An induction annealing machine heats metal parts without touching them. It uses electromagnetic fields to make eddy currents in the metal. These currents heat the metal and make it softer. This process helps the metal bend more easily. It also keeps the surface clean. Many industries use this method for safety and accuracy.

Canroon is a trusted company for these advanced machines.

Key Takeaways

Induction annealing machines heat metal parts without touching them. They use electromagnetic fields to make heat with eddy currents. This process makes metal softer and lowers stress inside it. It also makes the metal more flexible and easier to shape. Induction heating works well and saves energy and time. It lets you control the heat very exactly. These machines can be used in many industries like cars, planes, and medical tools. They help make products better and safer. Picking the right induction annealing machine means looking at power supply choices and setup options. This helps meet your special needs.

Induction Annealing Machine Basics

What Is an Induction Annealing Machine

An induction annealing machine changes how metal acts. It heats metal parts without touching them. The machine uses electromagnetic fields to make heat. Annealing makes metal softer and easier to shape. Induction uses electric currents to heat metal. You can heat only certain spots on a part. This helps with tricky shapes or when you need exact results. Induction annealing is good for making lots of parts fast. It treats many pieces quickly and with accuracy.

When you use induction annealing machines, you can:

Make metal softer so it shapes easier

Remove stress inside the metal

Help metal bend without breaking

Make metal easier to work with

You also change how hard and tough the metal is. The heat spreads evenly across the part. You can control the heating very well.

Key Features and Applications

Induction annealing machines have special features. Here are some main features in the table below:

You see induction annealing machines in many industries. They are used in cars, planes, electronics, and medical devices. These machines treat parts of many shapes and sizes. They give fast, clean, and repeatable results.

Canroon has many induction annealing machines to choose from. You can pick models for small parts or big production lines. Canroon makes machines with smart controls and safety features. You get machines that work well and save energy.

Tip: When picking an induction annealing machine, look at the power supply and setup choices. Make sure the machine matches what you need for your work.

How Induction Annealing Works

Induction Heating Principles

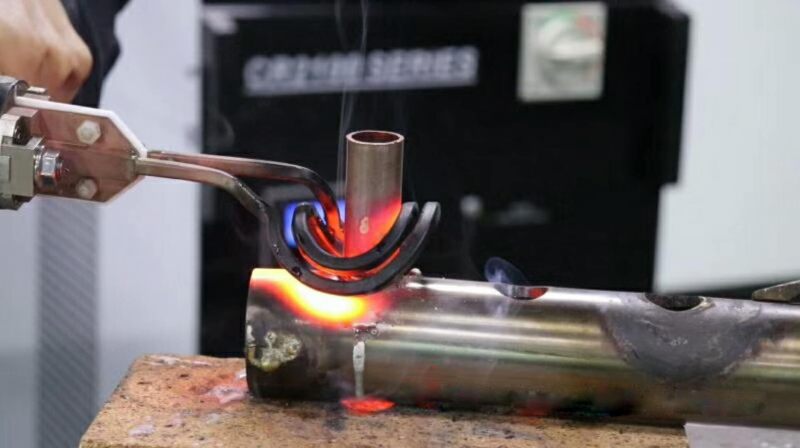

To understand induction annealing, you first need to know how induction heating works. When you put a metal part inside an induction coil, the coil uses AC to make a changing magnetic field. This field goes through the metal and makes electric currents called eddy currents inside the metal. The metal resists these currents, and this makes heat inside the part.

An induction coil makes a changing magnetic field with AC.

This field causes eddy currents in the metal you want to heat.

The metal’s resistance to these currents makes it get hot.

Induction heating is a way to heat metal without touching it. It uses electromagnetic fields to heat things that conduct electricity. When AC goes through a coil, it makes a magnetic field. This field makes eddy currents in the metal part. The eddy currents heat up the metal because of its resistance.

Three main electromagnetic ideas help explain this process:

Faraday's Law of Induction: A changing magnetic field can make an electric current in a conductor.

Eddy Current Loss: Eddy currents move inside the metal and make heat.

Hysteresis Loss: Some energy is lost because the metal’s magnetization is slower than the magnetic field.

This method lets you heat metal parts fast and only in the spots you pick. You do not have to touch the metal, so it stays clean and safe.

The Annealing Process

Induction annealing uses this heating method to change how metals act. When you heat a metal to a certain temperature and let it cool, you change its structure. This makes the metal softer and easier to shape. You can also use induction annealing to soften the necks of cases, which is important for making ammunition or other things that need flexible metal.

During annealing, atoms in the metal move around in the crystal lattice. This movement lowers the number of dislocations, which are tiny flaws in the metal’s structure. Because of this, the metal gets more ductile and less hard. When the metal cools, new crystals form, which makes the metal even better.

Annealing helps atoms move in the crystal lattice.

Fewer dislocations mean the metal bends better and is less hard.

Cooling lets new crystals grow, so the metal is easier to work with.

The process removes stress inside the metal, so it does not crack or break as easily.

Different metals need different temperatures for annealing. Here is a table that shows some common temperature ranges:

When you use induction annealing, metals get softer, more flexible, and easier to machine. You also remove stress from earlier steps, so the finished product is stronger and lasts longer. This process works for many shapes and sizes, and you can control the heat very well.

Tip: Induction annealing is a fast, clean, and energy-saving way to make metal parts better. You can use it for making car parts or softening the necks of cases for ammunition.

Induction Annealing Machine Components

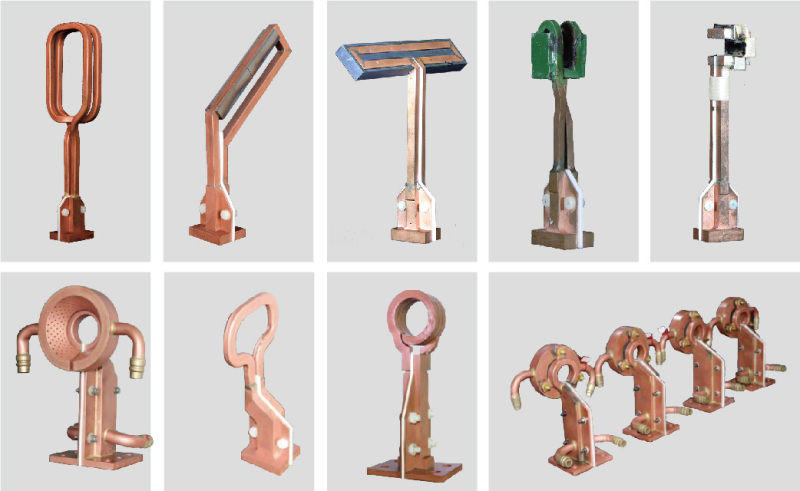

Induction Coil and Magnetic Field

Induction annealing machines have many parts that work together. The induction coil is the most important part. This coil makes a strong magnetic field when electricity goes through it. The coil’s shape and size are very important. If you pick the right coil, the metal heats up evenly. The coil’s design helps the machine heat metal better. The coil should be close to the metal part but not touch it. This way, you only heat the spots you want.

Here are some main parts and what they do:

Some machines have moving air claws and spinning lifting parts. These help you move metal parts safely and easily.

Control System and Safety

The control system lets you run the whole machine. You can set how hot it gets and how long it heats. You can also watch the process as it happens. New technology lets you make the machine do things by itself. This gives you the same good results every time. Some machines use PLC controls and IoT to watch the heating steps. These tools help you keep your work going without problems.

Safety is very important with these machines. You need systems that keep people and machines safe. Many machines shut down if they get too hot. They have ground fault protection and emergency stop buttons. Smart power controls stop the machine from getting too hot. You can check the safety from far away with remote monitoring. Canroon’s machines have safe designs and windows so you can see inside.

Tip: Always get training before using induction annealing machines. Set up and care for your machine the right way to keep it safe and working well.

Benefits of Induction Heat Treating

Precision and Efficiency

Induction heat treating lets you control heating very well. You can pick where inside the metal to heat. You also choose how wide and long the heated spot is. This means you only heat the part you need. Torch heating can be uneven and takes longer for heat to spread. Induction heat treating does not need extra soaking time.

Induction heat treating works quickly. It saves energy by heating metal right away. Less power is wasted. Induction heat treating can be up to 90% efficient. You spend less money on electricity and running costs. The product quality gets better too. Stress-relieved wire carries electricity better, which helps in aerospace and medical jobs. Springs and parts last longer because they do not get tired as fast. You get a smoother surface with fewer mistakes.

You control where and how hot you heat.

You save energy and money.

Your products last longer and work better.

Tip: Induction heat treating gives you the same good results every time. You can make more parts faster.

Comparison to Traditional Methods

Induction heat treating is better than older ways. Old furnaces waste more energy. They heat the whole room, not just the metal. Heat escapes into the air. Induction heat treating heats only the metal, so you use less energy and finish faster.

Here is a table that shows the main differences:

Induction heat treating machines need less fixing. There are fewer moving parts. You get your money back faster because you save energy and repairs. Companies see up to 20% better efficiency when making wire. Car makers use induction heat treating to stop engine parts from bending or breaking.

Canroon gives special benefits with its induction heat treating machines. You use energy better and control the temperature exactly. The machines work for many shapes and materials. You can change the process to fit your needs. Canroon’s machines make metals stronger and better for important jobs. You get more work done and better results. Heating without touching keeps parts clean and safe.

Note: Induction heat treating helps you save energy, make better products, and work faster. Canroon’s machines give you more control and better results.

You can use induction annealing machines to heat and soften metals without touching them. These machines make metal parts better for many jobs, like in cars. Here is how they help:

Induction annealing is also good for the environment.

You use less energy because heating is fast and exact.

You make less waste and can use more materials again.

You help your company reach green goals.

Canroon gives you machines that save energy and work well for many jobs. You get better metal parts and help the earth too.

FAQ

What metals can you anneal with an induction annealing machine?

You can use induction annealing on many metals. Some examples are steel, copper, brass, and aluminum. Induction annealing works best with metals that carry electricity well.

How do you control the temperature during induction annealing?

You pick the temperature with the control system. Sensors check the heat all the time. You can change the settings for each job.

Is induction annealing safe to use?

Induction annealing is safe if you follow the rules. Machines have emergency stop buttons and safety covers. Always wear safety gear and get training before you use the machine.

Can you use induction annealing for small parts?

Yes, you can use induction annealing for big or small parts. You pick the right coil and settings for your part’s size.

Previous:

Next:

Sign up for updates