When you pick a controller for your AC motor, make sure it works with your motor and your job. Matching the ac motor speed controller to your motor and where you use it helps you use less energy and avoid damage. This gives you better control, longer machine life, and easier repairs.

You use less energy

You keep your equipment safe

You make things safer and more reliable

Canroon’s team can help you with each step. Always think about the technical details and what you need for your setup when picking a controller.

Key Takeaways

Pick an AC motor speed controller that fits your motor type and job. This helps save energy and keeps things safe.

Look at voltage and current ratings closely. This stops the controller from breaking and keeps it working safely.

Pick the best control method for your needs. This makes the motor work better and last longer.

Think about things like heat and dust in your area. Choose a controller that protects against these problems.

Always look for safety features like overcurrent protection. This keeps your equipment and workplace safe.

Understanding Your Motor and Power Needs

AC Motor Types Overview

You should know your motor type before picking a controller. Different motors need different controllers to work best. Here is a table that shows the main AC motor types and where you use them:

Some motors have special covers. These include:

Open Drip Proof (ODP)

Totally Enclosed Air Over/Airtight (TEAO)

Totally Enclosed Non-Ventilated (TENV)

Totally Enclosed Fan Cooled (TEFC)

Totally Enclosed Severe Duty

Totally Enclosed Wash Down (TEWD)

Explosion Proof motors

The motor type changes which controller you should use. The table below shows how:

Canroon has controllers for all these motor types. You get help to match your motor and controller, so your system works well.

Voltage and Current Ratings

You need to match the controller’s voltage and current to your motor. Most motors use low voltages like:

200–240 V

380–480 V

575–690 V

The controller’s current rating should be as high as your motor needs. This includes the current when your motor starts and speeds up. If you do not match these ratings, your controller might stop working. Always check your motor’s full load amperage (FLA). The controller must handle this FLA and how your motor really works. This keeps your motor safe and stops problems.

A good controller also checks:

Voltage class

Overload ratings

Thermal environment

Harmonic controls

I/O and networks

Integrated PID

Safety ratings

You should look at these features to make sure your motor and controller work together. Canroon’s team can help you pick the best controller for your power needs.

Accurate Sizing and Duty Cycle

Sizing your controller is important. You need to know how long and how hard your motor will run. The duty cycle tells you how much time your motor works in each cycle. If your motor runs all the time, you need a controller for high duty cycles. If your motor runs sometimes, you can use a smaller controller because the motor cools off between uses.

Here are some tips:

Lower temperatures help your motor last longer. They keep the grease in the bearings fresh.

Managing heat helps your motor work better and improves its duty cycle.

Continuous duty means your motor works for a long time. This puts more stress on the motor and controller.

Intermittent duty lets your motor rest and cool down, so it lasts longer.

Higher duty cycles mean longer run times, but they can shorten your motor’s life.

You need a controller that matches your motor’s duty cycle and speed. This keeps your system safe and working well. Canroon can help you size your controller and pick the right features for your job.

Tip: Always check your motor’s real work pattern and speed before you buy a controller. This helps you avoid mistakes and keeps your system working well.

Defining Application Requirements

Control Methods and Protocols

You have to pick the right control method for your job. The control method changes how you set motor speed and torque. Here are some common ways AC motor speed controllers work:

Scalar (V/F) control keeps voltage and frequency balanced. You use this for simple tasks.

Vector control splits torque and magnetic flux. This gives you more control, even at slow speeds.

Sensorless control guesses motor position without sensors. You use this for easy setups.

You should also check for features like soft start, torque limits, and braking. These features help your motor work better and safer.

Modern controllers use special protocols. These help your controller talk to other machines. The table below shows how these protocols help:

Canroon has custom motion control that works with many protocols. This gives you options to fit your needs.

Inertial Load and Performance

You need to think about load inertia when setting up your controller. Inertia means how hard it is to change speed. Big loads, like heavy belts or robot arms, need more power to start moving. If you push your motor too hard with high inertia, it might stop working.

High inertia loads need more time to speed up and slow down. This keeps your motor safe from damage.

Smooth running depends on setting the right speed ramp for your load.

Always match your controller settings to your load for best results.

Canroon’s controllers let you change acceleration and deceleration for each job. You get steady speed and control every time.

Environmental Considerations

Where you use your controller matters a lot. Heat, water, and dust can cause problems.

Temperature is very important for VFDs. Hot places can make parts overheat and break early. Cold places can make things stiff and slow. Wet air can cause water drops, short circuits, and rust. Dust can block air and make things too hot.

You need to choose the right box and IP rating for your controller. The table below shows some common IP ratings:

Special seals, coatings, and grease help protect your controller in hard places. Canroon has solutions for wet, dusty, and hot spots. You get safe and steady control wherever you work.

Comparing AC Motor Speed Controller Features

When you look at ac motor speed controllers, check what features you need. Pick a controller that fits your motor and system. This helps keep everything safe. Canroon has motion control products for many jobs.

Compatibility and Adjustability

Your controller should work with your motor and system. Compatibility means it matches your motor type, voltage, and current. Adjustability lets you change settings for different jobs. This gives you better speed control and more choices.

Here is a table that compares AC motor controllers and DC motor controllers:

Canroon’s ac motor speed controller has built-in PLC features. You can program it for different tasks. Flexible connections let you use it in many places. It works in clean rooms, cooling systems, and exhaust fans. The small size saves space and makes setup easy. On-board PLC means you do not need extra controllers. This saves money and space. Built-in features help you start working fast.

Protection and Safety

Safety matters when you use an ac motor speed controller. Your controller should protect your motor and system. Canroon’s controllers have safety features to keep your equipment safe.

Here is a table with important safety features:

Your controller should stop too much current from hurting your motor. Overvoltage protection keeps your system safe from voltage spikes. These features help prevent damage and keep things running well.

Tip: Always look for safety features like STO and overcurrent protection before you pick a controller. This helps keep your workplace safe.

Installation and User Interface

Easy setup and a good user interface make your controller simple to use. You want a controller you can set up fast and change settings easily. Canroon’s controllers have options you can program and clear screens.

Manufacturers now use LCD screens instead of old keypads. These screens show words and pictures, so you understand settings better. You can put keypads in different places for more choices. Graphics and extra features make it easier to control speed and other settings.

Here are some things to check when you install your controller:

Make sure your controller matches your motor’s voltage and power.

Check load needs to pick the right controller for your motor.

Use remote mounting for keypads if you need to control your system from far away.

Canroon’s ac motor speed controller is easy to install and has a friendly user interface. You can program it for your job and change settings when you need to. This helps you get good speed control and keeps your system working well.

Note: A good user interface saves time and helps you avoid mistakes when setting up your controller.

Evaluating Variable Frequency Drive Options

When you choose a variable frequency drive (VFD), you need to look at both the cost and the benefits. You also need to decide if a standard or custom solution fits your job best.

Cost vs. Benefits

A variable frequency drive can help you save money and protect your equipment. You get better control over your motor speed, which means you use less energy and your motor lasts longer. The table below shows how VFDs help you:

You also need to pick the right control method for your application. Here is a table that compares common VFD options:

Tip: Pick a control method that matches your job. You save money and get better performance.

Off-the-Shelf vs. Custom Solutions

You need to decide if a standard VFD works for you or if you need a custom solution. Here are some things to think about:

Check if you use the drive indoors or outdoors.

Match the VFD to your motor’s current, voltage, and frequency.

Look at your motor’s torque needs.

Make sure your motor type fits the VFD.

Think about how often your motor runs and rests.

Decide if you need steady speed.

Know what your job needs from the motor and load.

If you need special features, a custom variable frequency drive may be better. Custom VFDs can handle tough environments, offer extra functions, and fit your exact needs. The table below shows what custom solutions can do:

Custom VFDs come ready to install in enclosures.

You get pre-tested systems that start up quickly.

Canroon can design a solution just for your job.

Note: If your job has special needs or tough conditions, ask Canroon about custom variable frequency drive solutions.

You can pick the right AC motor speed controller by making sure it matches your motor type, voltage, and what you need it to do. Always look for features like safety, how easy it is to use, and if it helps save energy. If you are not sure, Canroon experts can help you choose the best one for your system. Try not to make mistakes like not reading the manual or not testing the controller before using it.

Common mistakes to avoid:

Not reading the manual

Skipping software setup

Not testing before using it fully

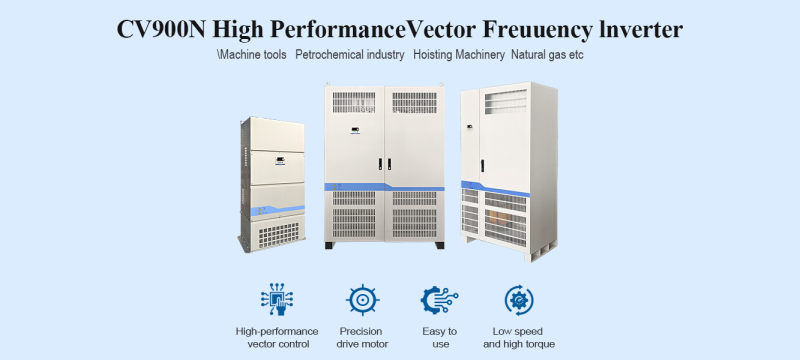

Canroon’s CV800D Series gives you advanced control, very good accuracy, and strong protection:

If you need help, look at troubleshooting guides or ask technical experts for help with fixing or upgrading your controller.

FAQ

What is the difference between an AC motor speed controller and a variable frequency drive?

An AC motor speed controller changes how fast a motor spins. A variable frequency drive, or VFD, does this by changing the power’s frequency and voltage. VFDs give you more control and help save energy.

How do I know which controller fits my motor?

First, check your motor’s voltage, current, and type. Make sure the controller matches these numbers. Think about how long and hard your motor works. If you are not sure, ask an expert for help.

Can I install the controller myself?

Many controllers are easy to install if you read the manual. You must connect the wires the right way and turn on safety features. If you are not sure, it is best to get a technician to help.

What safety features should I look for?

Look for overcurrent protection, Safe Torque Off (STO), and thermal overload protection. These features help keep your motor and workplace safe. Always check the safety ratings before you buy a controller.

Sign up for updates