An induction heating machine heats metal using electromagnetic fields. It works fast and is very accurate. Canroon is a top company with new technology. You put a metal part inside a coil. The coil makes a changing magnetic field. This field creates tiny electric currents in the metal. These are called eddy currents. The currents heat the metal quickly. Induction heating does not need direct contact or flames. This makes it safer and easier to control.

This helps you save energy and finish work faster with an induction heating machine.

Key Takeaways

Induction heating machines use magnetic fields to heat metal. They do this quickly and safely. There are no flames or direct touch. These machines work best with metals that conduct electricity. Examples are iron, steel, copper, and aluminum. You can control the temperature and heating time very well. The main parts are the power supply, induction coil, and work piece. These parts work together for good and even heating. Induction heating saves energy by only heating the metal. It does not heat the air. This makes it faster and better than old methods. People use this technology for hardening, brazing, melting, and making car parts. It gives clean, safe, and reliable results every time.

Induction Heating Machine Basics

How Induction Heating Works

Induction heating uses science to heat metals fast. You need an induction heating machine for this. The machine has a copper coil inside. When you turn it on, electricity flows in the coil. The electricity switches direction many times each second. This makes a magnetic field around the coil. If you put a metal part inside the coil, the magnetic field goes through the metal. The field makes tiny electric currents called eddy currents. These currents move inside the metal. They push against the metal’s resistance. This movement makes the metal hot. This is the induction heating process. You do not have to touch the metal or use fire. The process is clean and safe.

Note: Induction heating works because of electromagnetic induction. The coil acts like the main winding in a transformer. The metal part acts like the second winding. The heat forms right where you want it. This makes the process very efficient.

Some metals, like iron, get even hotter. They have special magnetic properties. The changing magnetic field makes their molecules rub together. This makes extra heat called hysteresis loss. You can change the temperature by adjusting the power or frequency. An induction heating system lets you control the heating very well.

Suitable Materials

Not every material works with induction heating. The induction heating machine works best with metals that carry electricity. Iron and steel heat up very quickly. Copper and aluminum also work, but they heat up in a different way because they have less resistance.

Here is a table to show which materials work best:

You can heat conductive materials directly with an induction heating system.

Non-conductive materials, like plastics or ceramics, do not heat up by induction. They do not let electric currents flow inside them.

Sometimes you need to heat non-conductive materials. You can do this by heating a metal part first. The metal then passes heat to the non-conductive material. This is called indirect heating. It is less efficient and harder to control.

Canroon makes advanced induction heating machines. These machines work with many kinds of metals. You can use them for different jobs in factories. The induction heating process gives you fast, safe, and accurate results.

Induction Heating Machine Components

When you use an induction heating machine, you work with a few main parts. Each part does something important. You should know how these parts work together. This helps you get the best results from your induction heating system.

Power Supply

The power supply gives energy to the induction heater. It changes normal electricity into the kind needed for induction heating. Most systems use power supplies that work at different frequencies and power levels. Some use line-frequency supplies, solid-state inverters, or radio-frequency power supplies. Medium-frequency power supplies help heat, melt, or harden metals. The power supply controls how much energy goes into the coil. Canroon makes power supplies that are efficient and reliable. This helps your induction heating equipment work well every time.

Tip: You can change the power supply settings to fit your work piece and heating job.

Induction Coil

The induction coil is the most important part of your induction heater. It makes a magnetic field when electricity goes through it. This field heats your work piece. The coil’s design changes how well your heater works. You need to think about the coil’s wall thickness, shape, and cooling system. If the coil wall is about one reference depth thick, you get good electrical and cooling efficiency. Thinner walls cool better, but if they are too thin, you lose electrical efficiency. Water pressure helps keep the coil cool. A good coil shape gives even heating and steady power. Engineers use computer models to design coils that last longer and work better.

Pick the right coil wall thickness for best results.

Use strong cooling, like high water pressure, to keep the coil cool.

Make the coil shape match your work piece for even heating.

Try to keep the coil temperature steady to stop damage.

Canroon makes induction coils that work well and last a long time.

Workpiece

The work piece is the metal part you want to heat. Its shape and size change how the induction heating system works. When you put the work piece close to the coil, you get stronger magnetic force and better heating. The middle of a solenoid coil heats the work piece the most. If you move the work piece away from the center, heating is not even. The height and shape of your work piece change how heat spreads. If the work piece is shorter than the coil, the ends may get too hot. You need to place your work piece carefully for even heating.

Put the work piece close to the coil for best energy transfer.

Keep the work piece in the center for even heating.

Match the coil and work piece shapes for good results.

Watch out for overheating at the ends if the work piece is shorter than the coil.

Canroon’s induction heaters help you heat many kinds of work pieces with accuracy and dependability.

Induction Heater Performance Factors

Many things affect how well an induction heater works. You need to think about the coil design, the frequency, and what your work piece is made of. Each one can change how your induction heating system works.

Coil Design

The coil is a very important part of the induction heater. There are different coil shapes for different jobs. Here are some common types:

Solenoid coils work best for rods or round pieces. They make a strong magnetic field inside the coil. This gives fast and even heating.

Pancake coils are flat and spiral. You use them for heating surfaces or when you can only reach one side.

Internal coils heat hollow pieces from the inside.

Shaped conforming coils are made to fit special shapes.

Multi-zone or multi-coil systems heat different parts at different speeds.

You can change the number of coil turns, the space between them, and how close the coil is to the work piece. These changes help heat the whole work piece evenly. Flux concentrators can send more energy to certain spots. This makes the heating more exact.

Frequency

Frequency changes how deep the heat goes into the work piece. High frequency heats just the surface. Low frequency lets heat go deeper. You should pick the right frequency for your job.

If you want to harden just the outside, use high frequency. If you want to melt or heat the whole thing, use low frequency. The right frequency helps you control the heat and get the results you want.

Material Properties

The kind of work piece you use matters a lot. Some metals heat up faster than others. Here are the main things to look at:

Relative permeability shows how well the work piece reacts to the magnetic field. Iron and steel have high permeability and heat up quickly.

Conductivity means how well a metal carries electricity. Copper and aluminum conduct well but may not heat as fast as iron because they have less resistance.

Surface condition is also important. Cracks or rough spots can change how the heater works.

You should check these things before you start heating. This helps you get the best results from your induction heating machine.

Note: Induction heating systems can cost more at first than other heaters. You pay more for special power supplies and custom coils. But you save money later because the induction heater uses less energy and works faster.

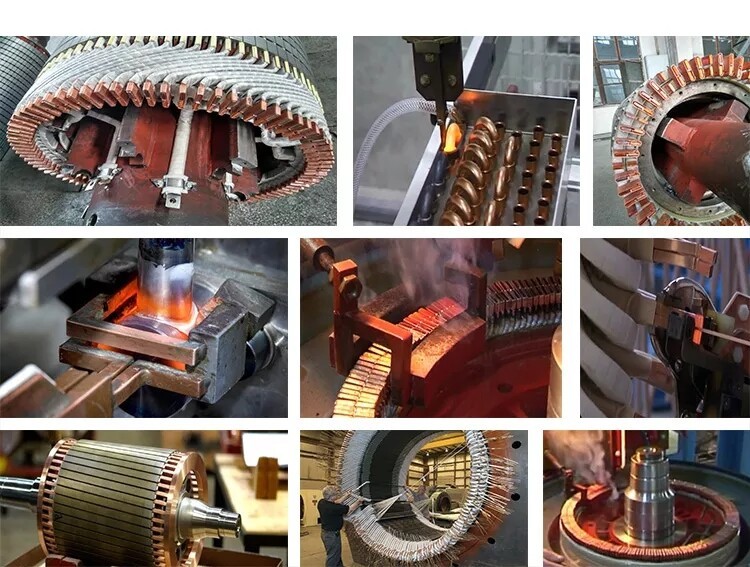

Induction Heating Applications

Induction heating helps people work faster and safer in many jobs. You can use these machines to heat treat metal, join metal pieces, and make car parts. The technology lets you control the heat very well. You get the same results every time. The work area stays clean. Canroon has machines for many industries. You can pick the right one for your job.

Surface Hardening

Induction heating is good for surface hardening. It heats just the outside of metal parts. Computers help you set the heat and time. This means you get the same result each time. Induction heating stops parts from bending. The inside stays strong. You can harden gears, shafts, and tools fast.

Induction hardening gives you:

Exact control of heat and depth

Quick work with less bending

Same quality for every part

Brazing and Soldering

Induction heating is used for brazing and soldering. You can join metals without fire. The heat goes only where you want it. This keeps workers safe. The process is clean and quick. You do not have to worry about burns.

You can join copper, steel, and aluminum with induction heating.

It works well for pipes, wires, and engine parts.

The joints are strong and do not leak.

Melting and Forging

Induction heating helps melt and forge metals. It heats metal from the inside with electromagnetic fields. This saves energy and heats evenly. You can reach melting or forging temperature fast. It works for steel, iron, and other alloys. After heating, you shape the metal with presses or hammers.

Tip: Induction heating makes fewer mistakes and keeps the air clean. You do not need to burn fuel or heat the air.

Automotive and Industrial Uses

Car factories use induction heating for many jobs. You can use it for shrink fitting, brazing, annealing, and heat treating. Induction heating helps make motors, battery parts, and hoses. You get fast and steady results. There are no open flames. The process works with machines and helps control quality.

Induction heating joins engine mounts and metal hoses.

The technology helps make strong car and truck parts.

Canroon makes induction heating machines for many jobs. You can use them for heat treating or making car parts. The technology gives you control, steady results, and safety every time.

Induction Heating Benefits

Efficiency

Induction heating machines help you save lots of energy. They heat metal right away. You do not waste energy on air or furnace walls. Studies show induction heating can be up to 85% efficient. This is about 33% better than old gas furnaces. Heating steel with induction uses less electricity. You spend less money and make more profit. The process keeps your workspace clean. It does not burn fuel or make smoke.

Tip: Induction heating lets you finish jobs faster. You waste less and get more work done.

Precision

Induction heating lets you control temperature and time exactly. You can set the machine to heat only the part you need. The rest of the material stays safe. This helps you avoid mistakes like overheating. You can use special settings for different shapes and materials. Many industries use induction heating for brazing, hardening, and soldering. With good control, you get strong and reliable products every time.

You can:

Set the heat for each job.

Make your products better and stronger.

Safety

Induction heating machines do not use flames or gas. This makes your workspace much safer. You lower the risk of fire and burns. The process works inside and outside. Wind or rain does not change how it works. You also lower the chance of accidents. The machine heats only the metal, not the air.

Note: Induction heating is safe and easy to repeat. It helps automation and lowers mistakes. You get fewer defects and less waste.

You now know that induction heating machines use electromagnetic fields to heat metals fast and accurately. Canroon’s new machines help many industries stay safe and keep work areas clean. Induction heating is special because it works quickly, saves energy, and gives you exact control. You can use these machines for hardening, brazing, melting, and other jobs.

Think about using induction heating for your next project. It helps you save energy, work safely, and get good results every time.

FAQ

What materials can you heat with an induction heating machine?

You can heat metals like iron, steel, copper, and aluminum. Plastics and ceramics do not work unless you use a metal part to transfer heat.

Is induction heating safe for you to use?

Induction heating does not use open flames. You lower the risk of burns and fire. The machine heats only the metal, so your workspace stays safe.

How do you control the temperature during induction heating?

You set the temperature using the machine’s controls. Sensors and timers help you keep the heat steady. You can adjust settings for different jobs.

Can you use induction heating for small parts?

Yes, you can heat small parts. You choose the right coil size and power level. Induction heating works for tiny pieces and large objects.

Tip: Always match the coil shape to your work piece for best results!

Sign up for updates