Project Overview

In a major long-distance oil and gas pipeline construction project in Dubai, precise post-weld heat treatment (PWHT) was required for field-assembled pipeline girth welds. PWHT is a critical process for eliminating welding residual stress, improving the microstructure of the weld seam and heat-affected zone, preventing delayed cracking, and enhancing pipeline service safety. Traditional heat treatment methods, such as ceramic resistance heating blankets, presented challenges including low heating efficiency, difficulty in controlling temperature uniformity, high energy consumption, and complex on-site cabling. To ensure the long-term operational safety of this energy artery, the project contractor, after rigorous technical evaluation, selected the CR2000 series Induction Heating System manufactured by Shenzhen Canroon Electric Co., Ltd. as the core equipment for the PWHT operations.

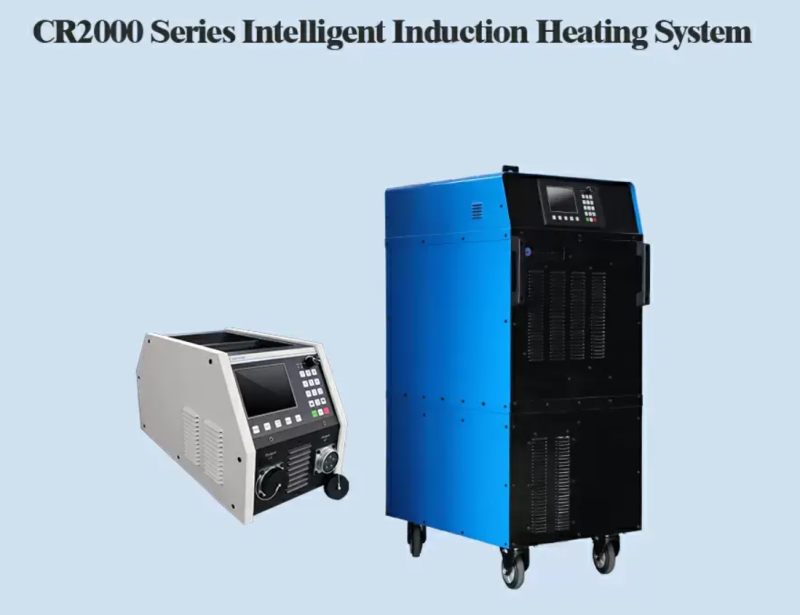

Introduction to the Canroon CR2000 System

The Canroon CR2000 is a modern heat treatment device designed based on advanced IGBT inverter technology and the electromagnetic induction principle. The CR2000 series induction heating system is powerful, delivers excellent performance, and is suitable for various specialized applications, including preheating for automatic girth welding, preheating for interface anti-corrosion coating application, PWHT for jacket components and flange connections, preheating for welding on offshore platforms, and rotor hot disassembly/assembly.

Core Advantages Demonstrated in This Project

Reliable Operation with Monitoring, Protection & Air-Cooling: The system features a highly efficient built-in air-cooling system. This ensures that power components (IGBTs) do not derate or shut down due to overheating during prolonged, high-power continuous operation (i.e., 100% duty cycle). This is crucial for pipeline heat treatment requiring several hours of continuous soaking, guaranteeing process stability and reliability.

High Efficiency & Energy Savings: Electromagnetic induction heating rapidly and uniformly generates eddy currents within the pipe metal for heating, achieving very high thermal efficiency (over 80%). Compared to resistance heating methods, it saves approximately 30%-40% in energy consumption. This not only reduces operational costs but also lessens the demand on site generator capacity.

Precise Temperature Control: The system is equipped with high-precision thermocouples and an intelligent temperature control module, enabling closed-loop, precise control of the heating zone. By arranging induction coils in multiple zones, it precisely manages the temperature gradient around the pipe circumference and through the wall thickness at the girth weld. This ensures strict adherence to the specified heat treatment temperature curve, effectively mitigating the risks of overheating or insufficient heating.

Ease of Operation & Enhanced Safety: The system's high level of integration simplifies on-site setup – typically requiring only the wrapping of the induction cable and connection of thermocouples to begin work. Furthermore, induction heating is "non-contact"; the pipe itself becomes electrified, eliminating electric leakage risks. The ambient temperature remains low, significantly improving worksite safety. The modular design of the unit also facilitates easy maintenance.

Application Implementation Process

Preparation: After welding the pipeline girth weld and completing non-destructive testing, the heating area on both sides of the weld is cleaned.

System Installation: The flexible electromagnetic induction cable is evenly and tightly wrapped around the specified width of the pipe on both sides of the weld. Thermocouples are installed at key locations – at the weld center and within the heat-affected zones – for real-time temperature monitoring and control.

Process Setup: Based on the steel material grade and pipe wall thickness, the PWHT procedure curve – including heating rate, target temperature (e.g., ±10°C), holding time, and cooling rate – is programmed into the CR2000's control panel.

Execution Process with the CR2000 System

Heating Stage: The CR2000 unit is started, delivering stable power output. The pipe heats up rapidly and uniformly due to induced eddy currents, with the heating rate precisely controlled.

Holding Stage: Upon reaching the target temperature, the system automatically adjusts power output to maintain the temperature within a very narrow range for the set duration (e.g., 2 hours), achieving precise temperature soaking.

Cooling Stage: Following the preset cooling rate, the system stops heating. Controlled slow cooling is then managed using installed insulation blankets until a safe temperature is reached.

Data Recording & Traceability: The complete temperature-time profile is automatically recorded and stored throughout the PWHT process, generating comprehensive data reports for quality traceability and audit purposes.

Application Results and Value Delivered

Enhanced Quality: Post-PWHT welds exhibited more uniform hardness distribution and effective elimination of residual stress, significantly reducing susceptibility to hydrogen-induced cracking. This improves the overall quality and service life of the pipeline.

Doubled Efficiency: Compared to traditional methods, the CR2000 system reduced heating time by nearly 50%. Its quick and easy setup and dismantling significantly accelerated the construction schedule.

Cost Savings: The high efficiency and energy-saving characteristics directly lowered electricity costs. Simultaneously, the equipment's reliability and durability reduced maintenance expenses and downtime.

Safety & Environmental Benefits: The absence of open flames and high-temperature cables on-site improved the workers' operational environment, aligning with modern engineering standards for Health, Safety, and Environmental (HSE) requirements.

Sign up for updates