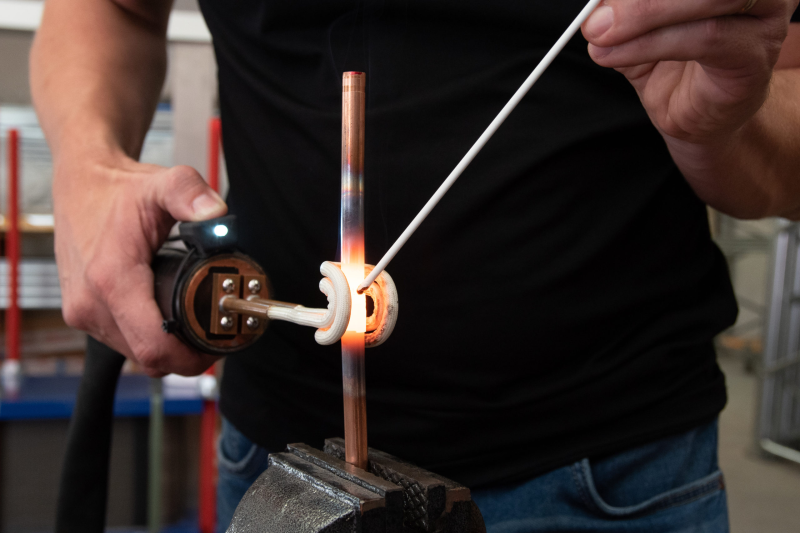

An industrial induction heater uses electromagnetic energy to heat metals fast. This method is very efficient. Factories use this technology when they need quick and exact heating. When you put a metal part in the heater, a changing magnetic field goes through the metal. This follows Faraday’s Law of Induction. It makes electric currents flow inside the metal. These currents are called eddy currents. They make heat without touching the metal.

The global market size for industrial induction heaters will be USD 1.94 billion in 2024.

The expected growth rate is a CAGR of 4.9% from 2025 to 2034.

Canroon is a leader in the industry. They offer advanced solutions that give steady and reliable results. You will learn how an industrial induction heater gives speed, safety, and saves energy in modern factories.

Key Takeaways

Induction heating uses electromagnetic energy to heat metals fast and well. It helps save time and energy. This technology lets workers control the temperature exactly. It lowers the chance of overheating. It helps make good quality products. Induction heating is safer than old methods. It does not use open flames or make harmful smoke. This keeps the work area cleaner. Big industries like automotive and aerospace use induction heating a lot. It helps them work faster and makes products stronger. Canroon's induction heating systems have advanced features. They can be used for many industrial jobs. They help make work more efficient.

How Industrial Induction Heaters Work

Electromagnetic Induction Basics

Induction heating uses electromagnetic induction. You put a metal part inside a coil. The coil has an alternating current. This current makes a magnetic field that changes. The magnetic field goes through the metal part. Energy moves from the coil to the metal.

Here is how induction heating works step by step:

The coil gives energy to the metal part with electromagnetic fields.

The electric energy turns into heat inside the metal. This happens because of the Joule effect, which uses the formula P=I²R.

The heat spreads through the metal by thermal conduction.

The magnetic field gets weaker as you move away from the coil. If the magnetic field changes faster, it works better on the metal. Induction heating systems can heat metals quickly and efficiently. You can control the process very well. This is important for many jobs in factories.

Eddy Currents and Heat Generation

Induction heating makes a changing magnetic field inside the coil. This creates eddy currents in the metal. Eddy currents are loops of electric current inside the metal part. These currents move through the metal and meet resistance. The resistance turns electric energy into heat. The metal becomes hot, not the coil.

Induction heating systems use an electromagnet and an electronic oscillator. They make a high-frequency current. This current creates a magnetic field that moves very fast. The field goes deep into the metal and makes eddy currents flow. The heat comes from these currents fighting the metal’s resistance. This process is fast and does not need flames or touching the metal.

Induction heating is very efficient. It heats the metal at a molecular level. You can reach high temperatures in seconds. You can control the process very well. This helps you avoid overheating or damaging the metal.

Non-Contact Heating Process

Induction heating does not need to touch the metal part. The coil and the metal never meet. The energy moves through the air with the magnetic field. This non-contact process has many benefits.

Induction heating saves energy. It can turn up to 90% of the energy into heat. This helps you save money.

You can control how much heat you use. This lowers the risk of warping or damaging the part.

The process is very fast. You can heat parts to high temperatures in less than a second. This saves time and helps you work faster.

Non-contact heating is safer. You do not have to touch hot parts. There are no open flames or harmful gases.

Canroon’s induction heating technology gives even more benefits. Their products use rapid precision heating. They can reach over 1000°C in seconds. You get a safe and clean operation. There are no flames or toxic gases. Canroon designs their systems for many different needs. You can connect them to your automation systems. Their modular design lets you pick the right setup for your job. This helps you improve your work and reduce waste.

Tip: If you use Canroon induction heating systems, you get speed, safety, and precision. This makes your work easier and more reliable.

Induction heating has changed how factories heat metals. You can heat parts quickly, safely, and with less energy. Many industries use induction heating for important jobs. If you want to see induction heating in your factory, you can look at Canroon’s solutions for the best results.

Advantages of Induction Heating

Efficiency and Energy Savings

Induction heating helps factories save a lot of energy. The heat goes straight into the metal. This means you do not waste energy on the air or other things. You get high efficiency and lower utility bills. Look at this table to compare:

Induction heating can cut energy use by up to 40%. You also spend less on fixing machines. These systems have fewer moving parts. Canroon’s induction heaters use smart controls and strong materials. This gives you good performance and less downtime.

Precision and Control

Induction heating lets you control temperature and time very well. You can heat metals fast and evenly. This helps you avoid mistakes and waste. New induction technology uses smart computers and electronics. This keeps the process accurate. You can watch the temperature live and change settings if needed.

You get even heating in the whole material.

You can choose the right temperature for each job.

Fast heating makes your work go quicker.

Smart controls help keep your products good.

Canroon uses new ideas like IoT and AI. These features let you check performance and change things right away. You can connect induction heaters to your factory’s automation systems.

Safety and Environmental Benefits

Induction heating is safer for workers. There are no open flames, so fire risk is lower. You also do not get bad fumes or smoke. This makes the air cleaner for everyone. Here are some safety benefits:

Induction heating is also better for nature. You do not burn fuel, so no gases like carbon dioxide are released. The process does not make solid waste or dirty water. Canroon’s induction systems help you meet green rules and lower your carbon footprint.

Tip: Induction heating is a cleaner, safer, and more efficient way to heat metals. You can make your work better and protect people and the planet.

Industrial Applications

Induction heating has changed how many industries work. You can use this technology in lots of places. It helps make things faster, safer, and better. Here are some ways induction heating helps different industries.

Automotive Sector

Induction heating is used in car factories a lot. It helps make cars stronger and last longer. Here are some ways it is used:

Hardening and tempering metal parts like gears and crankshafts. This makes parts tough and strong.

Brazing and soldering join metal parts in systems like radiators. You get strong bonds without hurting the parts.

Shrink fitting heats parts for tight assembly. This is important for bearings and other close-fit parts.

Preheating before welding gets the right temperature. This lowers defects and makes welds better.

Induction heating makes car building faster. Cars are better and stronger. It also helps the environment by saving energy. This technology helps make lighter and tougher cars. You save money and use less energy. Canroon helps car makers use induction heating for joining and heating parts. Their systems help you work better and get good results.

Note: The automotive sector uses induction heating the most. It makes up about 40% of the market.

Metalworking and Manufacturing

Induction heating is important in metalworking. It gives better control than old heating ways. Induction hardening makes metal surfaces harder. The inside stays cool, so parts last longer. This helps parts resist wear and last more. It also makes them stronger for tough jobs.

You use induction heating for:

Brazing and joining metal pieces.

Shrink fitting for putting parts together.

Hardening surfaces to stop wear.

Removing rusty bolts and loosening fasteners.

You get many benefits:

Speed: Metal heats up in seconds.

Safety: No flames means less fire danger.

Precision: Only the needed area gets hot.

Efficiency: Most energy turns into heat.

Eco-friendly: No smoke or fuel burning.

Canroon’s systems help you get these benefits. Their technology heats parts quickly and safely. You can connect their systems to automation lines for better control.

Aerospace and Marine

Aerospace and marine jobs need exact heating. Induction heating gives you control for important tasks. You use it for joining, bonding, and heating parts. It works well with special metals that need exact heat.

You can use induction heating in small spaces. This is good for ships and planes where safety is key. The process does not make sparks, so fire risks are lower. Heating is even, so sensitive parts stay safe.

Canroon works with aerospace and marine companies. They give custom induction solutions. Their systems help meet strict rules and speed up production.

Agriculture Equipment

Induction heating helps fix and keep farm machines working. It saves time and money. Here are some ways it helps:

Fast repairs and maintenance in the field.

Loosening turbo bolts and stuck fertilizer caps.

Portable heaters let you work safely without fire danger.

Saving parts that might be thrown away.

You work faster and spend less money. Induction tools help fix machines quickly and avoid buying new ones. Canroon has portable heaters for farms. These tools help keep machines running and lower downtime.

Tip: Induction heating is not just for factories. You can use it in fields, on ships, and in repair shops. This makes it useful for many jobs.

Induction heating is used in many industries because it is fast, safe, and accurate. Canroon’s solutions help you get the best from this technology, no matter your job.

Induction Heating vs. Traditional Methods

Heating Technique Comparison

You might wonder how induction heating is different from older ways like resistance or flame heating. The biggest difference is how each method heats the material. Induction heating uses electromagnetic fields to make heat inside the metal. Resistance heating needs direct contact or flames to work.

Here is a table that shows the main features:

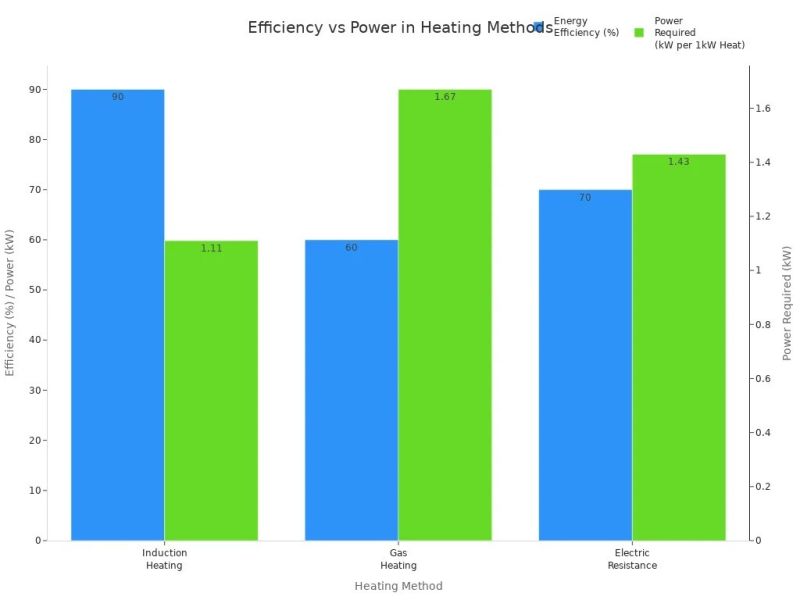

Induction heating works faster and uses energy better. You can see this in the chart below. It compares how much energy and power each method needs:

Induction heating can be up to 90% efficient. Gas and electric resistance heating are usually less than 80%. This means you need less power for the same job.

Unique Benefits of Induction Heating

Induction heating has special benefits that help you work better and safer. Here are some important advantages:

You get fast and exact heating without touching the part. This saves energy and stops heat from escaping.

There are no open flames or hot surfaces. This makes your workplace safer, especially near things that can catch fire.

Induction heating does not make bad emissions. This helps keep the air clean and protects nature.

You can control the temperature very well. This stops overheating and keeps your products good.

Canroon’s induction systems give even more benefits. Their machines heat up to 1450º F and use up to six control thermocouples for even heating. You can set ramp and hold times with a simple interface. The system helps you get the best results. Canroon uses IGBT technology, which saves energy and helps your company be greener.

Tip: If you start using induction heating, you might have some problems at first. Make sure you get good help and training. Canroon gives support and modern controls to help you use your system well.

Induction heating is great for speed, safety, and accuracy. You can spend less money, make better products, and keep your workplace safe.

Industrial induction heaters use electromagnetic induction to heat metals fast. These systems help you use less energy. They also make products better and safer. Many industries use induction heating now. It helps them get good results and spend less money.

Canroon uses smart digital controls and certified systems. If you want heating that works well, look at Canroon’s induction technology.

FAQ

What metals can you heat with induction heaters?

You can heat steel, iron, copper, and aluminum. Induction heaters work best with metals that carry electricity. These metals heat up quickly and evenly.

Is induction heating safe for workers?

Induction heating is safe for people at work. You do not need open flames or hot surfaces. There are no harmful gases. This lowers the chance of burns or fires.

How do you control the temperature during induction heating?

You use digital controls to set the temperature. You watch the process on a screen. You can change the settings for each job. This gives you exact results every time.

Can you use induction heating for small parts?

You can use induction heating for small parts. It heats them quickly and accurately. You do not overheat the parts. This keeps delicate pieces safe.

Why should you choose Canroon induction heaters?

Canroon heaters work well and are reliable. They help you save energy. You can finish jobs faster. Their designs are flexible. You also meet safety and environmental rules.

Previous:

Next:

Sign up for updates