Industrial factories all over the world use top VFD controllers. These come from trusted brands like Canroon, Siemens, ABB, and Yaskawa. Factories need these to handle tough jobs. Companies that buy VFD online get upgrades fast. They also get new variable frequency drive technology. More than 3.8 million VFDs help factories work better worldwide. They save up to 35% on energy costs. VFDs also make motors work better. Good suppliers help factories improve quickly. This helps them work better and have less downtime.

Key Takeaways

VFD controllers help save energy and make motors work better. They can lower energy bills by up to 35%.

Pick VFDs that fit your motor size and torque needs. Make sure they are right for your work area. This keeps things safe and efficient.

Buy VFDs from trusted online stores or brand websites. You can get expert advice, good prices, and fast delivery.

Install VFDs the right way with good wiring, cooling, and grounding. This helps VFDs and motors last longer and stops breakdowns.

Clean VFDs, check wires, and watch how they work often. This keeps VFDs working well and saves money over time.

Best VFD Controllers

Leading Brands

Factories need reliable vfd controllers from top brands. These companies are known for new ideas and many products. They also have a strong presence around the world. The brands below are known for good performance and helping save energy:

Siemens AG (Germany): The Sinamics G120 Plus series is flexible. It helps with smart manufacturing and Industry 4.0.

Rockwell Automation Inc. (U.S.): The PowerFlex 7000 series works for low and medium voltage. It helps with water management.

WEG (Brazil): The CFW500 series is reliable and saves energy. It is used in big mining projects.

Yaskawa Electric Corporation (Japan): The GA700 series has advanced safety and automation. It is popular in factory automation.

General Electric (U.S.): GE makes vfd controllers for many motors and industries.

ABB (Sweden): ABB spends money on research. The ACH580 series is marine-licensed and controls torque and speed well.

Danfoss (Denmark): Danfoss focuses on HVAC and marine. It uses AI for motor control and has many approvals.

Mitsubishi Electric (Japan): The FREQROL inverter series helps the car and water treatment industries.

Crompton Greaves Limited (India): This company makes vfd controllers for power and automation.

Parker Hannifin: Parker offers IoT-enabled vfd controllers with smart maintenance.

These brands help factories save energy and reach sustainability goals.

Top Models

Choosing the best vfd controllers depends on what you need. Some models are very popular because they are reliable and have great features:

Yaskawa V1000/A1000: These are small, work well, and are easy to use. They control motors well and fit many uses.

ABB ACH580 Series: This series is for HVAC and smart buildings. It has Bluetooth and built-in switches. ABB makes sure it works with new automation.

Rockwell PowerFlex 7000: This model works for low and medium voltage. It is good for tough jobs. It saves energy and protects well.

WEG CFW500: This model is known for being reliable and saving energy. It is used in mining and heavy industry.

Siemens Sinamics G120 Plus: This model is flexible and works with Industry 4.0. It is good for smart factories.

Danfoss VLT Series: This series has smart motor control and many approvals. It is great for HVAC and marine jobs.

Mitsubishi FREQROL: This series is strong and lasts long. It is used in cars and water treatment.

Tip: These vfd controllers save energy and help control processes. But, you should think about the first cost and how hard they are to install. Some need special motors and extra cooling.

Key Features

The best vfd controllers have important features for safe and efficient work:

Motor compatibility and overload protection keep things safe. Features like PID control and multi-speed programming make the vfd controller more flexible.

Real-time monitoring shows voltage, current, and frequency. This helps workers find problems fast.

Important protection includes overcurrent, undervoltage, and short-circuit safety. Surge protectors and breakers stop failures and keep things stable.

The best vfd controllers save energy by changing motor speed to match the job. This can cut electricity use by up to 50%. It lowers costs and helps the environment.

Vfd controllers also lower stress on motors. This helps machines last longer and reduces downtime. These benefits make them very important in modern factories.

Variable Frequency Drives Selection

Factory Needs

Each factory has its own needs when picking a variable frequency drive. First, workers must know what kind of motor they have. Some motors need a certain vfd controller to work well. Factories also look at how much work the machines do. Heavy machines need a vfd controller for constant torque. Lighter machines can use one for variable torque.

The place where the vfd controller is used is important. Hot or wet places can change how a variable frequency drive works. Factories inside with dry air use IP20 or IP21 enclosures. Factories outside or in dusty places use IP55 or IP66 enclosures. These keep out water and dust. High heat can make parts too hot and break them. Cold can make the drive work less well. Wet air can cause water drops, rust, or short circuits. Picking the right box and putting the vfd controller in a cool, dry spot helps it last longer.

Note: If factories ignore the place where the vfd controller is used, it can break more often and cost more to fix. Factories should always pick a vfd controller that fits their needs.

Application Match

It is very important to pick the right variable frequency drive for each job. Factories must look at how the machines work. Some jobs, like moving belts, need constant torque. Others, like fans and pumps, need variable torque. The vfd controller must match the motor’s voltage, current, and power.

A table can help show which vfd controller fits each job:

Factories must also think about where they put the vfd controller. Dust, water, and hot or cold air need special boxes and cooling. Good setup uses shielded wires, grounding, and easy ways to fix things. Long wires need reactors to keep the vfd controller and motor safe.

Tip: Ask vfd controller experts for help to pick the best variable frequency drive for your factory. This helps machines work well and last a long time.

Buy VFD Online

Trusted Platforms

Factories want safe places to buy VFD online. Official brand websites, like Canroon’s, are better than other sellers. You can talk to experts and see more products. Factories can ask for special solutions for their needs. Prices are lower because there are no extra seller fees. The company controls sales, so quality and shipping are better.

Ask for special features if needed

Pay less because there are no extra fees

See more types of products

Big online sellers like Grainger, RS Components, and AutomationDirect are also safe. They ship fast and let you compare products easily. Their customer service is strong. Factories should look at both price and value before picking a seller.

Secure Purchasing

Buying online should be safe for both the buyer and the factory. Good websites use secure servers and SSL to keep data safe. They follow payment rules and do not keep your payment info long. Only trusted workers can see private data. Using well-known websites and payment companies makes things safer.

Use safe servers with SSL

Make sure payment rules are followed

Pick trusted payment companies

Teach workers about online dangers

Use antivirus and security tools

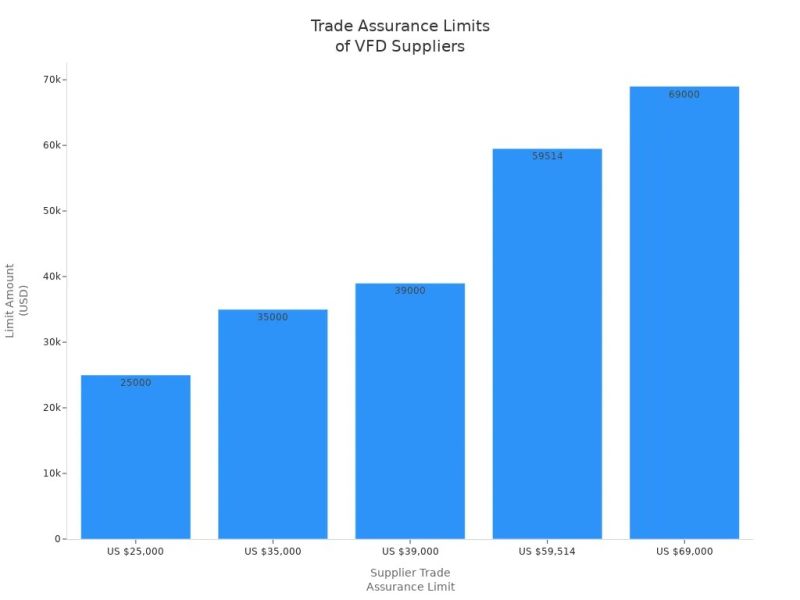

Warranties and delivery rules are different for each seller. The table below shows how trade protection, warranty time, and delivery promises can change:

Factories should always read warranty and delivery rules before buying VFD online. This helps them get good value and avoid problems.

Motor Efficiency & Power Boost

Installation Tips

Putting in VFDs the right way helps motors work better. It also makes factories stronger. Technicians must pick a VFD that fits the motor’s size and voltage. They should also match it to what the motor does. This helps the system use less energy. The VFD should go in a clean spot with good air flow. This stops it from getting too hot or dusty. Using shielded wires and good grounding keeps away electrical noise. It also stops interference. Changing how fast the motor starts and stops lowers stress on it.

Here are steps to follow:

Pick a VFD that fits the motor and where it will be used.

Put it in a cool, dry place that is not sunny.

Use shielded wires and ground them well.

Set the VFD for the job it will do.

Teach workers how to use and fix the VFD.

Note: If you make mistakes like loose wires or skip the manual, the VFD may not work right. It can also break faster. Only trained technicians should install VFDs and follow the instructions.

The table below shows how VFDs help motors and factories:

Maintenance

Checking VFDs often keeps them working well for a long time. It also helps factories save energy. Every day, listen for strange sounds and check heat and voltage. Each month, clean or change filters and look for dust or rust. Once a year, do a deep clean, tighten wires, and check cooling parts.

Clean fans and heat sinks so things do not get too hot.

Change capacitors every seven years. Change fans every three to five years.

Write down all checks and watch for error codes.

VFDs break less often than old motor controllers. They have solid parts and tools to spot problems early. This means less fixing and lower costs. VFDs help factories use less energy and keep machines working longer. Regular checks help motors and VFDs work their best. This helps factories make more and protect the environment.

Factories that pick top VFD controllers from brands like Canroon, Siemens, and ABB get better power and efficiency. VFDs help control speed exactly. They save energy and make machines last longer. Buying VFDs online from trusted sellers is fast. You get new features and expert help quickly.

VFDs help make products better and cut down on waste.

Soft start and stop features keep machines safe. They also lower the cost to fix things.

VFDs work with automation systems. This lets workers watch machines from far away.

Factories can work better and help the environment by picking the right VFD now.

FAQ

What is a VFD and why do factories use it?

A VFD changes how fast electric motors run. Factories use VFDs to save energy. They help motors last longer. VFDs let machines work at different speeds. This makes factories work better.

How can a factory choose the right VFD online?

Factories should look at motor size and voltage. They need to match the VFD to the job. Good online sellers give guides and expert help.

Tip: Always check the product details before you buy.

Are VFDs hard to install?

Trained workers can put in VFDs by using the manual. Good wiring and grounding are important. Most brands give easy steps and support.

What maintenance do VFDs need?

VFDs need checks for dust, heat, and loose wires. Cleaning fans and changing filters stops problems. Keeping notes on checks helps VFDs last longer.

Do VFDs come with a warranty when bought online?

Most trusted sellers give warranties for 12 to 18 months. Factories should read the warranty rules before buying. Some sellers also give trade assurance for extra safety.

Previous:

Next:

Sign up for updates