Choosing the best cooling method is important for induction heating. If you do big jobs or need the machine to run all the time, a water cooled induction heating machine works well. It gives steady and strong performance. For smaller jobs or if you need to move the machine, air-cooled models are better. You want advice that is easy to understand and trust. Canroon knows a lot about both choices. They help you pick the right one for your needs.

Key Takeaways

Pick water-cooled machines for tough jobs. They give strong power and work well for a long time.

Use air-cooled machines for small jobs. They are simple to set up, easy to move, and save money for light work.

You must do regular maintenance. Check water quality in water-cooled systems. Clean filters in air-cooled systems to keep them working well.

Think about your workspace. Water-cooled machines need more space and setup. Air-cooled models are small and easy to move.

Choose the right cooling for your job. Water-cooling works best for thick metals and big jobs. Air-cooling is good for quick, light work.

Basics of Induction Heating

How It Works

Induction heating uses electricity and magnetism to heat metal fast. You put a metal part inside a coil. The coil has an alternating current. This current makes a magnetic field. The magnetic field heats the metal without touching it. Here are the main ideas of induction heating:

Induction heating works quickly and does not need to touch the metal. You can use it for melting, forging, or joining metals. The process is clean and exact.

Why Cooling Matters

Induction heating machines get very hot when you use them. You need a good cooling system to keep things safe and working right. Here are some reasons why cooling is important:

Cooling stops the machine from getting too hot. Too much heat can break parts and waste energy.

A strong cooling system helps the furnace work well. You melt metal faster and use less power.

Cooling protects workers and equipment. High heat can cause leaks or make materials weak.

Good cooling helps the machine last longer. It keeps electronic parts from breaking.

Proper cooling makes sure the induction machine works safely every time.

You should always check the cooling system before you use your induction heating machine. This keeps your work safe and helps you get the best results.

Cooling Methods

It is important to know how each cooling method works. Water-cooling uses water to take heat away from the coils and electronics. The water moves through pipes and grabs heat fast. This keeps the machine cool, even if you use it for a long time or at high power. You often find water cooled induction heating machine in factories. These places need strong and steady heat.

Air-cooled machines use fans to blow air on hot parts. The air takes away some heat, but not as much as water-cooling. Air-cooled models are good for small jobs or if you need to move the machine. You can set up an air-cooled machine quickly. It does not need extra things like pumps or water tanks.

Here is a table that shows how air-cooling and water-cooling are different:

Tip: If you need to heat thick metal or use your machine all day, water-cooling works better. For quick jobs or thin metal, air-cooling saves money and time.

Efficiency

Efficiency means how well the machine turns electricity into heat. Water cooled induction heating machine has higher heating efficiency. Water-cooling keeps the coils and electronics cool, so the machine works at full power. You get more heat and waste less energy.

Air-cooled machines are less efficient. The fans cannot cool the parts as well as water-cooling. If the machine gets too hot, it may slow down or stop to stay safe. Air-cooled models are best for short jobs or when you do not need full power.

Water cooled induction heating machine can reach very high temperatures, up to 2000°C or more. Water-cooling gives strong cooling and lets you use more power. Air-cooled machines usually reach up to 600°C. Their cooling is okay, and they cannot use as much power.

Note: If you want the best heating efficiency and need to work with thick metal or high heat, pick water-cooling. If you want a simple setup and lower costs, air-cooling is good for light jobs.

You should pick the cooling method that fits your job. Water cooled induction heating machine gives strong power and high efficiency for big jobs. Air-cooled models help you save money and work fast for small jobs.

Performance

Power Output

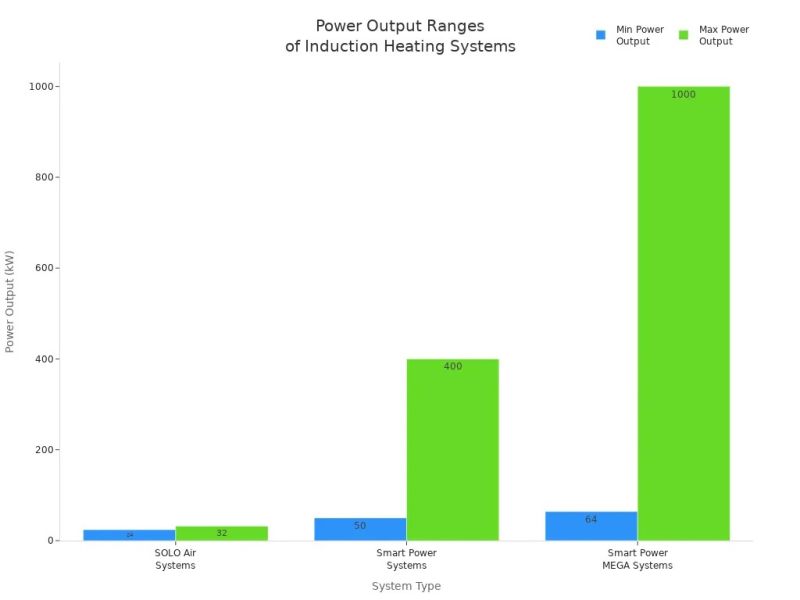

You want to know how much power your induction heating machine can deliver. Power output affects how fast you can heat metal and how thick the material can be. Water-cooled systems give you higher power ranges. You can use them for heavy-duty jobs and large parts. Air-cooled systems work best for lighter tasks and smaller pieces.

Here is a table that shows the power output ranges for different induction systems:

You see that water-cooled machines, like Smart Power and Smart Power MEGA, reach much higher power levels. Air-cooled models, such as SOLO Air, stay in the lower range. If you need to heat thick metal or run your induction machine all day, water-cooled systems give you the strength you need.

Heating Speed

Heating speed matters when you want to finish jobs quickly and keep product quality high. Induction machines heat metal fast, but cooling methods change how quickly you reach the right temperature. Water-cooled systems keep the coil and electronics cool, so you can use high power for longer periods. You get faster heating and steady results.

Air-cooled machines use fans to remove heat. If the coil gets too hot, the machine slows down to protect itself. You may notice slower heating, especially with thick materials. Good cooling helps you keep the induction coil at the best temperature. Water flow rate also plays a big role. If water moves quickly, heat leaves the coil faster, and you get better heating speed.

Here is a table that explains how cooling affects heating speed:

Tip: If you want fast heating and high product quality, choose a water-cooled induction machine for demanding jobs. Air-cooled models work well for quick, light tasks.

Maintenance

Routine Care

You want your induction heating machine to last and work well. Regular care helps you avoid problems and keeps your machine safe. For water-cooled systems, you should check the pH and conductivity levels every few months. This step helps you spot changes in water quality early. You also need to flush the water system to remove any sediment. If you see algae, treat the water with anti-algae solutions. Replace the water in the closed loop at least once a year, or sooner if it looks dirty. Always follow the maintenance steps from your machine’s manual.

For air-cooled machines, routine care is simpler. Clean the air filters and fans to keep airflow strong. Dust and dirt can block the fans and make the machine overheat. Check for loose wires or signs of wear. A clean and well-checked machine runs better and lasts longer.

Tip: Good maintenance keeps your machine safe and helps you avoid costly repairs.

Common Issues

You may face some common problems with both water-cooled and air-cooled induction heating machines. Water-cooled systems can overheat if water flow drops or pipes get blocked. Sometimes, you might hear strange noises. These sounds can mean there is internal arcing or an electrical problem. Power output may change if something is wrong inside the machine.

Leaks are another issue for water-cooled models. Worn seals, gaskets, or corrosion can cause water to escape. If you lose cooling water, your machine will not work as well. Leaks can also damage other parts.

For air-cooled machines, overheating often happens when fans or filters get clogged. Always listen for odd sounds and watch for changes in performance.

Note: Induction heating focuses heat on the metal part, so you do not have to touch hot surfaces. This design makes your work safer.

Cost

Initial Cost

When you choose an induction heating machine, you need to think about the initial cost. Water-cooled machines usually cost more at the start. You pay for extra parts like pumps, water tanks, and cooling pipes. These machines also need a more complex setup. Air-cooled machines have a lower initial cost. You do not need extra equipment. You can set them up quickly and start working right away.

Here is a table to help you compare:

Tip: If you have a tight budget or need a portable solution, air-cooled machines help you save money at the start.

Operating Cost

You also need to look at the cost to run your machine every day. Water-cooled machines use more energy because they run pumps and sometimes chillers. You must check and replace water, treat it for algae, and fix leaks if they happen. These steps add to your operating cost.

Air-cooled machines use less energy. Fans use less power than pumps. You only need to clean filters and fans. You do not have to worry about water treatment or leaks. This makes air-cooled machines cheaper to run for small jobs or short periods.

Water-cooled: Higher running costs, more maintenance

Air-cooled: Lower running costs, less maintenance

Note: If you plan to use your machine all day or for big jobs, water-cooled systems may cost more to run, but they give you better performance.

Environment

Space Needs

Think about how much room your machine will need. Water-cooled machines take up more space. You need to set up water tanks, pumps, and pipes. These parts use extra floor space in your shop or factory. If your workspace is small, fitting a water-cooled system can be tough.

Air-cooled machines need less room. You only need the main unit and space for air to move. These machines are easier to move around. If you want something portable or have little space, air-cooled models are better.

Note: Always leave enough space around your machine. This helps keep things safe and makes maintenance easier.

Noise

Noise can change how comfortable your work area feels. Water-cooled and air-cooled machines make different sounds. You should know how loud each one is before you choose.

Here is a table that shows the average noise levels:

Air-cooled machines are as loud as a vacuum cleaner. It can be hard to talk near them. Water-cooled machines are quieter. They sound like people talking or soft music. If you care about noise, water-cooled systems are better for your workspace.

You should also think about how much energy the machines use. Air-cooled machines use fans, which add noise and use more power. Water-cooled systems use pumps, but they are usually quieter.

Tip: If you want a quiet place to work, choose a water-cooled induction heating machine.

Choosing the Right Machine

Application Match

You want to choose the right induction sealer for your job. Start by thinking about what you need to heat and how often you will use the machine. If you work in high-volume production, you need a system that can run all day without stopping. Water-cooled induction sealer machines work best for these jobs. They keep cool even when you use them for long hours. This means you get steady results and less downtime.

If you do smaller jobs or need to move your induction sealer from place to place, air-cooling is a better choice. Air-cooling works well for light tasks and quick jobs. You do not need extra water tanks or pumps. This makes setup easy and saves space. Air-cooling also helps if you have a small workshop or need a portable solution.

Different materials need different heating power. If you work with thick or large metal parts, you need more power. Water-cooled induction sealer machines give you the strength for these tasks. If you work with thin materials or small parts, air-cooling can handle the job.

Here is a table to help you match your needs to the right induction sealer:

Tip: The type of material you heat changes how your induction sealer works. Metals like steel heat up fast, while others need more time or power.

Decision Guide

You can use a simple checklist to help you decide between air-cooling and water-cooling for your induction sealer. This guide will help you pick the best machine for your needs.

Checklist for Choosing Your Induction Sealer:

Do you need high-volume production or long run times?

Yes: Choose water-cooling.

No: Air-cooling may be enough.

Is your workspace small or do you need to move the machine often?

Yes: Air-cooling is easier to set up and move.

No: Water-cooling can fit if you have space for tanks and pipes.

Are you heating thick or large metal parts?

Yes: Water-cooling gives more power and better results.

No: Air-cooling works for thin or small parts.

Do you want simple maintenance?

Yes: Air-cooling needs less care.

No: Water-cooling needs water checks and cleaning.

Does your facility have water supply and drainage?

Yes: Water-cooling is possible.

No: Air-cooling is the better choice.

Here is a table that shows how each system fits different needs:

Note: Induction heaters make a lot of heat. You must have a good cooling system to keep your machine safe and working well. Air-cooling is simple and quick to set up. Water-cooling is better for high-volume production and tough jobs.

Canroon recommends water-cooling for factories that need high-volume production and strong, steady heating. If you run an induction sealer all day or work with thick metals, water-cooling gives you the best results. For small shops, repairs, or portable jobs, Canroon suggests air-cooling. Air-cooling gives you the advantages of easy setup, less maintenance, and lower cost.

You should also think about your facility. If you cannot set up water tanks or pumps, air-cooling is the right choice. If you want the highest power and fastest heating, water-cooling is the way to go.

Remember: The right induction sealer helps you save time, money, and effort. Match your machine to your job for the best advantages.

Case Studies

Industrial Use

You may work in a factory or a large workshop. In these places, you often need to heat big metal parts or run machines all day. Water-cooled induction heating machines fit this job well. They give you strong power and steady performance.

Example:

A car parts factory uses a water-cooled induction heater to harden steel shafts. The machine runs for many hours each day. It keeps the temperature steady, so every shaft gets the same treatment. Workers do not worry about overheating. The water cooling system removes heat fast. This helps the factory finish more parts in less time.

Key Benefits:

You get high power for thick or large metal parts.

The machine can run all day without stopping.

Water cooling keeps the system safe and reliable.

Tip: If you need to heat many parts or work with thick metals, water-cooled machines help you reach your goals.

Portable Solutions

Sometimes, you need to move your induction heater to different places. You may work on repairs, small jobs, or in a tight space. Air-cooled induction heating machines make your work easier in these cases.

Example:

A maintenance team uses an air-cooled induction heater to remove rusted bolts from large machines. The heater is light and easy to carry. The team moves it from one site to another. They do not need water tanks or pumps. They plug in the machine and start working right away.

Key Benefits:

You can move the machine easily.

The setup is quick and simple.

Air cooling works well for short jobs and thin materials.

Note: Air-cooled machines save you time and effort when you need a portable solution.

You now know which cooling method fits your job. Use water-cooled machines for heavy-duty, nonstop work or thick metals. Choose air-cooled models for light, portable tasks or small spaces. Think about your workspace, your budget, and how often you use the machine. Canroon offers expert help and a wide range of solutions.

Need help choosing? Contact Canroon for advice tailored to your needs.

FAQ

What is the main difference between air-cooled chillers and water-cooled chillers?

You will see that air-cooled chillers use fans to remove heat, while water-cooled chillers use water to carry heat away. Air-cooled chillers work well in small spaces. Water-cooled chillers fit best in large factories with high power needs.

Which is easier to install, air-cooled chillers or water-cooled chillers?

You can install air-cooled chillers quickly because they need less equipment. Water-cooled chillers require pumps, pipes, and water tanks. Air-cooled chillers save you time during setup. Water-cooled chillers take more planning and space.

How do air-cooled chillers and water-cooled chillers affect maintenance?

You will find that air-cooled chillers need simple care, like cleaning fans and filters. Water-cooled chillers need you to check water quality and flush the system. Air-cooled chillers have fewer parts to maintain. Water-cooled chillers need more regular checks.

Are air-cooled chillers or water-cooled chillers better for high temperatures?

You should choose water-cooled chillers for high temperatures and heavy-duty jobs. Air-cooled chillers work best for lighter tasks and lower heat. Water-cooled chillers handle thick metals and long run times. Air-cooled chillers suit quick jobs and thin materials.

Which is quieter, air-cooled chillers or water-cooled chillers?

You will notice that water-cooled chillers make less noise than air-cooled chillers. Air-cooled chillers use fans that can be loud. Water-cooled chillers use pumps, which are quieter. If you want a quiet workspace, water-cooled chillers are a better choice.

Sign up for updates