You can find vfd drives in many factories today. These variable frequency drive systems help save energy. They also help control machines better and make equipment last longer. With vfd, you can set motor speed to what you need. This helps stop waste and saves money. Look at the table below to see how fast more companies use vfd:

Canroon’s vfd solutions are very flexible for many uses. You get good automation, flexibility, and better efficiency with each drive.

Key Takeaways

VFD drives help save energy. They change motor speed to fit what is needed. This lowers costs and stops waste.

They make machines easier to control. They also protect equipment. Motors last longer and work better.

VFDs help many industries. These include HVAC, pumping, manufacturing, mining, and renewable energy. They help things run safer and smoother.

Using VFD drives helps with automation. It makes processes better. This improves product quality and cuts downtime.

Putting in and taking care of VFD systems is easy. They give long-term benefits for efficiency and reliability.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems play a big role in many buildings. You can use vfd drives to control these systems and improve energy efficiency. When you use a variable frequency drive, you can change the speed of the motor to match the needs of your building. This helps you save energy and lower costs.

Fans

Fans move air through your building. If you use an ac drive, you can adjust the fan speed based on how much air you need. This means the motor does not run at full speed all the time. You get less noise, less wear on equipment, and reduced power consumption. Many commercial buildings now use vfd to control fans. For example, Canroon’s drives help offices and malls keep air fresh while saving energy.

Pumps

Pumps move water or other fluids in HVAC systems. With an ac drive, you can set the pump speed to match demand. This keeps the system running smoothly and avoids wasting energy. You also protect your equipment from damage. Canroon’s adjustable speed drive solutions help hotels and hospitals lower energy consumption and extend the life of their pumps.

Compressors

Compressors help control temperature by moving refrigerant. Using a vfd, you can control the motor speed and match the cooling load. This makes the system more efficient and cuts down on energy use. You also get better process control and less stress on your equipment. Many HVAC applications now use Canroon’s drive technology to improve performance and reliability.

Tip: Using vfd in your HVAC systems can lower your energy bills and make your equipment last longer.

Pumping Systems

VFD drives have made pumping systems easier to use. You can change pump speed to fit what you need. This helps save energy and lowers power use. Many places use vfd for irrigation and water work because it helps a lot.

Irrigation

VFD can help irrigation systems by changing pump speed when water is needed. You only use energy when you need water. This stops over-pumping and keeps equipment safe. VFD gives better control of water flow and pressure. You save water and pay less for energy. Many farms use ac drive to keep crops healthy and spend less money.

Here are ways vfd helps irrigation:

You can set motor speed for water needs.

The drive keeps pressure steady when things change.

Soft start and stop features protect pumps and pipes.

You can use vfd with solar panels for off-grid water.

The system lasts longer and needs less fixing.

Canroon has drive solutions that help your irrigation work better. You save energy and get better crops.

Water & Wastewater

Water and wastewater systems must work well and be efficient. VFD lets you change pump speed for the right flow. This saves energy and stops waste. You also use less power and pay less to run things.

Note: The Grant PUD Industrial Motors & Drives program says vfd can save up to 20% energy each year in pumping systems.

Here is a table that shows energy savings:

Canroon’s vfd drives help you reach energy goals and keep systems working well. You get good performance and save money for a long time.

Conveyor Applications

Manufacturing

Conveyor systems are found in most factories. They move products from one spot to another. When you use a vfd drive, you can control conveyor speed better. This means you can match the speed to what you need. You can start and stop the conveyor slowly. This helps protect your machines and keeps products safe.

Many food and drink factories use vfd drives to keep lines working. You can waste less during filling and packing. You also make sure products stay the same each time. Some vfd drive options, like VLT® FlexConcept®, are easy to set up and take care of. You can use these drives in dry, wet, or very clean places. Bottling lines and meat plants use vfd drives for conveyors and other machines. This saves energy and helps you control your process.

Here are ways vfd drives help in factories:

Keep conveyors running longer and lower costs.

Make clean areas safer with special solutions.

Change conveyor speed for different loads.

Make motors work together for smoother flow.

Tip: Changing conveyor speed with a vfd drive helps you meet new production needs fast.

Material Handling

Material handling needs conveyor systems that are flexible and strong. You can use a vfd drive to set conveyor speed. This lets you move things at the right speed. You can stop jams and keep things moving well. With a vfd, you can start and stop the conveyor gently. This keeps your machines safe and stops damage.

You can pick the speed for the size or weight of items. This makes your system work better. Many places use vfd drives for exact speed and motor control. You can move many kinds of products and fit your industry’s needs.

A vfd drive gives you:

Gentle start and stop to protect machines.

Exact speed control for better moving.

Flexibility for different jobs.

Note: Using vfd drives in material handling helps you move more items and have less downtime.

Mining & Quarrying

Mining and quarrying sites use big machines every day. You need strong tools to keep work safe and running well. VFD drives help control motors in tough places. These drives make energy use better and help machines last longer. They also make your equipment more reliable.

Here is a table that shows why vfd drives are important in mining:

Crushers

Crushers break rocks and minerals into smaller pieces. VFD drives help you change the speed and torque of crushers. This lets you use the right power for each rock size. You save energy and keep your machines safe from harm. Soft start features lower stress on motors. This helps machines last longer and work better.

VFDs let you change torque for hard or soft ore.

You get smoother work and less damage to parts.

The drive uses only the power needed, so you save money.

Fewer breakdowns mean more work gets done.

Tip: Using vfd in crushers helps you do hard jobs and keeps your machines safe and working well.

Conveyors

Conveyors move things across the site. You need steady speeds to keep work smooth. VFD drives give you exact speed control, even when loads change. This keeps things moving and stops spills. You also get less belt damage and need fewer repairs.

VFDs help you start and stop conveyors gently, which protects motors.

You can pick the best speed for each job, making machines more reliable.

Less stress means your equipment lasts longer.

Digital monitoring helps you find problems early and fix them fast.

VFD drives in mining and quarrying help make work safer and more reliable. You get better control, use less energy, and your machines last longer.

Cranes, Hoists & Elevators

Smooth Operation

You want cranes and hoists to work well every time. VFD drives help you control motors very accurately. You can move loads at slow or fast speeds. This makes it easier to put things in the right spot. It also helps stop loads from bouncing. Your equipment gets less worn out and works better. VFD lets you start and stop machines gently. This helps motor parts last longer. Ramp-to-stop braking lowers force on the crane and uses the brakes less. The drive protects against getting too hot or using too much power. This makes your system more reliable.

Here are ways VFD drives help smooth operation:

You can control loads exactly with many speed choices.

Soft starts and gentle stops lower shocks and bouncing.

You get smoother movement than old controls.

Less damage means your machines last longer.

Tip: VFD drives help your machines run smoother and more reliably, even with big or fragile loads.

Safety

Safety is very important when lifting heavy things. VFD drives give you better control and help stop accidents. You can set the system to stop if the load is too heavy. The drive sends quick warnings if something is wrong. This helps you fix problems before they get worse. VFD drives help you follow safety rules and keep your workplace safe.

You also get these safety benefits:

Controlled speed changes lower stress and stop load swinging.

Smoother work means less fixing and more uptime.

Anti-sway keeps loads from swinging and lowers risk.

Better brake control means safer stops and less brake wear.

Fault codes help you find problems early and fix them.

Note: VFD drives in cranes and hoists help you lift loads safely and keep your machines working well.

Paper & Pulp Industry

Process Control

VFD drives have changed how the paper and pulp industry works. These drives help you control motors very well. You can change motor speed and torque for each step. This helps make better products and saves energy. VFD lets you start and stop machines slowly. This keeps your equipment safe and helps it last longer. You also get live data from built-in monitors. This helps you find problems early and keep machines working.

Here are ways vfd drives help with process control:

You pick the right motor speed for every job.

You waste less and keep product quality the same.

Motors work together for printing and coating jobs.

Pulp and paper processing is smoother.

You use tools to plan repairs and stop breakdowns.

Tip: VFD drives help you run your paper mill with fewer problems and more control.

Energy Savings

You can save a lot of money on energy with vfd drives. These drives let you match motor speed to the job. This means you do not waste power. You see big changes in how much energy you use. For example, the Fiskeby Board mill in Sweden saved 80% energy on one pump. Other companies saved between 20% and 80% after using vfd drives.

Here are some real results:

Fiskeby Board mill saved 80% energy on one pump.

A Dutch water company saved 20% with vfd motor-drive solutions.

Farms in South Africa saved 40% on irrigation pumps.

You can expect to save energy in your own plant too. When you use vfd, you pay less for power and help the planet. Your equipment lasts longer and you spend less on repairs.

Note: VFD drives give you big energy savings and better efficiency in every part of your paper and pulp plant.

Wire & Cable Manufacturing

Speed Control

You must control motor speed to make good wire and cable. Vfd drives help you pick the right speed for each step. You can change the motor speed fast with vfd. This helps match the speed to each job, like drawing or winding wire. It stops problems like wire breaking or stretching. Vfd cables also cut down on noise and block interference. Your machines work better and last longer.

You set motor speed for drawing, coiling, or winding wire.

Vfd drives let you change speed for different wire sizes.

The system is reliable, so you have less downtime.

Vfd cables keep your equipment safe from harm.

Tip: Vfd drives help you control speed better, so you make more wire with fewer errors.

Production Quality

Making good wire depends on speed and tension control. Vfd drives give you exact motor speed control. This keeps wire thickness and shape the same. You can start and stop machines slowly with vfd. This stops the wire from snapping or getting uneven. New vfd systems let you watch your process from far away. You can spot problems early and fix them fast.

Here is a table that shows how vfd drives help your line:

Real companies have seen big changes with vfd upgrades. One plastics company used vfd drives for extruders and winders. The drives reused energy and made things safer. Another company put vfd on their annealing line. They had less waste and better products. Safety features like Safe Torque Off let you stop machines fast. This keeps your team safe and your line working.

Note: Vfd drives help you make better wire and cable by giving you exact speed control and strong safety features.

Textile Industry

Automation

Automation is changing how textile factories work every day. When you use variable frequency drives, you control motor speed better in spinning, weaving, dyeing, and finishing. This helps keep product quality high and lowers mistakes. Automation lets you change speed fast for each job. You can go from spinning yarn to weaving fabric without stopping the machines.

Here are some ways automation with VFD drives helps you:

You get exact speed control, so products stay the same.

You save energy by matching motor speed to your needs.

Machines run smoother, so there is less shaking and noise.

You can change speed quickly for new textile jobs.

You connect VFD drives to automation systems for better control.

Tip: Automation in textile plants helps you spend less and make more. VFD drives also help your machines last longer by lowering stress.

You see these benefits in spinning, weaving, dyeing, and cutting. For example, with automation in spinning, yarn stays the same thickness. In weaving, fabric quality stays high. In dyeing and finishing, colors are even and you save energy. Automation also means less downtime and fewer repairs.

Process Optimization

Process optimization means using your machines in the best way. VFD drives help by letting you set the right speed for each step. You can save up to 50% on energy bills by matching motor speed to the load. This helps you control costs and keep your business strong.

VFD drives give you exact speed and torque control. You do not run motors at full speed if you do not need to.

You get better product quality because speed stays steady. This means fewer mistakes and less waste.

Soft start and stop features protect your machines. You spend less on repairs and your equipment lasts longer.

You can connect VFD drives to automation systems like SCADA or PLCs. This lets you watch and change speed from one place.

Many mills have fewer motor problems and better production after adding VFD drives. You can handle different fabric types and sizes easily. With process optimization, you get more uptime and earn your money back faster.

Note: Process optimization with VFD drives helps you keep up with market changes. You can change speed and settings fast, so you stay ahead in textiles.

Food & Beverage

Mixing

VFD drives are used in many mixing jobs for food and drinks. These drives help you change how fast mixers, agitators, and homogenizers spin. You can pick the speed for thick or thin products. This helps make your food and drinks the same every time. VFD drives let you change speeds slowly and smoothly. This stops sudden starts or stops. Your machines do not get damaged as easily, and your food stays safe.

VFD drives also help you use less energy. You can run pumps and fans slower when you do not need full power. This means you pay less for electricity. You can connect VFD drives to control systems. This lets you watch and change mixing while it happens. Many VFDs have surfaces that are easy to clean and resist chemicals. They work well in wet places and tough conditions.

Here are ways VFD drives help with mixing:

You can set mixer speed for each recipe.

Slow starts and stops protect your machines and food.

You get live data to watch and improve mixing.

You can check machine health to fix problems early.

VFD drives work with smart tech to make mixing better.

Tip: VFD drives help you make good food and keep your machines working longer.

Packaging

You need to control machines well in packaging lines to keep food safe. VFD drives help you set the right speed and torque for conveyors and pumps. You can pick the best speed for each step. This keeps your food the same every time. Programmable drives let you match speed and torque to each job. This helps you waste less and make better food.

VFD drives also help you save energy when cleaning machines. You use less water and power. Smart tools help you find problems fast, so you do not stop work for long. Safety features like Safe Torque Off keep workers safe during cleaning and use. VFDs work with robots and other drives to make packaging lines quick and exact.

Here is a table that shows how VFD drives help packaging:

Note: VFD drives help you follow food safety rules and keep packaging lines working well.

Renewable Energy

Variable frequency drives (VFDs) are important in renewable energy. You can use these drives to make wind and solar power work better. VFDs help you use your equipment well and save energy.

Wind Turbines

VFDs help wind turbines work at their best. These drives change voltage and frequency to match the grid. This gives steady power and better performance. Many top companies make VFDs for hard places, like offshore wind farms. You get features like liquid cooling and strong parts. These keep your systems working well.

VFDs also help with energy storage systems. These systems store extra wind energy for later use. You get better control of frequency and voltage for the grid. This means wind turbines give steady power, even when wind changes. IoT in new VFDs lets you watch how things work and plan repairs early.

Change turbine speed for best energy.

Help the grid stay steady with control.

Use smart tools for early repairs.

Make systems work well in tough places.

Solar Pumping

Solar pumping systems with VFDs save energy and water. You can set pump speed for what you need right now. This uses less energy and lowers costs. Soft-start and soft-stop protect pumps and make them last longer. You can change pump speed for different crops or fields.

When you use VFDs with solar panels, you use more solar energy. Maximum Power Point Tracking (MPPT) keeps pumps working, even if sunlight changes. Studies show VFD solar pumps save energy and make pumps last longer. These good things help farms and city water systems.

Canroon gives green energy solutions with new VFDs. The CV900S Series Solar Pump Inverter gives you good control and high efficiency. Canroon’s VFDs help you use less energy and make systems work better in green energy projects.

Tip: Using VFDs in renewable energy helps you save energy, protect your machines, and support a cleaner world.

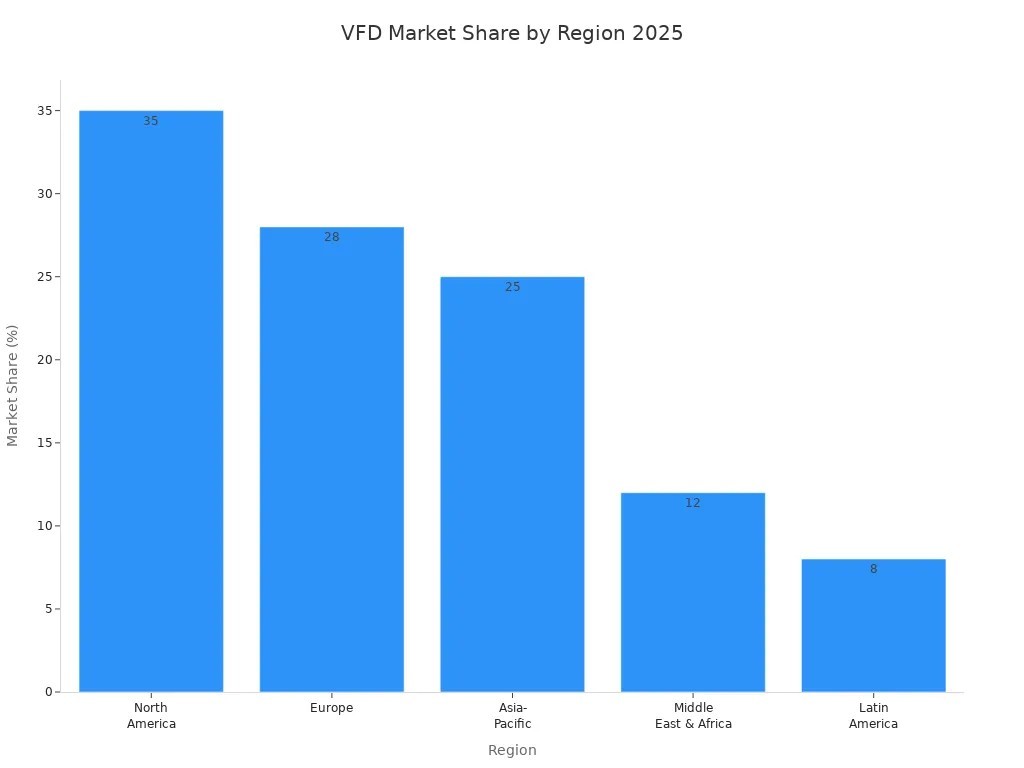

You see vfd drives making a big difference in many industries. They help you save energy, lower costs, and improve how your machines work. Companies in North America, Europe, and Asia-Pacific use these drives to meet new rules and boost efficiency. If you want to get started, follow these steps:

Smart planning helps you get the most from your investment.

FAQ

What is a VFD drive?

A VFD drive lets you control the speed of an electric motor. You can save energy and make machines last longer. You use VFDs in many industries, like factories and farms.

How do VFD drives help save energy?

You set the motor speed to match what you need. This stops motors from running too fast or too slow. You use less electricity and lower your power bills.

Can you use VFD drives with old motors?

Yes, you can use VFD drives with many older motors. You should check the motor’s type and condition first. Some motors may need upgrades for best results.

Are VFD drives hard to install?

Most VFD drives are easy to install. You follow the manual and safety steps. Many companies, like Canroon, offer support and training for setup.

What maintenance do VFD drives need?

You should keep VFD drives clean and dry. Check for dust and loose wires. Inspect cooling fans and filters often. Regular checks help your VFD last longer.

Previous:

Next:

Sign up for updates