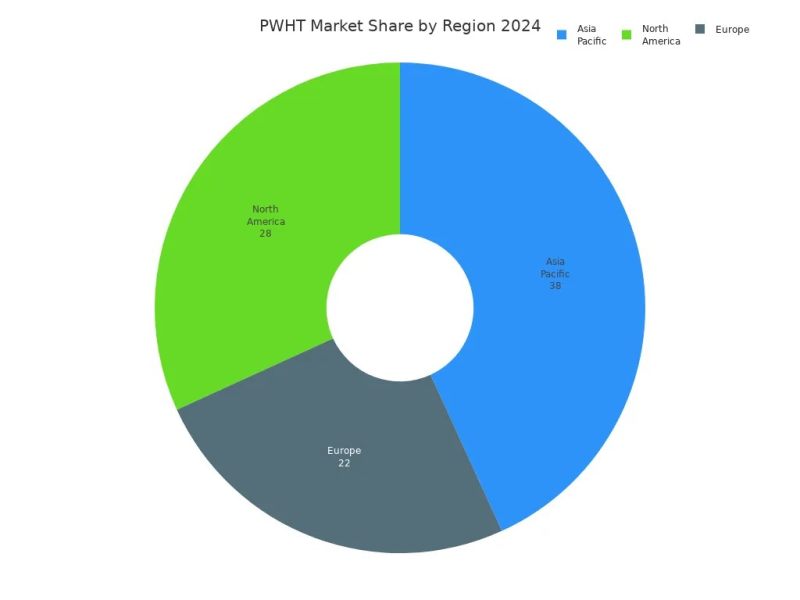

The need for PWHT machine solutions is growing around the world. This is because industries like oil & gas, power generation, and shipbuilding use them a lot. The Canroon CR2000 Series PWHT machine and Canroon CR2100 Series PWHT machine are top models. They help keep welds strong by lowering leftover stress during welding. Induction heating gives fast and even heat. This makes welds better and saves energy. PWHT is important for things like pipelines, pressure vessels, and structural steel. These jobs need advanced welding equipment and exact welding technology. The chart below shows how much of the PWHT market each region has:

Key Takeaways

Induction PWHT machines heat metal fast and evenly. This saves energy and makes welds stronger.

Picking the right PWHT machine depends on the job, material, and site. This helps make welds strong and safe.

Digital controls and tools keep the temperature just right. This stops cracks and keeps welds from failing.

Portable PWHT machines are easy to set up and move. They work well for repairs and hard-to-reach spots.

Top PWHT machines like Canroon and Miller are reliable. They save energy and meet industry rules.

PWHT Machine Comparison

Top 10 Models Overview

The best 10 PWHT machines help make welds strong. Each machine has special features for different jobs. The table below lists the main models, their heating types, power, temperature control, and best uses:

Key Features and Applications

Induction heating is the most used method in top PWHT machines. This method lets you control heat depth and temperature very well. It heats the metal from inside, so there is less bending and less energy used. Induction heating is also fast and heats evenly. This makes it great for pipelines and structural steel.

Some machines use resistance heating. This method heats long pipes evenly and helps keep welds strong. Newer machines have digital controls. These let workers set the right temperature steps. This helps make welds better and more reliable.

Tip: Induction heating pipe heaters work with many pipe sizes and materials. They heat pipes faster and use less energy. This saves money and helps the environment.

PWHT machines are used for many welding jobs. They are important for pipeline welding, making pressure vessels, and building ships. Using the right machine gives good results and meets safety and quality rules.

PWHT Machine Reviews

Canroon CR Series Induction PWHT Machine

The Canroon CR Series is a top brand for post-weld heat treatment. This welding machine uses induction heating to heat metal quickly and evenly. It has digital temperature controls for exact heat cycles. This helps lower leftover stress and makes welds stronger. The CR Series comes in many power levels. It works well for pipelines, pressure vessels, and structural steel. Its strong build means it works in shops and on job sites. People like that it saves energy and can handle big welding jobs. The Canroon CR Series keeps weld quality high and meets tough industry rules.

Pros:

Digital controls for exact temperature

Saves energy

Cons:

Needs skilled workers to use well

Why it stands out:

The Canroon CR Series gives steady results and works for important welding jobs. It is a top pick for weld strength and stress relief.

Miller ProHeat 35 Induction Heater

The Miller ProHeat 35 Induction Heater can reach up to 1,450°F. This makes it good for tough welding jobs. It has flexible, liquid-cooled cables that fit many pipe sizes and flat areas. It heats up faster than old methods by using direct induction. You can set the temperature by hand or let the machine do it. This makes heat cycles exact and easy to repeat. The system is safer because it does not use open flames or hot wires. This lowers burn risks and keeps the work area cleaner. Even heating helps welds stay strong and stops cracks from hydrogen. The ProHeat 35 can use air-cooled, liquid-cooled, or rolling induction. It works for many jobs like making pipes, building ships, and heavy welding.

Key Features:

Heats up to 1,450°F

Fast and even heating

Many ways to control heat

Ideal Applications:

Pipe making, field work, shipbuilding, mining, and big welding jobs.

Pros:

Makes job sites safer

Cuts down heat cycle time

Saves power and runs nonstop

Cons:

Setup may need training

Why it stands out:

The Miller ProHeat 35 is great for stress relief and weld strength. It heats fast and evenly and has good safety features.

Stork Cooperheat Multi-Channel System

The Stork Cooperheat Multi-Channel System is best for big welding jobs with many joints. This welding machine can control many heating zones at once. It uses special controllers and thermocouples to set current and temperature. The system uses low voltage ceramic heaters that can be changed for each job. Its design lets you heat many joints or big welds at the same time. It has a strong power transformer and can run up to six channels. This lets you control the temperature for many zones at once. Remote sockets and data links help with hard welding jobs.

Pros:

Heaters can be changed for each job

Good for big projects

Cons:

Takes up more space than single-channel machines

Why it stands out:

The Stork Cooperheat system gives better control and saves time. It is a top pick for jobs needing many heat treatments at once.

MYD Series Induction Weld Heater

The MYD Series Induction Weld Heater is small and easy to move. It is good for post-weld heat treatment. This welding machine uses induction heating for quick and even heat. This keeps welds strong. Workers can set it up fast for pipe welding and repairs. The MYD Series has digital controls for exact heat cycles. This stops overheating. Its light weight makes it good for repairs in the field. The MYD Series works with many pipe sizes and materials. It is useful for many welding jobs.

Pros:

Easy to move and set up

Heats fast with digital controls

Good for field repairs

Cons:

Not as strong as bigger machines

Why it stands out:

The MYD Series is easy to carry and works well. It is great for repair and maintenance welding.

Red-D-Arc Induction Heating System

The Red-D-Arc Induction Heating System gives fast, even, and controlled heating. It is used for weld preheating, stress relief, and post-weld heat treatment. This welding machine uses electromagnetic induction without touching the metal. It heats faster and safer than flames or resistance. It keeps the temperature even in the heat zone. This is important for strong welds. The system saves energy and cuts down heating time. Red-D-Arc is safer because it does not use flames or hot parts. This means less smoke and a better work area. It works with many shapes and parts, so it is good for field welding.

Pros:

Fast and even heating

Safer and cleaner work area

Works with many shapes and parts

Cons:

May need special training to use best

Why it stands out:

Red-D-Arc makes welds stronger and helps workers do more. It is best for field jobs where safety and speed matter.

Thermatool Induction PWHT Unit

The Thermatool Induction PWHT Unit gives lots of power and smart controls for hard welding jobs. This welding machine can give from 250 kW to 1000 kW of power. It works at different frequencies. It uses special inductors to focus heat on the weld area. SmartAnneal™ and Speed Power Control give real-time feedback and exact heat. The system has automation like recipe recall and seam-tracking. Thermatool units are over 92% efficient and have modular power supplies. Users get 24-hour help and a worldwide service team.

Pros:

High power and very efficient

Smart controls and automation

Great customer support

Cons:

Costs more at first

Why it stands out:

Thermatool units give strong, steady heat for big welding jobs. They help keep welds strong and cut down on delays.

DWT Resistance Heating System

The DWT Resistance Heating System uses electric resistance for even heating. It is good for vessel welding and repairs. This welding machine has manual or digital controls. Workers can set the right temperature steps. The system works for long pipes and big structures. It spreads heat evenly. DWT systems last a long time and are easy to use. They work in shops and on job sites. The resistance heating helps keep welds strong by lowering heat differences and bending.

Pros:

Even heating for big jobs

Lasts long and easy to use

Works in shops and fields

Cons:

Heats slower than induction machines

Why it stands out:

DWT systems give steady heat treatment. They help keep welds strong in vessel welding and repairs.

Heatmasters Digital PWHT Machine

The Heatmasters Digital PWHT Machine has advanced digital controls for exact temperature. This welding machine uses resistance heating for even heat on steel and vessel welds. Workers can set and watch temperature cycles in real time. The system has many power levels for small or big jobs. Heatmasters machines are known for being reliable and easy to use. The digital controls help make sure welds are always good.

Pros:

Exact digital temperature control

Reliable and simple to use

Works for many job sizes

Cons:

May need calibration for best results

Why it stands out:

Heatmasters machines are easy to use and precise. They are a good pick for steel and vessel welding.

EFD Induction Minac Series

The EFD Induction Minac Series is a mobile induction heating machine for many jobs. This welding machine is strong, saves energy, and can do many things. It works for welding, hardening, tempering, brazing, straightening, and heating before or after welding. The Minac Series gives help with setup, coil services, and repairs. Its design uses less energy and is safe and cheap to run. The system fits many welding setups and works in shops or on site.

Pros:

Easy to move and use for many jobs

Saves energy and is strong

Works for many uses

Cons:

May need special coils for some jobs

Why it stands out:

The Minac Series is flexible and saves energy. It helps keep welds strong in many welding jobs.

PWHT Solutions Mobile Unit

The PWHT Solutions Mobile Unit is light and easy to move for on-site heat treatment. This welding machine sets up fast in the field. It keeps temperature exact within 0.5 degrees. It uses special parts like the Twin Heat Module and flexible ceramic pads for even heating and easy setup. The Variable TAU - 50100 lets you change welding settings. The mobile unit works fast and saves money. It is good for tough jobs like military shipbuilding. Its design lets it adapt on site and gives steady heat treatment.

Pros:

Light and easy to move

Fast setup and quick results

Cons:

Not as strong as big, fixed machines

Why it stands out:

The PWHT Solutions Mobile Unit is flexible and fast for on-site heat treatment. It helps keep welds strong and meets strict rules.

Post-Weld Heat Treatment Applications

Pipeline Welding

Pipeline welding needs strong welds and must follow rules. Induction PWHT machines like the Canroon CR2000 Series and Miller ProHeat 35 work well here. These machines give exact temperature control and even heat. This is important for pipelines made from chrome-moly and HSLA steels. Workers can set how fast to heat, how long to hold, and how to cool down. Induction systems let you use many thermocouples to watch the weld zone. They also keep records to meet ASME and API rules.

Induction PWHT machines help by:

Heating quickly so jobs finish faster

Saving energy and being safer (no flames)

Being easy to move for field work

Having power from 60 kW to 300 kW for different pipes

Note: Even heating and good control lower leftover stress and hardness. This helps pipelines last longer and makes welds better.

Pressure Vessels

Making pressure vessels needs careful control of heat and time. Machines like the Stork Cooperheat Multi-Channel System and Heatmasters Digital PWHT Machine do this well. They have digital controls, many thermocouples, and keep records for proof. Workers can set the right temperature, like 1100°F to 1250°F for carbon steel. They also keep the heat for the right time, based on how thick the metal is.

What pressure vessel PWHT needs:

Exact temperature control for each material

Slow heating and cooling to stop cracks

Good records and checks

Can be used in shops or in the field

Portable resistance heating with blankets works well outside. Big furnaces are best for shop jobs. These machines keep pressure vessels safe and reliable.

Structural Steel

PWHT machines help structural steel projects by giving even heat and easy setup. The Canroon CR2100 Series and Heatmasters Digital PWHT Machine are good picks. They have digital controls and can handle big beams or tricky shapes. Even heat stops bending and keeps welds strong in bridges and buildings.

Good things for structural steel:

Even heat for big parts

Digital controls for the same results every time

Can be used for many steel types and thicknesses

Tip: The right welding machine keeps steel strong and stops cracks or bends during welding.

Power Plants

Building power plants is hard and needs special PWHT. Workers must lower leftover stress to stop cracks and corrosion. Machines like the Thermatool Induction PWHT Unit and Stork Cooperheat Multi-Channel System give strong power and exact control. They are used for boilers, turbines, and pipes. These machines help keep parts the right size and make the metal strong.

Power plants use tough materials that get very hot. PWHT machines must handle hard welds and different metals. They must also follow strict rules like ASME Section I. New machines with smart controls and feedback help get the same good results every time.

Shipbuilding and Offshore

Shipbuilding and offshore jobs need PWHT machines that are easy to move and tough. The Red-D-Arc Induction Heating System and PWHT Solutions Mobile Unit are great for these jobs. They set up fast, are easy to carry, and keep the temperature just right. This is important for big ships and repairs at sea. Flexible cables and ceramic pads help heat welds on curved or odd shapes.

Why these machines help shipbuilding and offshore:

Fast, even heat for big or tricky parts

Easy to move for work on site

Safer because there are no flames

These machines help welds stay strong in tough sea conditions. They also help ships last longer and meet safety rules.

Repair and Maintenance

Repair and maintenance need PWHT machines that give exact, local heat. The MYD Series Induction Weld Heater and DWT Resistance Heating System are good for this. They use electric resistance or induction coils to soften metal before welding and lower stress after. These machines fit many shapes and can be run by remote for safety.

PWHT machines help repair and maintenance by:

Making metal strong again and stopping cracks or bends

Giving even heat below change temperatures

Making repairs faster and cutting down wait time

Giving special help for hard jobs

Callout: PWHT machines are very important for better welds and stopping failures during repairs, especially in oil and gas, chemical, and airplane work.

PWHT Buying Guide

Selection Factors

Picking the right welding machine for pwht starts with knowing what the job needs. Every project is different and needs its own plan. The table below lists the main things to think about when choosing a pwht machine:

Tip: Always pick a welding machine that matches the material and job size. This helps make sure the pwht process is safe and meets quality rules.

Matching Machine to Application

Different welding machines are better for certain jobs. Induction heating is best for high-alloy steels and big field work. Resistance heating works well for carbon steel and shop jobs. Portable machines are good for repairs and far-away places. Digital controls and new monitoring tools help workers follow strict rules. Operators should check if the machine can reach the needed temperature and fit the shape of the part. Picking the right machine makes welds better and means less fixing later.

Why Choose Canroon

Lots of people trust Canroon for pwht jobs. The CR2100 Series Induction Heating System heats up fast, is accurate, and saves energy. This welding machine keeps the temperature even and gives good heat treatment. Workers say the controls are easy to use and there are many heating modes for different jobs. Canroon machines work with many coil types and part shapes, so there are fewer mistakes. The company gives full help, not just the machine, which shows they care about customers.

Note: Canroon is known for being reliable, saving energy, and giving good service. Their welding machines help users get good results every time they do pwht.

The best 10 PWHT machines all have their own special strengths. They help lower stress and make welds better. Picking the right machine helps welds stay strong and makes projects turn out well. The table below shows how different things affect weld strength and project results:

Canroon is a trusted brand for post-weld heat treatment. You can use the buying guide and tips to pick the best machine. Here are some next steps you can take:

Check what each model can do

Think about trading in old parts

Talk to suppliers if you need help

Sign up to get alerts when new stock comes in

Read more articles to learn more

See what other customers say about the machines

FAQ

What is the main benefit of using induction PWHT machines?

Induction PWHT machines heat metal fast and evenly. They use less energy and help stop weld problems. Many companies pick induction because it controls temperature well and sets up quickly.

How does a user select the right PWHT machine for a project?

A user should think about what material they will weld. The size of the job and the needed temperature are important too. It also helps if the machine is easy to move and has digital controls. Picking the right machine makes welds strong and results better.

Can PWHT machines be used outdoors?

Many PWHT machines, especially portable ones, work outside. Some units like the Canroon CR Series and PWHT Solutions Mobile Unit set up fast. They keep the temperature steady even when used outdoors.

Why is temperature control important in PWHT?

Good temperature control stops overheating and cracking. It makes sure the weld gets the right heat. This keeps welds strong and meets industry rules.

Do PWHT machines require special training?

Operators need some training to use PWHT machines safely. Digital controls make them easier to use. But workers still need to know about heat cycles and safety steps for best results.

Previous:

Next:

Sign up for updates