If you want the best induction metal heater for precision heating in 2026, look for models with smart controls, strong power, and good safety features. Induction heating is changing how people work with metals. It gives fast and accurate results. You do not need open flames, and you save energy. Here are some facts:

The induction heating system market is growing quickly. It will be worth billions by 2035.

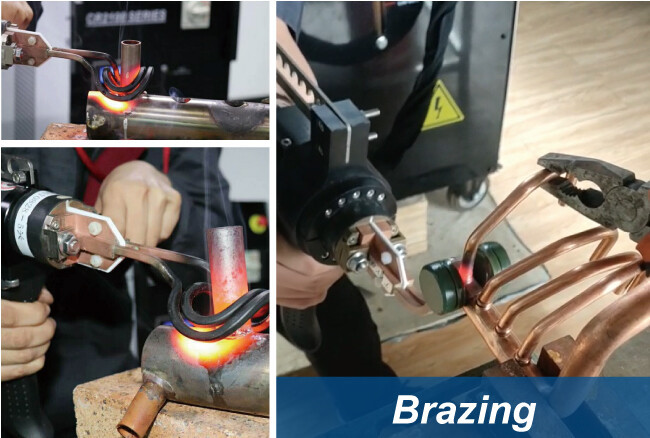

People use it for automotive hardening, metal sheet annealing, and spot welding.

Malaysia’s market is growing because of better mechanical properties and more precision.

Look at this easy comparison of induction heating benefits:

When you choose a heater, think about power, frequency, safety, cost, your material, and coil design. Canroon gives you reliable solutions to help you work well. This guide will help you pick the right tool. It works for big factories and small workshops.

Key Takeaways

Induction metal heaters heat things quickly and exactly. They do not use open flames. This makes your workspace safer and helps you work better.

Pick models with smart controls and strong power. Good safety features are important for reliable use.

Think about what you need to heat. Check the material type and job size. This helps you pick the right heater for your work.

Induction heating uses up to 50% less energy than old ways. This means you spend less money over time.

Pick a well-known brand with good help and support. This makes sure you get the best results and help when you need it.

Top Induction Metal Heaters for 2026

Quick List of 7 Best Models

Here are seven top induction metal heaters for 2026.

HeatMaster Pro 800

PowerForge X5

ThermoFlex Ultra

TitanHeat 3000

FlexiHeat Mobile

EcoInduct Lite

These induction metal heaters work for many tasks. Some are great for big factories. Others are good for small shops or repairs in the field. Each one has something special to offer.

Why These Induction Metal Heaters Lead the Market

You may ask why these induction metal heaters are the best. Let’s look at the reasons. The best induction metal heaters use new technology. They have smart coils and strong power. Their controls can connect to the internet. You can change settings to fit your needs. If your business grows, these induction metal heaters can grow with you.

Here is a table that shows what is important when picking induction metal heaters:

These induction metal heaters do more than just heat. They let you watch and control the temperature as you work. You use less energy, so you save money and help the earth. The design makes it easy to fix or upgrade parts. If you need something special, you can get it fast.

Tip: Pick induction metal heaters with smart features and good support. This helps you get the best results for your work.

If you want heating that is reliable, efficient, and flexible, these induction metal heaters are the top choices for 2026.

Induction Heating Basics

How Induction Heating Works

You may wonder how induction heating works. It uses electricity and magnetism to heat metal. The metal does not need to be touched. A coil makes a magnetic field that changes. When you put metal in the coil, the field moves through it. This makes eddy currents inside the metal. These currents heat the metal fast and evenly.

Here is a simple table to show the main ideas of induction heating:

Induction heating gives you lots of control. You can change the coil, power, or frequency. This helps you get the results you want.

Key Advantages for Precision Heat

Induction heating is great for safe and precise heating. It works fast and saves energy. Here are some top reasons people use induction heating:

Tip: If you want to make your work better, induction heating gives you speed, safety, and accuracy. You can use it in many industries. It works for both big and small projects.

Induction heating lets you heat only the part you need. You waste less energy and get better results. Your team is safer because there is no fire or hot surfaces. If you want a modern way to heat metal, induction heating is a smart choice.

Induction Metal Heater Tool Reviews

Are you trying to find the right induction metal heater for your work? These tool reviews will help you choose. Each review explains what makes each model special. You will learn how each one works and where it is best used. Let’s look at the top seven induction heating tools for 2026.

Canroon CR2100: High-Precision Industrial Heater

The Canroon CR2100 is a good choice for factories. It is portable, so you can move it easily. The digital control helps you change settings fast. You can use it to heat pipes or other metal parts. The water cooling system keeps it safe and cool. Even if you are new, the controls are easy to use.

Unique Features:

You can carry it anywhere

Water cooling keeps it from overheating

High-frequency output heats metal fast and evenly

Controls are simple for everyone

Pros:

Heats up quickly and with high accuracy

Water cooling makes it safe

Easy to use and move around

Cons:

Works best in factories or big workshops

Needs a 3-phase power source

Ideal Use Cases:

Pick this induction metal heater for factory jobs or pipe heating. It is also good for any job that needs strong, steady heat. Canroon is known for making quality products, so you can trust it.

HeatMaster Pro 800: Compact Workshop Solution

If you have a small shop, the HeatMaster Pro 800 is a great fit. It is small but still powerful. The control panel is easy to use. You can set the temperature and time without trouble. The coil spreads heat evenly, so your work looks smooth.

Key Specs:

Power: 8 kW

Frequency: 30-80 kHz

Coil: Adjustable, multi-turn for better energy transfer

Safety: Overheat protection and auto shut-off

Cost: Mid-range, good value for small businesses

Unique Features:

Small size fits anywhere

Quick to set up and use

Works for steel and other metals

Pros:

Fits in tight spaces

Good for beginners

Has strong safety features

Cons:

Not made for big factory jobs

Only works with small parts

Ideal Use Cases:

This induction metal heater is great for fixing cars, making tools, or small jobs. It is perfect for shops that need a heater that does not take up much space.

PowerForge X5: Energy-Efficient Performance

If you want to save energy, try the PowerForge X5. It uses less power but still works well. You can change the frequency and power for each job. The coil can fit different shapes, so you get even heat.

Key Specs:

Power: 5 kW (high power density)

Frequency: 10-100 kHz (adjustable)

Coil: Customizable, multiple-turns for even heating

Safety: Built-in sensors for temperature and current

Cost: Higher upfront, but lower running costs

Unique Features:

Uses less energy to save money

Smart controls for exact heating

Coil fits many shapes

Pros:

Saves money over time

Works well with many materials

Sensors keep it safe

Cons:

Costs more at first

Needs setup for custom coils

Ideal Use Cases:

Use this induction metal heater if you want to save energy. It is good for small factories or busy workshops. It also helps if you want to be more eco-friendly.

ThermoFlex Ultra: Advanced Control Features

Do you want more control over your heating? The ThermoFlex Ultra lets you change many settings. You can adjust power, frequency, and coil position. The digital screen shows you what is happening. Safety features turn it off if there is a problem.

Key Specs:

Power: 12 kW

Frequency: 1-120 kHz (wide range)

Coil: Adjustable and interchangeable

Safety: Multiple alarms and emergency stop

Cost: Premium price for advanced features

Unique Features:

You can watch and control everything in real time

Works with many types of metal

You can swap out the coil

Pros:

Gives you lots of control

Works with many shapes and metals

Has strong safety features

Cons:

Costs more than other models

May be too hard for simple jobs

Ideal Use Cases:

This induction metal heater is best for labs or advanced factories. Use it when you need to control every part of the heating process.

TitanHeat 3000: Heavy-Duty Capacity

The TitanHeat 3000 is made for big jobs. You can get it in two versions. The strong metal case keeps it safe. You can add extra parts if you need them. The touch screen is easy to use. It keeps the temperature steady, so every part is the same.

Unique Features:

Strong build for tough jobs

Touch screen for easy control

Saves space and money

Pros:

Handles big, heavy parts

Keeps heat the same everywhere

Easy to upgrade

Cons:

Too big for small shops

Costs more at first

Ideal Use Cases:

Pick this induction metal heater for big factories or heat treatment plants. It is good for places that need to heat lots of metal at once.

FlexiHeat Mobile: Portable Field Heater

Sometimes you need to bring the heater to the job. FlexiHeat Mobile is easy to move. It is light and has wheels. The controls are simple, so you can start fast. The coil wraps around pipes or odd shapes for even heat.

Key Specs:

Power: 4 kW

Frequency: 20-60 kHz

Coil: Flexible, wraps around objects

Safety: Insulated housing, auto shut-off

Cost: Affordable for field use

Unique Features:

Easy to move anywhere

Coil fits many shapes

Fast to set up and pack away

Pros:

Great for repairs outside the shop

Simple controls

Safe for outdoor jobs

Cons:

Not as strong as big models

Not for big jobs

Ideal Use Cases:

This induction metal heater is perfect for fixing things on-site or pipe work. Use it when you need heat away from your shop.

EcoInduct Lite: Budget-Friendly Precision

If you want good results for less money, try EcoInduct Lite. It gives you even heat and good control. The coil is simple but works well. You can set the temperature and time. Safety features keep it from getting too hot.

Key Specs:

Power: 2 kW

Frequency: 50-100 kHz

Coil: Basic, single-turn for small parts

Safety: Overcurrent and overheat protection

Cost: Low, best for budget buyers

Unique Features:

Low price

Easy controls

Safe for new users

Pros:

Good value for the price

Simple to use

Great for small, careful jobs

Cons:

Not for big or tough jobs

Only works with small parts

Ideal Use Cases:

Use this induction metal heater for hobbies, small repairs, or learning about induction heat.

Tip: When you read these reviews, think about power, frequency, safety, cost, and coil design. High power heats thick metal faster. Low frequency is best for big parts. High frequency works better for small jobs. Custom coils help you get even heat and better results.

These reviews help you compare the best induction metal heater for your needs. You can pick a high-tech model for a factory or a simple one for your shop. Each review gives you the facts you need to choose well.

Specs and Performance Comparison

Performance Metrics Overview

You want to know how these induction heaters compare. Here is a tool chart that shows power, frequency, heating efficiency, and safety features. This makes it easier to pick the right one for your job. Some are good for taking off rusted bolts. Others are better for big factory work.

Induction heaters work well and give you choices. Each one helps you heat metal fast and safely. Safety features like thermal shutoff and heat shields keep you safe from burns or shocks. You can use these heaters for small or big metal parts. You do not have to worry about getting hurt.

Efficiency and Cost Analysis

Induction heating is very efficient. It can reach up to 90% heating efficiency. Old ways only get 40-60%. This means you save energy and money. Induction heaters also need less fixing because they have fewer moving parts. They heat things faster, so you finish work quickly.

You can see how much energy you save. Induction heaters help you spend less and work better. You use less power and have less downtime. Your workspace is safer too. If you need to heat bolts or metal parts, induction heaters do a better job and cost less. This shows why induction is a smart way to heat metal.

Tip: Pick induction heaters for the best efficiency and safety. You get steady heat, save money, and finish jobs faster.

Choosing the Right Induction Metal Heater

Assessing Your Application Needs

You want the best tool for your job. Start by thinking about what you need to heat. Ask yourself: What kind of metal do you use? How big are the parts? Do you need deep heat or just surface heat? These questions help you find the right heater for your work.

Here’s a quick table to guide you:

Tip: Write down your needs before you choose. This helps you focus on what matters most.

Key Features to Consider

When you pick an induction metal heater, look for features that boost precision and make your work easier. Here are the most important ones:

Power output—Make sure it matches your part size and type.

Frequency—Pick the right one for your heating job.

Heating speed—Faster heating saves you time.

Temperature control—Keeps your process safe and steady.

Supplier reputation—Choose brands known for performance and reliability.

You also want energy efficiency. Many heaters reach up to 90% efficiency. Adjustable power levels give you more control and precision. Higher frequencies help with small, detailed jobs. Lower frequencies work better for large parts.

Matching Models to Use Cases

Not every heater fits every job. You need to match the model to your task for the best performance and reliability. Here’s a table to help you decide:

If you want precision for small parts, go for a model with a high frequency and focused coil. For big jobs, pick a heater with more power and a sturdy design. Always check if the model fits your workspace and safety needs.

Note: The right heater gives you better results, saves energy, and keeps your team safe.

Real-World Induction Heating Applications

Industrial Success Stories with Canroon

You may wonder how induction heating helps in real life. Here is a story from a factory. Canroon helped a company that makes carbon fiber parts. The team made a new heating area inside the coil. They worked carefully with carbon materials. The process made a very hot spot. This showed the system was ready for the customer. This project proved Canroon’s induction heating works well and is reliable. You can see why precision and control are important. They help every part come out just right. Many companies trust Canroon for energy-saving solutions. These keep their factories running smoothly.

If you look at the benefits, you will see why many people pick induction heating for factories:

Workshop and Hobbyist Use Cases

You do not need a big factory to use induction heating. Many small shops and hobbyists use these tools every day. Here are some common uses:

Jewelry making: You can melt and shape gold, silver, or platinum.

School projects: Teachers use induction heaters to show how metals change in science class.

Induction heaters make small jobs easier. You can plug many models into a normal outlet. Some have a battery, so you can work if the power goes out. People like how these heaters save energy and work well.

Here are more reasons why users like induction heating for making things:

Easy to install

Save $54 to $71 on energy each year

82% of users are happy with their heater

You can trust induction heating for jobs that need reliability, energy savings, and good control. Whether you work in a big factory or a small shop, these tools help you every day.

You’ve seen how induction metal heaters can save you energy and boost your work speed. Here’s a quick look at what matters most:

If you run a factory, go for high-power models. For workshops, pick compact heaters. Hobbyists should choose simple, safe options. Check this guide before you buy:

Need help? Canroon’s experts are ready to guide you.

FAQ

What makes induction metal heaters better than traditional heating tools?

Induction heaters warm metal much faster. They use electricity instead of fire. This makes your work area safer. You also save energy when you use them. You get better results and waste less metal.

How do I choose the right temperature control system for my project?

Think about what kind of metal you have. Also, check how big your job is. Pick a system that lets you set the heat easily. You should be able to watch the temperature as you work. Good controls stop your metal from getting too hot.

Can I use induction heaters for restoration work?

Yes, you can use them for this. Induction heaters help take off rusty bolts. They also heat old metal parts. Many people use them to fix cars, bikes, and machines.

Where can I find reliable mini-ductor reviews?

You can look at forums and company websites. User blogs are also helpful. Reviews from real people help you choose the best mini-ductor. Always read honest stories and detailed tips.

Sign up for updates