You can use a bearing heating machine safely by following safety steps. Focus on proper installation to work efficiently. Many bearing failures happen because people skip correct mounting or heating steps. Handle bearings with care to avoid problems. Use reliable brands like Canroon to lower the risk of damage. This helps your equipment last longer. Always put safety first to protect yourself and your tools.

Key Takeaways

Always wear safety gear like gloves and safety glasses. This helps protect you from burns and injuries.

Check the bearings and work area before you start. Clean and look at the bearings to stop damage when heating.

Watch the temperature closely. Heat most bearings to 80–110°C. This helps them fit right and not get damaged.

Follow the manufacturer's instructions for your bearing heating machine. This keeps you safe and helps the machine work well.

Keep bearings in a clean, dry place. This stops rust and damage. Handle them gently to keep them in good shape.

Bearing Heating Machine Basics

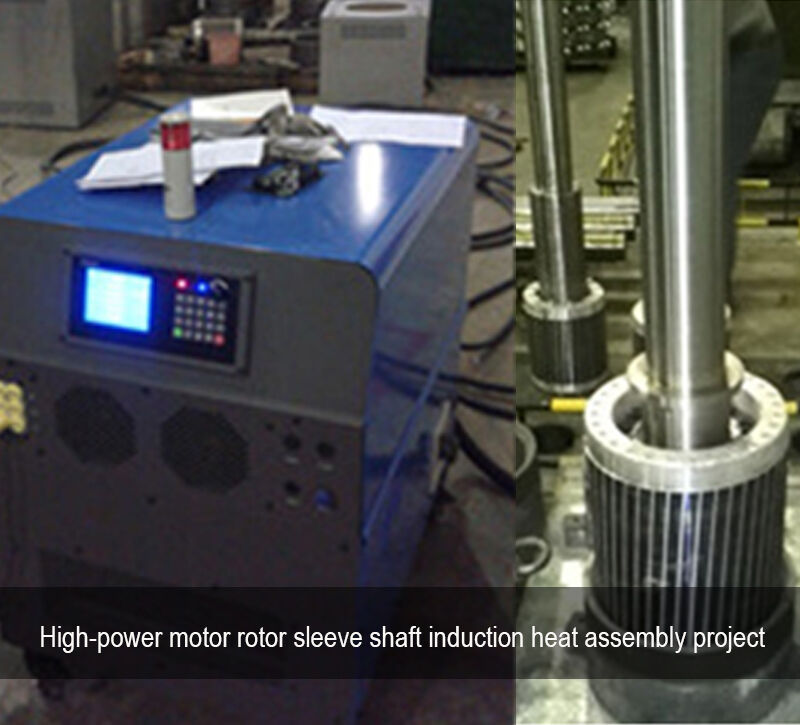

What Is a Bearing Heating Machine

A bearing heating machine helps put bearings, couplings, and gears in place. It makes these metal parts get bigger by heating them up. You use the machine to warm the parts before putting them on shafts. The machine heats the bearing from inside using electromagnetic induction. This way is quicker and safer than using ovens or oil baths. You can set the heat and time with a control panel. The main parts are the induction coil or yoke, control panel, temperature sensors, and demagnetization circuit. The coil makes a magnetic field that heats the bearing. The temperature probe checks the heat so you do not overheat it. The demagnetization circuit takes away any magnetism left after heating.

Tip: A bearing heating machine helps keep things clean because you do not need oil or fire.

Why Proper Use Matters

If you use a bearing heating machine the wrong way, you can break the bearing or the equipment. Not handling or mounting it right can make bearings stop working early. Using too much force or heat can cause damage and cost more to fix. Bad assembly and wrong lubrication can also hurt the bearing. Induction heating helps avoid these problems. You can control the heat well, so the bearing gets just big enough to fit. This keeps the bearing clean and safe from burns or fire.

Here is a quick comparison of induction heating and traditional methods:

Always follow the instructions for your bearing heating machine. This helps you avoid mistakes and keeps your equipment working longer.

Safe Operation Steps

Pre-Inspection and Setup

Check the bearings and your work area before you start. This helps you avoid mistakes and keeps things safe. Here are the steps:

Look at the bearings and write down how they look. See if there is any old lubricant and check its condition.

Clean the bearings with light oil or kerosene. First, do a simple clean, then rinse them well.

Check the bearing raceways and outside parts. Look for cage wear, changes inside, or any damage.

Decide if you can use the bearing again or need a new one.

Store bearings flat, dry, and clean. Do not keep them in wet or dirty places.

Keep bearings away from vibration so they do not get damaged.

Never drop bearings or use the wrong tools to put them on.

Tip: Always wear gloves and safety glasses when you check and set up. This keeps your hands and eyes safe from sharp edges and chemicals.

Operating the Bearing Heating Machine

You need to follow the right steps to stay safe and get good results. Here is what you should do:

Read and follow the instructions from the maker. Each machine may have special steps.

Make sure your work area is clean and has nothing that can catch fire.

Check that the machine is off and not plugged in before you set up.

Put the bearing on the induction coil or yoke. Do not take off crossbars or yokes while it is running.

Use the safety features on the machine, like over-temperature protection and automatic shut-off.

Start the machine and watch the temperature display. New machines, like Canroon, have digital controls and safety alarms.

Do not touch the bearing or coil while the machine is working. Stay a safe distance away.

Note: Canroon bearing heating machines have good safety features, like automatic temperature control and degaussing, to help you stay safe.

Temperature Control and Monitoring

It is very important to control the temperature when you use a bearing heating machine. If you heat the bearing too much, it can get damaged. If you do not heat it enough, it may not fit right.

You can use different tools to check the temperature:

You can also use infrared thermometers or digital displays on the heater. Adjustable thermostats help stop overheating.

Here are safe temperature ranges for different bearings:

Callout: Always watch the temperature closely. Controlled heating helps the bearing get bigger evenly and keeps the lubricant safe.

Bearing Installation

After you heat the bearing, you need to put it on quickly and carefully. Follow these steps to avoid damage:

Use hot mounting to make the inner ring bigger. This helps it fit on the shaft.

Never use a blowtorch or open flame. This can change the metal and make the bearing last less time.

Make sure the bearing heats evenly. If it does not, it can crack or get stressed.

Keep the highest heating temperature at 130°C for most bearings. For many types, 80–110°C is enough.

Use induction heating for the best results. This way gives you control and safety.

Slide the bearing onto the shaft smoothly. Do not use force or hit it with tools.

Let the bearing cool down on its own after you put it on.

Safety Tip: Using the right tools and ways stops misalignment and early failure. Most bearing failures happen because of bad installation, so go slow and follow each step.

Canroon bearing heating machines help you do these steps with built-in safety and control features. You can trust their machines to work safely and well every time.

Safety Precautions

Personal Protective Equipment

You need to wear the right safety gear when using a bearing heating machine. This helps keep you safe from burns and other injuries. Always put on gloves before you touch hot bearings. Gloves keep your hands safe from heat after heating. You should also wear safety glasses to protect your eyes from sparks or flying pieces. If you are near a hot oven, keep all your safety gear on the whole time.

Wear gloves that can handle heat when touching hot bearings.

Use safety glasses to keep your eyes safe.

Wear special clothes if you are close to the machine.

Tip: Never forget your safety gear, even for short jobs. Hot metal can burn you very fast.

Machine Safety Checks

Check the machine and your work area before you begin. A safe setup helps stop accidents from happening. Use this table to help you remember what to check:

You should also:

Make sure nothing that can catch fire is in the area.

Keep a fire extinguisher close by.

Turn off and unplug the machine before you set it up.

Use the right tools to move hot bearings.

Open windows or vents if you see smoke or smell fumes.

Callout: Always watch the temperature. Use the right heat so you do not damage anything.

Emergency Procedures

You must act fast if something goes wrong. Too much heat or a broken machine can be dangerous. Watch for strange heat in the motor, cabinet, or bearing housing. This could mean there is friction, not enough oil, or too much weight.

Always practice what to do in an emergency. If the machine stops working, you need to know how to stay safe.

If you see overheating:

Stop the process right away.

Check the temperature as soon as you can.

Lower the load if you are able.

Look at the lubrication and fix any problems.

Stay calm and follow your emergency plan. Quick action can stop injuries and save your equipment.

Efficiency Tips

Choosing the Right Machine

Pick the right machine for your job. The bearing’s size and type are important. If the machine is too small, it will not heat well. If it is too big, it wastes power. Canroon has many machines for different bearings. You can find one that fits your work and saves time.

The bearings you pick change how much energy you use and how long heating takes. This is because of friction, lubrication, and how the machine works. Picking the right bearing helps stop too much heat and makes things work better.

The lubricant you use changes how hot things get.

Lubricant thickness helps keep things working well.

The room’s temperature changes how heat moves in the system.

Maintenance and Calibration

Take care of your bearing heating machine. Check it often to find problems early. Do these steps:

Look at the machine every week for wear or noise.

Oil moving parts each month to stop friction.

Check if things line up every three months.

Test for shaking twice a year to find problems.

Change bearings if you see damage.

Use the right oil and do not use too much. For grease, add more based on how much you use the machine. For oil, check if it is clean and thick enough.

Pre-Heating Inspection

Check the bearing before you heat it. Look for rust, dirt, or damage. Make sure it is clean and dry. Check the box for wet spots. If you see problems, do not use the bearing. This step helps stop damage when you heat or install it.

Bearing Storage and Handling

Keep bearings in their box in a clean, dry place. Do not let them get too hot or wet. Store them flat so they do not bend. Use shelves, not the floor. Always wear gloves and never drop or hit bearings. Keep them closed until you need them. Use older bearings first. Check stored bearings for rust or damage often.

Tip: Storing and handling bearings the right way keeps them ready to use.

Canroon’s products help you follow these tips. This helps you work safely and get good results every time.

You can use a bearing heating machine safely if you follow each step. Be careful and do not rush. Always look at your equipment before you start. Wear your safety gear every time. Watch the temperature so it does not get too hot. Keep your bearings in the right place. Take care of your machine often so it works well.

Quick-Reference Checklist:

Check the bearings and the machine first

Put on gloves and safety glasses

Pick the right temperature

Use tools that fit the job

Store bearings in a safe spot

Remember: Being safe and working well keeps you and your equipment safe. Canroon makes good machines to help you do your work with trust.

FAQ

How hot should you heat a bearing?

You should heat most bearings to 80–110°C. Do not go over 130°C unless the maker says it is safe. Always check the temperature with a sensor.

Can you reuse a bearing after heating?

You can reuse a bearing if it shows no damage or wear. Clean and inspect it before heating again. Replace it if you see cracks or rust.

What safety gear do you need?

Heat-resistant gloves

Safety glasses

Protective clothing

These items protect you from burns and flying debris.

Why does induction heating work best?

Induction heating gives you fast, even heat. You control the temperature easily. This method keeps bearings clean and safe from fire.

Previous:

Next:

Sign up for updates