An induction quenching machine heats metal surfaces fast using induction. This makes the metal hard and strong. You use this process to make surfaces tougher. It helps parts last longer and work better. Canroon is a trusted company for induction quenching solutions. If you work in manufacturing or metalworking, you should know about induction quenching and induction hardening. This helps you pick the right equipment for your job.

Key Takeaways

Induction quenching machines heat metal surfaces very fast. This makes the metal hard and strong. The process helps metal parts last longer and work better.

The induction quenching process heats metal with a coil. Then, the metal cools down quickly. This makes the outside tough. The inside stays flexible.

Induction hardening saves energy and time. It heats only the needed areas. This lowers costs. It also helps control how hard the metal gets.

Induction quenching works with many metals. It can be used on steel and stainless steel. Many industries use it, like car making and factories.

Picking the right induction quenching machine helps you work faster. It also keeps the quality the same every time. Canroon gives advanced solutions that work well and are dependable.

Induction Quenching Machine Overview

What Is Induction Quenching

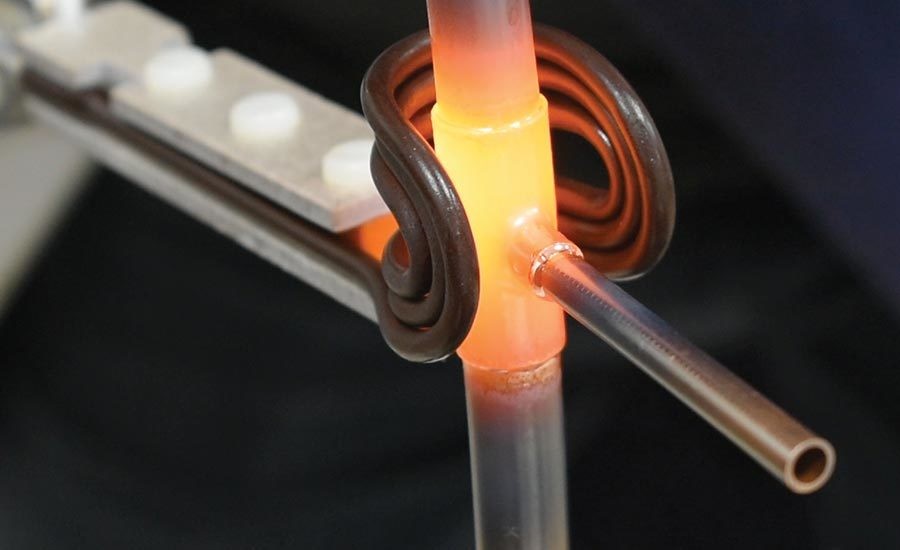

Induction quenching makes metal surfaces harder and stronger. It uses induction to heat just the outside of a metal part. First, you put the metal inside a coil. The coil makes a magnetic field. This field heats up the metal’s surface very fast. After heating, you cool the metal quickly with water or oil. This cooling step is called quenching. Fast cooling keeps the metal hard. Induction quenching is good for parts that need a tough outside but a softer inside. Many industries use induction quenching when they need strong and durable parts.

You can use induction quenching on many kinds of metals. Some common metals are structural steels, unalloyed steels, alloy steels, stainless steels, duplexes, and zirconium. Induction quenching helps these metals last longer and resist wear.

Key Features of Induction Quenching Machines

Induction quenching machines have several important parts. They include a heating inductor, a power supply, a load-matching station, and a water cooling system. Inductors come in different shapes and sizes for different jobs. The metal part sits inside the coil during heating. Some machines are small, about the size of a Euro pallet. Some models have CNC rotary tables to help with loading and unloading. You can use medium or high frequency energy for heating. Many machines have a water-cooled converter built in. You can treat metal pieces that are very light or quite heavy.

Canroon makes induction quenching machines with advanced controls. These controls let you set the temperature and energy very precisely. This means you get better results and faster cycles. You can change the hardness to fit your needs. Canroon’s machines are reliable and flexible for many uses.

Induction quenching machines treat metal parts like crankshafts, steering parts, drive pieces, linear technology parts, and screws. These parts need hard surfaces to handle stress and wear.

Tip: Pick the right inductor shape for your workpiece. This helps you get the best results for each job.

Induction Hardening vs. Other Methods

Induction hardening has many benefits over other methods. It heats only the surface, so it saves energy and cuts down on waste. The process is quick and accurate. You can control how deep and hard the treated layer is. Induction hardening is great for parts that need a hard outside and a tough inside.

Other ways, like flame hardening or furnace hardening, heat the whole part. These ways use more energy and take longer. You may not get as much control over hardness and depth. Induction hardening lets you treat just the areas you want.

Induction hardening machines help metal parts work better and last longer. You see induction hardening in cars, machines, and tool-making. Canroon’s induction quenching machines help you get great results with less work.

Induction hardening gives you better control and saves energy. You get a hard surface and a strong inside, which is important for many metal parts.

Induction Quenching Machine Process

Induction Heating Principle

An induction quenching machine heats metal parts fast. The process starts with induction heating. You put the metal part inside a copper coil. The coil connects to an induction heating generator. When you turn it on, the generator sends currents through the coil. These currents make a magnetic field around the metal. The magnetic field causes eddy currents in the metal. These eddy currents heat the surface of the metal.

Induction heating is best for making surfaces hard. You can change the heating zone by adjusting the coil’s frequency and shape. Multi-frequency induction hardening matches the heating area to the part’s shape, like gears or bolts. You get good control over how hard the layer is. The coil’s design is very important. If the coil fits the part’s shape, you get even heating and a strong hard layer. If the coil is not placed well, some spots may get too hot or not hot enough.

Note: The coil’s shape and position decide how well you heat the metal. Always match the coil to the part for the best results.

Modern induction quenching machines have advanced controls. You can set the temperature and energy levels very accurately. This gives you the same results every time. The induction heating generator helps you reach the right temperature quickly. Fast heating and cooling are important for this process.

Quenching and Cooling Steps

After heating the metal surface, you must cool it quickly. This step is called quenching. You follow several steps to make the metal hard and strong:

Preheating: Warm up the part before main heating. This helps stop thermal shock when you heat and cool fast.

Induction Heating: Use the induction heating generator to heat the surface layer. The heating is quick and controlled. Only the area you want gets hard.

Quenching: Cool the part fast with water, oil, or another medium. Quick cooling changes the metal’s structure. You get a hard surface layer that is tough and resists wear.

Tempering (Optional): Sometimes you reheat the part to lower stress inside. This makes the part tougher but keeps it hard.

Quenching gives you a hard outside and a strong inside. You control how deep and hard the layer is by changing heating time and quenching speed. Induction hardening machines let you repeat the process with high accuracy. You get reliable results every time.

Tip: Fast heating and cooling help make a strong hard layer. Always watch the temperature closely for the best results.

Bolt Induction Quenching Machine Applications

A bolt induction quenching machine treats bolts and fasteners. Induction quenching makes the surface of bolts harder. This helps bolts last longer and resist damage. The process creates a bainitic-martensitic structure in the hard layer. Bolts treated this way have better fatigue strength and higher toughness.

You find bolt induction quenching machines in car, building, and machine industries. These machines help you make bolts that handle heavy loads and tough jobs. Induction quenching lets you treat only the areas that need to be hard. This saves energy and cuts down on waste.

Induction hardening works for many metal parts, not just bolts. You can use an induction hardening machine for gears, shafts, and other pieces. The induction quenching machine gives you fast heating and cooling, good control, and steady quality. You get a hard layer exactly where you need it.

Callout: Induction quenching helps you make bolts and parts stronger and last longer. You get better performance and spend less on repairs.

Induction quenching is a smart way to make surfaces hard. You use induction heating for local heating, then quenching to make a tough, hard layer. The process is quick, efficient, and easy to control. You get better results using less energy and time.

Advantages of Induction Hardening Machine

Surface Hardening Benefits

Induction hardening machines make metal surfaces much tougher. Induction quenching forms a hard layer on the outside. This layer helps parts last longer and resist damage. The process heats only the surface, so the inside stays strong and flexible. Your parts work better in tough jobs, like making cars or gears. Induction hardening improves how your parts perform. You see less bending and almost no rough spots. The process gives you the same results every time, so you can trust the quality.

Short hardening times

Hardening of small part zones

Nearly scale-free parts

Reduced distortion

Repeatable hardening process and results

Tip: Induction quenching helps you get the same product quality every time.

Efficiency and Precision

Induction hardening machines work quickly and use less energy. You heat only the areas that need to be hard. This saves up to 30% energy compared to ovens. You can add these machines to automated lines easily. This lowers your costs and helps you make more parts. You control the process with high accuracy. You can change the frequency and coil shape to fit the part. This control makes your products stronger and last longer.

Precision and control

Energy efficiency

Reduced distortion

Improved hardness

Enhanced productivity

Note: Induction hardening gives you better control and uses less energy than other ways.

Industry Applications

Induction hardening machines are used in many industries. Car companies use them for crankshafts and powertrain parts. Additive manufacturing uses induction quenching for 3D-printed gears. Gear makers use induction hardening for strong gears. Heat treaters and powder makers also use these machines. Induction quenching machine technology fits many types, so you can pick the best one for your job.

Induction hardening machines help you save energy and lower CO2 emissions. You can use rainwater for cooling, which helps save water. Waste heat from the system can lower your impact on the environment. Picking the right induction hardening machine helps you make better parts, save money, and protect nature. Canroon offers advanced machines with energy-saving features, high efficiency, and important certifications like ISO and CE.

Callout: Canroon is a leader in induction quenching technology. You get machines that work well and save energy.

You now know how induction quenching machines work. These machines are important in manufacturing for many reasons. Here are some main benefits:

You get very accurate results every time.

You finish jobs faster and make more parts.

You keep your workspace safer and cleaner.

You spend less money to run your machines.

You always get the same good quality.

If you pick Canroon’s induction quenching solutions, you save energy. You can add these machines to your production line easily. You control how the metal heats up and get steady results. Try induction hardening to make your parts tougher and your work easier.

FAQ

What metals can you harden with an induction quenching machine?

You can harden steel, stainless steel, alloy steel, and some special metals like zirconium. Induction quenching works best on metals that respond to magnetic fields.

How do you control the hardness of the metal surface?

You set the heating time, temperature, and quenching speed. The machine lets you adjust these settings for each part. You get the hardness you need for your job.

Is induction quenching safe for your workspace?

Yes, induction quenching is safe. The process does not use open flames. You keep your workspace clean and cool. Machines have safety controls to protect you.

Can you use induction quenching for small parts?

You can use induction quenching for small parts like bolts, gears, and screws. The machine heats only the area you want. You get strong, durable surfaces on tiny pieces.

Previous:

Next:

Sign up for updates