You can take out stuck, rusted bolts fast and safely with an induction bolt heater. This tool heats the metal right away. You do not need to use fire. Using fire can be risky. Torches can cause accidents near things like rubber or wires. Induction heaters make your work area safer.

Stay safe: Induction heating does not make flames, so it helps stop fires near things that can burn.

Here is how induction heaters are different from old ways:

Getting ready and following safety steps helps you do a good job every time.

Key Takeaways

Induction bolt heaters help take out rusted bolts safely. They do not use open flames. These tools work fast and are easy to use. - Always wear safety gear to stay safe. Put on goggles and heat-resistant gloves before you start. - Clean the area around the bolt very well. This helps the heat move better and makes the job faster. - Watch the temperature closely as you heat the bolt. This stops damage to the bolt or other parts. - If the bolt will not move, heat it again. You can also use penetrating oil. Try to turn it gently with some force.

Tools and Safety Gear

Required Equipment

You need the right tools to take out rusted bolts safely. Gather all your tools before you begin. Here is what you should have:

Wire brush

Safety goggles

Heat-resistant gloves

Protective clothing

Non-contact thermometer (optional)

Wrench or socket set

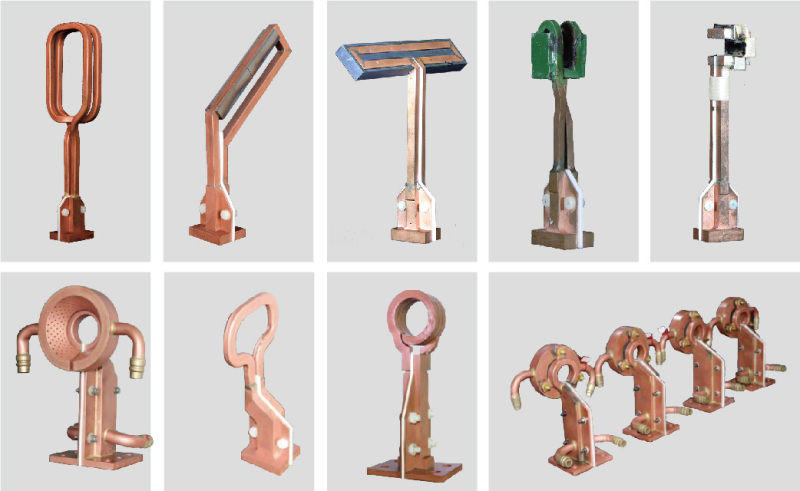

The Canroon induction bolt heater heats bolts fast without using fire. It comes with three coil sizes for different bolts. The heater uses electromagnetic fields to heat bolts quickly and exactly. Its handle is easy to hold, so your hands do not get tired. Overheat protection and a cooling fan help keep you safe and make the tool last longer.

Safety Precautions

Protect yourself and your workspace before using the induction bolt heater. Wear safety goggles to keep your eyes safe from sparks. Put on heat-resistant gloves to stop burns. Wear clothes that cover your skin and do not melt. Keep your work area dry and clean. Take away anything that can catch fire. Make sure the induction bolt heater works right and the coils fit the bolt. If you use a non-contact thermometer, you can check the temperature and stop the bolt from getting too hot.

Tip: Always read the user manual for your induction bolt heater before you start. This helps you know how to use the tool safely and the right way.

Stay careful and follow these steps every time. You will lower risks and make it easier to remove bolts.

Preparing for Induction Heating

Cleaning the Bolt Area

Start by making sure the bolt and its surroundings are clean. Dirt, grease, and rust can block heat and slow down your work. Use a wire brush to scrub away loose rust and debris. Wipe the area with a clean cloth to remove any leftover dust or oil. A clean surface helps the induction bolt heater work faster and more evenly.

Tip: Always clear your workspace before you begin. Remove any flammable materials and make sure you have enough room to move safely.

Follow these steps to prepare the bolt for heating:

Select the right tool for the job. Make sure your induction bolt heater matches the size and type of bolt.

Clear the area around the bolt. This keeps you safe and gives you better access.

Clean the bolt with a wire brush. Remove as much rust and dirt as possible.

Check that the bolt is dry before you start heating.

Setting Up the Induction Bolt Heater

After cleaning, set up your induction bolt heater for the best results. Choose the right coil size for your bolt. Wrap the coil around the bolt, making sure it touches the metal closely. Good contact helps the heater warm the bolt evenly. Place the heater so you can see the bolt and reach it with your tools.

Here are some important factors to consider when setting up your heater:

Note: Start with a lower temperature and increase it slowly. This helps the rust break apart without damaging the bolt.

Once you finish these steps, you are ready to use the induction bolt heater to remove the rusted bolt.

Using the Induction Bolt Heater

Applying Heat to the Rusted Bolt

You can start heating the rusted bolt once you finish setting up your induction bolt heater. Follow these steps to make sure you do it safely and effectively:

Plug in your induction bolt heater and turn it on.

Select the right coil size for your bolt. Wrap the coil around the bolt so it touches the metal closely.

Set the temperature to a low setting first. You can increase it slowly if needed.

Watch the bolt as it heats up. You will see the rust begin to break apart. The metal may change color, usually turning a dull red.

Use a non-contact thermometer to check the temperature. Try to keep the heat focused on the bolt, not the surrounding parts.

Tip: Move the coil slightly if you need to heat a larger area. Do not let the coil touch any wires or rubber parts.

You need to monitor the heat to avoid damage to nearby components. Here are some best practices for heat application:

Check the temperature and flow rate of any process fluid near the bolt.

Watch the load current of pumps if they are close to the work area.

Test the coil seasonally with a resistance meter to make sure it works well.

Keep a record of your heating sessions for future reference.

Continuous monitoring helps you prevent damage and keeps your workspace safe. You should also inspect your induction bolt heater regularly. Check the coils and attachments to make sure they are secure and working properly. This helps you avoid problems and keeps your equipment in good shape.

Removing the Heated Bolt

Once the bolt is hot, you can start removing it. The heat expands the metal and breaks the rust bond. Here are the most effective techniques for removing a heated rusted bolt:

Spray penetrating oil, such as ATF or a diesel mix, on the bolt after heating. The oil helps loosen the rust.

Tap the bolt lightly with a hammer. This helps the oil work into the threads.

Use a wrench or socket set to turn the bolt slowly. Do not force it. If the bolt does not move, heat it again and repeat the process.

If the bolt head is damaged, weld a nut onto it for better grip.

Pour a small amount of water around the threads after heating. The steam can help push out the rust.

Note: Always let the bolt cool down before touching it with your hands. Use gloves to protect yourself from burns.

You should avoid damaging the threads. Turn the bolt gently and stop if you feel resistance. If the bolt sticks, repeat the heating and oil steps. Do not rush. Patience helps you remove the bolt without harming the surrounding parts.

Regular maintenance of your induction bolt heater is important. Clean the coils and check the power supply often. Make sure the cooling system works well. Inspect the bolts and washers for wear. Replace any damaged parts right away. This keeps your tool working smoothly and helps you avoid downtime.

Tip: Use 300 series stainless steel bolts with heavy brass washers for your induction bolt heater. Tighten them twice at 35 to 40-foot pounds for best results.

You can remove even the most stubborn rusted bolts with these steps. Careful heating and gentle removal protect your equipment and make your job easier.

Tips and Troubleshooting

Handling Stubborn Bolts

Sometimes, bolts stay stuck even after you heat them. You have several ways to handle these tough bolts. Start by using your induction heater to focus heat on the bolt. Let the bolt cool down after heating. This helps break the rust. You can also heat the area around the bolt. This makes the hole expand and loosens the bolt. Try using an impact wrench to add force. Apply a good penetrant like Kroil or CRC Freeze-Off to help break the rust. If the bolt still will not move, make relief cuts in the bolt head or nut. Use a chisel and hammer to break it free. As a last step, drill through the bolt to relieve tension.

Preventing Damage

You want to protect your parts while removing bolts. Keep the heat focused on the bolt. This stops damage to nearby parts. Apply penetrating oil before you start. Let the oil soak in for a few days if possible. This helps loosen the rust and makes removal easier. Always use the right coil size and keep the coil close to the bolt. Do not overheat the bolt. Watch for color changes. Stop heating if the bolt turns bright orange.

Focus heat only on the bolt.

Use penetrating oil daily for several days.

Choose the correct coil size.

Avoid overheating by watching the bolt’s color.

Tip: A dull red color means the bolt is hot enough. Bright orange is too hot and can cause damage.

Common Issues

You may face some problems while using an induction bolt heater. Here are the most common issues and how to fix them:

Note: The induction heater works only on metal, not on plastic or rubber. Always check that your bolt is made of iron or steel. If your tool does not heat, test your outlet and let the unit cool if it overheats.

You can take out rusted bolts fast and safely with an induction bolt heater. Always remember to follow these safety rules: Use Lockout/Tagout (LOTO) steps to keep things safe. Wear gloves that protect from heat, plus aprons and face shields. Let hot parts cool down before you touch them. Use tongs to pick up bolts that are still hot. Make sure guards and interlocks are in place and working.

Using the right method is important:

If you need help, Canroon gives you technical support. You can also find a download center, warranty help, and answers to common questions.

FAQ

How does an induction bolt heater work?

You use electromagnetic fields to heat the metal bolt directly. The heat breaks the rust bond. You do not need an open flame. This makes the process safer and faster.

Can you use an induction bolt heater on all bolts?

You can use it on most steel or iron bolts. It does not work on aluminum, brass, or plastic bolts. Always check the bolt material before you start.

Is induction heating safe for car repairs?

Yes, you can use it safely for car repairs. The tool heats only the bolt. Nearby parts like wires or hoses stay safe. Always wear safety gear and follow the instructions.

What should you do if the bolt does not come loose after heating?

Try heating the bolt again. Let it cool, then apply penetrating oil. Use a wrench to turn the bolt gently. Repeat the process if needed. Do not force the bolt.

Sign up for updates