You can operate an induction bolt heater effectively by following clear steps. Always put safety first. Wear the right protective gear and work in a clean area. Check that you set up the machine according to the manufacturer’s instructions. Make sure you use the right coil and keep an eye on the heating process. This approach helps you avoid accidents and get the best results every time.

Key Takeaways

Always put safety first by wearing the right gear. Wear gloves and safety goggles to stop injuries.

Keep your workspace neat and tidy to lower accident risks. This also helps you work better.

Pick the right coil for your bolt size and type. This helps you heat bolts well and keeps your tools safe.

Check and take care of your induction heater often. This stops problems and helps it last longer.

Use Canroon's help resources if you have trouble or need help. This keeps your work safe and works well.

Induction Bolt Heater Safety

Personal Protective Equipment

You need to wear the right personal protective equipment before you use an induction bolt heater. This gear keeps you safe from burns and flying pieces. It also protects you from other dangers. The table below lists the main types of protective equipment and what they do:

You should always wear gloves and safety goggles. If you work with big bolts or high heat, you may need a full thermal-resistant suit and a face shield. Do not skip this step, even if the job is quick.

Workspace Setup

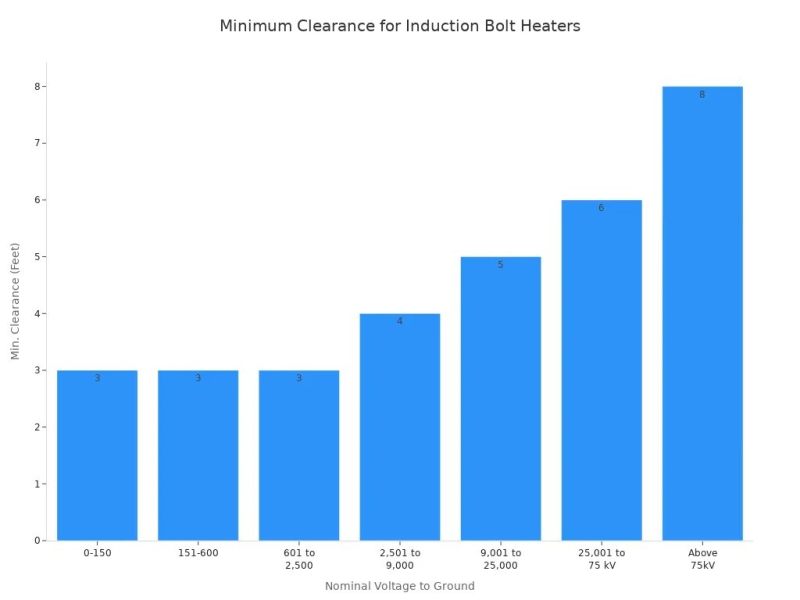

A clean and tidy workspace helps stop accidents. You need enough room around the induction bolt heater to move safely. Industry rules say you must have a certain amount of space, depending on the voltage. The chart below shows the least amount of space you need for different voltages:

Keep the area clear of mess and things that can catch fire. Make sure you unplug the heater before you put in or change the coil. Always follow the manufacturer’s rules for safe use.

Electrical Safety

Induction bolt heaters use high-voltage power. This can shock you or even cause electrocution if you do not follow safety rules. You must check all cables and connections before you turn on the machine. Regular checks and good insulation help stop accidents. Different places have their own electrical safety rules. For example, North America uses UL and CSA rules. Europe uses EN 60335-2-6. These rules focus on electrical safety, emergency stops, and safe ways to start and stop the machine.

Tip: Always watch the heating process. If you see sparks, smoke, or hear odd sounds, stop the machine right away and check for problems.

Proper training is important too. You should know how to use the operator terminal, fix problems, and follow all safety steps. This helps you stay safe and keeps your equipment working well.

Operation Steps

Preparation

You need to get the induction bolt heater ready before you start. Getting ready helps you avoid mistakes and keeps you safe. Follow these steps to use it the right way:

Clean the induction heating coils after you use them. Dirt or trash can make the heater work badly.

Check if the coil lines up with the bolt. Good setup stops uneven heating.

Look at the cooling system. Make sure water moves well and the control panel is tight.

Get all your safety gear. Put on gloves, safety goggles, and heat-resistant clothes.

Check the workspace. Take away things that can burn or block your way.

Tip: Keeping your area clean and neat helps you do things right and lowers the chance of accidents.

Coil Installation

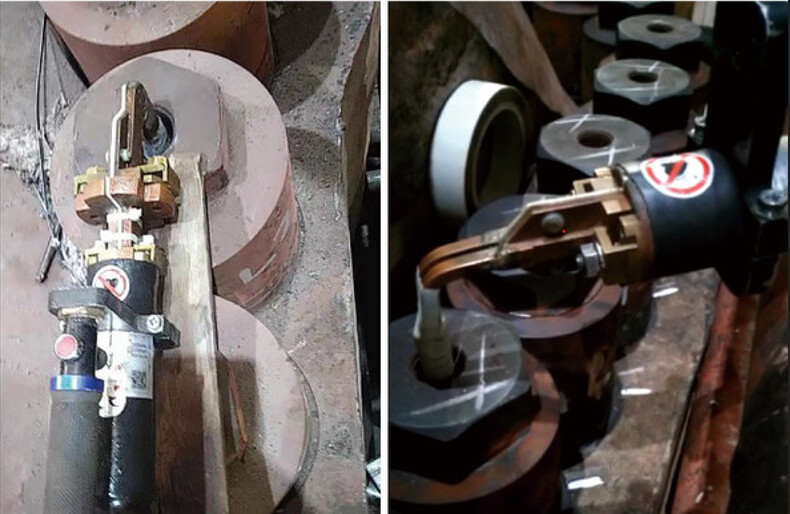

Putting in the induction heating coils is very important for safe use. You need to follow these steps to stay safe and work well:

Pick a coil that fits around the bolt with a small space. The coil should not touch the bolt.

Turn off and unplug the induction bolt heater before you put in the coil.

Open the coil ports by turning the twist-lock or loosening thumb screws. This depends on your model.

Push the coil all the way into the ports. Make sure it is tight.

Lock the coil so it does not move.

Make sure the coil does not touch the bolt. A close fit works better but stops damage.

Always wear safety glasses when you put in the coil.

Do not use the induction bolt heater if the coil is not locked.

Note: A coil that fits close (but does not touch) gives you the best results. Big bolts may need more time to heat.

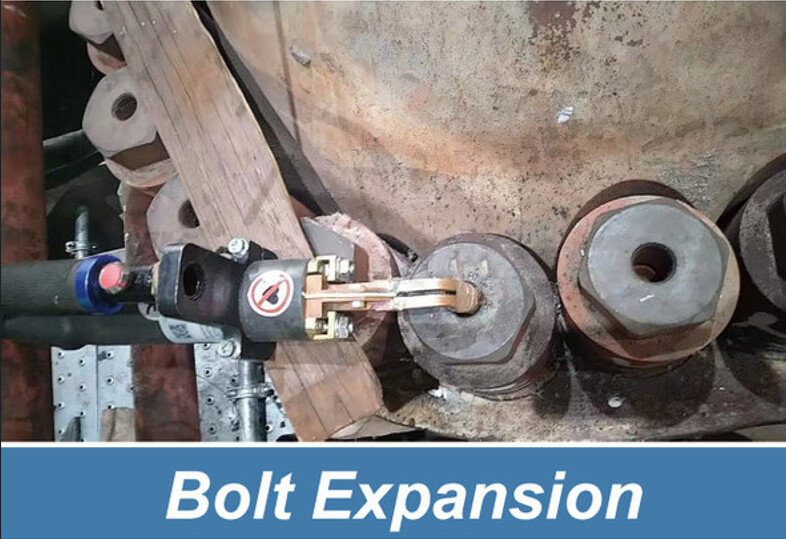

Induction Heating Process

Now you can start heating with the induction bolt heater. You need to pay close attention to each step:

Set the power and time on the control panel for the bolt size and material.

Start the induction bolt heater and watch it carefully.

Check the coil terminals for voltage and current signals. This shows if the coil energy is right.

Use signature monitoring if your machine has it. This saves each cycle and helps you find problems.

Watch key things like power and timing. This makes sure the bolt heats evenly and does not get hurt.

Tip: Always watch the bolt while it heats. If you see sparks, smoke, or hear weird sounds, stop the machine and check for trouble.

Shutdown

You need to turn off the induction bolt heater safely when you finish. Follow these steps:

Turn off the power with the control panel.

Unplug the machine from the wall.

Let the coil and bolt cool down before you touch them.

Take out the coil slowly. Clean it and look for damage.

Check the workspace and make sure it is safe before you leave.

Remember: Doing shutdown steps the right way keeps your equipment working well and helps stop accidents.

Equipment & Coil Choice

Coil Selection

You must pick the right coil for your induction heater. The coil should fit the bolt size and the job you need to do. Using the right coil helps you do a better job. It also helps your equipment last longer. The table below shows different coil types and what they do:

Tip: Clean your coils often and check them for damage. This helps your induction heater work well and last longer.

Induction Heating Compatibility

Induction heating works best on metals that carry electricity. Ferrous metals, like steel, heat up fast because they are magnetic. You can use induction heating on non-ferrous metals too. These include aluminum and copper. But these metals need more power and higher frequencies. The table below shows which metals work best:

When you choose an induction heater, think about the bolt size and metal type. Big bolts or bolts that need deep heating take more time. They may need a lower-frequency system. Small bolts or jobs that only need surface heat work better with higher-frequency systems.

Canroon Product Tips

Canroon induction heaters have features that help you work better. They heat up fast and protect plastics nearby. You get sound and light signals while using them. These heaters can save you a lot of work time. They also help the environment by using fewer chemicals. Here are some things to think about when picking your equipment:

Remember: Always check the power and accessories you need before starting. This helps you get the best results from your induction heating equipment.

Troubleshooting & Maintenance

Common Issues

Sometimes, you might have problems when using induction heating for bolts. If you know what to watch for, you can fix things faster. The table below shows common problems, why they happen, and how to fix them:

Tip: Always watch the heating process. If you see sparks or smoke, stop and check the machine.

Maintenance Checklist

Taking care of your induction heating system helps it work well. You should do these things:

Check if the furnace is clean every day.

Make sure all parts are tight and not loose.

Look for leaks or wet spots in the system.

Watch for signs of too much heat.

Check for broken or loose parts.

You can use this table to help plan your checks:

You spend less money and get more work done.

It also makes using induction heating safer for everyone.

Support Resources

If you need help with your induction heating machine, Canroon has many ways to help. You can find answers, get manuals, or ask for technical help. The table below shows where to look:

Canroon gives you an 18-month warranty from when they ship.

You can get repairs for normal use during the warranty.

After the warranty, you can pay for repairs for as long as you want.

You can call for help any time, and someone will answer fast.

Note: Call Canroon support if you cannot fix a problem or see damage while using induction heating. Quick help keeps you safe and your machine working.

You can operate an induction bolt heater safely and effectively by following each step with care. Always wear protective gear and choose the right coil for your job. Check your equipment often and keep your workspace clean. Regular maintenance helps prevent problems. For extra help, use Canroon’s support resources.

Quick Do’s and Don’ts:

✅ Make sure thermal tape stays intact.

✅ Monitor heating time and stop at smoking, not glowing.

❌ Do not use damaged parts or skip safety checks.

FAQ

How do you know which coil to use for your bolt?

You should match the coil size to your bolt. The coil should fit closely around the bolt without touching it. Check the manufacturer’s guide for the best coil type for your job.

What should you do if the heater does not turn on?

First, check the power supply and cables. Make sure you plug in the machine. Inspect the control panel for error messages. If you still have trouble, contact Canroon support.

Can you use an induction bolt heater on all metals?

You can use it on most metals. Ferrous metals like steel work best. Non-ferrous metals like aluminum need more power and higher frequencies. Always check your machine’s compatibility before starting.

How often should you clean the coils?

You should clean the coils after every use. Dirt or debris can cause poor heating and damage. Use a soft cloth and follow the manufacturer’s cleaning instructions.

Previous:

Next:

Sign up for updates