Finding a freqency converter that fits your budget and keeps up with your work can feel tricky. You want a cost-effective freqency converter, but you also need something that matches your technical needs and handles tough jobs. Here are some things you should check before you purchase a freqency converter:

Check if the freqency converter works with your motor type and power needs.

Make sure the freqency converter offers the right speed control range.

Look for protection against harsh environments in your freqency converter.

See if the freqency converter has features for your specific application.

Confirm the freqency converter meets industry certifications.

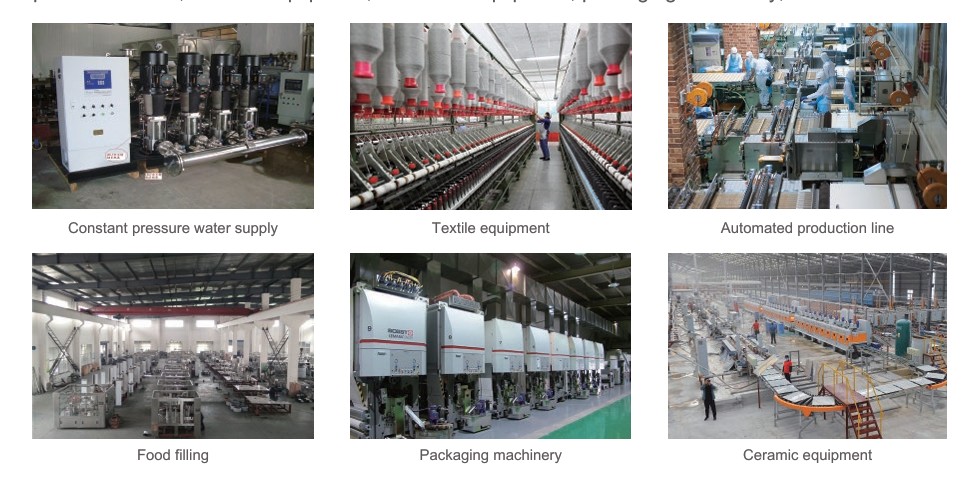

You’ll see freqency converter used for motors, pumps, and HVAC systems. Canroon stands out as a trusted choice for freqency converter reliability.

Key Takeaways

Make sure the frequency converter fits your motor type and power needs. This helps your equipment work well.

Pick a frequency converter. It saves energy and costs less to fix over time.

Use a frequency converter. It gives clean power and helps your equipment last longer.

Think about the size and cooling needs of your frequency converter. This stops it from getting too hot and keeps it working well.

Look at reviews and ask experts for advice. This helps you buy the right one for your needs.

Assessing Power Needs for Industrial Frequency Converter

Application Power Requirements

Picking the right industrial frequency converter starts with knowing your power needs. Your frequency converter should match your motor’s voltage and handle the output frequency your job needs. If you choose a converter that is too small, your equipment may not work well. If you pick one that is too big, you will spend more money than needed.

Here’s an easy way to figure out what you need: First, check your motor’s voltage and current. Next, look at your application’s load type. Is it constant torque, constant power, or variable torque? Each type needs a different plan. Multiply the horsepower needed at the lowest level by the turndown ratio, then by 2.5. This helps cover startup needs.

Tip: For heavy loads or lots of starts, pick a frequency converter with extra capacity. This helps your system stay strong.

Industrial machines, HVAC systems, and renewable energy setups use frequency converters to control speed and torque. This makes things work better and helps parts last longer.

Size and Installation Factors

Size is important when you install an industrial frequency converter. You need a unit that fits your space and matches your cooling needs. Frequency converters make heat, so make sure your setup has good airflow or cooling.

Here are some things to remember: Match the output voltage of your frequency converter to your motor. Check the highest output frequency your converter can handle. Plan for heat to escape. Good cooling helps your converter last longer.

Don’t buy a huge frequency converter if your job does not need it. The right size saves money and energy. If your motor is not fully loaded, you can size your converter by current instead of power. Standard series sizing works, but always check your real load.

Note: Picking the right frequency converter size means less waste and better performance. You get reliable operation without paying for extra capacity you do not need.

Setting a Budget for Freqency Converter

Price vs. Performance

You want to get

a freqency converter. The price can be very different for each model and use. Look at this table to see what you might pay for some models:

You do not always need the priciest converter. Sometimes a middle-priced one is just right for your job. Think about which features are most important for your work. If you want steady power and smooth performance, you may need to spend more. If you only need simple speed control, a cheaper model could be fine.

Tip: Always look at both features and price before you buy. The lowest-priced freqency converter may not last long or work well for you.

Long-Term Costs and Maintenance

When you think about price, remember long-term costs too. A higher price at first can mean less money spent later. Here’s why:

You pay more at the start, but your equipment lasts longer.

Good converters help motors last, so you fix things less.

You spend less on repairs and lose less time over the years.

USA-made frequency converters are built with better accuracy and are more reliable, which is important for sensitive electronics. Import-quality converters may not be as exact and can get too hot or have safety problems. KCC Scientific LLC converters give 0.0002% frequency accuracy, which import models do not have, so your devices get clean power.

If you want your machines to be safe and last, pick USA-made converters. They often have better ratings and help your machines run well. You can avoid overheating and get more accurate power for your devices.

Environmental and Operational Considerations

Reliability and Certifications

You want your frequency converter to work well for a long time. The place where you use it can change how long it lasts. Here is a table that shows what can hurt your converter and how:

Keep your converter away from magnets and dusty places. Dust and heat can break it quickly.

When you buy a frequency converter, check for safety labels. Look for EN 61010, IEC62321, and EN61326. These show it is safe to use. EMC and RFI labels mean it will not mess up other electronics. If you work in a tough place, these labels are even more important.

Tip: Always look for safety labels before you buy. Certified converters help keep your machines safe and follow the rules.

Maintenance Tips

Taking care of your frequency converter helps it work well. It also saves you money on fixing it. Here are some easy things you can do:

Check your converter for damage, wear, or if it gets too hot.

Wipe off dust and dirt to stop it from getting too hot.

Make sure the air around it is cool.

Tighten all the wires.

Update the software when you need to.

Test the converter often to find problems early.

Change old parts before they break.

Make sure it is grounded right.

Write down all the work you do on it.

Teach your team how to take care of the converter.

Most problems like getting too hot or power trouble happen when you do not take care of it. If you do these easy checks, your converter will last longer and work better.

Note: A little care helps a lot. You can stop big repairs and save time if you check your converter often.

Tips for Choosing a Frequency Converter

Professional Advice

You want to make a smart purchase, so start with these tips for choosing a frequency converter. First, talk to an expert if you feel unsure. Experts can help you figure out your power needs, load type, and the right converter for your job. Here are some things you should check before you purchase:

Look at your equipment’s voltage and current ratings.

Decide if you need a converter for motors, pumps, or other machines.

Think about the environment where you will use the converter. Hot, humid, or dusty places need special models.

Pick a converter with a simple user interface. This makes setup and monitoring easier.

Choose a brand with a good reputation. Reliable brands give you better support and fewer problems.

If you list your requirements, you can match them to the right converter. You should also think about your budget and how much you want to spend over time. Compatibility with your current system matters, especially if you plan to upgrade later.

Tip: Write down your needs before you purchase. This helps you avoid buying the wrong converter and saves you money.

Reviews and Support

Reading reviews is one of the best tips for choosing a frequency converter. Other buyers share their experiences, so you learn what works and what does not. Look for feedback about reliability, ease of use, and customer service.

Canroon stands out for its support. You get help with urgent orders thanks to their ERP system. They offer OEM and ODM services if you need something custom. You also get an 18-month warranty, which gives you peace of mind after your purchase.

If you have questions, Canroon’s team answers fast. Many users say their support makes the purchase easy and stress-free. When you follow these tips for choosing a frequency converter, you get a product that fits your needs and comes with strong support.

You now have five tips to help you pick a cost-effective frequency converter. If you use these tips, you can skip common mistakes and make a smart choice. Here is what you get:

The right frequency converter gives you more value as time goes on. Always think about cost, what you need, and how reliable it is before you buy. If you want help, you can contact Canroon or look at their products today.

FAQ

What is a frequency converter used for?

You use a frequency converter to change the speed of motors or pumps. It helps you save energy and control machines better. Many people use them in factories, HVAC systems, and renewable energy setups.

How do I know which size frequency converter I need?

Check your motor’s voltage and current. Match those numbers to the converter’s ratings. If you feel unsure, ask an expert or use a sizing chart. Picking the right size helps your equipment work well.

Do frequency converters need regular maintenance?

Yes! You should clean dust, check wires, and make sure the air flows well. Regular checks help your converter last longer and prevent breakdowns. A little care goes a long way.

Are solid-state frequency converters better than rotary ones?

Solid-state converters use less energy and need less maintenance. They work better for most jobs today. Rotary converters cost less at first but break down more often. You get more value from solid-state models.

Previous:

Next:

Sign up for updates