You want to get rid of that stubborn rusted bolt, right? An induction bolt heater can help you do it fast and safe. You don’t need to mess with flames or worry about damaging nearby parts. This tool heats the bolt directly, breaking the rust bond in seconds. You get precise control, so you avoid the risks that come with torches. If you want a simple way to tackle tough bolts, this method changes the game.

Key Takeaways

Induction bolt heaters are safe and work well. They help you take out rusted bolts without fire. This keeps other parts safe from harm.

You must wear the right safety gear. Always put on heat-resistant gloves. Wear safety glasses and flame-resistant clothes. This helps stop injuries.

Follow each step in order. Get your workspace ready first. Put the coil in the right spot. Heat the bolt. Then use a wrench to turn the bolt loose.

If the bolt will not move, heat it again. You can also use penetrating oil. This helps break the rust.

Clean your induction heater often. Check the coils for problems. This keeps the tool working well and safe to use.

What Is an Induction Bolt Heater?

An induction bolt heater is a special tool that helps you remove rusted bolts without using fire. You use it to heat metal bolts quickly and safely. This tool works much better than a torch because it gives you control and keeps nearby parts safe.

How It Works

You might wonder how this tool heats a bolt without touching it. Here’s what happens:

The induction bolt heater uses electromagnetic fields to heat metal.

When you place the coil around a bolt, the tool sends a high-frequency current through the coil.

This creates a magnetic field that passes through the bolt.

The bolt heats up from the inside out, breaking the rust and making it easy to turn.

Tip: You don’t need to worry about flames or burning nearby wires and hoses. The heat goes right where you want it.

Let’s look at the main parts that make this tool work:

Key Benefits

You get a lot of advantages when you use induction heating tools for rusted bolts:

No open flames, so you stay safer.

Fast heating means you spend less time on each bolt.

The heat only goes to the bolt, so nearby parts don’t get damaged.

Even heating helps you avoid breaking or stripping the bolt.

You use less energy and get the job done quicker.

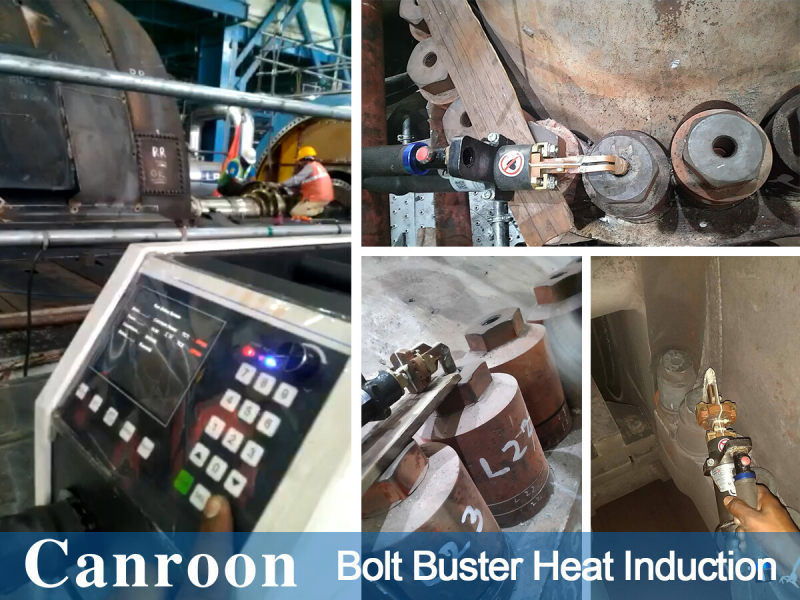

If you want a tool you can trust, check out Canroon. This company leads the way in induction heating tools. They use advanced technology and have strong quality control. Many people in the auto, aerospace, and electronics industries rely on Canroon because their tools work well and last a long time.

Using an Induction Bolt Heater

Ready to tackle that rusty bolt? Let’s walk through the steps so you can use your induction bolt heater safely and get the job done right. Here’s how you can remove stubborn hardware with confidence.

Tools and Safety Gear

Before you start, gather everything you need. Safety comes first, so don’t skip this part. Here’s a checklist to keep you protected:

Heat-resistant gloves and flame-resistant clothing protect your hands and body from burns.

Safety glasses or a face shield with ANSI-approved lenses shield your eyes from sparks and debris.

Hearing protection helps if you’re working in a noisy shop.

Safety footwear with non-slip soles keeps you steady on your feet.

Protective sleeves or arm guards add extra protection for your arms.

Make sure all electrical equipment is grounded to prevent shocks.

Inspect power cables and connections for any damage before you plug in.

Use insulated tools and rubber-soled shoes to lower electrical risks.

Stay away from damp surfaces and never use the tool with wet hands.

If you have a pacemaker or medical implant, keep a safe distance from the induction bolt heater.

Tip: Always double-check your gear before you start. It’s better to spend a minute on safety than risk an injury.

Work Area Prep

A clean and safe workspace makes everything easier. Here’s what you should do:

Clear the area around your induction bolt heater so you have room to move.

Remove any flammable materials nearby. The tool gets hot, and you don’t want anything catching fire.

Make sure your workbench is dry and stable.

Keep a fire extinguisher close, just in case.

Always wear your safety glasses when you use the induction coil.

You want a space where you can focus on the bolt, not on dodging clutter or worrying about accidents.

Coil Placement

Now, let’s get to the main event. The coil is the part that does the magic. Place the induction coil around the bolt you want to heat. Make sure the coil fits snugly but doesn’t touch the bolt directly. You want the magnetic field to wrap around the bolt for even heating.

Choose the right size coil for your bolt.

Position the coil so it surrounds the bolt evenly.

Avoid letting the coil touch the bolt or other metal parts.

Note: Proper coil placement gives you the best results and keeps the heat focused where you need it.

Applying Heat

Time to fire up the induction bolt heater. Here’s what happens:

The tool uses electromagnetic induction to create heat inside the metal bolt.

The bolt heats up quickly, expanding as it gets hotter.

This expansion breaks the rust or corrosion bond that’s holding the bolt tight.

You don’t need to blast the bolt for a long time. Usually, a few seconds is enough. Watch the bolt and stop heating once you see it start to smoke or glow slightly.

Tip: If the bolt doesn’t budge after the first try, let it cool for a minute. Then, heat it again. Sometimes, repeating the process works better.

Bolt Removal Steps

You’re almost there! Here’s a simple step-by-step guide to finish the job:

Put on all your safety gear.

Prepare your workspace and clear away anything flammable.

Inspect your induction bolt heater and cables.

Place the coil around the bolt, making sure it fits well.

Turn on the heater and apply heat for a few seconds.

Turn off the heater and remove the coil.

Use a wrench to try loosening the bolt. If it’s still stuck, apply a penetrating oil and tap the bolt gently with a hammer.

Repeat the heating and loosening steps if needed.

Once the bolt comes loose, remove it and let it cool.

Apply an antiseize compound to the threads before reinstalling, so you don’t face the same problem next time.

Proper usage tips: Don’t rely only on heat and force. Use penetrating oil and gentle tapping to help loosen really stubborn bolts. Handheld induction heaters may only heat the surface, so make sure you give the bolt enough time to expand. Always finish with an antiseize compound to keep future bolts from seizing up.

With these steps, you can use your induction bolt heater to remove even the toughest bolts. The rapid heating and expansion break the rust bonds, making removal much easier. Follow these tips, and you’ll handle stuck bolts like a pro.

Removal Tips and Tricks

Protecting Surroundings

You want to keep everything around your bolt safe while you work. Here are some easy ways to protect nearby parts and make sure your induction bolt heater does its job without causing trouble:

Clean the coils after each use. This keeps your tool working well and stops dirt from spreading heat where you don’t want it.

Pick the right coil size for your bolt. A snug fit helps heat only the bolt and not the stuff around it.

Apply heat slowly. If you rush, you might damage wires, hoses, or paint close to the bolt.

Clear away flammable materials before you start. You don’t want anything catching fire.

Make sure the part you’re heating is clean. Dirt and grease can cause uneven heating.

Check your induction heater for wear. A damaged tool can make things go wrong fast.

Secure the coil properly. If it’s loose, you won’t get even heating.

Fix alignment issues early. A crooked coil can lead to costly repairs or damage.

Tip: Always double-check your setup before you turn on the heater. A few seconds spent here can save you a lot of hassle later.

Heat Duration

You might wonder how long you should heat a rusted bolt. Most bolts loosen up after about 10 to 20 seconds of heating with an induction bolt heater. The exact time depends on the bolt’s size and the temperature in your workspace. For example, you can heat a 5/8” bolt to a cherry red in just 10-12 seconds. Usually, you don’t need more than 20 seconds for most bolts. Watch the bolt closely. If it starts to smoke or glow, stop heating and try to loosen it.

Reapplying Heat

Sometimes, a bolt stays stuck even after you heat it. Don’t worry. Let the bolt cool for a minute, then heat it again. You can repeat this process a few times. Each round of heating helps break up more rust and makes the bolt easier to turn. If the bolt still won’t move, try adding penetrating oil between heating cycles. This combo works well for stubborn bolts.

Following these best practices for usage helps you avoid damage and makes bolt removal much smoother. You’ll get better results and keep your workspace safe.

Safety Precautions

Personal Protection

You want to stay safe when using an induction bolt heater. The right gear makes a big difference. Regular gloves and glasses are not enough for this job. Here’s what you should wear every time:

Heat-resistant gloves protect your hands from burns.

Safety goggles or a face shield keep sparks and debris away from your eyes.

Wear a protective apron or flame-resistant clothing to shield your body.

Make sure your shoes cover your feet and have non-slip soles.

Always use gear that fits well and covers your skin.

Keep a safe distance from the tool while it’s running.

Tip: Never skip your safety gear. Protective equipment is your best friend when working with hot tools.

Fire Safety

Induction heaters get very hot. You need to think about fire safety, especially if you work in a small space. Here’s a quick guide to keep your area safe:

Note: A clean, well-ventilated area helps you work safely and keeps accidents away.

Handling Hot Bolts

Bolts get extremely hot after induction heating. You need to handle them with care to avoid burns or injuries. Here’s what you should do:

Let the bolt cool down before you touch it. Forced air can help speed this up.

Use heat-resistant gloves if you need to move the bolt while it’s still warm.

If you must measure or adjust the bolt, wait until it returns to room temperature.

After cooling, check the bolt for any changes or damage before reusing it.

🔥 Always treat bolts as if they are hot right after heating. It’s better to be safe than sorry!

Troubleshooting

Bolt Won’t Move

You’ve heated the bolt, but it still won’t budge. That’s frustrating! Sometimes, the problem comes from the induction heater itself. If your machine doesn’t have enough power, especially less than 50kW, it might not heat larger bolts well. The coil size matters too. If the coil is too small or too far from the bolt, the heat won’t reach deep enough. Always check that your induction bolt heater matches the size and material of the bolt. Pick the right coil and make sure it wraps close to the bolt. If you’re working on frozen body mount bolts, double-check your setup before trying again.

Tip: If the bolt stays stuck, let it cool down, then repeat the heating process. Sometimes, a second round does the trick.

Heavy Rust Issues

Rust can make bolts stubborn. When you’re heating up a rusty nut, you want the heat to break the rust bond. If rust is thick, try applying penetrating oil after heating. The oil seeps into cracks and helps loosen things up. You can alternate between heating and oil to get better results. For bolts with heavy rust, patience helps. Heat, oil, and gentle tapping with a hammer can work together to free the bolt.

Don’t rush. Let the oil work before you try again.

Broken Bolt Solutions

A broken bolt can feel like a nightmare, but you have options. Heat the bolt until it glows orange. This expands the metal and makes it easier to remove. After heating, add penetrating oil to help it seep in. If you need more grip, weld a nut onto the broken bolt. Let it cool, then try turning it out. You can also switch between heating and oil for stubborn bolts. If induction heating doesn’t work, try an Oxy-Acetylene torch or MAP gas. Once you get the bolt out, use Never-Seize on the threads to stop future problems.

Heat until orange for best expansion.

Use penetrating oil after heating.

Weld a nut for extra grip.

Alternate heat and oil.

Try other heat sources if needed.

🔧 Always check the bolt for damage before reusing it.

You now know how to use an induction bolt heater to tackle rusted bolts with ease. Always follow the steps: wear your safety gear, prep your workspace, place the coil, apply heat, and remove the bolt. Canroon stands out for efficiency, safety, and eco-friendliness:

Many users say these tools are “worth their weight in gold.” You can feel confident, even with tough bolts, because you have the right tool and tips. If you run into challenges, just remember to check your power supply, use magnetic materials, and let the coil cool. With these tricks, you can handle any stuck bolt like a pro!

FAQ

How hot does an induction bolt heater get?

You can heat a bolt to over 1,000°F in seconds. The tool focuses heat on the bolt, so nearby parts stay cooler. Always wear gloves and eye protection.

Can I use an induction bolt heater on any bolt?

You can use it on most steel bolts. It works best on magnetic metals. It may not heat stainless steel or aluminum bolts as well.

Is it safe to use near car electronics?

Yes, it is safer than a torch. Still, keep the coil away from sensitive wires and sensors. Always double-check your setup before you start.

What should I do if the bolt still won’t move?

Try heating the bolt again. Let it cool, then add penetrating oil. Repeat the process. If the bolt stays stuck, use a breaker bar or seek professional help.

Sign up for updates