You use induction tempering to heat treat metals. It makes metals tougher and more bendable after hardening. This method uses electromagnetic induction. It heats metal parts fast and evenly. Many industries use this process. For example, it is used in energy, cars, planes, and making machines. These areas need strong and long-lasting parts.

Canroon gives advanced induction tempering solutions. They help you get good and steady results.

Key Takeaways

Induction tempering makes metal parts tough and bendable after hardening. This process stops parts from breaking and helps them last longer.

The method uses electromagnetic induction to heat metal fast and evenly. This lets workers control the temperature well and get better results.

Induction tempering saves energy by heating only the needed metal part. It works faster and better than old methods that heat metal slowly.

Safety matters when using induction tempering machines. Always follow safety rules and wear protective gear to stay safe at work.

Pick induction tempering for strong metal parts. It works well in many industries, like automotive, aviation, and metal processing.

What is Induction Tempering

Definition and Purpose

You use induction tempering to make metal parts better after hardening. This process helps metals become stronger and less easy to break. Metal parts get tougher and can bend more without snapping. Induction tempering lets you control the heat so metal does not get too soft or too hard. You use this method when you want parts to last longer and work well in machines, cars, and tools.

Induction tempering lets you heat metal fast and evenly. You can pick the exact temperature for each part. This helps you find the right mix of strength and flexibility.

Key Principles of Induction Heating

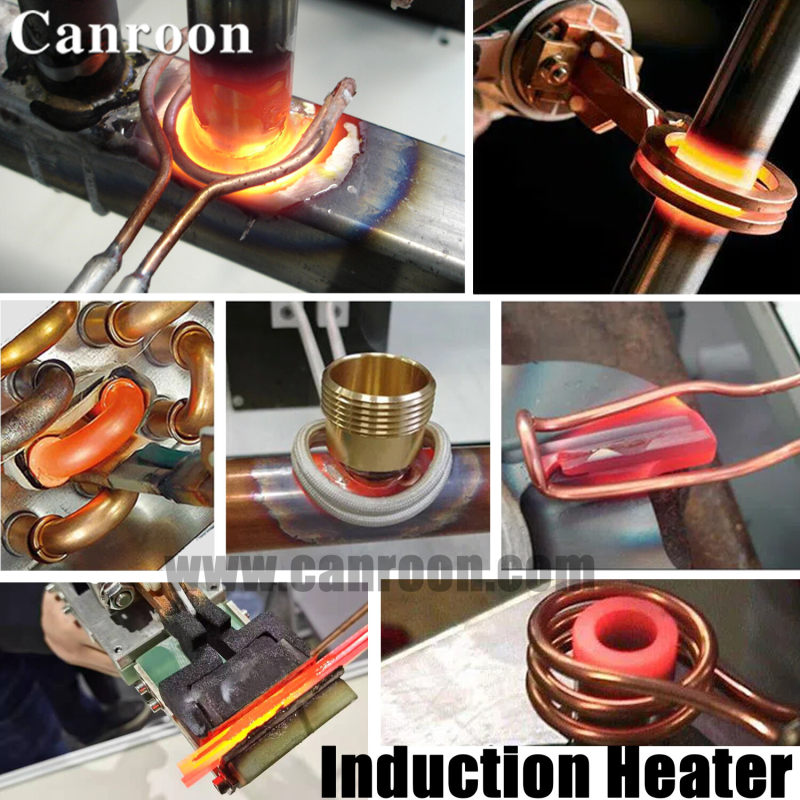

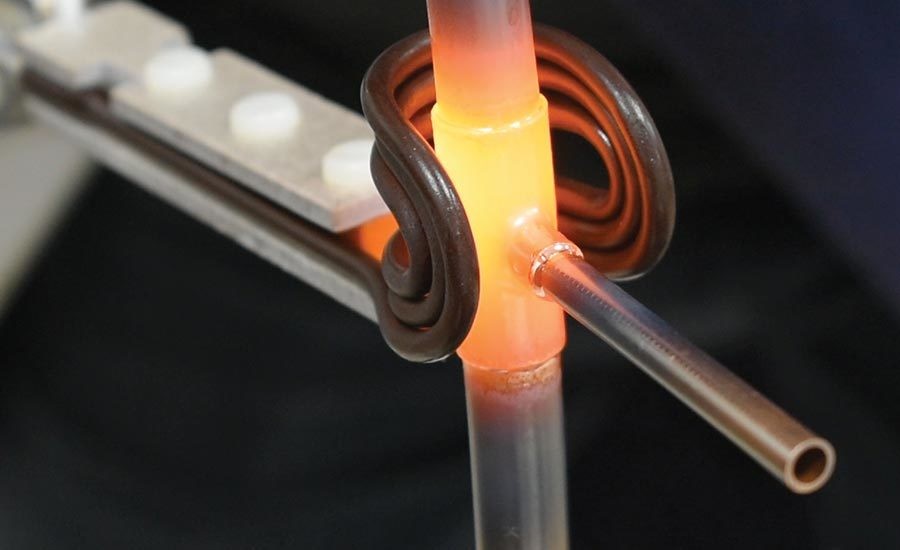

Induction heating uses science to warm metal from inside. You put the metal part inside an induction coil. The coil makes a magnetic field around the metal. This magnetic field causes electric currents, called Foucault currents, to move inside the metal. These currents meet resistance in the metal. The resistance changes electric energy into heat. You get quick and controlled heating without touching the metal.

How Induction Heating Works:

Put the metal part in the coil.

The coil sends out a magnetic field.

The magnetic field makes electric currents in the metal.

The metal heats up because of resistance inside.

Induction tempering uses this way to heat only the part you want. You do not waste energy heating the air or other things. You can change the temperature and time for each job. This helps you get the best results for every metal part.

You can see how induction tempering gives you control and speed. You get strong and reliable parts for many uses.

Induction Tempering Process

Step-by-Step Overview

You do induction tempering after hardening the metal. This process uses electromagnetic induction to heat metal from inside. You put the metal part in a coil. The coil makes a magnetic field. This field causes electric currents in the metal. These currents heat the metal fast and evenly.

Here is how you do induction tempering:

Prepare the Metal

First, harden the metal part. Clean it to remove oil and dirt.Set Up the Coil

Put the metal part inside the induction coil. Make sure the coil fits well.Adjust the Settings

Pick the right temperature and time. Use the control panel to set these.Start Heating

Turn on the induction machine. The coil makes a magnetic field. The metal heats up from inside.Monitor the Process

Watch the temperature closely. Systems like OptiBake help you control each plate’s temperature. You get even heating.Cool Down

When the metal reaches the set temperature, let it cool. This step makes the metal tough and flexible.

Tip: New machines use less energy and do not make harmful gases. You help the planet and save money.

New induction tempering machines give you more control and work better. For example, OptiBake uses induction heating for wafers. You get better quality and more flexibility. You use half the energy compared to old ovens. You do not make CO2, CO, or NOx. You control each plate’s temperature for steady results.

Canroon has advanced induction tempering machines. You get good performance and easy use. Their machines help you get the best results for your metal parts.

Required Equipment

You need special tools for induction tempering. Here is what you need:

Induction Power Supply

This device gives electricity to the coil. You can change the power for each job.Induction Coil

The coil makes the magnetic field. Pick the shape and size for your metal part.Temperature Control System

This system lets you set and check the heat. Some models let you control each part’s temperature.Cooling System

You need to cool the metal after heating. Water or air cooling works well.Safety Devices

Use guards, insulation, and grounding to keep people safe.

Here is a table of safety rules for induction tempering equipment:

Note: Always follow safety rules. You keep yourself and others safe when using induction tempering machines.

Canroon gives machines with advanced safety features. You feel safe while working. Their machines help you work faster and safer.

Induction Tempering vs. Other Methods

Comparison with Conventional Tempering

You might ask how induction tempering is different from conventional tempering. Both methods make metal better, but they do not work the same way. Induction tempering uses electromagnetic induction. It heats metal fast and evenly. Conventional tempering uses ovens or furnaces. These heat metal slowly from the outside.

Here is a table that shows the main differences:

Induction tempering saves time and energy. It heats metal in just minutes. Conventional tempering takes much longer. Induction tempering uses less energy. It heats only the part you need. You get better mechanical properties. This process stops unwanted grain growth inside the metal.

Tip: Induction tempering lets you control the temperature. You can change settings for each part. Conventional tempering does not give you this much control.

Advantages and Limitations

Induction tempering has many good points. You get fast and even heating. You save energy and spend less money. You can set the temperature for each part. This method works well for parts with tricky shapes. You also make less pollution because it does not burn fuel.

Here are some key advantages:

Fast process time ⏱️

Lower energy use ⚡

Precise temperature control

Better mechanical properties

Cleaner and safer work environment

There are some limits too. Induction tempering needs special machines. You must use induction coils and power supplies. The first cost is higher than other ways. You need trained workers to run the machines. Some very big parts may not fit in the coils.

Note: If you want strong and reliable metal parts, induction tempering is a smart choice. You get high quality and good results for many uses.

Applications and Benefits

Industrial Uses

Induction tempering is used in many industries. It helps make parts strong and dependable. You see it in metal processing, cars, planes, and making plastic. Here is a table that shows how each industry uses induction tempering:

Induction tempering also works for small and tricky parts. Here are some examples:

Hydraulic parts like pump pistons, valve shafts, and gear pieces

Steel tools such as vices, pliers, hammers, and wrenches

Car parts like crankshafts, rods, valves, and gears

Canroon gives smart solutions for these industries. Their machines work quickly and give steady results.

Benefits for Metal Properties

Induction tempering makes metal better in many ways. It helps parts get tougher and bend easier. This process stops metal from breaking or bending too much. It also takes away stress inside the metal. You get parts that last longer and work well in tough places.

Here are some main benefits:

Parts get tougher and do not break easily.

Parts bend more without snapping.

Stress goes away, so parts stay strong.

Heating is even, so every part is good.

You use less energy and make less pollution.

Tip: Induction tempering helps make products safer and more dependable. Canroon’s machines help you reach high goals in metalworking and making things.

You now know that induction tempering helps metal parts get stronger and bend easier. You saw each step in the process and learned about the tools you need. You also found out how it is different from other ways to treat metal. Induction tempering uses less energy and gives better results. Canroon has new machines that help you stay safe and work fast.

Pick induction tempering if you want strong metal parts.

Count on Canroon for smart machines in your field.

Tip: Use induction tempering to make your metal parts better and help your factory make good products.

FAQ

What is the main goal of induction tempering?

Induction tempering makes metal parts stronger. It helps stop them from breaking. You get a good mix of strength and flexibility. This means parts can bend but not snap.

How does induction tempering save energy?

You heat only the metal part you want. The process is quick and does not waste energy. You do not heat the air or other things. You use less electricity than old ovens.

Can you use induction tempering for all metal parts?

You can use induction tempering for many metal parts. It works well for parts with tricky shapes. Very big parts might not fit in the coil. You should check the size before you start.

Is induction tempering safe for workers?

You stay safe if you follow safety rules. New machines have guards and insulation. They can shut off by themselves. Always wear safety gear and check the equipment first.

Why choose induction tempering over other methods?

You get faster results and better control. Metal parts work better after this process. Induction tempering makes less pollution and saves money. Many industries use it for top-quality parts.

Previous:

Next:

Sign up for updates