Canroon, Miller, and other top brands give new pwht machine choices for big jobs in 2025. Engineers use post weld heat treatment to make pipelines, pressure vessels, and steel stronger. New pwht technology uses induction heating and careful temperature control to make welds better and safer.

Key Takeaways

- Post Weld Heat Treatment (PWHT) makes welds stronger and stops cracks. It is very important for jobs in petrochemical, energy, and aerospace fields.

- Pick PWHT machines by looking at how they heat. Induction heating works quickly and saves energy. Electrical resistance gives you better control.

- Good temperature control is very important. It helps stop errors and saves money by making sure welds are good.

- Always make sure you follow rules like ASME. This keeps your PWHT work safe and dependable.

Think about the total cost when you buy a PWHT machine. Do not just look at the first price. Also think about energy, repairs, and help you might need.

PWHT Machine Comparison

Key Features

People in factories look at many things when picking a pwht machine for 2025. The Canroon CR2000-020B-14TF and Miller ProHeat 35 are top choices. These machines have strong features and work well. They follow rules like ASME Section VIII and PED 2014/68/EU. Quality checks use outside inspection reports and test certificates. The table below shows the main features:

Tip: Always look for proof of reliability and rule-following before you buy a pwht machine.

Heating Methods

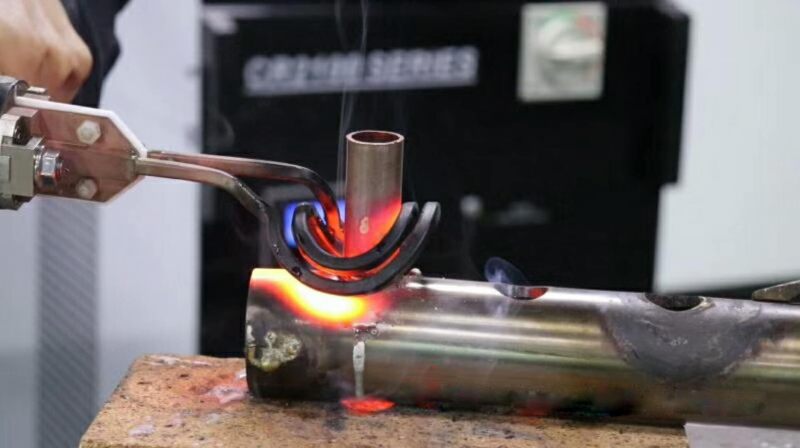

PWHT machines use different ways to heat welds. Electrical resistance heating uses bendy ceramic parts and special control boxes. Induction heating makes heat by moving metal molecules with a magnetic field. Combustion heat is good for big things inside special ovens. Some machines mix heating and cooling to control temperature better. The table below compares these ways:

Induction heating works fast, so it is good for high heat jobs. Electrical resistance is strong and lets you control heat well, great for welding pre-heat. Induction is best for jobs like taking couplings off turbines. Electrical resistance is good for welding pre-heat because the tools are strong and can handle a lot. Electrical resistance lets you control heat at many spots, but induction usually controls just one spot.

Temperature Controls

New pwht machines use smart temperature controls. These machines keep the base material at the right temperature before and after welding. This helps stop cracks and mistakes. Miller ProHeat 35 uses induction and can control temperature, and it works with 400-460V CE power. Some machines, like the 65kVA 6 Channel PWHT, let you control heat in many places after welding. AEC Digit gives exact control for pre-heat and stress relief.

Good temperature control stops mistakes and saves money by lowering weld problems.

Machines with many channels let workers set and watch heat in many places for better results.

Post Weld Heat Treatment Overview

Industrial Applications

Post weld heat treatment is very important in many jobs. Engineers use it to make welded joints stronger and safer. The table below shows how different jobs need pwht to keep things working well:

Many factories in petrochemical work use heat treatment after welding. This keeps their equipment safe in hard places. The energy sector uses pwht to stop cracks and slow down old parts. Shipbuilders use stress relief so ships can handle big waves. Aerospace companies use post-weld heat treatment to make plane and car parts stronger.

Benefits of PWHT

PWHT gives many good things for welded parts.

It makes the weld tougher and able to hold more weight.

It stops stress corrosion cracking by lowering stress and fighting rust.

It gets rid of trapped hydrogen, so there are fewer cracks.

Modern pwht furnaces and induction heating systems control temperature very well. This helps with stress relief and keeps welds safe. Good temperature control stops expensive weld problems. PWHT machines and furnaces help every weld meet high quality rules. These steps protect pipelines, tanks, and other important things.

Note: Picking the right pwht way, like induction heating or furnaces, gives the best results for stress relief and weld strength.

PWHT Machine Reviews

Canroon CR2000-020B-14TF

The Canroon CR2000-020B-14TF is a trusted pwht machine for factories. Many people say it works well and lasts a long time. Engineers pick this model because it heats up fast and helps with stress relief. The machine lets you control the temperature closely. This stops weld cracks and makes the weld better.

People share good things about the Canroon CR2000-020B-14TF:

ABDULMALIK NASIRU says, "I got the item on time, the VFDs are very good, I will buy more soon."

Ahmed says, "Canroon VFD is great quality, good price, nice service, and fast help after buying, more orders coming."

Karim says, "Canroon induction heater is top quality, heats up fast, I have used it for over 5 years, it works well with no problems, picking Canroon induction heater is smart, Ms. Sandy gives great service, we want more heaters."

These stories show the Canroon CR2000-020B-14TF works well and is dependable. Many factories use this pwht machine for jobs that need quick heating and steady results.

Miller ProHeat 35

The Miller ProHeat 35 uses induction heating for post-weld heat treatment. This pwht machine makes work safer and the job site better. Workers find it easy to set up because it uses bendy heating cables and special blankets. The ProHeat 35 has built-in temperature control. You can set it by hand or use a program for weld jobs.

The Miller ProHeat 35 helps engineers finish welds faster and with fewer mistakes. Its induction heating helps with stress relief and is good for big welds.

Other Leading Brands

Other brands also make strong pwht machines for factories. Many companies build machines that work with furnaces and let you control the temperature well. These machines help with post weld heat treatment and stress relief for pipes, tanks, and steel frames. Engineers want machines that heat well, are easy to use, and give good help for welding. Top brands care about safety, lasting a long time, and making welds strong.

Tip: When picking a pwht machine, read what users say and look at things like how fast it heats, how you control the temperature, and the help you get after buying.

Application Recommendations

Pipelines

Engineers pick PWHT machines for pipelines by looking at many things. The kind of metal is important. Some metals can crack, so they need careful heat treatment. The way welding is done matters too. Hot welding often needs post weld heat treatment to keep welds strong. If the pipeline has high pressure or gets very hot, PWHT is more needed. The right temperature, holding time, and cooling rate must be used. How thick the metal is changes how much heat treatment is needed. Preheating helps stop cold cracks and may mean less extra PWHT is needed. Good records help keep track and make sure the work is good.

Metal type

Welding way

How the pipeline is used

Metal thickness

Preheat steps

Records for quality

PWHT machines with good temperature controls help keep welds strong in pipelines. These machines help lower stress and make pipelines safer in tough places.

Pressure Vessels

Making pressure vessels needs careful PWHT steps. ASME rules help guide the work, but rules have changed. In 2014, ASME B31.3 stopped needing PWHT for some metals. The new ASME B31P-2017 tries to make rules the same, but not many use it yet. ASME Section VIII Division 1 says how to soak bands, but does not give clear rules for heated bands. If PWHT is not done right, thick vessels can get high stress and might break.

Note: Engineers should use the newest rules and pick machines with good temperature control for pressure vessels. This helps stop weld problems and keeps things safe.

Structural Steel

PWHT needs for structural steel are not the same as for pipelines or vessels. The table below shows what is needed:

Most jobs with structural steel do not need post weld heat treatment, especially if the steel is low carbon or high-strength low-alloy and less than 1.5 inches thick. If the steel is thicker or used in special ways, engineers may use PWHT to make welds tougher and lower stress.

Tip: Always check project rules and steel type before choosing PWHT for structural steel.

PWHT Furnaces and Advanced Features

Induction Heating Systems

PWHT furnaces are important for post weld heat treatment. Old furnaces use combustion or electrical resistance to heat big parts. Induction heating systems are a newer choice for pwht. These systems use electromagnetic fields to heat metal fast and directly. This makes the process quicker and more efficient.

Induction heating systems have many benefits over old furnaces. They save energy because they only heat the needed parts. The process is very fast and can finish in seconds. Induction systems do more than just heat; they can smelt and weld too. Operators do not need to preheat, so they save time. Induction heating uses clean electricity, which helps protect the environment and keeps workers safe. The system gives quick and efficient heat, so jobs finish faster and use less energy. Operators can set exact heating levels for steady results. Induction heating spreads heat evenly, so there are no hot or cold spots.

PWHT furnaces with induction heating help engineers get good post-weld heat treatment. These systems make welds better and lower the chance of problems.

IoT and Automation

New pwht furnaces have smart features like IoT and automation. These tools change how engineers watch and control post-weld heat treatment.

Using IoT for monitoring and automation helps collect live data and control settings. It makes welds better and more even. IoT lets engineers watch welding details and change things quickly. This is important for keeping welded parts strong.

Automation lets operators set heating cycles and temperature plans with little work. IoT sensors check temperature and other data and send alerts if things change. These features help keep welds high quality and lower mistakes. Engineers can see data from far away, so they can manage many jobs at once.

PWHT furnaces with IoT and automation make post weld heat treatment safer and faster. These new tools help industries follow strict rules and work better.

PWHT Machine Buying Guide

Material Compatibility

Picking a PWHT machine starts with knowing what metals you have. Different metals need different heat treatment steps. Engineers must match the machine to the metal used in welding. Carbon steel, alloy steel, and stainless steel need special temperatures and heating times. Some machines work better for thick metal. Others are good for thin metal. Always read the manufacturer’s guide for which metals work. Using the wrong machine can make welds weak or not relieve stress.

Tip: Check the metal type before you pick a PWHT machine. This helps stop cracks and makes sure the weld is strong.

Power Requirements

Power needs are important when picking a machine and planning costs. Industrial PWHT machines have different power levels. The table below shows common choices:

Machines with more power use more energy. More energy means higher costs. Resistance heat treatment units are used in oil and gas, power plants, and chemical factories. These units help keep things safe and strong. Picking the right power level helps post weld heat treatment work well and keeps costs low.

Machines with high power finish jobs faster but cost more.

Machines with less power save energy but take longer to finish.

Compliance and Safety

PWHT machines must follow strict safety and rule standards. Some jobs need machines that control temperature and watch the process. These steps help with safety:

Good temperature control is important. Use special thermocouples to check heat and stop overheating.

Follow rules for each metal, like ASME Section VIII Division 1.

Only trained people should do PWHT. Keep the work area safe from wind and rain.

Write down all steps, like temperature logs and checks, so you can look back later.

Check the metal after stress relief. Use your eyes and hardness tests to find problems.

Note: Following safety rules keeps workers safe and makes sure welds meet the law.

Cost Considerations

Cost matters when buying a PWHT machine. Buyers should think about more than just the price. The table below shows what to look at:

After-sales help and warranty are different for each maker. The table below compares two top brands:

Help from experts and service requests lower downtime and keep machines working.

Good after-sales help means you get spare parts and expert help fast.

Tip: Think about warranty, support, and how the machine fits with your other tools when you look at total cost.

Canroon is known for working well and having good temperature control. Miller and other brands also make strong machines for big jobs. It is important to pick a machine that fits the job, like welding pressure vessels or fixing gas turbines. The best PWHT machine makes welds stronger and helps stop stress.

Read the buying guide before you choose a machine.

Ask experts if you need help picking a product.

Picking the right PWHT machine helps keep welds safe and strong for every job.

FAQ

What does PWHT mean in welding?

PWHT means Post Weld Heat Treatment. Engineers heat metal parts after welding them together. This process helps make the metal stronger. It also lowers stress and stops cracks from forming.

How does induction heating work in PWHT machines?

Induction heating uses electromagnetic fields to heat metal fast. The machine sends energy into the metal. This makes the metal get hot quickly. Induction heating saves time and uses less energy than old ways.

Tip: Induction heating is great for jobs that need quick and even heat.

Which industries use PWHT machines most often?

Oil and gas

Power generation

Shipbuilding

Aerospace

These industries use PWHT machines to keep pipelines and steel safe. They also use them to make vessels and other big parts strong.

How can buyers check if a PWHT machine meets safety standards?

Buyers should always check for safety before buying a machine.

Previous:

Next:

Sign up for updates