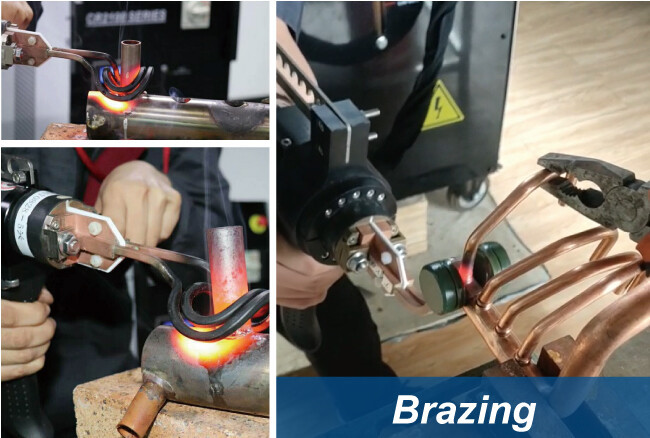

You want your factory to work well. Induction brazing is a top choice today. More companies use it because it makes strong joints. It gives the same results every time. It heats things quickly and saves time. Big industries like cars and planes use brazing induction heater technology. They like it for its accuracy and trustworthiness.

New machines and smart controls help production go faster. They also make work safer for everyone.

Key Takeaways

Induction brazing heats things up much faster. This helps make products quickly and saves energy.

This way lets you control the temperature very well. It makes strong and clean joints with little oxidation.

Induction brazing is safer because it does not use open flames. It also lowers bad emissions, so it is cleaner.

The equipment for induction brazing costs more at first. But you save money on energy and fixing things later, so it is a good choice.

Many industries like aerospace and automotive use induction brazing. They like it because it works well and makes good products.

Quick Verdict: Induction vs. Traditional

Key Differences

You have two main ways to braze: induction or traditional. Each way uses its own tools and steps. The table below shows how they are different in important areas:

You need different equipment for each way. Induction brazing uses induction generators, coils, and control systems. You can heat the joint area fast and only where you want. Traditional brazing uses flame torches, flux, filler rods, or furnaces. You often have to heat the whole part, which takes more time and energy.

Induction brazing can finish in 15 seconds or a few minutes. Traditional ways take much longer and use more energy.

Why Induction Leads Today

Factories pick induction brazing for many good reasons. Here are the main benefits:

You control the temperature exactly. This helps you avoid overheating and breaking parts.

You heat just the joint area. This saves energy and keeps the rest cool.

You use less power and waste less energy.

You can work with advanced materials. New designs use light alloys and composites, and induction works well with these.

You make strong, reliable joints. This matters for cars, planes, electronics, and medical devices.

Many industries now choose induction brazing. Car factories work faster with quick, repeatable cycles. Aerospace companies like induction for its accuracy and low risk of bending parts. Electronics makers use it to protect fragile pieces. HVAC and medical fields like the clean process and safety.

You help the environment by cutting down on harmful emissions. Induction brazing does not use open flames or burn fuel.

The brazing induction heater stands out because it gives you control, speed, and safety. You can join many kinds of metals and meet strict quality rules. As manufacturing gets better, you need a method that keeps up. Induction brazing is leading the way.

Brazing Induction Heater Efficiency

Faster Heating Cycles

Factories want to work fast. Induction brazing helps speed things up. It heats only the joint, not the whole part. This means parts get hot faster. Workers do not wait long for the right temperature. More jobs finish in less time.

Induction heating is much quicker than flame brazing. More parts get done in the same time. Less heat escapes into the air.

Induction brazing takes seconds or a few minutes. The time depends on the part’s size and shape. Traditional ways, like flame or furnace brazing, take longer. You lose time and energy heating everything.

Induction brazing gives exact temperature control.

You waste less material by not overheating joints.

Simulation software helps plan jobs for faster work and better results.

Canroon helps factories work faster. Their brazing induction heater uses smart controls and special coils. You get even heat and the same results every time.

Energy Savings & ROI

Energy costs matter to factories. Induction brazing saves money. It uses up to 90% less energy than old methods. You heat only what you need, so less power is wasted.

Utility bills go down because the heater works well.

You help the planet by using less energy and making fewer emissions.

Canroon’s machines make these savings happen. They heat metals 20–40% faster than older ways. You can pick machines from 10KW to 60KW for your job. Safety features like auto-shutoff keep workers and equipment safe.

Buying a brazing induction heater pays off fast. You finish more parts quickly. You spend less on energy and fixing machines. You also meet tough safety and quality rules. Canroon’s machines help you reach your goals and keep costs low.

Cost Comparison

Upfront Investment

When you start, costs are different for each method. Induction brazing equipment costs more at first. It uses advanced electronics and power systems. Traditional brazing setups cost less to buy. They use simpler tools and technology.

The higher price for induction equipment may seem tough. But you get better control and results with induction machines. You pay more at first, but your factory works better later.

Operating & Maintenance Costs

After buying the equipment, you need to think about running costs. Induction brazing uses less energy because it heats only the joint. This saves money on power bills. The machines have fewer moving parts, so repairs cost less.

Traditional brazing uses more fuel and takes longer to heat parts. You pay more for gas or electricity. The tools wear out faster and need replacing more often. These costs add up over time.

Induction brazing helps you spend less each day and keeps machines working longer.

Long-Term Savings

Looking at the big picture, induction brazing saves a lot of money. Many manufacturers switched to induction and saw real benefits.

A refrigeration equipment maker saved money by making its brazing process more efficient.

You finish more parts in less time, so you make more products without extra costs.

Using less energy and fixing machines less often helps you keep more profit.

You pay more at the start, but induction brazing saves money every day. Over the years, these savings can be much bigger than the first cost.

Precision & Quality

Controlled Heating

You want every joint to be strong and look good. Induction brazing lets you control the heat very well. You can heat just the spot you need. The rest of the part stays cool and safe. This helps you avoid overheating and weak spots.

Induction brazing uses electromagnetic fields to heat metal. The heat goes right to the joint area. You do not have to heat the whole part. Joints come out clean with less oxidation. Your products stay strong and look nice.

Here is how induction brazing and traditional methods compare:

Induction brazing helps you meet tough quality rules. You can use it in cleanrooms and with machines. You waste less material and spend less time cleaning up.

Joint Consistency

You want every joint to be the same. Induction brazing makes this easy. You control the heat exactly. Each joint gets the right amount of energy. You get the same results every time.

Induction heats only the needed spot, so joints match.

Less oxidation means joints stay clean and strong.

You spend less time cleaning after brazing.

You can repeat the process with machines.

You keep quality high, even for thousands of parts.

Induction brazing helps you earn trust from customers. You deliver products that meet high standards. You save time and money by making fewer mistakes. Your factory works better, and your products last longer.

Safety & Environment

Brazing Induction Heater Safety

You want everyone to be safe at work. Brazing induction heater systems help protect your team. These machines use smart tools to lower danger. They have features that watch for trouble and stop accidents early.

Here is a table with safety features found in brazing induction heater systems:

Induction brazing helps the environment too. This process does not burn fuel, so it avoids bad emissions. You use less energy because heat goes right into the metal. Many industries pick induction brazing to follow strict environmental rules.

Tip: You can make your workspace cleaner and safer by using induction brazing.

Traditional Method Risks

Traditional brazing methods have more risks. You use open flames, fuel, and chemicals. These can cause accidents and health problems.

Common safety problems include:

You might breathe in bad fumes if the area is not ventilated.

You need to clean base metals to stop extra fumes.

You must use enough flux to protect metals and lower fume danger.

You heat metals all over, which can make more fumes.

You should know what coatings are on metals because some make toxic fumes.

You must follow safety rules for filler metals.

Other risks with traditional brazing are:

Electric shock from touching charged metal.

Fumes and gases that hurt your lungs.

Fire and explosions from sparks and heat.

Burns if you do not wear the right protection.

Welder’s flash that can hurt your eyes.

You see more accidents and health problems with traditional ways. You also make more pollution because you burn fuel and create smoke.

Note: You can lower risks and help the planet by choosing safer, cleaner brazing methods.

Application Suitability

Industries for Induction Brazing

Many modern factories use induction brazing. This method is good for jobs that need speed and accuracy. It also makes strong joints. Induction brazing works when you join metals with different melting points. Many companies pick induction because it saves money and energy.

Here are some industries that use induction brazing the most:

Aerospace & Defense: You need to join light metals and keep parts strong. Induction brazing helps make safe airplane parts.

Automotive: You want to build cars and trucks fast. Induction brazing gives quick cycles and clean joints.

Medical Device Manufacturing: You must follow strict safety and cleanliness rules. Induction brazing lets you make exact joints without open flames.

These industries pick induction brazing for many reasons. The process costs less and works faster. You can join different metals easily. You get better results and save energy too.

Tip: If your job needs strong joints and fast work, induction brazing can help you reach your goals.

Where Traditional Excels

Sometimes, traditional brazing works better. These methods use flame torches or furnaces. You can use them for jobs that do not need to be fast or very exact.

You may pick traditional brazing for large parts or quick fixes. It works for custom jobs or when you do not want to buy new machines. Traditional methods give you more choices for special projects.

Note: You should think about your needs before picking a brazing method. Induction brazing is best for lots of parts and exact jobs. Traditional brazing is good for repairs, prototypes, and special parts.

Pros & Cons

Induction Brazing: Pros & Cons

You want to know if induction brazing fits your needs. This method gives you many benefits, but you should also think about its limits.

You get high precision. The heat goes only where you want it.

You see the same results every time. This helps you trust your process.

You save energy. The brazing induction heater uses less power than older methods.

You keep your team safe. No open flames mean fewer accidents.

You should also consider some challenges:

You pay more at the start for the equipment.

You need custom coil designs for different jobs.

You may find it less flexible for small batches.

You need skilled workers to set up and run the machines.

Tip: If you want fast, repeatable, and safe joints for many parts, induction brazing works well. Canroon offers solutions that help you get the most from your investment.

Traditional Brazing: Pros & Cons

You may choose traditional brazing for certain jobs. Here is a table to help you compare its strengths and weaknesses:

You see that traditional brazing works well for small workshops, repairs, and custom jobs. You spend less at first and can change your process by hand. You may not get the same speed or control as with induction, but you have more flexibility for special projects.

Note: Think about your production size, speed, and quality needs. Canroon can help you choose the right method for your factory.

You want your factory to do well. Induction brazing is fast and saves energy. It is also safe for workers. You get strong joints that look clean. There is less waste with this method. Studies say brazing gives high strength and low bending. It also saves money. But you need to clean surfaces well. Your team must learn how to do it right.

Here are ways to make your process better:

Use fillers that are good for the environment.

Pick more suppliers to keep costs steady.

Get machines to help your team work faster.

You can ask Canroon for help and special brazing plans.

FAQ

What is the main benefit of induction brazing?

Induction brazing heats up joints very quickly. You can control the heat easily. Only the joint gets hot, so you save energy. You also make joints that are clean and strong.

Can you use induction brazing for all metals?

Induction brazing works for most metals. It is best for copper, brass, aluminum, and steel. Some metals need special coils or settings to work well.

Is induction brazing safe for workers?

Induction brazing is safer than older methods. There are no open flames, so fewer fumes are made. Machines have auto-shutoff and guards to protect workers.

How do you choose between induction and traditional brazing?

Think about how many parts you need to make.

Check how much money you can spend.

Decide how fast and good you want your work.

Induction is best for big jobs that need exact joints. Traditional brazing is good for small fixes or custom work.

Previous:

Next:

Sign up for updates