If you want the best freqency converter in 2025, you will see these names a lot: Canroon CV800D Series, Hitachi, Mitsubishi, ABB, Schneider Electric, and General Electric. When choosing a freqency converter, you care about price, how well it works, and if it lasts. The freqency converter market is growing very fast. Experts think it could be worth more than USD 27 billion in 2025, and it might go over USD 62 billion by 2034. Canroon is special this year, and its CV800D Series freqency converter gets lots of notice for good value and strong performance.

Key Takeaways

Think about the Canroon CV800D Series for good value and strong performance. It has a wide output frequency range. It uses advanced control technology. This makes it good for homes and factories.

Look for energy efficiency when picking a frequency converter. Some models, like ABB’s ACS880, can boost efficiency by up to 32%. This helps you save money on your electric bills.

Make reliability a top priority when choosing. Pick converters that work well and last a long time. This means fewer problems and steady performance.

Check if the converter works with your machines. Make sure it connects easily. It should meet the power needs of your equipment.

Always look at the specifications and certifications before buying. This helps make sure the converter fits your needs. It also follows safety rules.

Top Frequency Converter Models

If you need a frequency converter in 2025, you will see some names a lot. These models are popular because they work well and have good features. They help make your work easier and save you money. Let’s see why each one is special.

What makes a frequency converter popular?

You want a model that does its job well. It should save energy and fit with your machines. It should also be a good deal for the price. Many people like smart features such as IoT connectivity or predictive maintenance.

Here are the main things people look for when picking a top model:

Canroon CV800D Series

The Canroon CV800D Series gets lots of attention this year. It is small but powerful. You can use it for many jobs, like running big machines or keeping your HVAC system working at home. The CV800D Series gives you a wide output frequency range from 0Hz to 400Hz. This means you can control your equipment better. It can handle overloads, running at 150% of its rated current for up to a minute. You get advanced control technology and several speed control modes. Its protection level is IP20. Canroon makes sure you get important certifications like CE and ISO9001. This means it is safe and reliable.

Output Frequency Range: 0Hz to 400Hz

Power Range: 0.4kW to 15kW

Input Voltage: 1PH 110V/220V ±15%; 3PH 220V/380V ±15%

Overload Capacity: 150% rated current for 60 seconds

Speed Control Modes: V/F Control, Vector Control

If you want a frequency converter for home or industry, the Canroon CV800D Series is a good choice.

Hitachi and Mitsubishi

Hitachi and Mitsubishi are known for making reliable frequency converters. Their models last a long time, even in tough places. Hitachi models are easy to set up and use. Mitsubishi gives you advanced motor control and helps save energy. Both brands have different sizes and power levels. You can find one that fits your needs, whether you have a small shop or a big factory.

Hitachi: Easy controls and strong build quality.

Mitsubishi: Advanced motor control and energy-saving features.

ABB and Schneider Electric

ABB and Schneider Electric are leaders in reliability and user happiness. ABB’s ACS800 and ACS580 series give you great motor control and help save energy. Schneider Electric’s Altivar range is flexible and saves energy too. You can use these frequency converters in many places, like factories or big buildings. Both brands make their products easy to use and take care of.

If you want something that works well and keeps energy costs low, ABB and Schneider Electric are smart picks.

General Electric and VFDSU 62.2KW

General Electric (GE) makes frequency converters that are strong and work with many machines. You can use GE models in lots of industries. They have good safety features. The VFDSU 62.2KW model is also popular for heavy-duty jobs. It gives you high power and works well in tough places. If you need a frequency converter for big machines or hard jobs, these models are a good choice.

GE: Strong design and works with many machines.

VFDSU 62.2KW: High power for heavy-duty jobs.

Tip:

Always check the specs and certifications before you buy. Make sure the frequency converter fits your equipment and safety needs.

Key Features

Efficiency

You want your machines to run smoothly and not waste energy. Efficiency matters a lot when you pick a frequency converter. Some brands stand out for saving more power. For example, ABB’s ACS880 model can boost efficiency by 32%. Siemens’ SINAMICS G120 is close, with a 30% improvement. Here’s a quick look:

When you choose a converter, check how much energy it can save. This helps lower your bills and keeps your machines running longer.

Reliability

You need a device you can trust every day. Reliable converters keep your work going without trouble. Some models, like the ACS8080, reach up to 98% efficiency and cut down on power problems. They also last a long time. Tests show these drives can work for 20 years, even in tough places. Here are some things that make a converter reliable:

High efficiency, up to 98% in some models.

Less harmonic distortion, which means smoother power.

Tested for long life under extreme conditions.

If you want fewer breakdowns, look for these features.

User Experience

You want a converter that is easy to use and fix. Many users report common issues, but you can avoid most of them with good setup and care. Here are some problems people see and what you can do:

Tip: Always check the manual and keep your converter clean. This helps you avoid most problems and makes your experience better.

Frequency Converter Comparison

Specs Overview

You want to know what makes each model stand out. Let’s look at some specs that matter most. Power range, output frequency, and overload capacity help you pick the right device for your needs. Here’s a quick summary of top models:

Tip: Always check the power range and output frequency before you buy. This helps you match the converter to your machine.

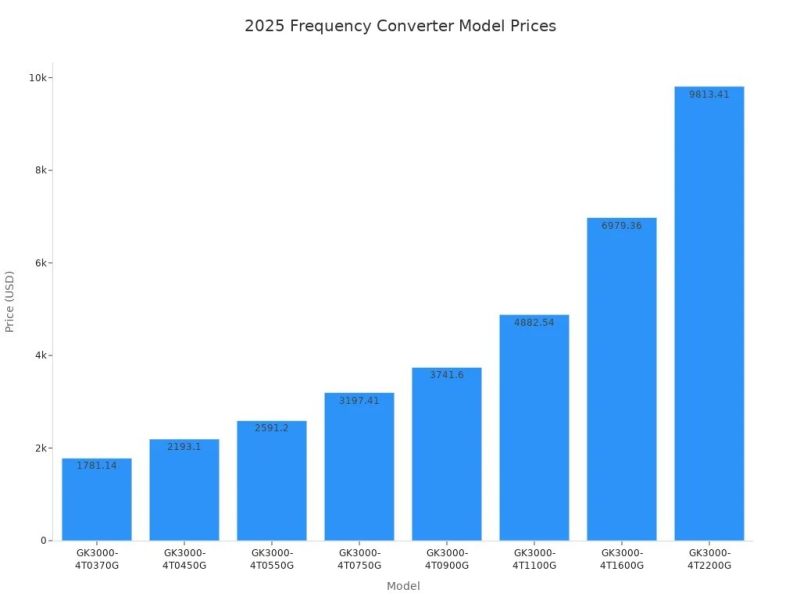

Price Range

You probably want to know how much you’ll spend. Prices can change based on power and brand. Here’s a table showing the price range for GK3000 models in 2025:

Note: Prices go up as power increases. You can find affordable options for home use and higher-priced models for big machines.

Use Cases

You might wonder which model fits your needs. Here’s a simple guide:

Canroon CV800D Series: Great for storage and heavy-duty machines. You get smooth power conversion for both home and industry.

Siemens SINAMICS V20: Perfect for basic motor control. You can set it up easily at home or at work.

Hitachi SJ-P1: Flexible for many uses. You can install it quickly in shops, factories, or even small projects.

If you need a frequency converter for your home, pick a model with lower power. For industrial jobs, choose one with higher power and strong overload protection. Bench-top models work well for testing and small machines.

😊 Quick tip: Think about what you need most—power, price, or easy setup. This helps you choose the right model for your job.

In-Depth Reviews

Canroon Frequency Converter Review

You want a device that saves energy and works for many jobs. The Canroon CV800D Series is special because of its smart design. You can use it at home or in a factory. It works with single-phase and three-phase systems. The modular build lets you save space. You can add more power if you need it. AI-enabled controls help you use less energy. This means you can lower your bills. It is very efficient, up to 98%. Basic models start at about $1,550. You get good value for your money.

ABB Frequency Converter Review

ABB is good for strong motor control and saving energy. The ACS800 and ACS580 models help your machines run smoothly. You get reliable performance and easy setup. Many people say ABB drives last for years. They work well even in tough places. You can trust ABB for small and big jobs.

Hitachi Frequency Converter Review

Hitachi makes things simple for you. The controls are easy to use. You can set it up fast. People like the simple design and quick delivery. Many reviews say Hitachi products work well without problems.

Mitsubishi Frequency Converter Review

Mitsubishi gives you advanced motor control. The models help you save energy. They keep your machines running well. Mitsubishi drives work in small shops and big factories. You can count on them to last a long time. They give strong performance.

Schneider Electric Frequency Converter Review

Schneider Electric helps you use less energy. Their frequency inverters can save you over 30%. They match motor speed to what you need. You get high-quality parts and smart monitoring. The system stops overheating and overloading. Advanced diagnostics give you real-time feedback. You can spot problems early.

Saves over 30% energy by optimizing motor speed

Reduces needless energy waste

High-quality components boost reliability

Prevents overloading and overheating

Real-time diagnostics help you fix issues fast

General Electric Frequency Converter Review

General Electric gives you reliable performance in many industries. You get new technology and green solutions. GE keeps making its products better. You get a device that works well and lasts.

High reliability and strong performance

Advanced technology from ongoing research

Commitment to sustainability and green solutions

Technical Challenges

Common Issues

Frequency converters in 2025 can have new problems. Harmonic distortion is a big issue. It can make power noisy and unstable. This can cause machines to act weird. Factories spend lots of money to fix these problems. Heat is another challenge. Smaller and stronger converters make more heat. Keeping them cool is hard. Sometimes, you need special cooling systems. These can be expensive.

Here are the most common technical problems you might see:

💡 Tip: If you hear strange sounds or see overheating, check for these problems first. Fixing them early can save you time and money.

Troubleshooting

You want your frequency converter to work well. If something goes wrong, you can fix most problems easily. Try these steps:

Check Mechanical Load: Look for broken or worn parts. Replace anything that causes too much friction.

Check Incoming Voltage and Acceleration Rate: Lower the acceleration rate or steady the voltage if you see faults.

Motor Not Starting: Change the settings, check the wires, or test the motor. Replace it if needed.

Overcurrent Trips: Lower the load, check motor windings, and change acceleration or deceleration times.

Noise and Vibration: Change the carrier frequency, tighten mounts, and check motor bearings.

Harmonics and Interference: Add harmonic filters and make sure everything is grounded right.

Communication Errors: Double-check settings, swap cables, and use shielded wires.

Frequent Tripping: Make the power supply steady, lower the load, and reset parameters.

Overheating: Keep airflow clear, use fans or heat sinks, and keep converters away from heat sources.

Input Voltage Fluctuations: Use voltage stabilizers, watch power quality, and think about a UPS.

Harmonic Distortion: Put in harmonic filters or try active front-end converters.

😊 Note: Check your converter often and fix problems quickly. This helps it last longer. If you need help, ask an expert or look in the manual.

Types of Frequency Converters

Home Use

You may want a frequency converter for your house. These models are small and simple to install. You can use them with air conditioners, washing machines, or pumps. Home converters help you save energy. They keep your devices working well. Most home models use single-phase power. You get easy controls and clear screens. Some have smart features like remote monitoring. If you want to lower your electric bill, a home frequency converter can help.

💡 Tip: Always check the power rating before you buy. Make sure the converter matches your device.

Here’s what you get with home models:

Industrial Use

You need a stronger converter for factories or big buildings. Industrial frequency converters handle heavy loads and tough jobs. These models work with three-phase power and high voltages. You get advanced controls and safety features. Many industries want energy-saving solutions. The Sinamics G220 by Siemens is a top choice. It gives high performance and uses new technology to lower harmonics. This helps your machines run better and last longer. Manufacturing, power, and marine sectors pick converters like the Sinamics G220 because they meet strict needs.

Industrial converters often have:

Strong design for harsh places

Smart diagnostics for fast fixes

Flexible settings for many machines

😊 If you work in a factory, choose a model that can handle your biggest machines.

Bench-Top Models

You might need a frequency converter for testing or small projects. Bench-top models are great for labs, workshops, or classrooms. These converters are light and easy to move. You can use them to test motors, do experiments, or teach students. Bench-top models have clear screens and simple buttons. You get quick setup and easy changes. They don’t need much space, so you can keep them on a table or shelf.

👍 Bench-top converters help you learn and try new things without spending a lot.

Conversion Efficiency

Power Output

You want your machines to work hard without wasting energy. Power output tells you how much work your frequency converter can handle. When you use a high-quality converter, you get steady power for your motors and equipment. This means your machines run smoother and last longer.

If you slow down a motor, you do not just lower the speed—you also cut down the power it uses. For example, if you reduce the speed of a fan motor by half, the power it needs drops to only one-eighth of what it was before. That is a huge difference! This happens because of something called the fan law. When the fan spins slower, it needs less pressure and horsepower. You get more control and less waste.

Tip: Always match the power output of your converter to your machine’s needs. Too much or too little power can cause problems.

Energy Savings

Saving energy is one of the best reasons to use a frequency converter. You can see big changes in your electric bill when you switch from old control methods to high-efficiency converters. Let’s look at how much you can save:

When you use a frequency converter instead of outlet or inlet dampers, you can save up to 55% on energy. That means more money stays in your pocket. As you slow down your fan or pump, the power needed drops fast. You do not just save energy—you also help your machines last longer.

You get the best results when you use the right converter for your job. Lower speeds mean less wear and tear. Your equipment runs cooler and quieter. You help the planet by using less electricity. Everyone wins!

Choosing the Right Frequency Converter

Assessing Needs

You need a frequency converter that fits your job. First, think about where you will use it. Is it for your house, a workshop, or a big factory? Check what kind of power your machines need. Some use single-phase, and others use three-phase. Look at the input and output specs. Your space is important too. If it gets hot, dusty, or shakes, pick a converter that can handle it.

Here are some things to check:

Input and output details

Things like heat, dust, and shaking

Type of converter (single-phase for small jobs, three-phase for big ones)

Features that make it quieter

Protection from electrical problems

If you want your machines to work well, make sure your converter matches your setup.

Budget Considerations

Money is important when you buy a converter. You want to save money but also get something that lasts. Think about how much power you need. Bigger converters cost more money. If you only need a small one for your house, you can spend less. For big jobs, you may need to pay more.

Here’s a quick tip:

Always check prices for models with the same power. Sometimes, a smaller design saves you money and space.

Canroon says to look for energy-saving models. These help you spend less on your electric bill. You also want a converter that is easy to set up and does not break often.

Feature Prioritization

You want the best features for your needs. Some converters have smart controls and safety systems. Others are made strong for tough places. Canroon says to check these things:

If you want a converter for your house, pick one with simple controls and quiet running. For factories, choose one with strong safety and a tough build. Always pick features that fit your job.

You now know the top frequency converter models for 2025. Each brand brings something special—some save more energy, others last longer, and a few offer great value. Always compare efficiency, reliability, and price before you buy. Canroon stands out if you want a reliable pick for many jobs. Use this guide to help you choose the right model. Need more help? Reach out to Canroon for expert advice or check out more reviews!

FAQ

What is a frequency converter?

A frequency converter changes the frequency of electricity. You use it to control motor speed. It helps machines run better and saves energy. You can use it at home or in a factory.

How do I pick the right frequency converter for my needs?

You should check your machine’s power and voltage. Look at the size and features. Pick a model that matches your job. If you need help, ask the seller for advice.

Can I install a frequency converter by myself?

You can install small converters at home if you follow the manual. For big jobs, you should call a professional. Safety matters. Always turn off the power before you start.

What problems can happen with frequency converters?

You might see overheating, noise, or error codes. Sometimes, the converter trips or stops working. You can fix most issues by checking wires, cooling, and settings.

How much money can I save using a frequency converter?

You can save up to 55% on energy bills. The converter helps your machines use less power. You spend less money over time. Your equipment lasts longer, too.

Previous:

Next:

Sign up for updates