You use induction stress relieving to take away bad stresses inside metal parts. Making things like welding or cutting can leave metals with hidden strains. These stresses can make metal bend or break early if you do not treat it right. Induction uses electromagnetic energy to heat metal fast and evenly. It only heats the spots that need help.

Induction lets you control the process better. This helps you stop parts from bending the wrong way.

Induction stress relieving works faster and uses less energy than old ways.

You save money and get more accuracy, especially for tricky parts in aerospace.

Canroon gives you good induction heating solutions for your metal work needs.

Key Takeaways

Induction stress relieving lowers hidden stresses in metal parts. This makes them stronger and less likely to bend or break. This method heats metal fast and evenly. It saves time and energy compared to old heating ways. Good preparation and equipment setup are very important. This makes sure the parts are clean and heated right. Slow cooling after heating is needed to keep the metal strong. It also stops new stresses from forming. Induction stress relieving helps metal parts work better and last longer.

What Is Induction Stress Relieving?

Definition

Induction stress relieving is a type of induction heat treatment. It helps take away stress inside metal parts. You can use it before or after you shape or cut metal. The process uses careful heating to make the metal better and stop extra stress from forming. You can treat the whole part or just certain spots, depending on what you need. The heat and cooling time change with different metals.

You heat steel or other metals to a set temperature.

You keep the metal at that temperature for a certain time.

You cool the metal slowly so it becomes stable.

Purpose

Induction stress relieving makes metal parts stronger and more dependable. This treatment lowers stress inside and helps stop bending or cracking. Here are some main reasons to use it:

Lower stress inside and extra stress

Reduce the chance of bending or cracks when finishing

Help your metal parts last longer

Make your parts resist cracking and breaking

Keep the shape and size steady for better use

Tip: Induction stress relieving annealing works better than many other ways because you can control it closely.

How It Works

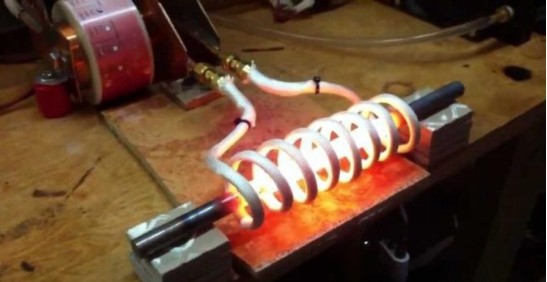

Induction stress relieving uses induction to heat metal parts fast and evenly. You put the part inside an induction coil. The coil gets alternating current, which makes a changing magnetic field. This field causes electric currents, called eddy currents, to move inside the metal. These currents heat the metal from the inside out.

You use induction stress relieving when you want fast, focused heating and better control. This method helps stop tiny cracks and keeps your metal parts strong and steady.

Induction Stress Relieving Process

Preparation

You get your metal parts ready before you start. This step is important because it helps remove stress from making or shaping the metal. If you skip this, your parts might bend or crack later. Make sure your parts are clean and have no oil, dirt, or rust. Clean parts help the heat treatment work better.

Tip: Always check what kind of metal you have. Each metal needs its own settings for induction stress relieving.

Follow these safety steps when you prepare:

Learn about your metal’s properties. This helps you pick the right process.

Control how fast you heat and cool the metal. This stops new stress from forming.

Keep your work area clean and use a safe atmosphere if needed.

Wear safety gear and make sure your area has fresh air.

Use tools that are checked and set right. This stops overheating or underheating.

Use holders to keep your parts in place. This stops them from bending.

Watch and write down all the steps for good quality.

Equipment Setup

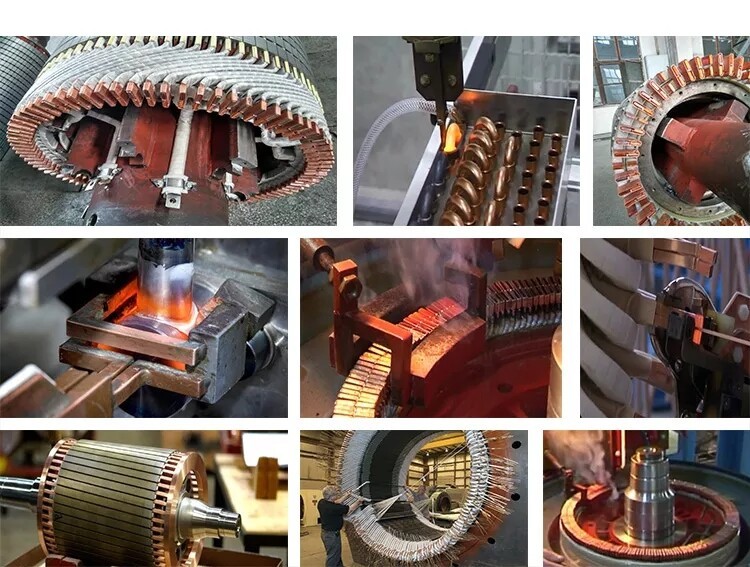

You need the right tools for induction stress relieving. Canroon gives you heating systems that let you control the process. These systems use coils that go around or near your metal part. You can pick different coil shapes for different jobs.

Here is a table with common equipment types:

Set up the coil so it heats only the spot you want. This helps you not overheat other areas. Connect the coil to the power and set the temperature and time. Make sure everything is tight before you start.

Heating Steps

Turn on the induction system to begin. The coil makes a magnetic field that heats your metal fast and evenly. For welded steel, heat both the weld and the base metal. Follow the right temperature plan so you do not hurt the metal.

Heat the part to the right temperature, which is below the lower transformation point for steel.

Hold the temperature for a set time. This lets the process lower stress and stop tiny cracks.

Heat slowly and carefully. This keeps the part’s shape and stops new stress.

Note: Induction stress relieving works well for steel and welded parts. You can use it for both small and big pieces.

Cooling

After heating, cool the metal slowly. Slow cooling is very important for this process. If you cool too fast, you can make new stress or cracks. Slow cooling keeps the metal strong and stable.

Let the part cool in still air at about 40°F (22°C) per minute until it gets to 1100°F (593°C).

From 1100°F (593°C) to 300°F (150°C), slow the cooling to 15°F–25°F (8°C–14°C) per minute.

Below 300°F (150°C), you can cool at any speed.

You often use a furnace or a special area for cooling. This is good for parts that might bend or crack. Slow cooling helps the metal stay strong and tough.

Remember: The right way to cool keeps your metal from bending and makes your stress relieving work better.

Benefits of Stress Relieving Process

Improved Ductility

You want metal parts to bend, not break. Induction stress relieving helps with this. The treatment makes metal softer and easier to shape. It changes how the grains in the metal line up. This makes the metal less likely to snap when bent. You also lower the chance of tiny cracks. These cracks can get bigger and cause problems later. Induction stress relieving annealing keeps steel parts strong and flexible.

Reduced Internal Stresses

Welding, cutting, or shaping metal adds stress inside. If you leave this stress, parts might twist or break. Induction stress relieving removes these hidden forces. You heat the metal just right with induction. This lets the metal relax and become stable again. Your parts keep their shape and size after heavy use. Reducing stress helps you avoid expensive repairs.

Enhanced Performance

You want metal parts to last longer and work better. Induction treatment helps you do this. It boosts how long your parts can handle repeated use. Fatigue means metal gets weaker over time. The right induction process can raise the fatigue limit by about 50% for notched parts. Look at the table below to see how this works:

Induction also helps parts keep their size after many cycles. You save energy because induction is up to 90% efficient. Old furnace methods only reach 40% to 60%. Induction heats only the part you need, so you waste less energy. Canroon’s services use precise induction equipment. You get fast, accurate, and repeatable results every time.

Tip: Induction stress relieving is best when you need high precision and want to save energy.

Best Practices

Equipment Choice

You must pick the right induction equipment for your job. The right equipment helps you heat metal evenly. This gives you better results. Check the table below to see what matters for big metal parts:

Think about coil design too. Multi-turn coils heat parts more evenly. Use shields or field concentrators to send energy where you want it.

Process Control

You need to control the induction heat treatment process. This helps you get the best results. Important things to watch are:

Use tools like thermal cameras or temperature controllers. These help you keep the temperature steady. Always write down your process steps. Keep records of temperature, time, and settings. This helps you do the same thing next time and find problems early.

Tip: Heating too fast can make small grains but may cause stress. Control your heating speed to keep parts the right size.

Common Issues

You might have problems during induction stress relieving. Cracking happens a lot, especially with steel. If you see cracks, check the carbon level and coil setup. Watch for different types of stress. These can cause cracks under the surface or make parts weaker.

If you see uneven heating, check the coil and power supply. Use the same materials and pre-heat hard spots. Watch the temperature with cameras. Change old coils if needed.

Take care of your equipment. Clean coils after each use. Check the cooling system and airflow. Flush water paths every six months. Store your heater in a dry place to keep out dust and water.

Good care and careful watching help you avoid mistakes and keep your induction system working well.

You use induction stress relieving to help metal parts last longer. This process heats and cools metal in a careful way. It makes parts stronger and lowers the chance of cracks. Warping is less likely to happen, too. In cars, induction helps axle shafts handle more stress. In planes, it makes parts harder and keeps their shape better, as shown below:

This method is also clean, safe, and quick. Induction lets you use machines and start right away. You can control the process very well. Canroon gives you smart induction systems, tips for care, and real stories from users. To learn more, look at Canroon’s guides or ask their team for help with your next job.

FAQ

What metals can you use induction stress relieving on?

You can use induction stress relieving on steel, stainless steel, and some other alloys. Most metals that conduct electricity work well. Always check your metal type before starting.

How fast does induction stress relieving work?

Induction stress relieving works much faster than furnace methods. You can finish many jobs in minutes instead of hours. The exact time depends on the size and type of your part.

Does induction stress relieving change the shape of my part?

Induction heats only the area you need. This helps your part keep its shape and size. You see less warping or bending compared to other heating methods.

What safety steps should you follow during induction stress relieving?

Wear gloves and safety glasses.

Keep your work area clean.

Check all equipment before use.

Watch the temperature closely.

Can you use induction stress relieving on welded parts?

Yes, you can use induction stress relieving on welded parts. This process helps remove stress from the weld and the area around it. Your welded parts become stronger and last longer.

Sign up for updates