To choose VFD for your 3-phase motor, you must match the VFD’s voltage and current to your motor’s nameplate. Always look at the nameplate carefully. If you miss details, you can run into problems such as incorrect protection or power ratings. Many people make mistakes when they choose VFD by forgetting the motor’s insulation class or not matching the voltage properly. They also overlook environmental factors. Every application, whether pumps or conveyors, requires specific torque and control. CANROON offers expert help and effective solutions to help you choose VFD correctly and avoid these common issues.

Key Takeaways

Always look at your motor’s nameplate for voltage and current. Check other important details before you pick a VFD.

Size the VFD by using the motor’s full load amps. Do not use just horsepower. Add a safety margin to stop overheating and damage.

Make sure the VFD voltage and phase match your motor and power supply. This helps stop faults and makes things work better.

Pick a VFD with features that fit your load type and starting needs. This helps the motor run smoothly and saves energy.

Put the VFD in a clean and cool place. Make sure it has good grounding and protection. This keeps it safe and working well.

Motor Data

Nameplate Info

The nameplate on a 3-phase motor has important details. You should read it before picking a VFD. The nameplate shows how the motor works and what it needs. Here are the main things you will see:

Power rating (HP or kW) and current rating (amps)

Insulation class and IP rating

Motor configuration, such as STAR or DELTA connection

Shaft torque across the speed range

Thermal overload capacity

Suitability for low-speed operation

Efficiency code (IE1 to IE4)

Ambient temperature and altitude limits

Duty cycle (how long the motor can run before cooling)

Tip: Look at the wiring diagram on the nameplate. Use a multimeter to check connections. This helps you avoid wiring mistakes and keeps your motor safe.

Voltage and Amps

The VFD’s voltage and current must match the motor’s nameplate. The table below explains why these numbers are important:

Service Factor

The service factor tells how much extra load the motor can handle for short times. Most motors have a service factor of 1.15. When you use a VFD, the service factor drops to 1.00. This means the motor cannot handle overloads above its rated current with a VFD. Always pick a VFD based on the motor’s full load current, not just horsepower. If you ignore the service factor, you might overheat the motor, cause shutdowns, or even damage the motor and VFD. Following this rule keeps your system safe and reliable.

VFD Sizing

Full Load Amps

When picking a VFD for your 3-phase motor, start with the motor’s full load amps (FLA). Do not just look at horsepower. FLA shows how much current the motor uses at its rated load. You can find FLA on the motor nameplate. If the VFD is too small, the motor gets hotter. More heat can make the insulation wear out faster. Every 10 °C rise can cut insulation life in half. This can make the motor fail early. Using a motor above its service factor or with a VFD that is too small can cause shutdowns and damage.

Tip: If you cannot find FLA, use this formula:

FLA = (Motor Horsepower × 746) / (Voltage × √3 × Efficiency × Power Factor)Always add a safety margin to your answer.

If the VFD is too big, it wastes energy. Your electric bill can go up. The drive may also run less efficiently. The best way is to size the VFD by FLA. Then add a margin for safety and good performance.

Voltage Match

You must match the VFD voltage to the motor and your building’s supply. If you do not, you can get strange current, overheating, and insulation failure. Voltage imbalances can cause current problems. This may hurt the VFD’s inside parts. Always check the voltage on the motor nameplate and your building’s supply.

Matching voltages helps stop:

Overheating and early motor failure

Tripping and shutdowns

Damage to VFD parts

Wasted energy and poor efficiency

Note: Most VFDs work with voltage from +10% to -15%. Stay in this range for safe use. For extra safety, use line reactors or surge arrestors. These help with voltage spikes and noise.

Sizing Rules

Follow these rules to pick the right VFD size:

Base VFD size on FLA, not horsepower. Big brands say this is best.

Add a safety margin. For most jobs, size the VFD at least 20% above the motor’s FLA. For heavy loads like conveyors or crushers, pick a VFD with 150% overload for one minute. For pumps and fans, 120% is usually enough.

Match the VFD voltage to the motor and supply. This stops faults and keeps things working well.

Single-phase input needs special care. If you use single-phase power for a three-phase motor, double the VFD size. This keeps the VFD safe from high input current and stops failure.

Check the load type and duty cycle. Heavy loads or lots of starts may need a bigger VFD. Motors that run all the time need VFDs made for nonstop use.

If the VFD is too small, you risk:

Hotter running

Shorter life

More shutdowns and repairs

If the VFD is too big, you may get:

Higher energy use

Extra costs

When picking a VFD, always think about the motor’s FLA, voltage, load type, and power supply. This keeps your system safe, efficient, and reliable.

Choose VFD for Application

Load Type

You must know your load type before picking a VFD. Different machines need different VFD features. Some loads always need the same torque. Others need torque that changes. The table below lists common loads and what to think about:

Conveyors and cranes need VFDs that give extra torque at any speed. Fans and pumps use less torque at low speeds. This helps save energy. Some pumps need anti-clog features to work well. Always check what your machine does. Pick a VFD that fits its needs.

Tip: If your conveyor moves heavy things, choose a VFD with more overload ability. This keeps your motor safe and stops shutdowns.

Starting Torque

Starting torque matters when you pick a VFD for a 3-phase motor. Motors use a lot of current and make strong torque when starting. VFDs control voltage and frequency. This makes starting smoother. Here is what you should check:

1. Make sure the motor’s voltage matches the VFD’s voltage. 2. The VFD’s output current must be as much as the motor’s full load amps. 3. The VFD’s power rating should match the motor’s rating. 4. For high starting torque, get a VFD with overload ability. 5. Think about your environment and how often you start the motor.

A VFD keeps starting current at about 1.2 to 1.5 times the rated current. This protects your motor from stress. It also keeps your system working well. If the VFD is too small, the motor may not start. If it is too big, you waste energy.

Control Features

Modern VFDs have many control features to help your machines. You can control speed and torque better. You also get more safety and easier automation. Here are some features to look for:

Auto-tuning and sensorless vector control help the motor work well.

Safety functions like Safe Torque Off and safe stop modes protect people and machines.

Connectivity options such as Modbus TCP and EtherNet/IP help with diagnostics and integration.

Energy-saving functions include regenerative braking and load matching.

Special features like clog prevention for pumps and vibration reduction for fans.

These features help your machines run smoothly. They save energy and keep your equipment safe. You can also connect your VFD to automation systems for better control and monitoring.

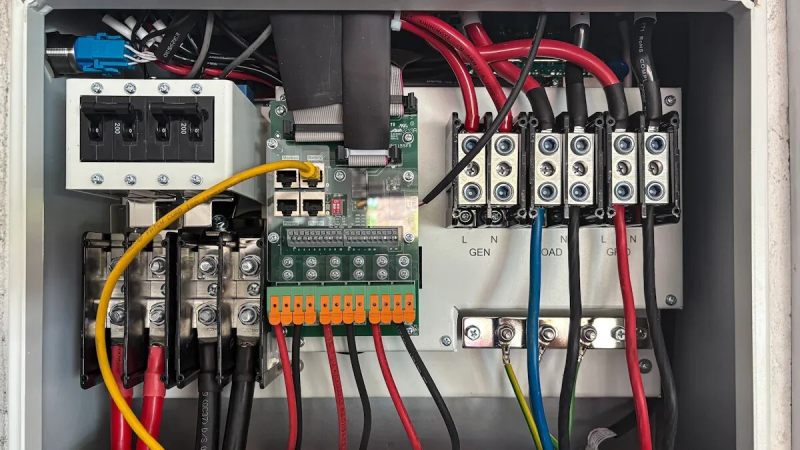

Installation & Environment

Power Supply

Check your power supply before you put in a VFD. Make sure the voltage and frequency are right for both the VFD and the motor. In the countryside, power can dip or surge. These changes can break your equipment. Use line reactors to stop spikes and slow down big fault currents. Always use the wiring diagram from the maker. Turn off all power before you start working. Good grounding keeps your system safe and cuts down on electrical noise. Keep control wires away from power cables to stop interference. Pick the right cable size for your VFD’s current. The table below shows what you need to check for safe power:

Tip: Use EMC filters and shielded cables to lower electrical noise and meet rules.

Ambient Conditions

The air temperature and height above sea level affect your VFD. High heat can make the VFD overheat. Most VFDs work best at 40°C or 50°C. If it is hotter, lower the VFD’s rating by 1% for each degree over the limit. High places have less cooling. You may need to lower the VFD’s rating if you install it above 1000 meters. Good airflow and clean air help your VFD last longer. Keep dust, water, and chemicals away from the VFD. Use sun covers or put the VFD out of the sun to stop extra heat. Always check the area before you install the VFD.

Keep the temperature right to stop overheating.

Use good airflow and cooling.

Keep out dust, water, and chemicals.

Lower VFD ratings for high places or hot spots.

Check and clean the VFD often.

Enclosure Type

The right enclosure keeps your VFD safe from dust, water, and weather. Pick the enclosure based on where you put the VFD. The table below shows common enclosure types and what they protect against:

If you put the VFD outside or in tough places, use sealed enclosures and cooling systems. For important loads, add line reactors, filters, and surge protection. Clean and check connections often to stop problems. When you plan your setup, think about the total cost. Good VFDs may cost more at first, but they save money by stopping breakdowns and repairs later.

CANROON Support

Technical Help

CANROON gives you strong help with your VFD. You can get support any time, day or night. If you need help, just ask and someone will answer. CANROON has training tools so you can learn how to use your VFD. If something goes wrong, you get quick help to fix it. You also get a warranty and service for repairs. Here are some things you get:

Fast help to solve problems

Warranty and service for long-term care

Spare parts when you need them

Good help means you fix problems fast and keep your system working.

Product Options

CANROON has many VFDs for different jobs. The CV900N model is flexible and strong. You can use it for small motors or big motors. It works with single-phase and three-phase power. Here are some important features:

You can use CANROON VFDs for pumps, fans, elevators, and big machines. The design lets you control motors well, keeps things safe, and makes it easy to watch your system.

After-Sales Service

CANROON gives you more than just a VFD. The after-sales service helps your system last longer. You get help with installing, fixing, and keeping your VFD working. CANROON helps with things like insulated bearings and line filters. These protect your motor and help it last longer.

CANROON is known for:

Fast answers when you need service

Help at your site and upgrades for your system

Regular checks to keep things working

Strong warranty and good customer care

Many people like CANROON for good quality, fair prices, and helpful service. You can trust CANROON to help you before and after you buy.

To choose vfd for your 3-phase motor, follow these steps:

Gather motor data like voltage, full load amps, and load type.

Size the VFD based on current, not just horsepower, and add a safety margin.

Match voltage and phase, and check environmental conditions.

Select control features that fit your application.

Quality VFDs help your system run safely and last longer. You can ask CANROON for expert support with complex setups.

Reliable VFDs reduce wear, prevent faults, and extend equipment life.

Built-in protection and self-diagnostics keep your motor safe.

FAQ

What happens if you choose a VFD that is too small for your motor?

If you pick a VFD that is too small, your motor can overheat. The VFD may trip or shut down. This can damage both the motor and the VFD. Always match the VFD to your motor’s full load amps.

Can you use one VFD for multiple motors?

You can use one VFD for several motors if they start and stop together. All motors must have the same voltage and similar ratings. You must size the VFD for the total current of all motors. Use separate overload protection for each motor.

How do you know if your VFD needs extra cooling?

Check the VFD’s temperature during operation. If it feels hot or shows warning lights, you may need extra cooling. High ambient temperatures or poor airflow can cause overheating. Use fans or air conditioning to keep the VFD cool.

Do you need special cables for VFDs?

Yes, you should use shielded cables for VFDs. These cables reduce electrical noise and protect your system. Shielded cables also help you meet safety standards. Always follow the VFD manufacturer’s wiring recommendations.

What maintenance does a VFD require?

You should check the VFD for dust, loose wires, and signs of wear. Clean the cooling fans and filters. Inspect connections and look for warning lights. Regular checks help your VFD last longer and work safely.

Sign up for updates