Imagine you use shrink fitting equipment for the first time. You may worry about getting burned or starting a fire. Many new users feel this way. You need to know how to use heat tools safely. Always read the manual and follow Canroon’s safety rules. Go slowly and check each step you do. The table below lists common safety worries for beginners:

Key Takeaways

Always put safety first by wearing gloves and goggles when using shrink fitting tools.

Know how shrink fitting works: heat the outside part to make it bigger, put the inside part in, and let it cool to make a strong hold.

Use the correct tools, like heat guns or induction heaters, to heat things well and stop accidents.

Clean and check your equipment often to keep it working well and stop problems during projects.

Go slowly and follow each step to avoid mistakes that can make the fit weak or not straight.

Beginner’s Guide to Shrink Fitting

What Is Shrink Fitting

You may wonder what shrink fitting means. This beginner’s guide will help you understand the basics. Shrink fitting is a process that uses heat to join two parts together. You heat the outer part so it gets bigger. This lets you fit it over another part that is a little larger at room temperature. When the outer part cools, it shrinks and holds the inner part tightly. This creates a strong connection that does not come apart easily.

Here are some key points about shrink fitting:

Shrink fitting uses thermal expansion and contraction to join parts.

The outer part gets heated and expands.

The inner part stays cool and fits inside the expanded outer part.

When the outer part cools, it contracts and grips the inner part.

This method creates a strong, vibration-resistant joint.

You will see shrink fitting used in many industries. For example, car makers and airplane builders use it to make sure parts stay together under stress.

How Shrink Fitting Works

This beginner’s guide explains how shrink fitting works step by step. You start by heating the outer component. When you heat it, the metal expands. This makes the hole in the outer part bigger. You can now slide the inner part into place without using force.

Tip: Always check the temperature needed for your materials. Too much heat can damage the parts.

After you fit the parts together, you let them cool. As the outer part cools, it shrinks back to its original size. This shrinking action creates a tight grip on the inner part. The joint becomes very strong. You cannot separate the parts without reheating them.

Thermal expansion is the key idea here. When you heat metal, it gets bigger. When it cools, it gets smaller. Shrink fitting uses this property to make a secure fit.

Key Benefits for Beginners

This beginner’s guide highlights why shrink fitting is a good choice for new users. You do not need glue or bolts. The process is simple if you follow the steps and use the right shrink fitting equipment.

Some main benefits include:

Strong Joints: The connection is tight and does not loosen with vibration.

No Extra Materials: You do not need adhesives or fasteners.

Clean Process: The parts stay clean because you do not use oil or grease.

Easy to Learn: You can master the basics with practice and patience.

Reliable Results: The fit is consistent if you control the heating and cooling.

Shrink fitting works well for many jobs. You can use it for gears, pulleys, and other machine parts. If you follow this beginner’s guide, you will build confidence and skill with each project.

Shrink Fitting Equipment Essentials

Basic Tools and Machines

You need the right tools for good results with shrink fitting equipment. First, you need a strong heat source. Many people use heat guns, ovens, or induction heaters. You also need tongs or pliers to hold hot parts safely. Temperature sensors help you see if the metal is hot enough. Safety gear like gloves and goggles keeps you safe from burns and flying pieces.

Here are some basic tools and machines you might use:

Heat gun or induction heater

Tongs or pliers

Temperature sensor or infrared thermometer

Safety gloves and goggles

Workbench or stable surface

Always pick tools that fit your project’s size and type. Using the right shrink fitting equipment helps you stay safe and work faster.

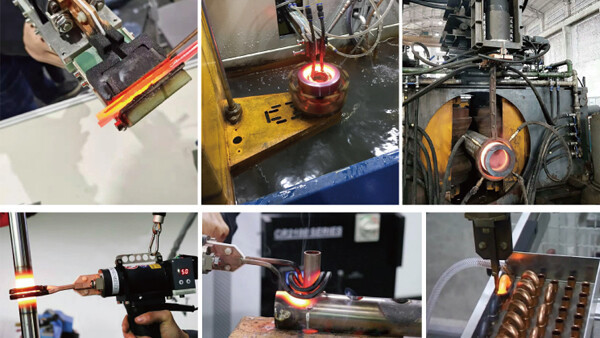

Induction Heating in Shrink Fitting

Induction heating has changed how people use shrink fitting equipment. This way heats metal parts fast and right where you need. You do not need flames or oil. Induction heating uses less energy and saves you money. You also do not get smoke or fumes, so your workspace stays clean.

Tip: Induction heating lets you control the temperature better. This helps you get a tight and exact fit each time.

Here are more benefits of induction heating in shrink fitting equipment:

Heats the part quickly and directly

Uses less energy and costs less to run

No flames, smoke, or oil needed

Safer and cleaner work area

Easy to use with automatic machines

Induction heating makes a perfect fit between parts. This is important when you need strong and accurate joints. The process does not make smoke or waste, so you clean up less. You also work in a safer place.

Canroon Shrink Fitting Solutions

Canroon has many kinds of shrink fitting equipment for both new and skilled users. You can find induction heaters, temperature sensors, and safety tools in their products. Canroon makes machines that are easy and safe for beginners. Their equipment heats parts fast and evenly, so you make fewer mistakes.

Pick shrink fitting equipment that fits what you need. Canroon’s machines help you work faster and safer. Their tools use less energy and keep your space clean. You can trust Canroon to help you learn and get better at using these tools.

Note: Picking the right shrink fitting equipment helps you get better results and stay safe. Always read the manual and follow Canroon’s safety tips.

Shrink Packaging Systems and Related Technologies

Shrink Fit Holders vs. Other Clamping Systems

There are many clamping systems used in machines and assembly. Shrink fit holders are special because they use heat to hold tools tightly. When you heat the holder, it gets bigger. You put the tool inside. As the holder cools, it gets smaller and locks the tool. This way gives you a steady grip and good accuracy. Tests show shrink fit holders work well for fast machines. Their design makes them stable and dependable.

Let’s look at two common types in this table:

Pick shrink fit holders if you need high accuracy and a tight seal. Other types may let you change tools faster or stop more shaking.

Heat Shrink Tubing Overview

Shrink packaging systems have many products. Heat shrink tubing is very useful for electric and machine jobs. You use heat shrink tubing to cover wires and connectors. When you heat the tubing, it gets smaller and wraps tightly. This keeps out water, chemicals, and damage.

There are many kinds of heat shrink tubing. Some are bendy, and some are thick for tough jobs. Pick the right tubing for your needs. For example, you might need tubing for high heat or strong chemicals.

Here are some ways people use heat shrink tubing:

You will see shrink packaging systems in many fields. These systems help you keep cables neat, safe, and sealed.

How to Use Heat Shrink Tubing

You need to know how to use heat shrink tubing the right way. First, measure the size of the cable you want to cover. Pick the right shrink ratio and tubing type. Make sure the tubing is big enough to fit over the cable. Check that it will shrink tight when heated. Think about how thick and strong you need the tubing to be.

Follow these steps for a good fit:

Measure the biggest part of your cable.

Pick the right shrink ratio and tubing type.

Make sure the tubing fits over the cable.

Check that it will shrink tight.

Choose the right thickness for strength.

Pick materials for heat, bending, and chemical needs.

Cut the tubing a little longer than the cable.

Slide the tubing on and check the fit before heating.

Use a heat gun or other heater to shrink the tubing. The tubing will get tight and protect your cable. Picking the right tubing and following these steps helps you get the best results.

Tip: Always check the kind of heat shrink tubing before you start. This helps you match the tubing to your job and get a strong seal.

Shrink Fitting Process Steps

Workspace and Equipment Prep

You need to prepare your workspace and tools before you start shrink fitting. Follow these steps for the best results:

Check that your holders and tools match the right size and shape.

Turn on your heat shrink machine and make sure it works.

Set the hole size of the shrink fit holders to match your tool holder.

Place the tool holder on a stable base so it does not move.

Heat the chuck for the correct time. For example, heat a 10 mm diameter chuck for about 3.2 seconds.

Insert the tool quickly and smoothly into the hot holder. Make sure you push it in all the way.

Let the chuck cool down before you start using the machine.

Tip: Careful setup helps you avoid mistakes and keeps you safe.

Heating and Cooling Methods

Induction heating works very well for shrink fitting. This method heats metal parts quickly and only in the area you need. You do not heat the whole part, so you protect other areas from damage. Induction heating also makes your workspace safer because it does not use open flames. Advanced controllers let you watch and control the temperature closely. This helps you get even heating and a strong fit every time.

Fitting and Cooling Parts

You must fit and cool the parts with care. After you heat the outer part, insert the inner part right away. Push it in smoothly and fully. Do not wait too long, or the outer part may cool and shrink before you finish. Let the parts cool down naturally. Do not rush this step. Cooling too fast can cause cracks or weak spots.

Common Mistakes to Avoid

Many beginners make the same errors during shrink fitting. Watch out for these common mistakes:

Picking the wrong size for your heat shrink tubing or holders.

Forgetting to clean the parts before fitting.

Heating the parts unevenly or not enough.

Rushing through the steps and missing important details.

Note: Take your time and follow each step. This helps you get the best results and keeps your work safe.

Safety Tips for Shrink Fitting Beginners

Essential PPE

You must wear the right personal protective equipment when you use shrink fitting equipment. Gloves give your hands protection from burns and sharp edges. Safety goggles shield your eyes from sparks and flying pieces. Heat-resistant aprons add another layer of protection for your body. Closed-toe shoes keep your feet safe from hot parts that might fall. Ear protection helps when you work in noisy areas. Always check your gear before you start. Good protection means fewer accidents and more confidence at work.

Handling Hot and Cold Parts

You handle very hot and very cold parts during shrink fitting. You need to use tools like tongs or pliers for protection. Never touch heated metal with bare hands. For tight fits, you can cool the insert with liquid nitrogen or carbon dioxide. This cooling gives better insulation and makes the process safer. You heat the outer part to expand it, then fit the cooled insert inside. Sometimes, you use both heating and cooling for extra protection and better results. Start heating near the outside edge of small parts. This method helps with easier removal and more protection. Remember, steel expands at a rate of 0.0000064 per inch per degree Fahrenheit. For large parts, make sure you heat enough for proper insulation and protection. Choose vendors with experience to avoid problems with metals and thermal stress. Always wait for parts to reach a safe temperature before you touch them. This step gives you more protection and prevents burns.

Safe Workspace Setup

A safe workspace gives you the best protection and helps you work better. Adjust your chair so your feet rest flat on the floor. Your knees should form a 90-degree angle for comfort and protection. Set your desk height so your forearms stay parallel to the floor. Place your monitor at eye level and about an arm’s length away. This setup gives you neck protection and reduces strain. Keep your keyboard and mouse close for better insulation from awkward movements. Good lighting helps you see clearly and adds protection for your eyes. Take breaks every 30 minutes to relax your muscles. Practice good posture for more protection and comfort. Use ergonomic accessories for extra support. If you work with wire insulation, keep your tools organized and your area clean for the best protection.

Tip: A safe workspace and the right protection help you avoid injuries and work with confidence.

Maintenance for Shrink Fitting Equipment

Cleaning and Inspection

You need to keep your shrink fitting equipment clean to make sure it works well. Dirt and dust can cause problems during cable repair or other tasks. Start by wiping down surfaces after each use. Check for any signs of wear or damage. Look at connectors and heating elements closely. If you see any cracks or loose parts, plan a repair right away.

Follow these steps to keep your equipment in top shape:

Assign a trained operator or technician to check the equipment.

Use a maintenance checklist to track cleaning and inspection tasks.

Train everyone who uses the equipment to spot early signs of trouble.

Tip: Regular cleaning and inspection help you avoid bigger repair jobs later.

Storage and Longevity

Proper storage helps your shrink fitting equipment last longer. You should always store your tools in their original opaque packaging. This protects them from UV light, which can damage some parts. Keep the storage area between 41°F and 77°F. High temperatures can cause early shrinkage or damage. Try to keep the humidity below 60%. Too much moisture can lead to rust or weaken adhesives, which is a problem for cable repair.

Do not stack heavy items on top of your accessories. This prevents bending or breaking.

Store heat-shrink tubes flat, not upright, to avoid stress on the material.

Remember: Good storage habits mean fewer repairs and better results for every cable repair project.

When to Service or Replace

You should know when your equipment needs service or a full repair. Watch for signs like slow heating, uneven shrinking, or strange noises. If you notice these issues, stop using the equipment and call a technician. Sometimes, small problems need a quick repair. Other times, you may need to replace a part or the whole machine.

Here are some signs you need to act:

The equipment does not heat up as fast as before.

You see damage that cleaning cannot fix.

Repairs do not solve the problem.

Regular checks and quick repairs keep your shrink fitting equipment safe and ready for every job.

Troubleshooting for Beginners

Misalignment or Poor Fit

Sometimes, parts do not fit tightly together. This can happen if you do not heat the outer part the same all over. If you heat it unevenly, you might see wrinkles or gaps. Always watch how you heat the part and do not use too much heat. Picking the wrong size tubing or holder can also make the seal uneven. Gears can get stuck on the shaft when you put them on. You may feel unsure about how fast to work. If you hurry, the fit might not be strong.

Heat the part evenly to stop wrinkles.

Watch the heat so you do not overheat.

Bad heating can make 20% of jobs fail.

Gears can stick during installation.

Not knowing the right speed can change the result.

Tip: Go slow and check the temperature before you fit the parts.

Equipment Issues

Problems with your equipment can change how well shrink fitting works. You might make the fit too loose or too tight. These mistakes can cause leaks or weak seals. If you do not push the tube in far enough, it can shake loose. Tubing or fittings with dents or scratches will not seal right. The surface quality is important too. Bad surfaces can make the connection weak, especially when things move fast.

Surface Damage Solutions

If the surface is damaged, you will not get a good fit. Check all parts before you start. If you see dents or scratches, use new parts. Clean the surfaces to get rid of dust and oil. Use a soft cloth and do not use strong cleaners. If you find damage after fitting, take the parts apart and look for problems. You might need to polish or replace the damaged area.

Note: Always clean and check every part before you start. This helps stop leaks and weak joints.

Canroon Support Resources

You can get help if you have trouble. Canroon gives you guides, videos, and customer support for beginners. You can read the manual or watch videos to learn more. If you have questions, ask their support team. They can help you fix problems and get better at using the tools. You will feel more sure of yourself with expert help.

Use step-by-step guides.

Watch videos for common problems.

Ask support for quick help.

Tip: Try Canroon’s resources to fix problems and learn new skills.

You can learn to use shrink fitting equipment by taking easy steps. Get your workspace and tools ready before you start. Put on safety gear and read all instructions. Follow Canroon’s tips for each project. Take your time and check your work as you go.

Use the right PPE to stay safe

Heat and cool parts with care

Clean and look over your equipment often

Keep learning and use Canroon’s help resources. You will get better and feel more sure with every project.

FAQ

What is the safest way to heat parts for shrink fitting?

You should use induction heaters or heat guns. These tools let you control the temperature. Always wear gloves and goggles. Keep flammable items away from your workspace.

How do you know if the fit is tight enough?

Check for no gaps between the parts. The joint should not move when you touch it. Use a temperature sensor to make sure you heated the part correctly.

Can you reuse shrink fit holders?

You can reuse shrink fit holders if they show no damage. Clean them after each use. Inspect for cracks or wear before starting a new project.

What should you do if parts do not fit together?

Stop and check the size of both parts. Clean the surfaces. Try heating the outer part again. If the problem continues, ask Canroon support for help.

How often should you clean shrink fitting equipment?

Clean your equipment after every use. Wipe down surfaces and check for dust. Regular cleaning helps your tools last longer and work better.

Sign up for updates