You use a frequency converter to change how often electricity flows. This helps you control how fast an electric motor spins. The converter can change power from 50Hz to 60Hz. This helps machines work better in different places. More people are buying these devices every year. Look at this table to see how the global market is growing:

Canroon gives you good solutions for your frequency conversion needs.

Key Takeaways

A frequency converter changes how often electricity moves. This helps control how fast a motor goes. It also helps machines work better. Using a frequency converter can save energy. It can lower electricity bills by letting motors run at the right speed. Frequency converters help machines start slowly and smoothly. This makes them last longer and keeps them from wearing out fast. There are different types of frequency converters. Each type works best for certain jobs. You should pick the one that matches what you need. Canroon has good frequency converter options. These can help machines work better at home or in factories.

Frequency Converter Basics

Definition

A frequency converter is a device that changes how often electricity flows. You use it to control how fast a motor spins. The converter takes power from a source and changes its frequency. This lets you set the motor speed for your equipment. You can switch power from 50Hz to 60Hz or back. This helps machines work in different places.

You see frequency converters in factories, workshops, and some homes. They help you set the right speed for fans, pumps, and other machines. Canroon is a top brand that gives good frequency converter solutions for many industries.

Purpose

You use a frequency converter to help machines work better and save energy. The converter lets you control how fast a motor goes. You can change the speed to match the job. This means you do not waste power when the machine does not need to go fast.

Using a frequency converter helps your equipment last longer. Motors start smoothly and do not get damaged by sudden starts. You also get steady voltage and frequency, so your machines stay safe.

Here are some main jobs of a frequency converter in factories:

You save energy by changing the speed of fans and pumps to fit the work.

You get steady voltage and frequency, so machines run well.

You can set the speed exactly, which helps make things more accurate.

You can use the converter with many motors, so it works with different machines.

A frequency inverter also helps you use less energy. You can run motors slower and use much less power. For example, if you run a motor at half speed, you only need about 12.5% of the energy compared to full speed. This means you pay less for electricity. Many companies find that they get their money back in less than a year because of these savings.

You also get smooth starts for your motors. The converter lowers the shock and wear when starting. This helps your motors last longer and work better.

Variable frequency operation lets you change motor speed for different jobs. You can set the speed as needed, which makes your equipment more useful. This also helps you stop wasting energy and keeps parts from wearing out.

Canroon gives you advanced frequency converter technology. You get solutions that help you save energy, control machines better, and keep your equipment safe.

Operation

Components

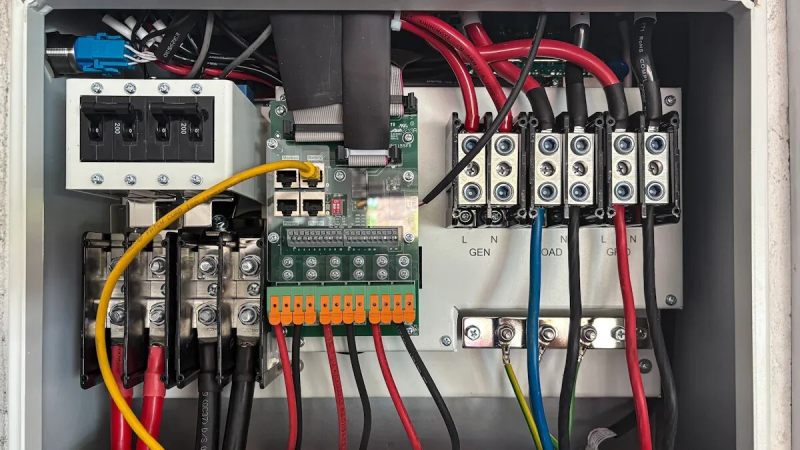

When you open a frequency converter, you see many parts. Each part does something important. Here are the main parts you find inside:

Rectifier: This part changes AC power to DC power. It uses diodes to do this job.

DC Link: This part makes the DC voltage smooth. It uses capacitors to keep the voltage steady.

Inverter: This part turns DC power back into AC power. It sets the frequency and voltage you need. It uses special switches for this.

Filters: These parts clean up the output. They help make the wave smoother and reduce noise.

Control System: This system checks how the converter works. It manages the parts and keeps things running right.

Cooling System: This part keeps the converter cool. It stops the converter from getting too hot.

Protection and Safety Devices: These parts keep the converter safe. They protect it from problems and help it work well.

Control and Monitoring Interfaces: These let you connect the converter to other systems. You can check the converter’s status with these.

Tip: Always use a good cooling system and safety devices. This helps your converter last longer and work better.

Process

A frequency converter changes power in three steps. You start with AC power from your wall. The converter turns AC power into DC power. Then it changes DC power back into AC power at the frequency you want. Here is how each step works:

Rectification

The rectifier takes AC power and makes it DC power. AC power goes back and forth, but DC power goes one way. Diodes help with this step. The DC power is not smooth, so the converter uses a DC link with capacitors to fix it.DC Link

The DC link acts like a filter. It uses capacitors to smooth out the DC voltage. This gives steady power for the next step.Inversion

The inverter takes the smooth DC power and makes it AC power again. You can set the frequency and voltage you need. The inverter uses fast switches to make pulses. These pulses look like a sine wave. By changing the width and timing of the pulses, you control the frequency and voltage. This is called Pulse Width Modulation (PWM).

Here is a table that shows how the inverter works:

Note: You can use a frequency inverter to control motor speed very well. This helps you save energy and keep your equipment safe.

Modern frequency converters use new technology for better results. You get better efficiency and energy recovery. The devices are smaller and lighter now. Many converters have modular designs. You can add more units if you need more power. Smart IoT lets you watch and control your converter from anywhere.

Here is a table comparing Canroon’s products with other brands:

When you set up a frequency converter, you may have some problems. Overheating can happen if there is not enough airflow. Always put the converter in a place with good air. Keep the vents clean and free from dust. Wrong wiring is another problem. Check all wires and follow the instructions. Use a checklist to make sure you have all the right parts and the power supply matches the converter.

If you use three phase frequency converters, you get more control and efficiency. These are good for big motors in factories and large machines. They help heavy equipment run smoothly and safely.

Types

When you want a frequency converter, you see different kinds. Each kind works best for certain jobs. You should know the differences to choose the right one.

Voltage Source

A voltage source frequency converter uses a DC voltage source. It changes how long the switches are on to control the output voltage. This type gives a low impedance output. That means it can handle load changes well. You use this converter for motor drives, renewable energy, and UPS systems.

Here is a table that shows how voltage source and current source inverters are different:

A voltage source inverter keeps the voltage steady. You use it when your equipment needs stable voltage.

Current Source

A current source frequency converter uses a DC current source. It changes the switching frequency and pulse width to control the output current. This type gives a high impedance output. You find this converter in high power drives and induction heating. Some motor drives use it when they need steady current.

The main difference is what each type controls. Voltage source inverters keep voltage steady. Current source inverters keep current steady.

AC/DC/AC

An AC/DC/AC frequency converter changes AC power to DC, then back to AC at a new frequency. This type is very flexible. You can use it with many motors and loads. It works well for homes and factories.

Here is a table with the good and bad points of AC/DC/AC converters:

You also see AC to AC, AC to DC, and DC to AC converters. Each kind fits different needs. For example, three phase frequency converters help control big motors in factories.

Tip: When you pick a frequency converter, check what you need, your power, control features, and budget. Choose a good brand and install it the right way.

How to Choose the Right Type

Decide what job you want the converter to do.

Match the power and voltage to your motor.

Look for control features like speed accuracy.

Pick a trusted brand.

Think about cost and setup.

A frequency inverter gives you good control for many jobs. Always check your needs before you buy.

Applications

Industry

You can find frequency converter technology in many industries. Factories use converters to change how fast motors spin. This helps them work better and use less energy. Many fields use converters, like healthcare, technology, aerospace, automotive, oil and gas, food, semiconductor, and renewable energy. Aerospace and defense companies need converters for exact power in planes and ground tools. Car factories use converters for machines that must keep a steady speed and power. On production lines, converters help set motor speed for better work. Material handling systems use converters for smooth moves and correct placement.

Manufacturing

Healthcare

Technology

Aerospace

Automotive

Oil and Gas

Food

Semiconductor

Renewable Energy

Daily Use

You also use frequency converter technology at home. Many appliances have converters to save energy. Air conditioners use converters to work better and use less power. Refrigerators and washing machines use converters to save energy too. Home water pumps use converters to change speed and save power.

You can save up to half your energy costs with inverters in fans and pumps when not running full speed. Three phase frequency converters help control big motors in large buildings and factories.

Benefits

You get many good things from using frequency converter technology. You can set motor speed for each job. This saves energy and money. Your machines last longer because they do not wear out as fast. Variable speed pumps let you change speed to fit the job, which saves money and works better. Frequency converters help motors start and stop smoothly and safely. You do not need hard-to-fix mechanical parts, so your system is easier to care for. Canroon has solutions for all uses, from factories to homes, to help you save energy and get good results.

Tip: If you pick a frequency converter for your job, you get better control, save energy, and make your equipment last longer.

Standards

Safety

It is very important to stay safe when using a frequency converter. International standards help protect people and equipment. These rules tell you how devices should work and how to set them up. Here is a table with some main safety standards:

Modern converters have many safety features built in. They protect against too much voltage, too much current, too much load, and getting too hot. These features help stop accidents and keep things working right.

Tip: Make sure your converter has these safety features before using it.

Compliance

You need to check if your frequency converter follows the rules where you live. In the European Union, look for the CE Marking. This mark means the product follows safety, health, and environment rules. Other important certificates are:

CE Marking for European safety and health rules.

ISO9001 for good quality management.

Special certificates for ships or dangerous places.

Canroon works hard to follow these rules. The company tests its products and checks quality carefully. Here is a table with Canroon’s main certificates:

You can trust Canroon to give you safe and good products. The company checks every frequency converter to make sure it meets all the important rules.

Now you understand that a frequency converter lets you change how fast a motor goes. This helps you save energy. You can use a frequency converter in lots of places. It works in factories and also in homes. These devices have many good points:

Pumps can use up to 50% less energy.

You can lower emissions and help the planet.

You use power better and spend less money.

Canroon gives you solutions you can trust. Pick a frequency converter to help your machines work well and last longer.

FAQ

What is the main job of a frequency converter?

You use a frequency converter to change the speed of electric motors. This helps you match the motor speed to your needs. You save energy and protect your equipment.

Can you use a frequency converter with any motor?

You can use most frequency converters with standard AC motors. Always check your motor’s type and the converter’s specifications. Some motors need special settings or extra protection.

How do you know which frequency converter to choose?

Tip: Check your motor’s power, voltage, and speed needs. Pick a converter that matches these. Look for trusted brands like Canroon for reliable performance.

Do frequency converters help lower energy costs?

Yes! You can save a lot of energy by running motors only as fast as needed. Many users see lower electricity bills and less wear on their machines.

Sign up for updates