Selecting the right igbt induction heater can make a big difference in your work. You need to think about what material you want to heat, the size of your workpiece, and how deep or even you want the heat. > Canroon’s years of experience help you match the right heater to your needs, making your process more reliable and efficient.

Key Takeaways

Pick a heater that fits your workpiece material and size. Different metals need different ways to heat.

Think about how deep and even you want the heat. Choose a heater with a coil that heats evenly.

Make sure the heater’s power matches your biggest job. Good heaters use less energy and help you save money.

Look for safety features like automatic shutoff and over-temperature protection. These keep the heater safe to use.

Talk to experts like Canroon for advice and help. This can stop mistakes and make your heating better.

Application Needs

Workpiece Material and Size

When you choose an igbt induction heater, you need to look at the type of material you want to heat. Different metals react in unique ways to induction heating. Here are some examples:

Steel absorbs less heat because it has high resistivity.

Copper needs more heat to reach the right temperature since it has low resistivity.

Magnetic materials heat up quickly due to hysteresis.

Non-magnetic materials require more power to achieve the same results.

The size of your workpiece also matters. Small parts need less power, while large parts require a heater with a higher power rating. Canroon’s team helps you match the right heater to your material and size, so you get the best results.

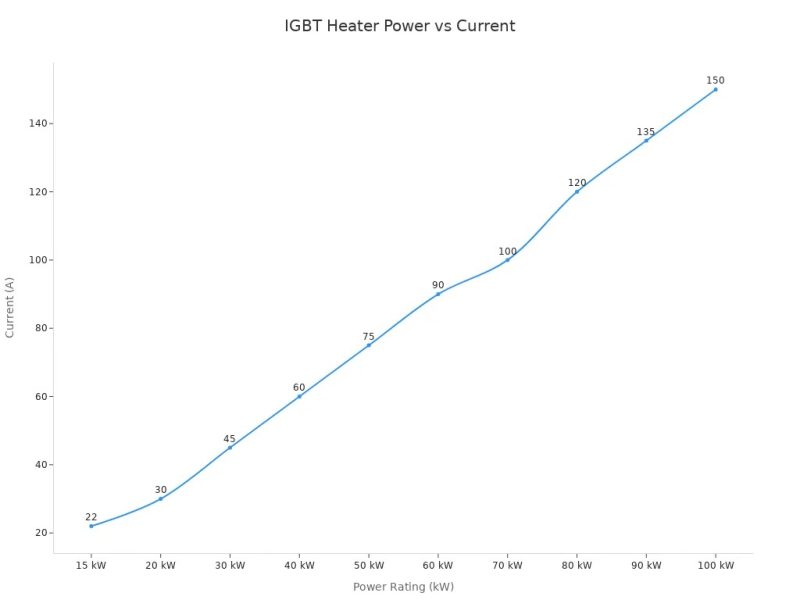

You can see how power rating changes with workpiece size in the table below:

Heating Depth and Uniformity

You need to think about how deep you want the heat to go into your workpiece. Some jobs need surface heating, while others require heat to reach deeper layers. Uniform heating helps you avoid cracks and weak spots. If you want even heat, you should pick an igbt induction heater with the right coil design and frequency. Canroon’s experts can help you choose a system that gives you the best heating depth and uniformity for your project.

Tip: Always check if your heater can deliver the right depth and evenness for your material. This step helps you get strong and reliable results.

Process Goals

Your process goals shape your choice of igbt induction heater. You may want to harden, weld, or solder your workpiece. Each goal needs a different heating profile. If you want fast heating, you need a high-power heater. If you want gentle heating, you should pick a system with lower power and better control. Canroon’s experience helps you match your process goals with the right heater, so you get the results you want every time.

IGBT Induction Heater Specs

Power Output and Efficiency

You need to pick the right power for your job. Small parts need less power. Big or hard jobs need more power. The table below shows what power ranges work best:

Modern igbt induction heaters use less energy than old ones. They heat up faster and waste less power. You can see the differences in the table below:

Tip: Pick a heater with enough power for your biggest job. Do not get one that is too big. High efficiency helps you save money and energy every day.

Frequency Selection

Frequency changes how deep and fast your heater works. Use lower frequency to heat the whole part. Use higher frequency for just the surface. The right frequency saves energy and gives better results. The tables below show how frequency changes your work:

Note: High frequency lets you heat small areas with control. Lower frequency is better for deep and even heating.

Coil Design

The coil is a very important part of your igbt induction heater. The coil’s shape and size must fit your part. A good coil gives even heat and saves energy. A bad coil can cause hot spots or uneven heat. Always check if the coil fits your part and job. Canroon can help you pick or design the right coil.

IGBT Voltage and Current Ratings

You need to check the voltage and current ratings of your igbt induction heater. These numbers show how much power the heater can safely use. If the ratings are too low, your heater may break or not work well. Always match the ratings to your power supply and part size. For example, a 100 kW heater may need up to 150A at 380V AC. See the table in the last section for more info.

Always use a heater with ratings that are right for your job. This keeps your system safe and working well.

Thermal Management

High-power igbt induction heaters get very hot inside. You need to control this heat to keep your heater safe. Here are some tips:

Make sure the bottom of the machine has good airflow.

Do not block the air coming in or out.

Check for dust or dirt that could stop air from moving.

If you do these things, your heater will last longer and work better.

Remember: Good thermal management stops overheating and keeps your heater working well.

Installation and Facility

Space and Layout

Plan your workspace before you put in an IGBT induction heater. The heater’s size and type decide how much space you need. Stationary heaters are big and stay in one place. Portable heaters are smaller and easy to move. Make sure there is enough room for the heater and workpieces. Leave space so people can walk around safely. A good layout helps you work faster and keeps you safe.

Think about what size and type of heater you need.

Stationary heaters need a set spot.

Portable heaters fit in small spaces and move easily.

Power Supply Compatibility

Check your power supply before you set up the heater. Most IGBT induction heaters need three-phase power. Match the heater’s voltage and frequency to your building’s power. This keeps your system safe and working right.

Tip: Always check if your power matches the heater. This stops damage and keeps things running.

Cooling and Ventilation

IGBT induction heaters get hot when you use them. You need good cooling and airflow to keep them working well. Water-cooled heaters are best for long jobs and high power. They heat fast and save energy. Air-cooled heaters do not need water. They work well for small jobs and are easy to use.

Water-cooled heaters keep things steady and stop parts from bending.

Air-cooled heaters are good for small jobs and simple setups.

Let air move around the heater. Clean dust and dirt from vents to help cooling.

Safety and Environment

Safety is important when you set up an induction heater. Keep the area clean and free of mess. Induction heaters do not touch the workpiece, so they last longer and need less fixing. They use less energy and save you money. Good safety keeps you and your equipment safe.

Note: A clean and safe place helps your heater last longer and keeps everyone safe.

Advanced Features

Automation Options

You can make your work faster with automation in IGBT induction heaters. Water-cooled high-frequency devices let you control temperature very well. These systems help heat your workpieces the same way each time. You finish jobs quicker and use less energy. The contactless heating keeps your equipment clean and stops it from wearing out fast. This method also lowers the chance of contamination. This is important for places like aerospace and automotive. Automation lets you set up your heater for jobs you do often. You save time and get the same results every time.

Tip: Automated controls help you reach the right temperature fast and keep your process steady.

Safety Features

Modern IGBT induction heaters have safety features to protect you and your equipment. Here are some common safety features:

These features help prevent accidents. You can work safely, knowing your heater will turn off if something is wrong. Emergency shut-off switches let you stop the heater fast if you need to. Over-temperature protection keeps your system safe from getting too hot.

Note: Always check your heater for these safety features before you use it.

Energy Efficiency

You use less energy with IGBT induction heaters. These heaters need less power than old ones. You get fast heating and better control. The system heats only the workpiece, so less energy is wasted. Efficient heaters help lower your electricity bills. You also help the environment by using less energy. Many heaters have smart controls that change power use to fit your needs.

Pick a heater with high energy efficiency.

Find models with smart energy-saving features.

Energy-efficient heaters give you strong performance and help you save money.

Manufacturer Support

Canroon Expertise

You want to feel confident when you choose an igbt induction heater. Canroon gives you that confidence. The company has many years of experience in the industry. You can ask their technical team any question about heating, installation, or operation. They answer quickly and clearly. You get advice that matches your project. Canroon’s experts help you avoid mistakes. You save time and money because you get the right information from the start.

Tip: If you are not sure which heater to pick, talk to Canroon’s support team. They will guide you step by step.

Customization

Every job is different. You may need a special coil shape or a unique control system. Canroon offers custom solutions for your needs. You can ask for changes in power, size, or features. The team listens to your ideas. They design a heater that fits your workpiece and process. You get a system that works better for your job.

Custom coil designs for odd shapes

Special controls for tricky heating jobs

Flexible power options for different workpieces

You do not have to settle for a standard model. Canroon helps you get the best results with a heater made for you.

Service and Warranty

Good support does not stop after you buy your heater. Canroon gives you strong after-sales service. If you have a problem, you can call or email for help. The service team answers fast. They help you fix issues and keep your heater running. You also get a clear warranty. This warranty protects your investment. You know what is covered and for how long.

Note: Always check the warranty details before you buy. Good service and warranty give you peace of mind.

You can find the best igbt induction heater by taking a few key steps. First, match the frequency and power to your job. Next, pick a coil design that fits your workpiece. Choose a control interface that is simple to use. Make sure the heater fits in your workspace. Check that it has good safety features. The table below shows these steps:

If you have questions, you can ask Canroon for help.

FAQ

What is an IGBT induction heater?

An IGBT induction heater uses special parts to heat metal fast. It gives quick and controlled heat. This tool works well for many factory jobs.

How do I choose the right power rating?

Pick the power rating that fits your part size and heat needs. Small parts need less power. Big or thick parts need more. If you are not sure, ask an expert.

Can I use one heater for different materials?

Yes, you can use one heater for many metals. You might need to change the coil or settings for the best results. Always read the manual or ask the maker for help.

What safety features should I look for?

Find heaters with automatic shutoff, over-temperature protection, and emergency stop switches. These features help keep you and your equipment safe.

How do I maintain my IGBT induction heater?

Clean the air vents often.

Check all cables and connections.

Follow the care guide.

Call support if you find problems.

Taking care of your heater helps it last longer.

Previous:

Next:

Sign up for updates