Drive Comparison

Reliability & Efficiency

You want your factory to work well every day. The best vfd controllers help you do this job. Each drive has special things that keep motors running smooth and for a long time. Canroon uses high-performance vector control. This helps motors last longer and work better. Yaskawa wins awards for being high quality and reliable. Siemens gives steady performance with proven technology. ABB is easy to set up and saves a lot of energy. Fuji Electric gives a three-year warranty and works in hard places. Mitsubishi uses sealed fans and special greases. This helps the drives last more than ten years.

You can save money by using these drives. ABB drives can lower energy use by 20%. You might get your money back in less than two years. Some systems save up to 49% on energy. This means you save a lot every year.

Application Suitability

You need a vfd that fits your work. Variable frequency drives are used in many industries. You see them in factories, HVAC, and water treatment plants. Shiny-Control Technology and Wuhu Zoncn Automation are rated high for these jobs. Shanghai Pumping Tech and Anyhertz Drive respond quickly in water treatment. Delixi and Shenzhen Micno work well in factories.

ABB makes special vfd solutions for HVACR. You get strong energy savings and good reliability. New variable frequency drives give smart monitoring and flexible use. This helps you work better and get more done.

Support & Service

You want good help for your drive. Good customer service keeps your system working well. You save money when you get help fast. Top brands give spare parts and strong warranties. You get answers when you need them. This keeps your variable frequency drive running and your power bills low.

Tip: Always check the warranty and service before you buy a vfd. Good support means less downtime and more savings.

Quick Reference Table

How to Choose the Right VFD

Assessing Industrial Needs

You should first know what your factory needs. This helps you pick the right vfd and avoid mistakes. It also helps your machines work better. Here are some steps to help you choose:

Decide what job you need the vfd for. Pick if you need variable torque, constant torque, or constant horsepower.

Check your power supply. Find out the voltage, frequency, and how power is given out.

Pick an enclosure that protects your vfd. This helps it last longer.

Make sure the drive works with your process. Look for feedback and ways to connect to your system.

Choose a brand with good support and a strong warranty.

Tip: Review all the details and talk to experts. Try out the drive in your setup to see how it works.

Performance & Compatibility

Your vfd should work well with your machines. Matching the drive to your motor and control system saves energy. It also helps your machines work better. Use this checklist:

Check your motor’s voltage and current. The drive must match these numbers.

Make sure the drive works with your control system. It should fit your setup.

Check if the drive can connect to your monitoring systems.

Note: If you skip these steps, you may have problems and spend more money. Always look for new features that help with automation.

Brand Support

You need good help from your vfd supplier. Good support keeps your drive working and helps your machines. Look at these things:

Pick a supplier who gives tips for cleaning and checking your drive.

Put your drive in a clean place with good air flow to stop it from getting too hot.

Brands like Canroon give custom solutions and fast shipping.

Block Quote:

To avoid mistakes, always check the details, talk to experts, and test the drive before you finish installing it.

If you follow these steps, your machines will work better and use less energy. Smart choices help you watch your machines, make them last longer, and get more work done.

Top VFD controllers help factories use less energy and save money.

More companies want these drives because they make systems smarter and more reliable.

VFDs help you use less power and make machines last longer.

You get better results when you pick VFD features that fit your needs and learn about new technology.

Ask Canroon or other trusted brands for advice or a demo. Keep learning so you can choose the best for your business.

FAQ

What does a VFD controller do?

A VFD controller changes the speed of an electric motor. You can use it to save energy and make machines work better. It helps you control how fast or slow your motor runs.

How do you pick the right VFD for your factory?

You should check your motor’s voltage and current. Look at your job needs. Pick a VFD that matches your system. Ask for help from trusted brands if you need advice.

Can a VFD help you save money?

Yes! You use less electricity when you control motor speed. This lowers your power bills. You also spend less on repairs because your machines last longer.

What safety features should you look for in a VFD?

You need protection against overheating and overloads. Look for drives with alarms and automatic shut-off. These features keep your machines safe and help prevent damage.

Do VFD controllers work with smart factory systems?

Most new VFD controllers connect to smart systems. You can monitor and control them from your computer or phone. This helps you fix problems quickly and keep your factory running.

Sign up for updates