You should look at the most important things when picking an induction surface hardening machine. Make sure the machine’s features fit your workpiece size, material, and what you want to make. Go step by step so you can choose with confidence. Canroon gives expert help to pick the right equipment for you.

Key Takeaways

Know what kind of workpiece you have and its size. This helps you pick the right induction surface hardening machine. - Learn about the materials you use. Set clear goals for how hard you want them to be. This helps you harden them well. - Think about how much you need to make. Pick a machine that works fast enough for your needs. - Make sure the machine lets you change power and frequency. This helps you use it for different jobs. - Look for a company that gives good help and a strong warranty. This keeps your machine working well.

Define Your Needs

Workpiece Type & Size

Start by thinking about what kind of workpieces you have. Check their size and shape. Some induction surface hardening machines work better with small gears. Others are good for big shafts or flat plates. Make a list of the workpieces you use most. Measure how long, wide, and thick they are. This will help you pick a machine that fits your jobs.

Tip: If you use many sizes, pick a machine with adjustable coils. This lets you change workpieces fast.

Material & Hardness Goals

Know which materials you use the most. Steel, iron, and some alloys work well with induction hardening. Each material needs a special heating pattern to get the right hardness. Decide how hard you want the surface to be. Some jobs need a thin, strong layer. Others need the hardening to go deeper. Write down your hardness goals for each material.

Production Volume

Think about how many parts you want to make each day. If you need to make a lot, you need a fast and steady induction surface hardening machine. If you only make a few, a simple machine is fine. Make a chart for your daily, weekly, and monthly goals.

High volume: Needs fast cycles and automation.

Low volume: Can use manual or semi-automatic machines.

Changing volume: Pick flexible machines that fit your schedule.

Note: Picking the right machine for your production volume saves time and money.

Induction Surface Hardening Machine Specifications

Power & Frequency

When you pick an induction surface hardening machine, check the power and frequency settings. These settings decide how deep and how fast the heat goes into your workpiece. Machines for car factories often use frequencies up to 300 MHz. They also use power levels that start at 500 Watts. These settings help you get the right hardness for different parts.

High frequency works best for thin materials. It makes a hard layer on the surface.

Low frequency is better for thick materials. It lets the heat go deeper inside.

More power helps you treat bigger parts or reach higher heat.

Here is a table that shows how frequency changes the case depth:

Tip: If you work with many sizes and shapes, pick a machine with adjustable power and frequency. This helps you get the best results for each job.

Heating Control Precision

You want your induction surface hardening machine to heat your parts evenly and accurately. Good machines let you control the temperature and power very closely. This helps you avoid making your parts too hot or too cold. Top brands now have machines with advanced temperature control and adjustable power settings. These features help you reach your hardness goals every time.

Precise temperature control keeps your parts safe.

Adjustable power settings let you fine-tune the process.

New machines use smart sensors to watch the heat and adjust it quickly.

Note: Better heating control means fewer mistakes and higher quality parts.

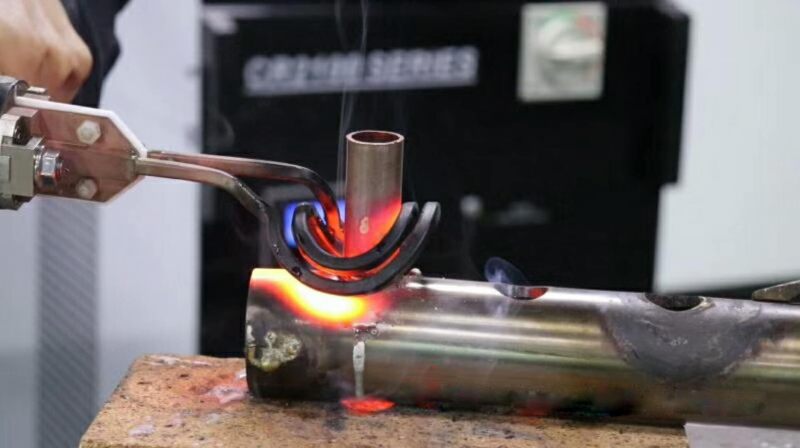

Coil Design Options

The coil is the part of the induction surface hardening machine that sends heat into your workpiece. You need to pick the right coil design for your parts. Some machines offer many coil shapes and sizes. This helps you treat gears, shafts, or plates without changing the whole setup.

Custom coils fit special shapes and sizes.

Quick-change coils save you time when you switch jobs.

Water-cooled coils keep the machine safe and working longer.

Callout: Ask your supplier about coil options. The right coil design can improve your results and make your work easier.

Facility & Installation

Space & Layout

Check your workspace before you get new equipment. Measure the spot for the induction surface hardening machine. Make sure there is enough space for the machine and the operator. Leave room for tools, cleaning, and fixing the machine. Think about extra space if you want more machines later.

Tip: Draw a simple map of your floor. Show where the machine, power lines, and walkways will be. This helps you avoid problems when you set up the machine.

Power Supply & Cooling

Every induction surface hardening machine needs strong, steady power. Check your building’s voltage and current. See if they match the machine’s needs. Some machines use three-phase power. Others use single-phase. Ask your supplier for the right numbers.

Cooling is very important. These machines get hot when they run. Most use water cooling. You might need a chiller or a water hookup. Make sure you have enough water flow and pressure.

Note: Good cooling keeps your machine safe and helps it last longer.

Integration with Automation

You can make more parts by using automation with your induction surface hardening machine. Check if your machine works with robots, conveyors, or sensors. Some machines have special ports or software for easy connection. Plan how parts will move in and out of the machine.

Use sensors to check parts and control quality.

Add conveyors to load and unload parts faster.

Connect to your factory’s main system for better data.

Callout: Ask your supplier about automation choices. The right setup can save time and help you make fewer mistakes.

Advanced Features & Safety

Automation Compatibility

You can make more parts if your machine works with automation. Many new machines connect to robots and sensors. This helps you move parts without much manual work. You can also watch each part as it goes through the process. Some machines let you set up automatic recipes for different jobs. Look for machines with easy ports for automation. Check if the software works with your factory’s system. Ask if you can add more automation later.

Tip: Automation helps you make more parts and fewer mistakes.

Safety Systems

Safety is very important. Good machines have safety features to protect you and your team. You might see emergency stop buttons and safety doors. Some machines shut down if they sense a problem. Others have shields to keep you safe from heat and moving parts.

Always check the safety systems before you start work.

Energy Efficiency

Energy costs can get high. You can save money by picking a machine that uses less power. Many new machines have smart controls that use energy only when needed. Some machines recycle heat to lower waste. You can ask for machines with energy-saving modes or better insulation. Choose machines with high energy ratings. Ask about features that cut down on power use. Track your energy use to find savings.

Note: An energy-efficient induction surface hardening machine helps your business and the environment.

Manufacturer Support & Service

Picking the right induction surface hardening machine is not just about the machine. You also need help from the company that makes it. Good support keeps your work going without problems. After-sales service helps you fix issues fast and keeps your machine working well.

Customization & Engineering

Each factory needs different things. Sometimes, you need a machine made for your own parts. Find a manufacturer that can make custom changes. They can design special coils, controls, or software for your jobs. Canroon works with you to make sure the machine fits your workpiece size, shape, and hardness goals.

Custom coils for special shapes

Software changes for your process

Engineering help for better results

Tip: Ask if the manufacturer can visit your factory or look at your drawings. This helps them make a machine that fits your needs.

Technical Support

You need help when something goes wrong. Good technical support gives you answers quickly. Canroon offers help by phone, email, and online. Their team helps you set up, learn, and fix problems. Fast help means less waiting and more work done.

Callout: Pick a supplier with a strong support team. This helps you feel safe.

Maintenance & Warranty

Regular care keeps your machine safe and working well. Ask about service plans and spare parts. A good warranty protects your money. Canroon gives clear guides for care and offers warranty for their machines. This helps you avoid big repair bills and keeps your work on schedule.

Regular check-ups

Easy to get spare parts

Warranty for parts and work

Note: Good service and warranty help you get the most from your induction surface hardening machine.

You can pick the right induction surface hardening machine by using a simple list. Think about what you need for your work. Look at the machine’s features and your workspace. Check if the machine has special options and good help from the maker. Use this list to look at different machines and choose the best one.

Measure your workpiece size and know the material

Make sure the machine has enough power and the right coil

Check if you have enough room and cooling

See if the machine has automation and safety features

Find out about help and warranty

Canroon can help you get a machine that works for your factory and goals.

FAQ

What is induction surface hardening?

You use induction surface hardening to make the outside of metal parts harder. The machine heats the surface quickly with electricity. Then you cool the part fast. This makes the outside strong while the inside stays tough.

How do I know which coil design I need?

You choose a coil based on your part’s shape and size. Ask your supplier for advice. Custom coils work best for special parts. Quick-change coils help if you switch jobs often.

Can I use one machine for different materials?

Yes, you can use one machine for many materials. You must adjust the power and frequency settings for each type. Always check the machine’s manual or ask your supplier for the right settings.

How often should I maintain my machine?

You should check your machine every week. Clean the coils and cooling system. Look for any loose wires or leaks. Follow the maintenance guide from your supplier for best results.

Previous:

Next:

Sign up for updates