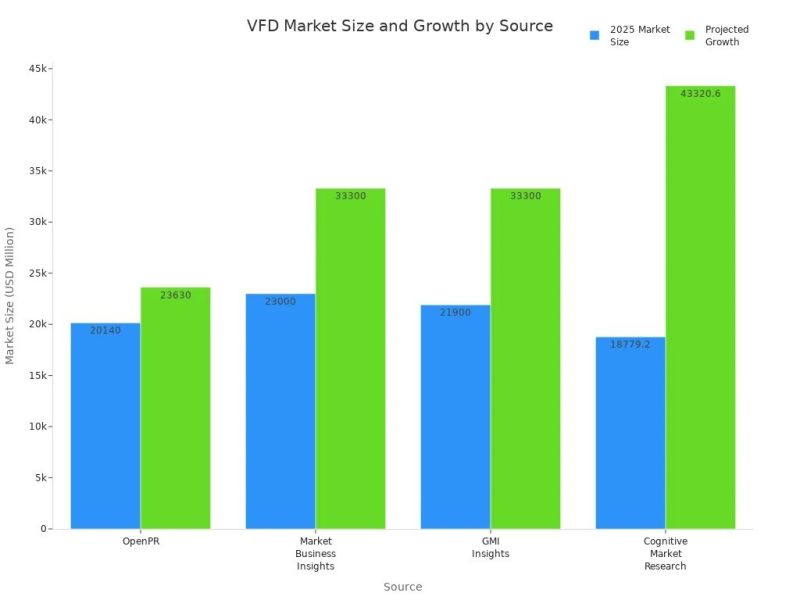

A variable frequency drive lets you change how fast and strong electric motors work. It does this by changing the frequency and voltage sent to the motor. You can use a variable frequency drive to make the motor do only what you need. This helps save energy and lowers how much you spend. Canroon is a top company for variable frequency drive solutions. They help factories and other places work better. In 2025, more people are using variable frequency drives. The market keeps getting bigger, as you can see below:

A variable frequency drive helps you use less energy. It also helps protect the planet and makes machines last longer.

Key Takeaways

A variable frequency drive (VFD) lets you change how fast and strong electric motors work. This helps you use less energy and spend less money. Using a VFD can save a lot of energy. Many factories say they use 20% to 65% less energy. VFDs help machines last longer. They start and stop smoothly. This means motors and machines do not break as much. These drives help you control things better. You can change speed and torque exactly how you want. This makes products better and work faster. In 2025, smart VFDs will have IoT features. You can watch them in real time and fix problems early. This stops big problems before they happen.

Variable Frequency Drive Basics

What is a Variable Frequency Drive?

Variable frequency drives help you control motor speed and strength. You can change how fast a motor goes by adjusting frequency and voltage. This lets machines run slower or faster when you need it. You get more control and save energy.

The vfd controller is the main part of a variable frequency drive. It lets you set motor speed and torque. You can start motors gently and stop them smoothly. This helps machines last longer and work better.

Tip: Using a vfd controller matches motor speed to your needs. This stops energy waste and lowers wear on your equipment.

In 2025, there are two main types of variable frequency drives. Voltage-Source Inverter (VSI) drives change AC power to DC, then back to AC. These drives give you good control and work for many jobs. Current-Source Inverter (CSI) drives control current instead of voltage. They are good for heavy loads and tough jobs, but they are bigger and cost more.

Canroon is a leader in vfd technology. You get expert help and smart solutions for your factory or building. Canroon’s vfd controllers help you use less energy and have more control.

Variable frequency drives are used in many places. Here is a table that shows common uses:

Variable frequency drives help machines work smarter. You get better control, save money, and help the environment.

A variable frequency drive (vfd) lets a fixed-speed motor run at different speeds.

You get flexible and efficient control for your machines.

The main job of a vfd is to control motor speed exactly. This helps all parts of your process work together. You save energy, get soft starts and stops, better control, less stress on machines, and even power factor correction.

Key VFD Components

Every vfd controller has important parts inside. Each part does a special job to help the vfd work well.

You use the vfd controller to set motor speed and torque. The rectifier changes power from AC to DC. The DC bus stores and smooths the power. The inverter turns DC back into AC with the frequency you want. The control circuitry makes sure everything works right. The filter keeps the power clean. The cooling system stops the vfd from getting too hot. Protection circuitry keeps your motor and vfd safe. The user interface lets you change settings and see how things are running. Feedback systems give you updates so you can keep everything working well.

Canroon’s vfd controllers use advanced technology for reliable and efficient motor control. You get a vfd control system that helps machines run smoothly and safely.

Note: Picking a vfd controller helps your equipment last longer and work better. You also save energy and lower your costs.

How VFDs Work

VFD Operating Principle

You use a vfd to change how an ac motor works. The vfd inverter takes the power from your wall outlet and turns it into the right kind of electricity for your motor. This process happens in several steps. Here is how a vfd inverter works from start to finish:

The vfd receives an AC supply, usually from the main power at 60 Hertz.

The vfd inverter uses a rectifier to change the AC power into DC power.

Capacitors inside the vfd smooth out the DC power, making it steady.

The vfd inverter then sends this DC power to an inverter circuit.

The inverter uses fast-switching parts to create pulses that look like AC power.

The vfd inverter uses special control methods to change the frequency of these pulses. This lets you control the speed of your ac motor.

Tip: You can use vfd speed control to make your machines run at just the right speed. This helps you save energy and protect your equipment.

In 2025, vfd technology has become smarter. You now see vfd inverters with IoT features. These smart vfd controllers connect to the internet and help you watch your machines in real time. You can use digital twins and edge computing to make your vfd motor run better and last longer. Smart sensors inside the vfd inverter give you more control and help you fix problems before they get big.

You can use a vfd inverter for many jobs. It works in factories, buildings, and even farms. The vfd motor controller helps you get the most out of your ac motor. You can start and stop motors smoothly, which makes your machines last longer.

Frequency and Voltage Control

The vfd inverter gives you full vfd speed control. You can change the frequency and voltage sent to your ac motor. This lets you set the exact speed you want. The speed of an ac motor depends on the number of poles and the frequency of the power. When you use a vfd, you can adjust the frequency to get the right speed for your job.

You must adjust both frequency and voltage together. If you lower the frequency but keep the voltage high, you can damage your vfd motor. The vfd inverter keeps both in balance. When you use vfd speed control, you get smooth motor speed control and safe operation.

You can use vfd speed control to slow down or speed up your ac motor.

When you run your vfd motor above its rated frequency, the torque drops. You need to watch your load to keep things safe.

You can pick from different control methods for your vfd inverter. Here is a table that shows the most common control algorithms:

You can use the Volts-per-Hertz method for simple jobs. If you need more precise vfd speed control, you can use vector control. Closed-loop vector control gives you the best motor speed control, especially when you need high accuracy.

Note: A vfd inverter helps you save energy, protect your ac motor, and get better control. You can use it for pumps, fans, conveyors, and many other machines.

The vfd inverter is now a key part of modern industry. You can use it to make your machines smarter and more efficient. With vfd speed control, you get the power to run your ac motor at any speed you need.

VFD Drive Benefits

Energy Savings

You can save a lot of energy with a vfd drive. Many factories save between 20% and 65% energy. Some reports say you can cut energy use by 20% to 50%. Sometimes, you may see a 5% to 15% drop in energy use. If you use a vfd drive for pumps or fans, you can cut energy use by half. This means you use less electricity and pay smaller bills.

VFD drives let you set motor speed for your needs.

You do not have to run motors at full speed all the time.

You use less energy and make your system more efficient.

Real examples show these savings. In HVAC systems, vfd drives change fan and pump speeds when needed. This saves power and keeps buildings comfy. Village Urban Resorts saw energy costs drop by 49% after using vfd drives on air units and pool pumps. They saved almost £500,000 every year. New vfd drive systems can lower energy use by 20% to 50%, depending on your building.

Equipment Longevity

A vfd drive helps your machines last longer. You get smooth starts and stops, so there is less stress. Motors do not get sudden shocks, so they do not break as easily. With a vfd drive, motors run only as fast as you need. This keeps them cooler and stops overheating. The vfd drive controls voltage and frequency, giving steady power and protecting your system.

Motors and parts wear out slower.

You spend less time and money fixing things.

The vfd drive checks for problems and gives feedback, making things work better.

Here is how vfd drives help with repairs:

Improved Control

You get better control over motors with a vfd drive. You can pick the speed and torque you want. This keeps your process safe and steady. In factories, vfd drives let you set conveyor belt speeds exactly. You make better products and stop delays. Vfd drives work with PLCs and HMIs, so you can change settings quickly and make more products.

You save energy by matching motor speed to the job.

You spend less on repairs and your machines last longer.

You get exact speed and torque, so your process works better.

Conveyors with variable speed keep things moving smoothly. This helps make better products. Soft starts and stops stop jams and spills, so your process runs well. You also make things safer by stopping sudden moves and lowering risks for workers.

Tip: Canroon’s vfd drive solutions give you smart motor control, lower costs, and better safety for your team.

Variable Speed Applications in 2025

Industrial Uses

Factories use variable speed drives for many machines. These drives help control pumps, fans, and conveyors. You can set the motor speed to fit what you need. This saves energy and helps machines last longer. Oil and gas companies use these drives for pumps and compressors. This lowers costs and keeps machines from wearing out fast. Water treatment plants also use adjustable speed drives. They change pump speed to match water flow. This keeps everything working well.

Note: Many factories now use smart variable speed drives. These drives connect to the internet. You can watch your machines in real time. You can find problems early and fix them before they get worse.

Commercial Uses

Many commercial buildings use variable speed drives. These drives help control HVAC systems. You can change fan and pump speeds to fit the building’s needs. This saves energy and lowers your bills. Pumps are used the most, making up about 34.2% in 2024. Oil and gas come next with 24.3%. HVAC systems also use these drives to help save energy.

Here are some main benefits of using variable speed drives in commercial buildings:

New Trends

New trends are changing variable speed technology. Smart integration and IoT are now important. You can check your systems from anywhere. You get alerts if something is wrong. Predictive maintenance helps you fix things before they break.

The use of smart technologies and IoT gives you real-time data. You can watch motor performance, save energy, and stop failures before they happen.

Here are some top trends for 2025:

IoT lets you control and watch drives from far away.

Machine learning and AI help drives get better.

Drives are smaller and easier to install.

More drives are used in renewable energy.

Safety features are getting better.

Smart pump systems adjust to real-time needs.

Modular designs make upgrades easy.

Canroon is a leader in these new ideas. You get advanced variable speed, adjustable speed drive, and adjustable frequency drive solutions to help you in 2025.

A variable frequency drive lets you change how fast a motor goes. You can also change how strong it works by adjusting frequency and voltage. This helps you save energy and makes your machines last longer. You also get better control over your process. In 2025, VFDs help you reach energy goals and spend less money. They are used in places like HVAC, water treatment, and factories.

Canroon gives smart and reliable VFD solutions for what you need.

You need to check if your motor works with a VFD. You should also look at the type of load and where you use it before picking a VFD. VFDs are important now because they make things work better, help the planet, and keep your business ready for new changes.

FAQ

What motors can you use with a VFD?

You can use a VFD with most three-phase AC induction motors. Some VFDs also work with permanent magnet and synchronous motors. Always check your motor’s compatibility before connecting a VFD.

Can you install a VFD by yourself?

You can install a VFD if you follow the manual and basic safety rules. For complex systems, you should ask a professional. Incorrect installation can damage your equipment.

How do you set the speed on a VFD?

You set the speed using the VFD’s keypad, a remote control, or a connected system. You enter the desired speed or frequency. The VFD adjusts the motor speed to match your input.

Does a VFD need regular maintenance?

Yes, you should check your VFD for dust, loose wires, and overheating. Clean the cooling fans and filters. Regular checks help your VFD last longer and work safely.

Previous:

Next:

Sign up for updates