If you want the best results for most factories, Canroon says to use a pwm inverter drive. You should think about some important things before you choose. The table below shows what you need to look at:

This blog helps you choose the right inverter for your special job.

Key Takeaways

PWM inverter drives work very well. They save energy and lower costs in factories. These drives let you control motor speed and torque easily. This helps machines work better in many places. Think about what your project needs before you pick an inverter. Look at things like power rating and where it will be used. Cleaning and checking connections often can make PWM inverter drives last longer. If you use sensitive electronics, pure sine wave inverters are best. They give clean power and help stop damage.

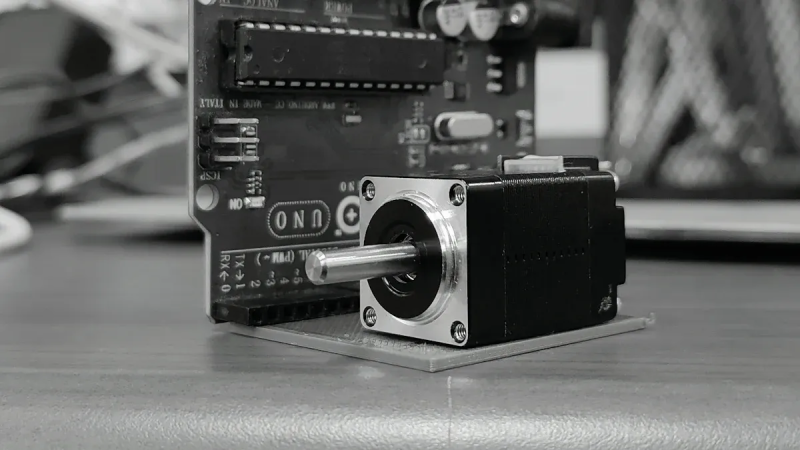

pwm inverter drive basics

PWM technology overview

A pwm inverter drive helps you change how fast and strong an ac motor works. It uses pulse width modulation to turn dc power into ac power. The drive sends quick on and off signals to the motor. These signals make the power look smooth, almost like a sine wave. This gives you better control and saves more energy than old inverter types.

Here is a table that shows how pwm inverter drive technology compares to traditional inverter technologies:

You can see pwm inverter drives work better and fit more motors. They also give cleaner ac power, which helps your machines last longer.

Main features and benefits

A pwm inverter drive has many good points for your needs:

High efficiency helps you use less energy and pay less money.

You can use it in many places like factories, HVAC, and pumps.

The drive keeps your motors safe from too much load, lost phase, or low voltage.

You can control motor speed and torque very well, so your work gets better.

The drive works with both dc and ac power, so you have more choices.

More companies pick pwm inverter drives because they want to save energy and get better results. Canroon’s products use advanced pulse-width modulation to help your motors work their best. You can count on these drives to work well even in hard places. If you need to control ac motors with good results, a pwm inverter drive is a smart pick.

Inverter types overview

Square wave inverters

A square wave inverter has a very simple design. It switches quickly between positive and negative voltage. There is no smooth change in the power. This inverter is cheap and easy to use. You can use it for simple tools and basic devices. It does not make clean power. Square wave inverters create a lot of harmonic distortion. Sensitive electronics may not work right with this inverter. Do not use square wave inverters for computers or medical machines.

Modified sine wave inverters

A modified sine wave inverter makes a stepped wave shape. It works better than a square wave inverter. Many solar inverters for homes use this type. You can run most home appliances with it. Some things, like laser printers or audio gear, may still have trouble. This inverter costs more than a square wave inverter. It costs less than a pure sine wave inverter. You get more efficiency and flexibility for your money.

Tip: If you want to use sensitive electronics, pick a pure sine wave inverter. This type gives you the cleanest power and keeps your devices safe.

MPPT and FD inverters

You will find mppt inverters in many solar systems. An mppt inverter finds the best power point for your solar panels. It changes voltage and current to get the most energy. This gives you better efficiency. MPPT helps you save money and use solar power well. FD inverters use smart control to match the load and power source. You can use mppt and FD inverters for solar pumps and water heaters. They also work for other renewable energy systems. These inverters cost more than square wave or modified sine wave inverters. You get higher efficiency and better performance for your money.

Here is a table to help you compare the main inverter types:

Think about what you need before you pick an inverter. If you want the best for solar, mppt gives you the most energy. MPPT helps your solar panels give the highest output. If you need something basic, a square wave inverter may be enough. For most homes and businesses, a modified sine wave inverter is a good choice.

Efficiency comparison

PWM inverter drive efficiency

A PWM inverter drive gives your system high efficiency. It uses pulse width modulation to control power. This helps you save energy and makes things work better. At full load, the efficiency can reach about 97.1%. Some models can even go up to 97.7%. These numbers mean PWM inverter drives are great for saving energy in factories.

You will see your motor control work better. The inverter keeps energy loss low. You get steady performance even if the load changes. It works well in dim light and tough places. You can trust the power it gives. The inverter protects your machines from problems like overheating or wasted energy.

You use less energy every day.

Your system stays efficient.

You get steady work in dim light.

The inverter keeps energy quality good.

Other inverter types efficiency

Other inverter types have different efficiency levels. Square wave inverters are not very efficient. They waste more energy because the power is not smooth. Modified sine wave inverters work better than square wave types. But they still have some problems with energy quality. These inverters are okay for simple systems, but not the best for saving energy.

MPPT inverters help you get high efficiency with solar power. They change the output to fit the energy source. You get good results even in dim light. FD inverters also make systems more efficient by matching the load and power. These types cost more, but you save more energy and get better results.

You should think about how efficient the system is before picking an inverter. Look at the problems and the quality you want. You get the best results when you choose the right inverter for your needs.

cost analysis

Initial and operating costs

When you pick an inverter, think about two costs. First, you pay to buy and set up the inverter. This is called the initial cost. Next, you pay for things like energy, fixing, and new parts. These are operating costs. PWM inverter drives usually cost less at first than pure sine wave inverters. They also use less energy, so you save money later. Your power bills and repair costs go down.

Some inverters, like modified sine wave types, are cheaper to buy. You might think this saves you money. But these inverters can hurt sensitive devices. You may need to get new appliances more often. This makes your operating costs go up. Pure sine wave inverters cost more at the start. But they work well with most devices. You get good power and fewer problems. Over time, you spend less on fixing and replacing things.

Note: To save money for many years, look at both the price to buy and the cost to keep your inverter working.

Cost differences by inverter type

You can look at inverter types by checking their costs and how they fit your budget. Here is a table that shows the main differences:

Pure sine wave inverters cost more at first, but you save money later because they work well and protect your devices.

Modified sine wave inverters seem cheap, but you might pay more if your things break.

PWM inverter drives are a good choice. You pay a fair price and save on energy and repairs.

Square wave inverters are the cheapest, but they waste energy and can cause trouble for your tools.

Pick an inverter that fits your needs and helps you save money over time. This is a smart way to spend your money.

Control and Flexibility

PWM inverter drive control features

PWM inverter drives give you many smart control features. You can change how fast or strong the motor works. You can set different controls for each job. This helps you get better results. The drive uses smart ways to control the motor.

PWM inverter drives can use machine learning. The drive learns from your system and changes how it works right away. Soft-switching helps the drive waste less energy. This means your system does not get as hot. You can pick how fast the drive switches. The drive can switch much faster than old systems. This gives you better control and saves energy, even in hard places.

Here is a table that shows some advanced control features in PWM inverter drives:

These features help your motors work better and last longer. You save money because your system uses less power.

Control options for other inverters

Other inverters only give you simple control. Square wave inverters just turn things on or off. You cannot change speed or strength much. Modified sine wave inverters let you do a little more. But you cannot set special controls for hard jobs. You might have trouble with sensitive devices.

MPPT inverters help you control solar systems better. You can change voltage and current to match the sun. FD inverters use smart control to match power and load. But they do not give you real-time control like PWM inverter drives. You may need extra tools to get more control.

Think about what kind of control you need before you choose. If you want the most control and options, PWM inverter drives are best. They give you more features and better results for your system.

Reliability and Maintenance

Reliability of PWM inverter drives

You want your machines to work well every day. PWM inverter drives give strong and steady results. They work in many places, but you need to watch for problems. High switching speeds can make extra heat. If you do not check the drive, it might get too hot. This can make the drive burn out or not last as long. Dust, wet air, and power surges can also hurt the drive over time.

You can make your PWM inverter drive last longer by doing smart maintenance. Canroon suggests these steps:

Install an input line reactor. This helps stop big power surges and keeps your drive safe from sudden voltage jumps.

Add shaft grounding rings. These rings move bad voltages away from the motor shaft. This helps your motor last longer.

Use an output filter for long cables. If your motor cables are longer than 100 feet, an output filter lowers voltage stress and keeps your motor safe.

Tip: Check your drive and motor often. Clean away dust and wetness. Make sure all wires and parts are tight and safe.

Reliability of other inverter types

Other inverter types last for different amounts of time. Microinverters last the longest, about 20 to 25 years. String inverters work for about 8 to 12 years. Central inverters have the shortest life, about 5 to 10 years. PWM inverter drives are like string inverters. They may last less time if you do not take care of them.

You can help your inverter last longer by keeping it clean. Check for loose wires and follow the right steps for your type. Canroon’s solutions help you get the most from your drive and avoid big repair costs.

application suitability

Best uses for pwm inverter drive

You can use a pwm inverter drive in lots of industries. It gives you good efficiency and strong control. You can change motor speeds and keep power steady. Factories, electric cars, and off-grid systems use pwm inverter drives. They work well when you need to control induction motors or keep the V/f ratio the same.

Here is a table that shows where pwm inverter drives work best and what you get:

You get almost perfect output quality. You can use pwm inverter drives with sensitive things. They work well in off-grid systems and electric cars. You get strong results even in hard places.

Tip: Use pwm inverter drives if you want high efficiency, strong control, and clean power for your needs.

When to choose other inverter types

Sometimes, you need other inverter types for your job. You can pick square wave, modified sine wave, or pure sine wave inverters if you want to save money. These work for most home appliances. Some loads work better than with square wave inverters. You get less harmonic distortion, so your electronics stay safe. You can use these inverters in many places.

You save money for simple jobs.

You can run basic things with square wave inverters.

You get okay output with modified sine wave inverters.

Use pure sine wave inverters for sensitive electronics and medical tools.

Here is a table that shows how different inverter types fit your needs:

You should look at your job and pick the inverter that fits. You get the best results when you match the inverter to your devices and budget.

Note: PWM inverter drives can make extra heat and switching losses. You might see electromagnetic interference in some jobs. You should fix problems if you see harmonics or noise.

PWM inverter drives can make power devices wear out faster because of high switching losses.

You might see torque jumps, noise, voltage spikes, and current ripples in sensitive loads.

The way pwm inverter drives work can change motor flux waveforms and make harmonics.

solar pump inverters applications

You can use solar pump inverters for many jobs. They use sunlight to run water pumps. You need to check some things before you pick a solar pump inverter. Look at the pump’s needs, solar panel setup, water use, efficiency, and safety features.

Here is a table that shows what you need for solar pump inverters:

You can use solar pump inverters for watering crops, animals, and villages. You get steady water even far from cities. You save money and energy. Pick a solar pump inverter that matches your pump and solar panels. You get better results with high efficiency and strong safety.

Tip: Check your water needs and solar panels before you pick a solar pump inverter. You get the best results when you match the inverter to your job.

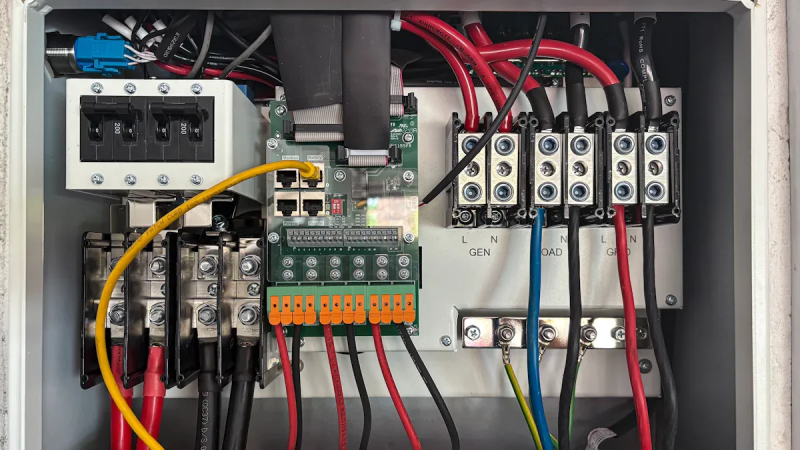

Choosing the right inverter

Key decision factors

You want to find the best inverter for your job. You should look at a few important things before you choose. Here is a list to help you pick the right one:

Power Rating and Voltage/Current Specifications

Make sure the inverter fits your machine’s power needs. Check if the voltage and current match your system.Switching Frequency

A higher switching frequency gives smoother power. But it can also make more heat. You need to balance smooth power and less heat.Control Features and Flexibility

Look for inverters with smart control options. Some let you change speed or torque. This helps you get better results.Protection Features

Pick an inverter with built-in safety. Good protection keeps your system safe from problems.Ease of Integration and Interface

Choose a model that connects easily to your setup. Simple controls save you time and effort.Cost

Compare what you get for the price. You want the best deal for your money.

Tip: Canroon says to check all these things before you buy. You get better results and save money when you match the inverter to your needs.

You also need to think about your workplace. Here are some things that can change how your inverter works:

Big temperature changes can make your system too hot or weak.

High humidity can cause rust and electric trouble.

Dust can block air and make your inverter overheat.

High places lower cooling power.

Chemicals can hurt parts and make them wear out faster.

Pick an inverter that can handle your work area. This helps you stop breakdowns and keeps your machines working.

Practical scenarios

You can see how these choices matter in real life. Here are some common jobs and what you should do:

You can make mistakes if you skip important steps. Here are some things to watch out for:

Picking the wrong battery type can cost you more.

Not checking battery size can make your system weak.

Ignoring compatibility can cause overheating.

Only looking at price can mean poor quality.

Forgetting about warranty and support can cause trouble later.

Note: Canroon says to always check compatibility, protection, and support before you buy. You get better results and fewer problems.

You can use these tips to pick the right inverter for your job. You get strong performance, long life, and good value if you follow Canroon’s advice.

PWM inverter drives help you save energy. They make less heat. You can control voltage and current very well.

Energy efficiency

Less heat

Good voltage and current control

Sometimes, these drives do not work well in low light or with high voltage.

Canroon says PWM inverter drives are great for homes and factories. You should pick the inverter that fits your needs. Ask Canroon if you want help choosing.

FAQ

What makes PWM inverter drives better for factories?

PWM inverter drives help factories save energy. They give strong control over machines. These drives keep things running well. You can use them in many systems. This helps you use energy in the best way.

Can I use PWM inverter drives in solar energy systems?

Yes, you can use PWM inverter drives with solar power. They help you change how fast motors run. You get steady power for pumps and other things. This helps you use more energy from the sun.

How do I choose the right inverter for my solar power systems?

Check your system’s power rating and voltage first. Make sure the inverter fits your control needs. Look for good safety features and easy setup. This helps your solar system work its best.

What maintenance does a PWM inverter drive need?

You should clean off dust and check wires often. Watch for too much heat in the drive. Use filters and grounding rings to stay safe. Regular checks help your drive last longer.

Are PWM inverter drives safe for sensitive electronics?

PWM inverter drives work well with sensitive electronics. They give clean power and lower harmonics. This keeps your devices safe and helps them work better.

Sign up for updates