When you buy an induction heater, the most important thing is to match it to your needs. If you pick the wrong size or coil design, you might get uneven heating or even damage your parts. Many people make mistakes like using a coil that is too far from the workpiece or choosing the wrong frequency. These issues can cause poor results and waste energy. You can avoid them by focusing on the right features and safety. Canroon’s experts can help you choose the best fit, so you get fast, safe, and efficient heating every time.

Key Takeaways

Pick an induction heater that fits what you need. This helps you heat things fast and evenly. It also saves energy. - Find important features like enough power and good temperature control. The right coil design helps it work better and keeps you safe. - Make sure your metal or cookware can be used with induction heating. This will help you use it safely and well. - Think about the size of what you want to heat. Also, check how deep you need to heat and how much space you have. This will help you avoid problems and extra costs. - Buy from trusted suppliers like Canroon. They give good advice and support. Their products are safe and work well.

Why the Right Induction Heater Matters

Performance and Efficiency

When you pick the right induction heater, you boost your performance right away. You get fast, even heating that goes straight to your workpiece. This means you spend less time waiting and more time getting things done. Here’s what you can expect:

You get precise control, so your parts heat up evenly every time.

The heater targets only the area you need, which cuts down on wasted energy.

You see better product quality because the heat spreads out smoothly.

Your production line moves faster, and you keep your results consistent.

With these benefits, your performance jumps to a whole new level. You save energy, reduce mistakes, and finish jobs quicker.

Safety and Reliability

Safety matters a lot when you use any heating tool. The right induction heater keeps your workspace safer. You do not have open flames or hot surfaces, so you lower the risk of burns or fires. The process does not create smoke or fumes, which means cleaner air for you and your team. Non-contact heating also means less wear and tear on your equipment, so you can count on your heater to last longer. When you trust your tools, you work with more confidence every day.

Cost Savings

Choosing the best induction heater helps you save money in many ways. You use less energy because the heater focuses only on the part you want to heat. This can cut your energy bills by up to half compared to old methods. You also avoid wasting materials since the heat stays where you need it. Fewer mistakes mean you do not have to redo work, which saves time and money. Over time, these savings add up and help your business grow.

Key Features of Induction Heaters

When you want to buy an induction heater, you should look for the most important features. These features help you do your job well. Let’s talk about what matters most.

Power and Heating Speed

Power output is very important to check first. The right power helps you heat parts fast and evenly. If the heater has too little power, you will wait longer. Too much power can waste energy or hurt your workpiece.

Here is a table that shows common power ranges and where they are used:

A higher power output means you can heat metal to 1000°C in less than a second. This fast speed helps you finish jobs quickly and keeps your work moving. Induction heating is much faster than old ways like ovens or flames. You save time and work better.

Temperature Control

Good temperature control is needed for the best results. With this, you do not overheat or underheat your parts. You can set the exact temperature you want. This gives you even heating and better quality.

Many induction heaters have digital displays and sensors. These tools help you watch and change the temperature as you work. If you need help, Canroon’s guides show you how to use these controls for great results.

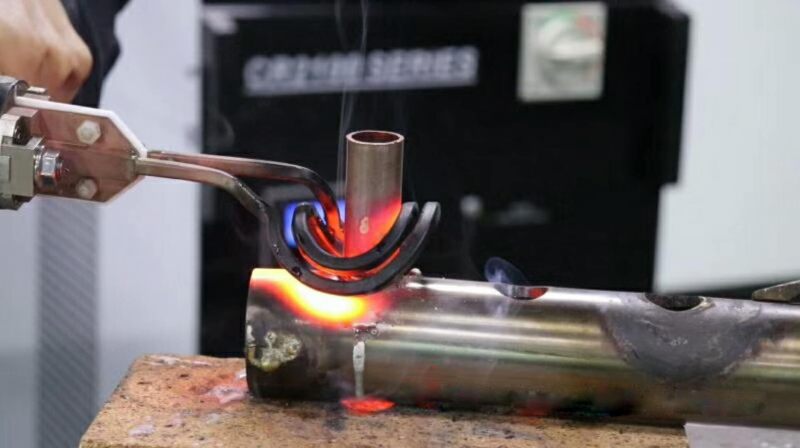

Coil Design

Coil design affects how well your induction heater works. The coil’s shape, size, and how close it is to your part all matter. A good coil design gives even heating and saves energy.

The right gap between the coil and workpiece (usually 0.5-3mm) helps transfer power well.

Single-turn coils heat small spots fast. Multi-turn coils spread heat more evenly.

Special coil shapes, like pancake or internal coils, fit different part shapes.

Using flux concentrators and magnetic shields puts energy where you need it.

Good coil materials, like copper or silver-plated copper, keep the coil cool and working well.

You can use multi-coil systems for big or tricky parts. These systems heat different areas at the same time, so you get even results. Canroon’s team can help you pick the best coil design for your job.

Safety Features

Safety features keep you and your equipment safe. Look for induction heaters with:

Automated power control devices

Fault detection sensors

Overheating protection

These features stop problems before they start. They keep your workspace safe and your heater working well. You can feel safe knowing your induction heater protects you.

Energy Efficiency

Energy efficiency is a big reason people pick induction heating. Modern induction heaters use 70-90% of the energy they take in. Old ways, like resistance heating, only use 45-75%. You get more heat where you want it and waste less energy.

In real factories, using induction heating can cut energy use by more than half. For example, one car factory used 62% less energy and finished jobs in seconds instead of minutes. You save money and help the environment too.

Tip: Coupling efficiency is important. The closer your coil is to the workpiece, the better the energy moves. A small gap gives you faster, safer, and more reliable heating. If the gap is too big, you lose efficiency and slow down your work.

When you pick an induction heater, always check these features. If you need help, Canroon’s guides and support team can help you choose the best one for your needs.

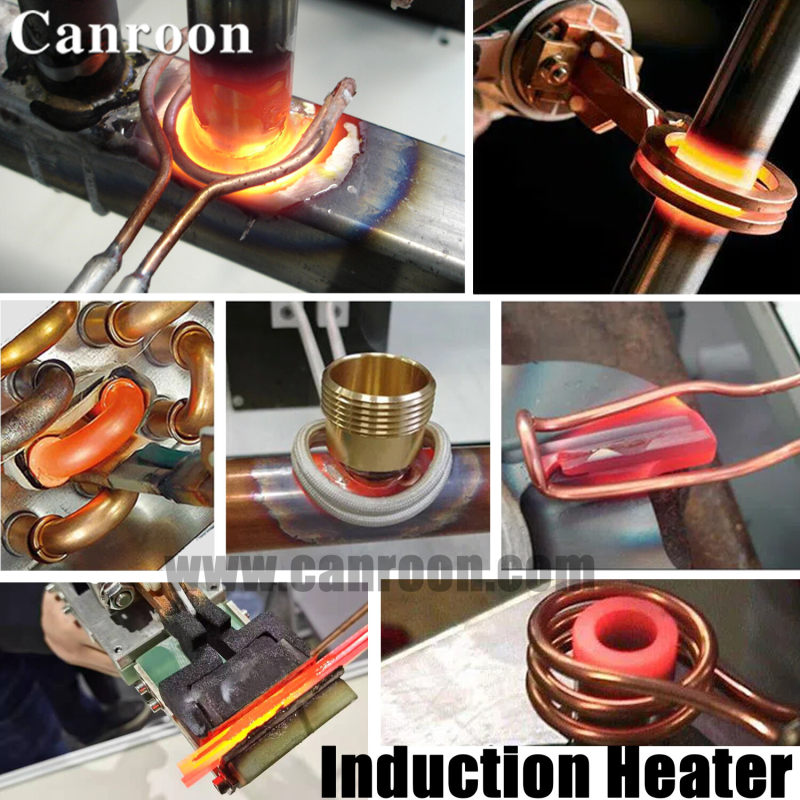

Application Requirements

When you look for the best induction heater, you need to match it to your application requirements. This means thinking about what you want to heat, how fast you need it done, and where you plan to use the heater. Let’s break down the most important things to check before you buy.

Material Compatibility

Not every metal works with an induction heater. You need to know the type of material you want to heat. Here are some metals that work well:

Steel

Aluminum

Copper

Brass

Nickel and their alloys

You see these metals in many jobs. For example, you can use induction heating for heat sealing aluminum foil in food packaging, fusing nickel coatings on steel, or welding copper-clad steel. Induction heaters also help with brazing, soldering, shrink fitting, and even curing adhesives on metal. These jobs show how flexible and effective induction heating can be. You get fast, clean, and strong results, even with big or oddly shaped parts.

Tip: Always check if your workpiece is made from a compatible metal. If you use the wrong material, the heater may not work well or at all.

Heating Penetration

Heating penetration means how deep the heat goes into your workpiece. This depends on the thickness and the material. When you use an induction heater, most of the heat starts at the surface because of something called the skin effect. Over time, the heat moves deeper. If you work with thick pipes or large blocks, you need to think about how to get the heat all the way through.

The frequency you choose changes how deep the heat goes. Lower frequencies push heat deeper, but they might not be as fast. Higher frequencies heat the surface quickly but do not reach deep inside. You also need to think about the metal’s properties. Some metals let heat move faster than others. If you want even heating, you can use special frequency settings to help the heat spread out better and avoid hot or cold spots.

Operating Frequency

You need to pick the right operating frequency for your job. This choice affects how deep and how fast your induction heater works. Here’s a simple table to help you decide:

If you work with thick steel bars, go for a lower frequency. If you need to heat a thin copper wire, a higher frequency works better. Most induction heaters let you adjust the frequency, so you can match it to your heating requirements. This helps you get the best results for every job.

Workpiece Mass

The size and weight of your workpiece matter a lot. Bigger and heavier parts need more power output to heat up quickly and evenly. If you use a small heater on a big part, you will wait a long time, and the heat may not spread well. For small jobs, like heating a bolt or a wire, you do not need as much power.

Some induction heaters can melt up to 6,000 kg of metal at once, like in big factories. Others are made for small labs or home use, where you only need to melt a few grams. Think about how much metal you want to heat at one time. This helps you pick the right size and power output for your induction heater.

Note: If you need to melt metals, look for features like easy-to-change crucibles, fast heating times, and safe pouring systems. These make your work easier and safer.

Space and Footprint

You also need to think about where you will use your induction heater. In a factory, you might have lots of space for a big machine. At home, you may only have room for a small unit. Some induction heaters need special electrical setups, like high-voltage plugs or strong circuit breakers. These can cost extra money and take time to install.

Home users often face challenges like upgrading electrical panels, fixing walls after installation, or even needing new transformers. These upgrades can get expensive. Industrial buyers usually focus more on performance and technical needs, while home users worry about cost, space, and power supply.

If you plan to use your induction heater at home, check your electrical system first. Make sure you have enough space and the right setup to avoid surprises.

When you match your induction heater to your application requirements, you get better results, save money, and avoid problems. Always think about the type of material, heating penetration, frequency, workpiece mass, and your available space before you buy.

Buying Tips

Compare Models

When you shop for induction stoves, you will see many choices. Each model has its own strengths. Some heat water super fast, while others keep a steady simmer so your food does not burn. You want even baking and broiling, especially if you cook on more than one rack. Some induction stoves have more usable oven space, so you can fit bigger pans. Others may look big but have less room inside. Self-cleaning is another handy feature. The best induction stoves make cleaning up easy after a messy meal.

Top models heat large pots quickly.

Good stoves keep a steady simmer for sauces and soups.

Even baking means your cookies come out the same on every rack.

Some stoves have more real cooking space inside.

Self-cleaning cycles help you clean tough messes.

Tip: Prices for induction stoves are now close to electric and gas stoves. You get more choices for your budget.

Read Reviews

Reading reviews helps you learn what real users think about induction stoves. Expert reviewers look at many things before they give a rating. They check the coil design, how well the coil fits the pan, and how fast the stove heats up. They also look at how much space the stove needs in your kitchen. Some stoves need special cooling or more power. Reviewers test extra features like temperature sensors and smart controls. They also check if the company has experience with induction stoves and offers good advice.

Reviewers check if the coil matches the pan shape.

They test how close the coil is to the pan for fast heating.

They look at how much space and power the stove needs.

They try out extra features like temperature sensors.

They see if the company helps with setup and has good support.

Note: Consumer Reports tests thousands of baked goods to see how well induction stoves bake and broil. They care more about how the stove cooks than how many features it has.

Warranty and Support

A good warranty gives you peace of mind when you buy induction stoves. Most top brands offer a two-year warranty on the whole unit. Some parts, like glass or temperature probes, may have shorter coverage. The warranty usually covers only the first owner and does not include damage from misuse or bad installation. Always read the warranty details before you buy.

You should always buy from a trusted supplier like Canroon. They give you clear instructions for setup and safety. You get guides that show you how to pick the right coil, install it, and keep your induction stoves working well. Good support means you can ask questions and get help fast. This makes your experience better and keeps your kitchen running smoothly.

You want the best results from induction stoves, so start by thinking about what you need to heat and how much you need to do. Experts suggest you look at things like the type of metal, how deep you want the heat to go, and the right power for your job. Induction stoves work well for many tasks, but you get the most out of them when you match their features to your needs. Canroon’s guides and support help you pick the right model, answer your questions, and make sure you feel confident using induction stoves. Try these tips and see how easy and safe induction stoves can make your work.

FAQ

What size induction heater do I need?

You should match the heater size to your job. Small jobs need less power. Big parts or heavy use need more. If you are not sure, ask a supplier like Canroon for advice.

Can I use any metal with an induction heater?

No, you cannot. Induction heaters work best with magnetic metals like steel or iron. Aluminum and copper need special settings. Always check your metal before you start.

How do I know if my cookware works on an induction stove?

Try this: Stick a magnet to the bottom of your pan. If it sticks, your pan works on an induction stove. If it does not, you need different cookware.

Are induction heaters safe to use at home?

Yes, induction heaters are safe when you follow the instructions. They do not have open flames. The surface stays cool. Always read the manual and keep the area clear.

Previous:

Next:

Sign up for updates