You should pick a stress relieving machine that fits your material, how much you make, and what you want to achieve. Stress relieving helps metal keep its shape and size. This makes parts safer and more dependable. If you skip or use stress relieving the wrong way, metal can bend, crack, or get thrown away. Picking the right machine can stop costly fixes and dangers. Canroon is ready to help you choose the best option for your factory.

Stress relieving makes metal steady and keeps its size close to the plan.

Good stress relieving stops bending and saves money by avoiding mistakes.

Key Takeaways

Pick a stress relieving machine that fits your material and how much you make. This helps you get better results. Think about the kind of metal you use. Also, think about how many parts you make and what you want to achieve. Regular stress relieving stops parts from bending or breaking. This makes them last longer and work better. Talk to experts like Canroon to help you choose the right machine. They can help you find the best settings for your needs. Follow the rules for your industry and test your process. This makes sure stress relief works well and keeps your parts good.

Stress Relieving in Manufacturing

What Is Stress Relieving?

Stress relieving makes metal parts stronger and more dependable. It is a kind of heat treatment. You heat the metal to a steady temperature that is not too high. Then you let it cool down slowly and carefully. The main reason for this is to get rid of leftover stresses from drawing, machining, or welding. These leftover stresses can make metal crack or bend.

Here is a simple table to help you understand stress relieving:

Stress relieving is different from other heat treatments. Annealing and tempering change the metal’s microstructure more. Stress relieving does not change the microstructure much. It helps keep the part safe and steady without making it softer or harder.

Why Stress Relief Matters

Stress relief helps you avoid expensive problems. When you remove leftover stresses, parts do not bend, crack, or break early. Your parts also stay the right size and shape, which is important for jobs that need high accuracy.

Stress relieving lowers leftover stresses, so parts do not bend or crack.

The original hardness and strength stay the same.

Parts keep their shape and size, so they fit and work right.

Parts last longer because they resist cracking and breaking.

Material stays steady, even when parts get used a lot.

It is good to know how stress relieving is not the same as other heat treatments. Annealing uses higher heat and changes the metal more. Tempering starts with hard metal and tries to balance hardness and toughness. Stress relieving uses lower heat and just removes leftover stresses without changing the main features.

Tip: If you want parts that work well and last, always think about using stress relieving in your heat treatment plan.

Choosing a Stress Relieving Machine

Key Selection Factors

There are a few things you should check before picking a stress relieving machine. The kind of material you use is very important. Metals and plastics need different ways to relieve stress. Plastics often need gentle heating and cooling to remove stress inside. Metals like steel or cast iron need other heat treatment steps. How you treat each material changes how strong and steady it is. So, you must pick a machine that works with your material.

How many parts you make matters too. If you make lots of parts every day, you need a machine that can keep up. If you make only a few parts, you can use a simpler machine. Think about how many parts you make and how fast you need them.

What you want from the process is also important. Some jobs need parts with very little leftover stress. Other jobs need parts that last longer or do not crack. You have to decide what is most important for your parts.

It is very important to control leftover stresses. This helps parts last longer and work better. Lowering bad tensile stress and adding good compressive stress makes parts stronger. This helps you pick the right machine for your needs.

Leftover stress can make parts weaker and not last as long. You need to control how you treat the parts to manage this stress. This helps you choose the best machine for your goals.

Knowing about leftover stress helps keep parts safe and strong. This knowledge helps you pick machines that can handle stress well and make parts last longer.

You also need to think about cost. Some machines are cheaper to run but may not work as well. Others cost more but give you better control and safety. Here is a table to show how costs can be different:

Taking care of your machine is important too. You need to check and fix your machine often. Good care stops problems and keeps your work going. Here is a table to show how different types of care help:

Matching Machine to Process Needs

Do not pick a stress relieving machine just because it is new or cheap. The best machine fits your work and your goals. If you use special alloys or plastics, you need a machine for those materials. If you want parts to last longer or have less leftover stress, pick a machine that can control heat very well.

Think about how your work goes each day. If you need parts fast, get a machine that heats and cools quickly. If you need parts to be very exact, pick a machine that controls temperature closely. Also, check if the machine is easy to use and if your team needs training.

Canroon has special solutions for many kinds of work. Their experts help you find the right machine for your needs. They give advice on the best process, machine, and settings. This help lets you avoid mistakes and get the best results.

Tip: Always ask an expert before you pick a stress relieving machine. You will save time and money, and your parts will be better for your customers.

Comparing Stress Relieving Methods

Furnace vs. Induction Machines

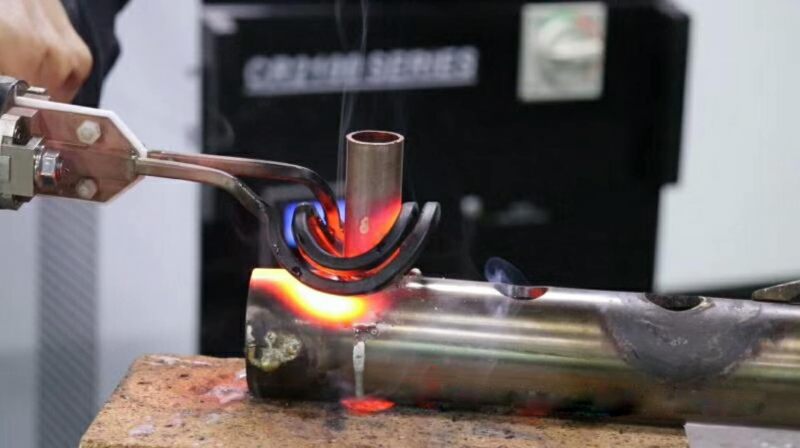

You can pick furnace or induction machines for stress relieving. Furnace machines use high heat to treat many parts at once. These machines are good for big groups and thick materials. Induction machines heat metal fast and focus on small spots. You get quicker results and use less energy with induction machines. The main part of induction furnaces can last 20 to 30 years. Some smaller parts may need to be changed sooner. Both machines help you control stress and make parts better.

When you use higher heat, you need more energy. The energy needed goes up faster as the heat rises. You should think about how much energy costs when picking a machine.

Vacuum and Other Methods

Vacuum stress relieving is best if you want to remove stress without changing the metal’s structure. People use this method after rough machining and before the last machining step. It helps you get parts that fit better. Vacuum methods also help in welding and machining, where stress can build up in joints. In additive manufacturing, vacuum heat treatment removes stress from 3D printed parts. This stops cracks and keeps the parts strong.

Technology Considerations

New technology makes stress relieving work better. Sub-harmonic frequencies give better results than old ways. These vibrations move and settle the stress in metal parts. You do not need high heat to get good results. In 1987, Richard Skinner showed that using a frequency just below the harmonic peak works best. Tests on eight metals proved this method helps relieve stress. You can use these new ideas to make your heat treatment better and get stronger parts.

Tip: Pick the right stress relieving method for your material and process. You will save energy, get better results, and make parts that last longer.

Heat Treatment Process Selection Guide

Step-by-Step Evaluation

You can follow a clear path to choose the right heat treatment process for your parts. Start by looking at the metal alloy you use. The type of metal changes which heat treatment works best. Next, think about the properties you want. Some jobs need parts that are very strong or flexible. The shape and size of your part also matter. Large or complex shapes may need special care during stress relieving.

Here is a table to help you check the main factors:

After you pick a process, you should check if it works well. Many manufacturers use tests to see how much stress remains in the part. For example, some studies show that vibration stress relieving can lower leftover stress by up to 70% in some cases. Other tests look for cracks or changes in the part after treatment.

You should also follow industry standards for stress relieving. For carbon steels, you may use temperatures from 150°C to 680°C, depending on how much stress you want to remove. Non-ferrous alloys and stainless steels need different settings to keep their special properties.

Consulting Experts

You do not have to make these choices alone. Experts in heat treatment solutions can help you match the right process to your needs. Canroon offers advice based on your material, part shape, and production goals. Their team can guide you through each step, from picking a machine to setting the right temperature.

Tip: When you talk to experts, bring details about your parts and what you want to achieve. This helps them suggest the best heat treatment process for your job.

You get better results when you work with people who know stress relieving inside and out. They can help you avoid mistakes and find the most cost-effective heat treatment solutions for your factory.

You should match your stress relieving machine to your material and production needs.

Check the type of metal, the number of parts, and the results you want.

Pick a machine that fits your goals and budget.

Test your process and follow industry standards.

For the best results, talk with Canroon or other experts. They can help you choose the right machine and settings for your factory.

FAQ

What materials can you use with stress relieving machines?

You can use stress relieving machines with metals like steel, cast iron, and aluminum. Some machines also work with plastics. Always check your machine’s manual for material compatibility.

How often should you perform stress relieving on parts?

You should perform stress relieving after major machining, welding, or forming steps. Regular stress relief helps parts stay strong and last longer.

Can you use stress relieving for small batches?

Yes, you can use stress relieving for small batches. Induction machines work well for small quantities. You save energy and get fast results.

How do you know if stress relieving worked?

You can test parts for cracks or measure leftover stress. Many manufacturers use hardness tests or visual checks. Good results mean parts keep their shape and strength.

Sign up for updates