If you want the best electromagnetic induction heater for work in 2025, you should look at the top products. You need a heater that works well, is safe, and is reliable every day. More people want electromagnetic induction heater solutions now. You can see this need in many industries. The market size will be over USD 11.66 billion in 2025. New technology in electromagnetic induction heaters brings new ideas.

The market grows by 5.2% each year until 2032.

The Induction Heating Systems market is worth USD 0.728 billion in 2025.

Professionals give these electromagnetic induction heater products high ratings:

Every year, more people want electromagnetic induction heater products. You need to keep up with this need and pick the best product for your work.

Key Takeaways

Electromagnetic induction heaters are becoming more popular. The market may be worth over USD 11.66 billion by 2025. Pick a heater that fits your work needs.

Induction heating has many good points. It saves energy, is safe, and is very exact. These things make it great for use in factories.

When you pick an induction heater, look at power output, frequency, and coil design. Make sure it fits what you need for your job.

Top products like the Mini-Ductor® Venom® and Solary Magnetic Induction Heater are liked for being fast and safe. They work well for many different jobs.

Always look at the warranty and support before you buy. A good warranty keeps your money safe and helps you take care of your equipment.

Electromagnetic Induction Heater Technology

How Induction Heating Works

You may wonder how an electromagnetic induction heater works. First, you put a metal like steel inside the coil. The coil uses electricity to make a magnetic field. This field makes eddy currents move in the metal. The metal resists these currents, and that makes heat. The heat goes right where you want it and works fast.

Here is what happens in the system:

Heat comes from eddy current loss and hysteresis loss in metals.

The power source frequency changes how much heat you get and how deep it goes.

Faraday’s second law explains how the magnetic field makes electricity in the metal.

The metal’s resistance makes it heat up as current moves through it.

You can control the heat very well, which helps when hardening or tempering parts.

Induction-based technology lets you heat only the spot you need. You do not waste energy on the whole area. That is why electromagnetic induction heater technology is popular in factories and workshops.

Benefits for Professionals

If you work with industrial heating, you want tools that save time and energy. Electromagnetic induction heater technology has many benefits over old ways. You get better efficiency, more safety, and cleaner results.

Check out this table to see why professionals pick induction heating systems:

You get heating that saves energy and helps you reach your goals. Induction heating systems also help the environment. You can count on electromagnetic induction heater technology to work well in tough places. If you want to work faster and smarter in your projects, induction heating is a great choice.

Electromagnetic Induction Heater Market Trends

Market Growth and Forecast

The electromagnetic induction heater market gets bigger each year. More industries want better ways to heat things. You can see this in factories, car shops, and tech companies. The market for these heaters in 2025 looks strong. Here are some important facts about the growth:

The global electromagnetic induction heater market will grow a lot from 2025 to 2031.

The growth rate will stay high, showing the market is getting bigger.

More companies use induction heating because it saves energy and works fast.

The market keeps growing as new industries start using these heaters.

Demand for these heaters will rise as technology gets better.

If you look at different places, you will notice some differences in the market:

You can see the market growing in every region. Asia-Pacific is the largest, but the U.S. and Europe also grow a lot.

Key Drivers in 2025

You might ask why the market is growing so fast. There are many reasons for this. First, companies want to save energy and spend less money. Induction heating uses less power and gives more control. This helps people work faster and safer. The market also grows because industries want to be cleaner and greener. Induction heaters do not make smoke or waste heat, so they help the planet.

There are also more rules about saving energy. These rules make companies use better heating systems. The market grows as businesses follow these rules. New technology, like better controls and automation, makes induction heating even more popular. You get faster heating, less waste, and better results.

The market keeps growing because people need safer and cleaner ways to heat metal. If you work with steel, cars, or anything that needs heat, you will see more induction heaters each year. The trends show this technology will not go away.

Top Electromagnetic Induction Heater Products

You want the best electromagnetic induction heater for your job. Let’s check out the top models that professionals use in 2025. Each one is good for different tasks. You can find one that fits your needs. It does not matter if you work in a shop, a factory, or outside.

Canroon CR2000 Series

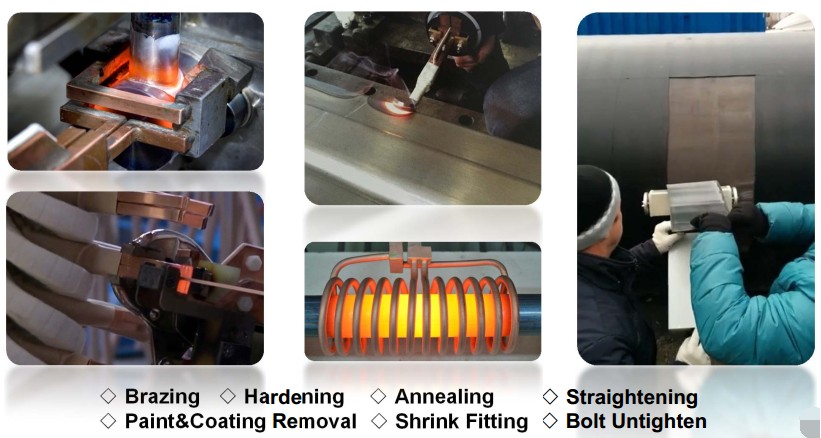

If you need power and control, look at the Canroon CR2000 Series. There are many models to pick from. You can choose the right electromagnetic induction heater for your workpiece size and job. The CR Series uses advanced induction heating. It gives fast and accurate results. You can use it for hardening, brazing, or shrink fitting.

Here is a quick look at the technical specs:

You get smart controls with PID closed-loop temperature control. You can change modes for different work pieces. The CR Series uses an isolation transformer to keep you safe. You do not need to worry about open flames or bad fumes. The air-cooled design keeps it running well, even in tough places.

Pros:

Many power choices for any workpiece

Fast and accurate induction heating

Modular and eco-friendly design

Works well in harsh conditions

Cons:

Heavy models are hard to move

Costs more for advanced features

Ideal Use Cases:

Large metal hardening

Precision brazing

Shrink fitting for big work pieces

Solary Magnetic Induction Heater

You want a tool that heats bolts and nuts fast. The Solary Magnetic Induction Heater does this job well. You can use it for car repair, machine work, or any job with stuck bolts. This electromagnetic induction heater uses induction heating to expand metal without fire.

You get a kit with an aluminum toolbox and ten coils. You can pick the right coil for your work piece. The built-in fan keeps the electromagnetic induction heater cool. LED lights help you see your workpiece in dark places.

Pros:

Heats bolts and nuts in 30 seconds

Safe near flammable materials

Easy to hold and use

Has many coils for different work pieces

Cons:

Only for smaller work pieces

Not for big industrial jobs

Ideal Use Cases:

Car repair shops

Machine maintenance

Removing rusty bolts from work pieces

Mini-Ductor® Venom® HP

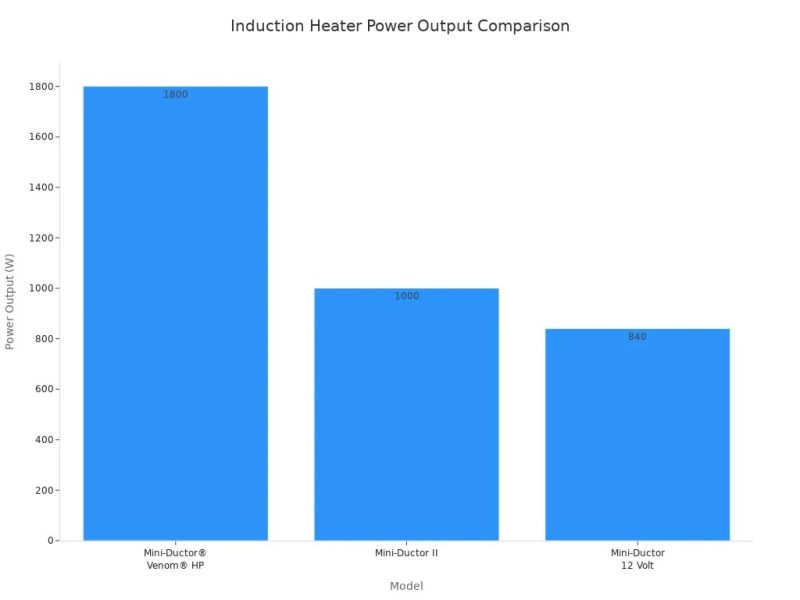

You need a portable electromagnetic induction heater for tough jobs. The Mini-Ductor® Venom® HP gives you 1800 watts of induction heating power. You can use it to loosen rusty bolts, nuts, and other metal parts on your work piece. You do not need an open flame, so you stay safe.

You get features like LED lighting, a usage indicator, and a fault override delay. The grip is easy to hold for a long time. The twist lock coil lets you change coils fast for different work pieces. You can read the manual in many languages.

You can cut labor by up to 75%

You can save parts you might throw away

You save money on supplies

You can use this electromagnetic induction heater for ABS sensors, bearings, exhausts, fuel tank straps, steering parts, truck bed bolts, and U-bolts. It works well on work pieces with rubber or plastic close by.

Pros:

Portable and light

Heats and loosens bolts without flames

Good for work pieces near flammable stuff

Cuts labor and saves parts

Cons:

Does not replace a torch for all jobs

Only for smaller work pieces

Ideal Use Cases:

Car repair

Saving rusty parts

Working near fuel tanks or plastics

EFD Induction Minac Series

You want flexibility and smart controls. The EFD Induction Minac Series gives you a small electromagnetic induction heater with a touch screen. You can use two power outputs for two work pieces at once. The pistol grip helps with induction brazing.

You can use this electromagnetic induction heater for heat treatment, brazing, shrink fitting, hardening, curing, and straightening. You get flexibility for many work pieces.

Pros:

Small and easy to use

Heats two work pieces at once

Touch screen controls

Works with many coil types

Cons:

Costs more than basic models

Needs training for advanced features

Ideal Use Cases:

Industrial workshops

Metal joining and hardening

Jobs with many work pieces

Ambrell EASYHEAT

You need a reliable electromagnetic induction heater for small and medium work pieces. The Ambrell EASYHEAT gives you up to 2.4 kW of induction heating power. You can use it for hardening, heat staking, hot forming, levitation melting, and more.

You can use this electromagnetic induction heater for many jobs. It works well for heating, hardening, heat staking, hot forming, levitation melting, material testing, medical device making, melting, metal-to-glass sealing, packaging, shrink fitting, soldering, and susceptor heating.

Pros:

Reliable and steady induction heating

Works for many work piece types

Good for small and medium jobs

Cons:

Not for very large work pieces

Less power than heavy-duty models

Ideal Use Cases:

Electronics making

Medical device production

Small metalworking jobs

Tip: When you pick an electromagnetic induction heater, think about your work piece size, job type, and safety needs. Each model has different strengths for your workpiece.

Product Comparison Table

You need to choose the right electromagnetic induction heater for your job. It helps to look at the top models side by side. This table shows how each heater does in power, efficiency, and how long it lasts:

Tip: Always check the efficiency rating. Most top models turn at least 90% of energy into heat. This means you waste less energy and save money.

Here are some things to think about when you compare products:

Power output: Bigger numbers mean faster heating for big jobs.

Duty cycle: If it runs all the time, you can work longer.

Warranty: Most brands give you 24 months, so you feel safe.

Reliability: Good quality and low failure rates mean fewer fixes.

Lifespan: Many heaters last up to 10 years if you care for them.

You can read more about fixing products and warranty at The Inductor.

When you look at these heaters, think about what you need for your job. Do you want more power or a lighter tool? Do you want a long warranty or easy help? Picking the right heater helps you work faster and stay safe every day.

Induction Heating Product Features

Power and Efficiency

Picking an electromagnetic induction heater means you need the right power. Power output tells you how fast you can heat things. If you work with big metal parts, you need more power. Small jobs need less power. You get the best results when you match power to your job.

You should also think about frequency. High frequencies heat small parts fast. Low frequencies heat bigger parts deeper. The coil design changes how well your heater works. Some coils heat up fast. Other coils heat more evenly. Cooling systems help your heater last longer. Air or water cooling keeps it safe and steady.

Tip: Always look at the control system. Good controls let you set the temperature. You can watch the process and get the same results every time.

Safety and Reliability

You want your electromagnetic induction heater to be safe and work well. Induction heating does not use open flames, so it is safer. Most heaters have safety features built in. These include overheating protection, automatic shut-off, and alarms. You can work near flammable things without worry.

Reliability means your heater works every day. Look for strong cooling systems and tough parts. Many brands give you a warranty. This helps if something breaks.

Here are some safety and reliability features you should look for:

Overheating protection

Automatic shut-off

Fault alarms

Strong cooling systems

Long warranty periods

Portability and Design

Sometimes you need to move your electromagnetic induction heater. Portability makes your job easier. Lighter models help you work in small spaces or on-site. Some heaters have handles or wheels. You can carry or roll them where you need.

Design is important too. A good heater has a display that is easy to read. You want simple controls and a grip that feels good. Some heaters come with toolboxes or cases. This keeps your coils and parts safe.

When you pick an induction heating tool, think about how you will use it. The right design saves you time and effort every day.

How to Choose an Electromagnetic Induction Heater

Application Needs

You need to pick the right electromagnetic induction heater for your job. First, think about what you will use it for. What kind of metal do you need to heat? How big are your workpieces? Some jobs need a lot of power. Other jobs need a tool you can carry. Make sure the heater matches what you do every day.

Here are some things to think about before buying:

Know what you will use it for. If you work with steel or cast iron, make sure the electromagnetic induction heater can heat those metals.

Check how much power it has. Big jobs need more power. Small fixes need less.

Look at the frequency. Thin metal heats up fast with high frequency. Thick metal needs lower frequency to heat all the way through.

Think about the coil shape. The right coil helps heat your workpiece evenly.

Decide if you need to move it around. Some electromagnetic induction heater models are easy to carry. Others stay in one place for big jobs.

Cooling is important. If your shop is hot, pick a heater with good cooling.

You want your electromagnetic induction heater to work quickly and not waste energy. Induction heating is faster than old coil ways. It uses less electricity and keeps your shop cleaner. If you pick the right size, you save energy. A heater that is too big wastes power. A small one makes you wait longer. Always match the electromagnetic induction heater to your job for the best results.

Warranty and Support

Warranty and support help you feel safe when you buy. Most electromagnetic induction heater brands give you a two-year warranty. This covers problems from making the product. If you find something wrong, you can call support in two months. Repairs must be done at special shops. You get a free repair cost check and a full test after fixing.

Here’s a quick look at common warranty options:

You can also get help with repairs. Some brands let you send your heater out for fixing and give you forms to check your warranty. Good support means you can use your electromagnetic induction heater more and wait less for repairs. If you use your heater every day, strong warranty and support help keep your tool working well.

Tip: Always read the warranty before you buy. Good support makes your job easier and protects your money.

You can pick from many good electromagnetic induction heaters in 2025. Brands like Canroon, Solary, and Mini-Ductor® are known for being strong, safe, and dependable. It is important to choose a heater that matches what you need for your job. The comparison table and buying guide can help you make a smart choice.

Find heaters that use less energy and work well.

Pick models that have good safety certificates.

Choose designs that fit where you work and how you work.

Experts say saving energy and helping the planet are very important now. New green heating tools can help you spend less and care for nature.

Watch what is happening in the market. If you buy the right induction heater now, you can be ready for the future and do better at your job.

FAQ

What metals can you heat with an electromagnetic induction heater?

You can heat steel, iron, copper, and aluminum. Most induction heaters work best with metals that have high electrical resistance. If you use the right coil, you can heat many shapes and sizes.

How do you keep your induction heater safe during use?

Always check for overheating. Use the built-in safety features like automatic shut-off and alarms. Keep the area clean. Never touch the coil when it is on. If you see a warning light, stop and let the heater cool.

Tip: Read the manual before you start. Safety first!

Can you use induction heaters for car repairs?

Yes, you can use induction heaters to loosen rusty bolts, nuts, and other metal parts. Many auto shops use portable models for quick fixes. You save time and avoid open flames.

How do you choose the right coil for your job?

Pick a coil that matches the shape and size of your workpiece. Try different coils for best results.

Previous:

Next:

Sign up for updates