Selecting the best VFDs and accessories is very important in factories. Variable frequency drives let workers control motors exactly. They also help save energy. Many places save about half their energy with VFDs. This means they spend less money. Their machines last longer too. Every factory needs different things. Picking the right VFD and accessories for each job keeps things safe. It also helps everything work well.

Key Takeaways

Picking the right VFD brand and model helps factories use less energy. It also keeps machines safe and makes them work better.

Using things like filters, reactors, enclosures, and cooling systems keeps VFDs safe. These accessories help VFDs work well in hard places.

VFDs change motor speed in many jobs like HVAC, pumping, conveyors, mining, and making products. This saves energy and helps machines last longer.

Choosing, installing, and taking care of VFDs the right way stops breakdowns. It also helps equipment last longer.

Remote controls and communication modules help workers use and watch VFDs from far away. This makes it easier and safer for them.

Top VFDs

Leading Brands

Factories need good drives to keep working well. Many factories pick from the top ten vfds to run electric motors. These brands are known for being strong and helpful. ABB, Yaskawa, Rockwell Automation, Schneider Electric, Danfoss, Eaton, Sumitomo Invertek, Unitronics, and KB all have good choices for different jobs.

ABB makes drives that save energy and are easy to use. Their drives work in many places.

Yaskawa is known for drives that work very well. Many companies use Yaskawa for elevators and conveyors.

Rockwell Automation has the PowerFlex series. These drives help with pumps and moving things in warehouses.

Schneider Electric makes tough drives for hard jobs. Their drives help many kinds of factories.

Danfoss is great for drives that save energy. Many factories use Danfoss for HVAC and water.

Eaton gives strong drives for hard work. Their drives help keep motors safe.

Sumitomo Invertek and Unitronics both have drives for special jobs.

Canroon makes drives that are cost-effective and adaptable. Their drives work well in both small machines and large industrial equipment.

Note: Picking a good brand means better help and longer use.

VFD Models

Factories use different drives for pumps, fans, and other machines. Each job needs a special vfd to work best. The table below lists some top variable frequency drives and what they are used for:

Many factories use the SINAMICS G120 from Siemens for pumps and fans. Yaskawa's drives help run elevators and conveyors well. Delta Electronics has the VFD-EL and VFD-B series for pumps and fans. ABB's ACS580 and ACS880 series help control motors in many places. Mitsubishi Electric's FR-F800 and FR-A800 series are good for HVAC and water. Fuji Electric's FRENIC series is used for small machines and fans. Rockwell Automation's PowerFlex series helps move things in warehouses.

These drives help save energy and keep motors safe. They also let workers change speed and stop machines from wearing out fast. Picking the right vfd helps factories work better and keeps machines running longer. Factories need the right drive for each job to work well.

VFD Accessories

Variable frequency drives need special accessories to work well. These parts help keep machines safe and running right. Accessories also make it easier for workers to use the machines. Each accessory has a job to help the vfd system work better.

Filters & Reactors

Filters and reactors stop bad electrical signals from hurting the vfd. They keep motors and other parts safe from damage. Factories use line reactors to make power smoother. This helps lower harmonics and stops motors from getting too hot. Filters block signals that can mess up sensitive equipment. Using good filters and reactors keeps the system safe and steady.

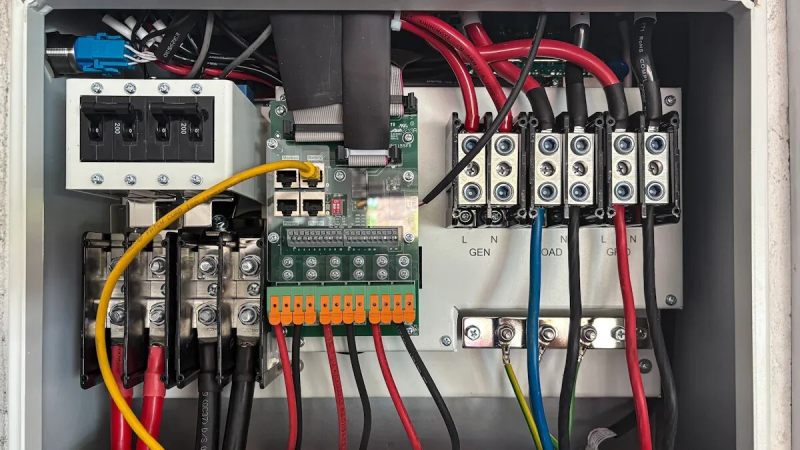

Enclosures & Cooling

Enclosures and cooling systems keep the vfd safe from tough places. Factories can have rain, dust, or chemicals. Enclosures with high NEMA ratings protect the drive from these things. Workers must close doors and lock latches to keep the drive safe. Cooling fans and air filters take away heat from the vfd. Clean filters and working fans help air move well. Vents should stay open for good cooling. Some factories put drives in cool rooms for extra safety. Without these steps, heat and dirt can hurt the vfd and make it not last as long.

Tip: Check enclosures and cooling parts often to stop shutdowns and big repairs.

Remote Controls

Remote controls let workers use the vfd from far away. These can be handheld panels, wireless remotes, or wall stations. Remote controls help start, stop, and change motor speed easily. Workers do not have to touch the drive. This keeps workers safe and saves time. It is helpful in big factories or hard-to-reach spots. Workers can act fast when things change.

Communication Modules

Communication modules link the vfd to other machines and systems. These use things like Ethernet, Modbus, or Profibus. They help share data between the drive and computers. With these modules, workers can watch how things work and change settings. They also get alerts if there are problems. This makes it easier to control everything and keep it running well. Factories use these modules to work better and stop delays.

Note: Picking the right accessories for each vfd keeps factories safe, saves energy, and helps machines last longer.

Applications

HVAC

Drives are important in HVAC systems. They control compressors, fans, and pumps. Drives change motor speed to fit what the building needs. When less power is needed, motors run slower. This saves a lot of energy. If you cut motor speed in half, you can use up to 90% less energy. Drives also help motors start slowly. This makes motors last longer. They keep the air cool and comfortable. Drives help keep the air clean and the temperature steady. They also lower electrical noise and make the system work better. In big buildings, this means saving money and making equipment last longer.

Tip: Shaft grounding solutions stop electrical bearing damage in HVAC drives.

Pumping

Drives help pumps work better in factories. They let workers change pump speed to match what is needed. This saves energy and keeps pumps from wearing out fast. In water plants, drives keep pressure steady. They stop water hammer from hurting pipes. Drives let pumps start and stop slowly. This protects the pipes and pumps. It is easy to change how much water moves. This helps save water and energy.

Conveyors

Conveyors in factories use drives for smooth movement. Drives control how fast and strong the conveyor moves. This makes starting and stopping easy. There are no sudden jerks. This helps the machines last longer. Drives save energy by slowing down when loads are light. New drives can connect to control systems. Workers can watch and fix problems from far away. This keeps conveyors working with fewer stops.

Drives help with:

Smooth starts and stops

Saving energy by changing speed

Handling different load sizes

Giving data to improve the system

Mining

Mining uses drives to run pumps, belts, and fans. Drives let machines go the right speed for each job. This saves energy and money. Some drives are made for tough mining places. They have double seals to keep out dust and water. Drives help workers control heavy machines safely. This lowers the chance of accidents and keeps people safe.

Manufacturing

Drives help many machines in factories. They control conveyors, pumps, and fans. Drives change motor speed to fit what is needed. This saves energy and makes products better. Drives help machines start and stop smoothly. This lowers wear and cuts repair costs. They stop machines from getting too hot or overloaded. Drives can also change single-phase power to three-phase. This lets factories use more kinds of machines. All these things help factories work better and cost less.

Selection & Maintenance

Choosing a VFD

When picking a variable frequency drive, first check the supply voltage. Make sure the drive matches the system’s voltage and phase. Look at the VFD output current rating. Compare it to the motor’s full-load amps and horsepower. Some motors need bigger drives if they have high torque or special pole counts. The enclosure is important too. Use a sealed enclosure in dusty or wet places. Factories should use reactors or filters to lower electrical noise. This is extra important in sensitive areas. Circuit breakers and fuses help protect the drive and motor. Some loads can send power back to the drive. These need extra care. High temperatures might mean you need a bigger drive. Single-phase input drives often need to be oversized. This helps protect the inside parts.

Tip: Picking the right size and protection helps the drive and motor last longer and work better.

Installation Tips

A good installation keeps the drive safe and working right. Many factories put drives in Motor Control Centers. This makes them safer and easier to reach. Always check the short-circuit rating of the panel. For wall-mounted drives, use ones with built-in disconnects and protection. Heavy drives are easier to fix with rollout chassis designs. This makes maintenance safer. The table below shows common mistakes and what can happen:

Maintenance

Checking drives and motors often keeps them working well. Factories should follow the maintenance plan in the manual. At least once a year, have a professional check for dust, loose wires, and correct settings. If a drive is not used for over a year, turn it on to keep the capacitors healthy. Spin the equipment during yearly checks too. These steps help stop problems and make the drive and motor last longer.

Note: Doing regular maintenance stops big repairs and keeps production running.

Picking the right VFDs and accessories helps factories work well and stay safe. Sometimes, there are problems like harmonics, voltage changes, and motors getting too hot. Filters, cooling, and regular checks can fix these problems.

Good drives cost more at first, but they save money later. They use less energy and need fewer repairs.

Certifications like ISO9001 and CE mean the product is high quality.

More people are buying VFDs now. New technology makes drives smarter and better.

Doing regular checks and installing things the right way helps factories get the most out of their VFDs.

FAQ

What is the main purpose of a variable frequency drive (VFD)?

A VFD changes how fast and strong a motor works. It helps factories use less energy and keeps machines from breaking. VFDs also help workers control how things run. Many places use VFDs to make motors fit each job.

How often should workers perform maintenance on VFDs?

Workers should look at VFDs at least once every year. They need to look for dust, loose wires, and check the settings. Doing these checks stops problems and helps machines last longer.

Can a VFD work with any type of motor?

VFDs do not work with every motor. Most VFDs are made for three-phase induction motors. Some VFDs can run special motors, but you must check before using them.

Why do factories use filters and reactors with VFDs?

Filters and reactors keep VFDs and motors safe from bad electrical noise. They lower harmonics and stop voltage spikes. This helps machines last longer and work better.

Previous:

Next:

Sign up for updates