You want to pick the right induction brazing generators for your business. Choosing the right equipment helps you get better results. Studies show that the right choice makes things work better. It also lowers mistakes and saves money.

Induction technology helps you put things together faster. It is safer and more steady than old ways.

Key Takeaways

Pick the best induction brazing generator to work better and save money. Induction brazing works faster and is safer than old ways. It does not use open flames. Think about what materials you use and how much you need to make when picking a generator. Make sure your workspace is big enough for the generator. Your workspace should also have the right setup. Keep the generator in good shape with regular care. Good help from your supplier is important for the best results.

Benefits of Induction Brazing Generators

Efficiency and Precision

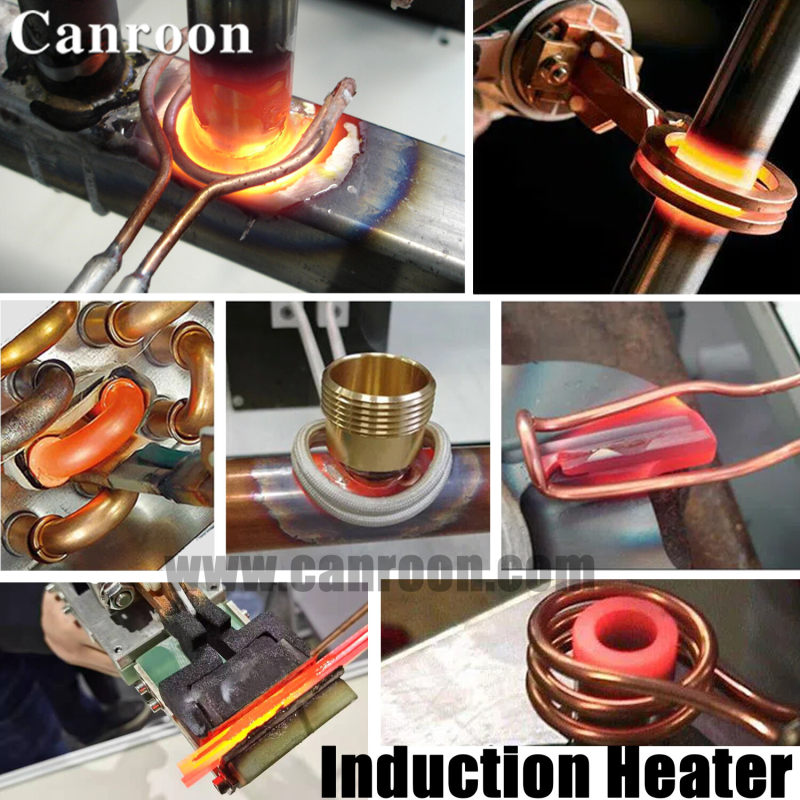

Induction brazing generators work fast and accurately. Induction heating gets metals hot in just seconds. Copper and other metals heat up quickly. You do not have to wait long for them. Energy is used only during the heating cycle. This helps save power. You can set up machines to braze many joints at once. Induction brazing lets you control the process. You can use preset heating plans. Even new workers can get good results. You just put the coil in place and press a button. This makes your job quicker and more dependable. Industries like heat pump and refrigeration need exact heat for strong joints. Induction brazing generators help you get that exact heat every time.

Safety and Clean Operation

Induction heating makes your workspace safer and cleaner. There are no open flames or hot surfaces. This lowers the chance of burns or fire. Only the part you want to braze gets hot. The rest of your work area stays cool and safe. Induction brazing cuts down on smoke and fumes. You do not have to worry about bad gases or messy leftovers. Your team works in a cleaner place. This helps everyone stay healthy.

Tip: Induction heating systems often have safety features. These include automatic shut-off and temperature controls. These features protect your staff and equipment.

Cost and Energy Savings

Induction brazing generators help you spend less money. Induction heating uses energy very well. Only the metal you need gets hot. This means you do not waste energy. In big factories, this saves a lot of money. Local heating means less heat escapes into the room. Your energy bills stay low and your workspace stays cooler. Some studies show induction heating can cut energy use by half compared to older ways. Over time, these savings help your business grow.

Assessing Application Needs

Material and Joint Compatibility

You need to check what your part is made of first. Not every metal heats up the same way with induction heating. Some metals get hot quickly. Others take longer to heat up. You should pick a generator that works well with your metal. This helps you get the best results.

Here is a table that lists materials that work well with induction brazing generators:

Induction heating can be used for many types of metals. Steel and copper are used a lot. Aluminum is used in cars because it is light. Filler metals melt at lower temperatures than the main metal. These help make strong joints. Some metals react too much and may not work well with induction. If a metal has many different elements, it can be harder to braze. Metals that make a strong oxide layer can stop the bond from forming well.

The way the joint is made is important too. The shape and size of the joint change how the coil works. You need a coil that fits your joint. This keeps the heat even and strong. If your joint is tricky, you might need a special coil. This makes sure the heat goes to the right spot. You can change the coil for different shapes and sizes. This helps you get the best joint every time.

Note: Always check what kind of heating you need for each material and joint. This helps you avoid mistakes and get strong, clean joints.

Production Scale and Complexity

Think about how many parts you need to braze each day. If you have a small shop, you might only need a simple generator. If you have a big factory, you need a generator that can handle lots of parts. How hard your process is also matters.

Here is a table that shows how process complexity affects your choice:

If your process has many steps or uses special shapes, you need a better generator. Advanced models help you control the heat better. They also help you save time and money. You do not want to guess or keep trying different ways. Advanced generators use computer programs to get the heat just right. This means you get better results and finish faster.

Tip: Pick an induction heating system that matches your production needs. This helps you avoid delays and keeps your work going smoothly.

Key Features of Induction Brazing Generators

Power and Frequency Selection

You have to pick the right power and frequency. Power decides how fast and deep things get hot. Induction brazing uses frequencies from 15 to 300 kHz. Match the frequency to your metal, depth, and thickness. High frequency heats only the surface. Low frequency heats deeper inside. This helps you control heating and make strong joints.

Your induction power supply must stay steady. If voltage or frequency changes a lot, heating gets uneven. Uneven heating can hurt your equipment or make bad joints. A steady power supply keeps things safe and reliable.

Steady voltage helps your heating and control work well.

Steady frequency gives you even heating and better joints.

Think about your business needs before you choose. Thick metals need more power and lower frequency. Small parts need less power and higher frequency. Matching these features saves energy and gives better results.

Tip: Always check power and frequency before starting. This helps you avoid mistakes and keeps things running well.

Coil Design Essentials

The coil is the most important part of your system. You need a coil that fits your part and process. The coil design affects heating and energy use. Good coil design gives even heating and strong joints.

Here is a table with key coil design features:

The coil’s shape changes how the magnetic field heats your part. If the coil is too far, you waste energy. If it is too close, arcing can happen. You need the right space for safe heating. High-purity copper is best for coils because it conducts well. Cooling the coil keeps it working and stops damage.

Here is another table showing how coil design affects energy and results:

Work with experts to design your coil. This helps you avoid mistakes and get the best results.

Automation and Safety

Automation makes brazing faster and safer. You can use tools like brazing pistols to hold parts and coils. These tools protect your hands and make work easier. Custom inductors and power units help you work faster and with less effort.

Induction brazing is safer than older ways. No open flames are needed.

Automation saves energy and cuts downtime.

Worker safety gets better with automated tools.

Modern generators have many safety features. These keep you and your equipment safe every day. Here is a table with common safety features:

Always check that your generator has these safety features. This keeps your team safe and your process smooth.

Note: Automation and safety features help you get better results and protect your investment. Pick generators that fit your business and keep your workplace safe.

Practical Considerations for Your Facility

Space and Infrastructure

Check your workspace before you set up an induction brazing generator. The size of the generator is important. Some generators are bigger than others. Measure your space and compare it to the generator’s size. Make sure there is enough room to use the generator safely. You also need space to get to the generator easily.

Your building must have the right power and cooling for induction heating systems. You need a steady power supply. Cooling water systems help the generator work well. Clean water stops clogs and keeps heating strong. Good airflow helps control heat and keeps your workspace nice.

Tip: Plan your workspace so you can move parts without trouble. Leave room for fixing and checking the generator. This helps you meet your heating needs and keeps things safe.

Maintenance and Support

Doing regular maintenance keeps your induction brazing generator in good shape. Follow what the manufacturer says for cleaning and checking. Some common problems are broken coaxial transformers, clogged units, water drops inside, and bad cable handling. You can see these problems in the table below:

You can stop many problems by cleaning filters and changing water often. Handle cables gently. Watch for water drops and keep water at the right temperature.

Manufacturers can help you with maintenance and support. You can get expert advice, training classes, and help at your site. Many companies help you make better processes and start up your equipment. You can also get help with inductor design and fixing. Spare parts are ready when you need them. Here is a table that shows common support services:

Note: Pick a supplier that gives good support and training. This helps your induction heating system work well and lowers downtime.

Supplier Evaluation and Canroon Advantage

Picking the right supplier is very important for your success. You need a partner who gives more than just machines. Look for good help after you buy, expert training, and technical support. These things help you use your induction heating system well and safely.

Technical Support and Training

Check if your supplier gives training and support. Good suppliers have online courses about induction heating. These classes teach you how heating works and how to use it safely. Some suppliers also give personal lessons. You can learn how to set up, use, and take care of your equipment. Training helps you avoid mistakes and get better results.

Tip: Training helps your team work safely and quickly. It also lowers downtime and makes your products better.

Here is a table to help you check suppliers:

Induction Heating System Integration

You want your induction heating system to fit into your production line easily. Modern induction machines work with both automatic and semi-automatic setups. You can pick hand-feed or full automation. Automation makes your work faster and keeps quality high.

Induction heating systems use settings you can program and watch in real time. These features help you control heating exactly. You get faster heating, less waste, and better results. This matters if you want to grow your business or meet strict rules.

Canroon is a supplier that stands out. You get custom solutions for your induction needs. Canroon gives expert help, training, and system setup. You can trust Canroon to help you reach your production goals.

Decision Checklist for Induction Brazing Generators

Step-by-Step Selection Guide

You want to make the right choice for your business. Use this guide to help you pick the best induction brazing generators for your needs.

Identify the metals and joints you need to braze. Write down the types and sizes.

Decide how many parts you want to process each day. This helps you choose the right size and power.

Check the power and frequency settings. Make sure they match your materials and production goals.

Look at coil design. Ask if you need a custom coil for your parts.

Review safety and automation features. These keep your team safe and make work easier.

Measure your workspace. Confirm you have enough room for the generator and cooling systems.

Plan for regular maintenance. Ask about support and training from the supplier.

Think about how the induction heating system will fit into your production line.

Tip: Write down your answers for each step. This helps you compare different options and see which generator fits your needs.

Final Review Points

Before you buy, check these important points. You want to make sure your choice is smart and safe.

Check the design of the induction brazing machine. Make sure it matches your process.

Ensure the machine fits within your budget.

Conduct a thorough inspection and review of previous products from the supplier.

Consider the shipping options to your location.

Look into aftercare services provided by the manufacturer.

Verify the warranty offered by the manufacturer.

Note: Careful review helps you avoid problems and get the best results from your induction brazing generators. Take your time and ask questions if you need help.

If you follow each step in the guide, you can make a good choice. A checklist helps you remember important things. This keeps your induction brazing process safe and working well. You will get better results if you plan ahead. Working with a trusted supplier like Canroon also helps. If you need help or advice, you can ask for a meeting.

FAQ

What is the main advantage of induction brazing over traditional methods?

Induction brazing heats things up much faster. You can control the process better. It uses less energy than older ways. Your workspace stays safer because there are no open flames. This means you are less likely to get burned or start a fire.

How do I know which power and frequency settings I need?

Match the power and frequency to your metal and part size. Thick parts need more power and lower frequency. Thin parts need less power and higher frequency. If you do not know what to pick, ask your supplier for help.

Can I use one induction brazing generator for different metals?

You can use one generator for many kinds of metals. Sometimes you need to change the coil or change the settings. Always check if your generator works with each metal before you start.

How often should I perform maintenance on my induction brazing generator?

Follow the schedule from the manufacturer. Most systems need cleaning and checking every few months. Clean the filters and cooling systems often. Doing quick checks helps you stop big problems before they happen.

What safety features should I look for in an induction brazing generator?

Look for automatic shut-off and thermal protection. Emergency stop buttons are important too. Good systems have ground fault protection and shields for electromagnetic fields. These features help keep you and your team safe.

Previous:

Next:

Sign up for updates