When you choose an induction heater for forging, look at some important things. You should check the coil design, coupling efficiency, your shop setup, any special heating needs, and how skilled the manufacturer is. Here’s a quick guide:

If you pick the right induction heater for your forging, your shop can be safer. You can work faster and make better products. Studies show that good temperature control lowers risks. Even heating saves energy and makes your work quicker. Brands like Canroon are known for good induction heating. Before you look at the details, think about what your project really needs.

Key Takeaways

Know what you need for forging. Different jobs and materials need different ways to heat and different settings.

Pick the right coil shape for your part. The right coil helps heat things evenly and saves energy.

Think about how big and strong the induction heater is. Big parts need more power. Small parts get hot faster with less power.

Make sure your induction heater has good safety features. Look for things like heat protection, emergency stops, and ways to keep workers safe.

Set up your workspace with care. Make sure you have enough room, a good power source, and a cooling system that works well.

Forging Application

Before you pick an induction heater for forging, you need to know what you want to make. Every forging project is different. You might work in aerospace, automotive, or even medical fields. Each industry has its own needs. Here’s a quick look at where people use induction heating for forging:

Material Type

You need to know what metal you plan to forge. Different metals heat up in different ways. Some common choices include:

Tip: Always match your induction heater for forging to the metal you use. This helps you get the right heat and avoid damage.

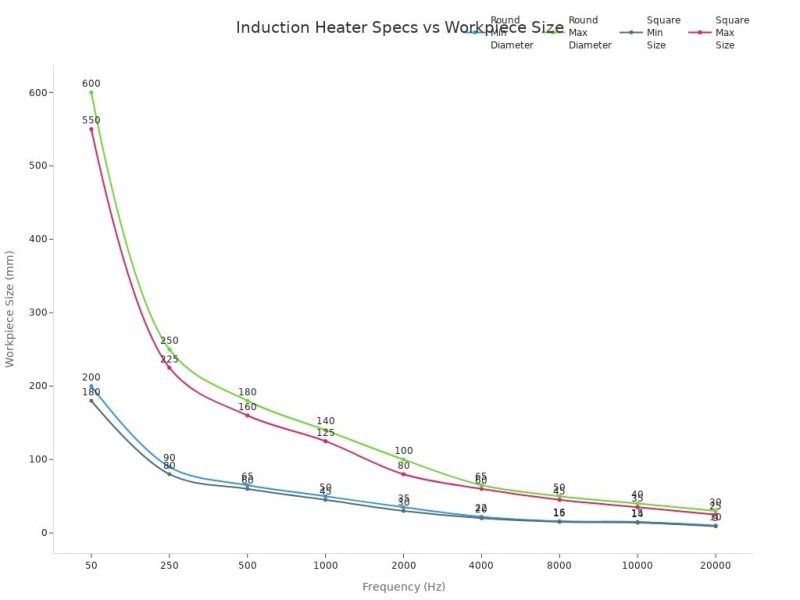

Workpiece Size

The size and shape of your workpiece matter a lot. Bigger parts need more power and lower frequency. Smaller parts heat up faster with higher frequency. Here’s a handy table to help you choose:

Heating Depth

You also need to think about how deep you want the heat to go. If you need to heat deep inside the metal, you need more power and a lower frequency. For just heating the surface, use less power and a higher frequency.

Choosing the right induction heater for forging means looking at your metal, your part size, and how deep you want the heat. When you match these, you get better results and save energy.

Induction Heater for Forging: Key Specs

When you look for the right induction heater for forging, you need to focus on three main specs: power output, coil size, and frequency. These specs decide how well your heater works for your project. If you match these specs to your needs, you get better results, save energy, and avoid problems. Canroon offers many options and can help you pick the best setup for your shop.

Power Output

Power output tells you how strong your induction heater for forging is. If you work with small parts, you do not need much power. If you handle big or heavy pieces, you need more power to heat them up fast and evenly. Here is a quick guide to help you see what power range fits your job:

You want enough power to reach the right temperature without wasting energy. Too little power means slow heating. Too much power can damage your parts. Canroon can help you choose the right power for your forging needs.

Tip: Always check your workpiece size and how many parts you want to heat at once. This helps you pick the right power output.

Coil Size

The coil is the part that wraps around or sits near your metal. Its size and shape change how well your induction heater for forging works. If you use the wrong coil, you might get uneven heating or waste energy. Here is a table that shows how different coil types affect heating:

If you want even heat, pick a coil that matches your part’s shape. Oval coils work well for round or column-shaped pieces. Rectangular coils are good for special shapes or 3D printed parts. Canroon can design custom coils to fit your needs.

Note: The right coil saves energy and gives you better results. Ask for help if you are not sure which coil to use.

Frequency

Frequency is how fast the magnetic field changes in your induction heater for forging. It controls how deep the heat goes into your metal. If you use high frequency, you heat the surface. If you use low frequency, you heat deeper inside. Here is a table to help you pick the right frequency:

If you work with small parts, use a higher frequency for quick, surface heating. For big parts, use a lower frequency to heat all the way through. Canroon’s team can help you set the right frequency for your job.

Pro Tip: Always match the frequency to your part size and the depth you want to heat. This gives you the best results and saves energy.

Why Specs Matter

When you pick the right specs, you get many benefits:

If you want a reliable induction heater for forging, always check these specs. Canroon can help you find a system that fits your needs, whether you work with small, medium, or large parts.

Facility Needs

When you set up an induction heater for forging, you need to think about your facility. The right setup helps you work safely and efficiently. Let’s look at three important things: space, power supply, and cooling system.

Space

First, check your workspace. You want enough room for the heater, the coil, and your workpieces. Make sure you have space to move around safely. If your shop feels crowded, you might need to rearrange equipment. Some induction heaters come in compact designs, but larger systems need more floor space. Always plan for extra room so you can load and unload parts without trouble.

Tip: Leave space for maintenance and future upgrades. You never know when you might need to add new tools or change your setup.

Power Supply

Next, look at your power supply. Induction heaters use a lot of electricity, especially in forging shops. Most systems need a strong, stable power source. Here are some things you should check:

Standard power use for induction heating in forging is about 400-450 kWh per ton of metal.

High-frequency systems work well for surface heating, like brazing.

Low-frequency systems heat deeper, which is better for forging.

The power you need depends on your material, how deep you want to heat, the frequency, and your coil design.

If your shop’s power supply is not strong enough, you might see slow heating or even system shutdowns. Talk to your electrician before you install a new system.

Cooling System

Induction heaters get hot fast. You need a good cooling system to keep everything running. Most shops use water cooling. Some smaller units use air cooling, but water works better for big jobs. Make sure your cooling system matches the size and power of your heater. If your cooling is too weak, your equipment could overheat and break down.

A reliable cooling system keeps your induction heater for forging safe and helps it last longer.

If you plan your space, power, and cooling needs, you set yourself up for success. You avoid downtime and keep your forging process smooth.

Safety and Features

Safety Controls

You want your forging shop to be safe. Modern induction heaters have many safety controls built in. These features help protect you, your team, and your machines. Here is a table that shows what to look for:

Tip: Always make sure your induction heater for forging has these safety features before you buy it.

Automation

Automation makes your job easier and safer. The system can do hard jobs and keep things working well. Here is how automation helps you:

Workers do fewer jobs by hand.

There are fewer mistakes from people.

Each part is the same, so accidents happen less.

The system can change power, frequency, and time by itself.

Sensors check heat and magnetic fields for perfect heating.

The whole process is tracked, so you waste less material.

Automated systems let you set the exact heat you need. You can watch the heating as it happens. This helps you find problems early and keep your shop running well.

Efficiency

You want to save energy and money. Induction heating systems do this better than old ways. They heat metal right away, so almost no energy is wasted. Here are some reasons why these systems work so well:

Induction heaters can be up to 90% efficient.

Most electricity turns into heat, not waste.

You pay less for power over time.

These systems help the earth by making less pollution.

You control the heat exactly, so your parts are better.

Less risk of dirt means your products are higher quality.

If you pick an efficient system, you get more work done, save money, and help the planet.

Support and Service

Choosing the right induction heater for forging is not just about the machine. You also want great support and service from the brand you pick. Good support helps you solve problems fast and keeps your shop running smoothly. Let’s look at what you should check before you buy.

Brand Reputation

A strong brand reputation means you can trust the company to help you when you need it. Top brands offer more than just equipment. They give you expert advice, training, and even help you set up your system. Here’s what leading companies usually provide:

Canroon stands out for its customer service and custom solutions. You can ask for special coil designs, touchscreen controls, or even help with handling tricky materials.

Maintenance

You want your induction heater to last a long time. Regular maintenance makes a big difference. Here are some simple steps you can follow:

Inspect and clean your machine often.

Check the cooling system and keep coolant at the right level.

Make sure the coil is lined up and the machine is calibrated.

Lubricate moving parts to stop wear.

Write down all maintenance work for future reference.

If you keep up with these tasks, you avoid big repairs and keep your forging process smooth.

Warranty

A good warranty gives you peace of mind. Most brands offer at least a one-year warranty, but some go up to three years for high-end models. Here’s a quick look at what you might get:

Some companies, like Canroon, also offer lifetime maintenance after the warranty. Always ask about the details before you buy.

Tip: Look for brands that offer training and fast support. This helps you get the most from your induction heater for forging.

Budget and Options

When you look at your budget for a new forging setup, you have a few choices. You can buy a brand-new machine or pick a used one. Each option has its own pros and cons.

New vs. Used

You might wonder if you should buy a new or used induction heater. Used machines can save you money up front. Prices for used induction heaters usually range from $10,000 to $200,000, depending on the model and features. If you want something smaller, a new 15Kw induction forge costs about $2,950, while a 25Kw model is around $4,495. New machines often come with better warranties and the latest safety features. Used equipment may need more repairs, but it can be a smart choice if you have a tight budget.

Tip: Always check the condition and service history before buying used equipment.

Cost-Saving Tips

You can save money in more ways than just the purchase price. Here are some smart tips:

Induction heating systems have fewer moving parts, so you spend less on maintenance.

The precision of induction heating means you waste less material and create less scrap.

Even if the initial cost seems high, you save money over time with lower energy bills and better efficiency.

If you plan ahead and keep your system in good shape, you will see savings add up year after year.

Value

You want the best value for your money. To find it, look at more than just the price tag. Ask yourself these questions:

Does the machine have enough heating power for your jobs?

How efficient is the heating process? Will it help you save on energy?

Is the frequency right for the size and type of metal you work with?

Frequency matters a lot. Higher frequencies heat the surface, while lower ones go deeper—this is important for larger pieces. When you compare models, think about how these features match your needs. The right induction heater for forging gives you strong performance, saves you money, and fits your shop perfectly.

You want your forging shop to work well. First, look at power, frequency, and the material you use. Think about the shape of your workpiece and how you will cool things down. Safety and efficiency are very important. Induction heating works quickly and gives the same results every time. It also helps keep your team safe. Good support means your shop will not stop working often. This can help you save money in the long run. If you need help, you can ask Canroon for advice or a demo. Pick an induction heater for forging that matches what you need. This will help your shop do well for many years.

FAQ

What size induction heater do I need for forging?

You should match the heater size to your workpiece. Bigger parts need more power. Smaller pieces heat up faster with less power. If you’re unsure, ask a supplier for advice.

Can I use one induction heater for different metals?

Yes, you can. You just need to adjust the power and frequency settings. Some metals heat up faster than others. Always check the specs before you start.

How often should I maintain my induction heater?

You should inspect and clean your heater every month. Check the cooling system and coils. Regular maintenance helps your machine last longer and work better.

Is induction heating safe for my shop?

Induction heating is safe if you follow safety rules. Look for heaters with thermal protection, emergency stops, and shields. Train your team and keep the workspace clear.

Previous:

Next:

Sign up for updates